The vast majority of our compatriots are confident that there is only one carriage - a structure used for mounting artillery pieces. But the Norwegians do not agree with this statement, and call the beams processed using a special technology, which are used specifically for the construction of buildings and structures, as a carriage. The second meaning of the word carriage seems to us more pleasant and correct.

Lafet - what is it?

Description of technology

Before erecting a log frame from a carriage, preparatory work is carried out. The logs should be laid one on one in a horizontal position, which allows the formation of crowns. The logs have a standard length of 6 m. In order to obtain joint strength, grooves are made located on top of the element. An inter-crown seal is placed there. There should be special notches in the corners of the logs. They are called locks and have wedge-shaped profiles.

For the construction of log houses, it is important that the wood has natural moisture. This technology involves drying the material in the finished log house. After installation, the house is maintained for some time, then it is dismantled. The logs are stacked using a Norwegian lock. During the shrinkage process, it self-jams under the influence of its own weight. This lock in buildings is the most reliable, since the carriage does not turn when jammed and turns out to be quite strong. The strength of the lock will depend on the density of the shrinkage.

Before you start assembling a log frame from a gun carriage, you need to approach the selection of material with all seriousness. Logs must not be damaged. They must comply with technical specifications and standards. This allows us to build high quality houses. As soon as lumber has been selected that is suitable in all respects, it is cleared of bark and treated with turpentine antiseptics and resin substances. Particular care should be taken to process the end part of the wood, as well as those places where the grooves and cuts are located. The logs are then sorted by size and shape. For this purpose measurements are taken. At this stage, defects in the form of protrusions and growths can be removed.

Log or timber?

The carriage is logs hewn on two opposite sides, which are, in fact, huge boards, which were the first to be used by the inhabitants of Scandinavia for the construction of houses, but the Norwegians were especially successful in this, becoming the authors of a special locking connection that ensures not only maximum structural strength, but and high thermal insulation qualities.

Houses built from gun carriages do not need additional insulation, although the wall thickness is no more than 20–24 cm.

In the domestic tradition, the carriage is sometimes called a gable or double-edged beam. But often we mean a log, that is, a log sawn in a special way (and, as a rule, even without the bark removed from both sides), which is laid in a horizontal plane and is mainly used as a load-bearing structure, for example, a floor joist.

If we talk about the carriage as a modern building material for the construction of houses, then it should be noted that this material is closer to a rounded log, which had two parallel sides cut off. Although, some builders, on the contrary, see it as a beam with two rounded sides, which seem to have been forgotten to remove.

Second stage of construction

After carrying out such processes, the log is transported to the cutting site. Log houses from gun carriages are assembled taking into account natural dimensions. After cutting is completed, the logs are marked according to the assembly drawings. Then the frame is dismantled and the material is loaded onto transport. It is delivered to the site where the house is assembled. Assembly work is carried out on a finished foundation. Installation is accompanied by the installation of dowels and dowels. They are wooden nails made from hardwood. These elements are located inside the bars. Pins are required to prevent the edges of the beams from aligning during drying. They keep the walls vertical.

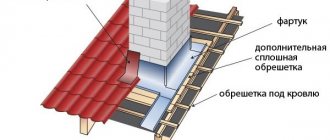

As soon as the Norwegian log frame from the carriage is installed, the roof is installed, doors and windows are installed. Then you can carry out finishing work related to landscaping.

Tools

To make a carriage and build a house, you should prepare certain tools, among them the following should be highlighted:

- band sawmills;

- compass;

- drill;

- chainsaw;

- axe;

- plane.

The sawmill must be equipped with a hydraulic and electronic system. The compass should be selected so that a level is built into it. The drill must have a hammer function. Any ax won't do. It must have a special configuration. Among the special equipment that will be needed are:

- truck crane;

- lifting equipment;

- trucks.

Construction Features

The log house of a bathhouse from a gun carriage is built using almost the same technology, which involves the use of round timber or timber. The foundation will be the same as for the roof. The main difference is expressed only in the construction of the walls. Standard log cabins have a bowl at the joint. The obvious downside here is the expectation of shrinkage. This may take a year or more.

The more dried the logs are, the better. This way they will shrink faster and smaller. As for the log houses made from gun carriages, logs of natural moisture are used for them. This is due to the fact that when constructing walls, an angular fastening method is used. When dry, the logs fit even more tightly to each other, they cling to each other. The shrinkage is not that significant.

Forest selection

Fire monitor lumber is made from pine, cedar, larch, and spruce.

When choosing, it is worth considering the features of raw materials:

- Pine is a practical lumber with a dense structure that is easy to process.

- Cedar is a durable, heat-intensive wood with a beautiful texture and is easy to process. The cedar trunk contains resin with natural antiseptics, so it does not grow mold or be undermined by insects.

- Larch is a durable, moisture-resistant tree that is resistant to temperature fluctuations. It has excellent thermal insulation and antiseptic properties.

For construction, it is better to choose logs without cracks at the ends, without traces of blue stains, pests or damage.

Ventilation. Is she needed?

If you want to build a log house from a carriage with your own hands, you must worry about ventilation. Typically, if there are wooden walls, rooms are ventilated due to gaps in the joints. But in the design under consideration there will be no gaps. In this regard, holes should be made under the roof for air exchange. These openings are called vents and must be located around the perimeter of the building. They should be located in every room. The steam room should have one hole at the top and two at the bottom.

How to markup yourself

Marking begins with marking the extreme lines and axes of the connected bars. It is necessary to use a hydraulic level. The top beam is aligned vertically and along the axis of the walls. If you look at the beam from above, you should see a square. The elements of the castle will be drawn from it.

Before you build a log bathhouse from a gun carriage with your own hands, you must make markings. The next step is to look at the side of the bottom beam. In this section, the lines of the drawn square are extended so that they connect with the center of the beam. This line will be the conditional horizon. By looking at the top of the bottom beam you should be able to figure out where to draw the straight lines. They will go through the corners of the square.

Conclusion

If we compare all the advantages and disadvantages of bathhouses built from gun carriages with other types of log houses, then we can say with complete confidence that this material is an excellent option. A bathhouse made from a gun carriage always turns out to be warm and comfortable, so the cost of it is completely justified.

For more information on this topic, watch the video in this article.

For the construction of baths, different materials are used; the most popular option is a bath made of timber. And to buy ready-made baths, barrel baths are often chosen. But there is another option that came to us from the Scandinavian countries - this is a gun carriage. Despite the fact that the popularity of this material is increasing every year, many are still unfamiliar with it, although the gun carriage has many advantages.

How to build a house with your own hands

If you decide to assemble a log house from a carriage using Norwegian technology, you must first select the material. Northern pine would be an excellent solution. It's relatively inexpensive. If the diameter of the trunk varies from 28 to 36 cm, then after processing the diameter can be 21 cm. Pre-treatment will involve the manufacture of a gun carriage using specialized equipment. The log will need to be sharpened and markings applied to it. These works are carried out by craftsmen, since the quality of joining the logs and the subsequent operational characteristics of the house depend on the correctness of this stage.

The marking is carried out with a line, which is applied with a special tool. It is important to cut out a castle that will represent a Norwegian bowl. Using a line, you will need to mark a longitudinal groove, which is selected with an ax. It is also called adze. At the next stage, you can start grinding the boards to ensure maximum density and smoothness of the joints.

At the final stage of preparation, the material is treated with an antiseptic. This is done with the help of special compounds that prevent the appearance of mold and rot stains. At the next stage, you can start cutting the log house from the gun carriage. The basis of the structure is a strip foundation, which looks like a monolithic concrete base. Before assembling the house, a layer of waterproofing should be laid on the foundation, which will prevent damage to the lower crowns.

Then assembly takes place, which takes a lot of time, because it requires the most durable fit of the elements. This is the only way to achieve an accurate connection. By looking at the photos of log houses made from gun carriages, you can understand which project to choose. But at the stage described, you will have to start selecting grooves in window and door openings. The groove width is 50 mm. It is inserted into the guide beam, which will be the basis for fastening the frames and door block. This will ensure the safety of windows and doors during shrinkage of the log house. Afterwards they will fall into place, dry and be pressed against the logs, which will guarantee the absence of cracks.

To install the ceiling, wooden beams with a section of 150 x 200 mm should be used. To make the interior of the house original, the ceiling is left open. As for finishing the house, it can be done using different stylistic solutions. Typically, craftsmen advise treating the wall with translucent protective compounds that allow you to preserve the natural beauty of the material. The use of boxes is encouraged, because treatment with different paints and varnishes increases the degree of protection of the building and makes it as attractive as possible.

Carriage: what is it?

A carriage is a semi-oval log with two parallel and two rounded edges. There is a rounded notch on the underside of the lumber. Standard size is 240×400 mm. The Norwegian cutting technology "carriage" is very similar to double-edged timber.

Fire monitor logs are suitable for the construction of cottages, country houses, baths. For objects up to 150 m2, lumber up to 210 mm is used, for houses from 150 m2 - 250 mm. Various lengths of logs are allowed due to the effect of Scandinavian felling. For construction work, chamber-dried lumber with natural humidity is used. The slab left over from the carriage is used for installing partitions and subfloors.