For the construction of baths, different materials are used; the most popular option is a bath made of timber. And to buy ready-made baths, barrel baths are often chosen. But there is another option that came to us from the Scandinavian countries - this is a gun carriage. Despite the fact that the popularity of this material is increasing every year, many are still unfamiliar with it, although the gun carriage has many advantages.

The history of the Norwegian logging

There are two versions of the origin of Norwegian logging, and both of them complement each other.

- The first version is historical.

In the past, the Scandinavian peoples lived modestly and ascetically. At the same time, savings were practiced on literally everything, including materials for construction. Therefore, there was a need for waste-free technology: after cutting the logs, the slab was used to make floors and roofs.

- The second version is technical.

Practicality is embedded in the Scandinavian mentality. The customers wanted to know that logs with internal defects were not used to build the house. To show the quality within the wood, the logs were sawn. After such treatment, stronger layers of wood appeared on the outside, which were less susceptible to various influences. This increases the service life of the Norwegian log house, which was also welcomed by the craftsmen and Customers.

Characteristics and production of material

Experts refer to the carriage as logs hewn on both sides with a size usually of 240x400 millimeters. Pine is most often used as the starting material. The name "softwood" in relation to it does not mean that the wood is weak. In fact, softwood species, including fir, are known for their structural strength and flexibility in construction. Pine and spruce are among the most economical types of wood. For construction using this method, you can use any type of construction wood that meets the classification of high-quality wood, class “A” and “B”. The log trunk must have a uniform structure; the permissible moisture content of the logs is allowed in the range from 12.0 to 15.0%.

Wood for log houses is divided into three classes:

- “A” - “extra”, the material of this class must be ideal, with one or two knots.

- “B” - “standard” allows for a number of knots and small defects in the form of small tears.

- “C” - “economy”, may have knots, cracks, “resin pockets” and other defects.

Compliance with the quality limit is not always strictly adhered to by some manufacturers. At large woodworking factories, where they value their reputation, quality requirements are met quite accurately. In small-scale production, class “B” often corresponds to “C” in reality. Therefore, when buying timber for the construction of a bathhouse, you need to be sure that it complies with the quality certificate. It is better to make purchases from reputable trading companies, in regional centers or Moscow.

If only class “A” and “B” wood is suitable for building a house, then for a bathhouse it is possible to use class “C”, cost savings of up to 30%, especially since not all defects are dangerous for the structure of the bathhouse. They are divided into several types:

- They are not critical, they do not interfere with the appearance of the finish coating and are used without any restrictions.

- Removable defects that can be easily repaired, such as knot holes, are quickly and easily sealed.

- Uncorrectable defects. Logs with such defects are easily discarded and used in the construction of other elements of the bathhouse. For example, floors and walls, where a shorter product length is needed.

The highlight of the design is the shape of the locking connection, which creates a structure with a high level of thermal insulation and strength characteristics. With a relatively small wall thickness, only 200-240 mm, this technology does not require thermal insulation, and in terms of its energy-efficient properties, a 200 mm wall made of canopy is comparable to a 400 mm wall made of brick. Such a structure can withstand the harshest northern winters.

Complex cutting performs a number of tasks that fully justify the money spent:

- Mechanical reliability.

- Large contact area, increasing the friction force between parts, which prevents them from moving.

- Creation of optimal load distribution in your pair.

- Fastening crown joints.

- Neutralization of areas with excess stress.

Only our Customers receive:

- Log houses from the best wood. We build only from high quality logs. We have our own equipped production sites. We use an ultrasonic flaw detector to detect hidden tubular and tobacco knots. Our cedar grows in a favorable northern climate that has not been subject to anthropogenic pollution. We only cut in areas that are not wetlands. Therefore, our cedar is 10% more resistant to pathogenic bacteria, the number of whorled knots is reduced by 5%, and the trunks are 15% straighter.

- Large selection of architectural solutions. Our carpenters are fluent in technology: Russian and Canadian felling, gun carriage, Post&Beam. We build from different types of wood: cedar, larch, Kirov pine. For houses and baths we use logs with a diameter of up to 700 mm. The design of the log houses includes large diameter pillars made from exclusive specimens. Only here you will find massive chopped trusses, carved parts, large wooden figures, and ends in a “wild” style. We build log houses with ecker windows and large balconies, and install panoramic glazing in the living rooms. Our architects design houses and baths by fathoms using the calculation of the “golden ratio”, make layouts according to Feng Shui and orient houses according to the cardinal directions.

- Favorable prices. We do not use the services of intermediaries or subcontractors; all turnkey work is carried out by our company. We offer house felling on an equipped site, assembly for shrinkage and subsequent finishing work. We develop interior and landscape design projects, carry out the design and installation of all engineering systems. Logs are sawed according to cutting maps, which are included in our projects. Estimates are compiled on the basis of specifications that are created automatically when developing a structural section.

The main stages of assembling a Scandinavian log house

Before you start building a bathhouse from a gun carriage with your own hands, it is recommended to draw up a detailed action plan. You need to start with a project. It is clear that not all owners of dachas and estates can do this on their own, so you can turn to specialists, friends who have a project for a bathhouse that has been built and tested. As a last resort, try to find standard design and estimate documentation on the Internet. Each project has a specifications and estimates section that the developer will need to prepare a construction plan and calculate the cost.

Next, you will need to choose a place for the bathhouse, sometimes due to the small free space, it has to be combined with some outbuildings or even with a residential building. When choosing a construction site, you need to take into account the level of groundwater, the presence of flooded areas, the location of reservoirs, types of precipitation and wind rose.

Tools and materials

The range of materials and their quantities are determined by the project in the specifications section. They are coordinated with the selected bathhouse design and are calculated according to the as-built drawings of the facility. Usually, when building a bathhouse, a standard package of building materials is purchased:

- A carriage having a cross-section of 200x200 mm for the construction of external walls;

- timber with a section of 150x100 for internal partitions;

- cement, crushed stone and sand for foundation construction;

- waterproofing materials;

- floor wood;

- thermal insulation material for insulation;

- roofing materials.

The list of working tools includes: an axe, a shovel, a hammer, a hacksaw, an electric drill, tools for inter-crown insulation and a mallet.

Log house project

Before starting construction of a bathhouse, choose a technology for connecting logs. One of the most ancient and popular is the “paw” method, in which the corner logs of the bathhouse are chopped into a “dovetail” shape. A tenon is created on the crown in the lower corner, and in the next corner a groove is created in a shape suitable for the size of the tenon. When connected, the cone decreases, compressing under the load of the log. Despite the fact that the log house also compresses under the force of gravity, the connections made not only do not crack, but are even more compacted. The “in the paw” technology has a completely different look, different from Russian log houses; the timber does not protrude beyond the corners of the building. This joining method is also known as a “residue-free” joining.

Its technology is simple: first, logs 1-1.5 meters long are cut from 4 sides, creating a square profile. The end of the beam and all the sides are strictly drawn according to the “paw” pattern and then the remains of the wood are carefully removed. If everything is done correctly, the “paws” will become self-clamping. Sometimes, in order to strengthen the strength of the joints, a root tenon is made, protruding on the inner edge of the log near the corner. It is even better to create a tenon obliquely, then the logs will not be able to maneuver in the structure of the building with access to the outside.

Bowl connection

The next method is the “bowl” connection. There are three varieties of this fastening in the world: Russian, Norwegian and Canadian. The Russian “bowl” is distinguished by the fact that the upper groove in the crown of the building along the contour is absolutely identical to the lower one. In the Canadian and Norwegian versions, the crown is made onto a cone, and the connection occurs due to a cone seal. From an aesthetic point of view, the Russian “bowl” has the best appearance, and Norwegian and Canadian technologies have better strength and heat-resistant characteristics, although they are also more expensive.

Step-by-step guide to constructing a structure

After completing the project, purchasing materials according to specifications, selecting a construction site and delivering timber to the felling site, preparatory processing of wooden products is carried out. Pre-processing steps:

- Carriage cutting;

- sharpening logs with a plane;

- paw marking is performed only by experienced carpenters; the strength of the structure will depend on the quality of this operation;

- bowl cutting, also performed by specialists;

- grinding the resulting parts for possible connection;

- treating the entire surface of the timber with an antiseptic solution to prevent the formation of mold.

Next, construction and installation work begins:

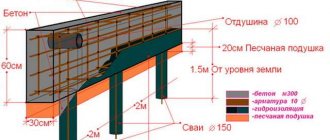

- The foundation is poured and waterproofed to prevent damage to the lower layers of wooden elements;

- carry out the assembly of the carriage, the most labor-intensive stage, requiring highly qualified performers;

- install doors and windows; to do this, grooves measuring 50.0 mm are made in the prepared openings and a guide beam is secured in them. This method of execution allows you to preserve windows and doors during shrinkage of the structure. Moreover, thanks to this operation, the boxes will be completely pressed against the beam.

When constructing a log bathhouse, special attention is paid to taking measures to protect the wood from moisture. Many developers are irresponsible about this process, believing that treatment with biocides is sufficient. This is not true; when building a log house, it is necessary to take all measures to prevent moisture from entering the walls. They are carried out both in relation to the frame crowns and all construction units of the bathhouse.

Measures to organize moisture protection:

- Waterproofing the upper part of the foundation and creating an underground ventilation system.

- The use of a backing board under the crown, which can be easily replaced over time.

- Installation of wide roof overhangs to protect the walls from direct contact with snow and rain, preventing direct precipitation from falling onto the walls of the bathhouse.

- Installation of visors.

Experts advise collecting timber in the autumn-winter period. During this period, the moisture freezes out slowly, and therefore the deformation proceeds evenly. Around the end of summer, the shrinkage process will be almost complete and it will be possible to begin finishing the premises.

Finishing work

Bathroom decoration is a matter of taste. Many owners often do not cover the ceiling, trying to create the atmosphere of an old house. Norwegian technology does not require any mandatory finishing procedures; in the Viking country, walls are often coated with protective varnish, thereby preserving the natural beauty of the wood.

In fact, there are two options for choosing finishing works:

- Without covering. The advantage of this option is its low cost. However, it is very impractical, since the structure of the bathhouse is located in a humid environment, the likelihood of moisture getting between the joints of the carriage is very high, and it will not last long.

- Covering bath walls using lining. In dry rooms, it is recommended to use coniferous wood, and in wet rooms, use aspen or linden. In this case, water will not be able to get into the joints and tow, so the wood will not rot.

A bathhouse made from a gun carriage is not a cheap structure, but the sophisticated technology tested by the Scandinavian Vikings creates an eternal building that will serve people for decades.

Features of Norwegian technology

- Norwegian cutting is a more complex solution than traditional Russian technology. For the construction of log houses, a carriage is used - a log with a rectangular cross-section. To achieve this shape, round blanks are hewn from opposite sides. The remains are used to create the roof and additional architectural elements of the house.

- The carriage is made as follows: first, the blanks are debarked, then hand-planed until flat side surfaces are obtained. A groove is cut out on one of the semicircular sides and a wedge-shaped corner bowl with a tenon inside is made.

- Thanks to its special shape, the Norwegian “lock” does not depressurize during wood drying. During the shrinkage process, the connection becomes jammed and the corners of the frame close tightly.

- The depth of the “lock” depends on the diameter of the log. Before sampling, the boundaries of future bowls are marked with a squiber. The saddle-shaped notch is selected manually using an adze.

- Four inclined planes (“cheeks”) are trimmed with a special Norwegian axe. This tool provides greater precision in work. Carpenters process the wood along the grain, which allows them to close the pores and resin channels. This approach increases the strength of wood.

- A secret tenon is made at the bottom of the bowl, and a groove is cut into the mating log. During the drying process, the log house settles and jams the connection with its weight.

- For additional fixation of the crowns, we use dried birch dowels, which are recommended for use in wooden house construction. Metal nails and rigid fasteners are prohibited in our company.

- Wooden “nails” are inserted strictly perpendicularly into pre-made technological holes. They are installed in a staggered manner. To securely fix the crowns, we hammer dowels into each crown and place them 1.5 - 2 meters apart.

What is a carriage

The carriage is a log that is half hewn. The main feature of the construction of walls from this material is the wedge-to-wedge connection, which is called the “Norwegian castle”. In addition, the lower part of the log is adjusted closely to the dimensions of the adjacent carriage.

Such a connection turns out to be much more reliable and stronger than the traditional “cup” when constructing ordinary log cabins. In ancient times in Scandinavian countries, this technology was used in the construction of fortresses, which indicates its reliability.

Connecting the carriage into a “Norwegian lock”

Advantages of houses made from carriages

- Strong and tight connection. This is achieved due to the self-jamming of the “lock” under the weight of the walls and roofing system. Such houses are energy efficient and have uniform shrinkage.

- As wood shrinks, the strength of the joints increases. Thanks to this, the logs do not twist under the influence of residual internal stresses, the design of the Norwegian log house is more static.

- The insulation is located inside the grooves, so moisture does not get into it. We use insulation based on Klimalan sheep wool, which lasts up to 100 years. We do not recommend our clients to use jute, which turns into dust after 5-7 years.

- After shrinkage, the notches remain sealed and no gaps form between the rims. Therefore, such log houses do not need caulking.

- Norwegian log houses are built from large diameter logs. They have few crowns, which reduces the number of “cold bridges”.

- The walls in such a mansion are integral with the roofing system: large-diameter logs are cut into the pediment. There is no usual ceiling; “wasps” are visible in it, which provides a very unusual interior.

May his domain name be famous forever!

Once, FORUMHOUSE participant Alexey, using maternal capital and money borrowed from relatives, bought a plot of land in mountainous Adygea, in the village of Sakhray, among mountains, forests and fast rivers, a stone's throw from the Caucasian Biosphere Reserve. A scythe, a saw, and fire - and in two summers the site was put in order, electricity was installed, and a building permit was obtained. They decided to build from a gun carriage.

But what about the carriage in such a place - and without forbs on the roof? No way!

At first it seemed that a house made of gun carriages was a prohibitively expensive project, and Alexei was already beginning to fall into despair.

AlexeyyaForumHouse Member

Sleepless nights, designing, studying the work of domestic, Norwegian and Lithuanian masters, communicating with our companies that own Norwegian secrets plunged me into sadness and melancholy - why is everything so expensive? And lo and behold, FORUMHOUSE, may its domain name be famous forever! I liked the prices and quality of cutting from craftsmen found through the portal, who do not have secretaries, accountants, sales managers, fascinating websites, credit dependence and other associated costs.

And now all the issues have been resolved: Alexey and his faithful comrade began the construction of pile-grillage foundations with a monolithic slab for the bathhouse and the house. During the 21-day vacation, the foundations were assembled and poured.

The timber was traveling to Adygea from the Kirov region, the local craftsmen cut it on their site, and they came to assemble the frame.

Alexey agreed that they would bring lumber and additional components for assembly, from jute to nails and screws.

When they discussed a project prepared by a specialist from an eminent St. Petersburg company that specializes in timber frames with a Norwegian log, the master shook his head and made an important critical remark: he said that it was necessary to add slugs (two long logs from gable to gable between the side walls and the roof apex ). In Norway, these are mandatory elements; without them, a heavy earthen roof can collapse under its own weight, and if you add a layer of snow...

AlexeyyaForumHouse Member

I believe that a critical assessment of the design documentation, discussion of comments and support by the craftsmen who cut the log house from the felling stage to the closing of the roof is good manners.

Flaws

The disadvantage of the Norwegian technology is the removal of a thick layer of wood, which makes the log vulnerable. To avoid rotting, we use certified antiseptic impregnations “Remmers”, which are applied to all subsequently hidden surfaces of the log during the assembly of the house.

Before transportation, lumber is treated with a transport antiseptic. The following processing is carried out after grinding. Such work is repeated after 3-5 years, depending on the climate and the manufacturer’s recommendations. All wooden parts of the rafter system and floor are also subject to comprehensive antiseptic treatment in production.

To protect the rim, a backing board treated with protective compounds is used. The best option for the first crown is moisture-resistant larch.

We offer a large selection of ready-made house and bathhouse designs. Each sketch is carefully designed. Small houses and bathhouses have smart layouts in which every meter is rationally used.

Large log cabins will include spacious living and dining rooms, home theaters and gyms. Multifunctional rooms with “second light” give a lot of sun and space. Large terraces encircling the houses on three sides, chic entrance lobbies decorated with chopped trusses and carved details look great.

The layout includes steam rooms and bedrooms with bathrooms, boiler rooms with separate access to the porch, wardrobes, storage rooms and heat-insulated vestibules. The library and study, workshop and laundry facilities are also in demand.

All finished projects can be modified to suit the conditions on your site. You can choose a different log diameter and any type of wood.

Exclusive design is an opportunity to build the house of your dreams. Our architects will develop a house concept based on a photograph or your stories. We will take advantage of the features of your terrain and provide a comfortable life outside the city for all members of your family.

Clearing with low grass

There are several ways to green a roof, and Alexey chose the most interesting one: cutting off wild turf somewhere and laying it on the roof.

He found a clearing with various herbs open to the sun and watched it all summer; I was convinced that even in the very heat the grass did not turn brown, remained green, something was blooming in it all the time, and one flowering replaced another. In November, in this clearing, he cut cubes of turf 25x25 cm with a height of an earthen ball of 20-25 cm. He laid a drainage membrane on the roof slope, turf on it, and covered the uneven areas and cracks with earth. Laying the cubes in the cold autumn rain took two days.

Alexeyya FORUMHOUSE user.

You need a clearing with low grass, with a predominance of meadow grass, so that you don’t have to mow it regularly, and the roof is green for the maximum time of the year.

Now on Alexey’s site there are two buildings under green roofs, a bathhouse, which is temporarily used as a small house, and the main house - it is still being completed.

During this time, he implemented another cool project: a large pond. It’s incredible that such a place to live was built by a man who a few years ago could do exactly one operation with his own hands: drive a nail into the wall, “and it’s not a fact that it’s straight.”

Alexey is a lawyer, and he never held tools in his hands until he moved from an apartment to a private house. And there it turned out that, if not all, then most of the construction and repair work a man could do himself. And over time, become a person who builds complex and beautiful houses, not doing like his neighbor, but trying new (or long-forgotten) ways in individual house building. And, as they write in his thread on FORUMHOUSE, maybe someday we will not have a dull today, but a pleasant-looking tomorrow! Read our article, which contains the best houses in the entire history of the portal, watch a video about an interesting wooden sauna house.