Having your own pool has always allowed a person to feel more self-sufficient and significant. In addition to status, there is also the opportunity to splash in the water in the heat. Some even organize artificial ponds inside the house so that you can feel like you are at sea at any time of the year.

But if the house is already in use, then the process of installing a pool can be fraught with numerous difficulties and high costs. Therefore, it is worth considering the rationality of installing such a structure.

Features of the pool on the ground floor

The room, half buried in the ground, is ideal for placing a temporary or permanent pool. The latter are easier and more profitable to construct at the stage of building a house, since later the process becomes more difficult and requires significant investments.

Advantages (they also apply to basements):

- The covered structure can be used in any weather and season.

- The area of the suburban area is saved. The space that the pool would occupy would be enough to accommodate a small decorative pond, gazebo, flower bed, play area and several trees.

- The pool on the ground floor is a backup water storage facility that increases the fire safety of the house.

- An artificial reservoir is several tons of water, which gives the foundation additional stability and prevents the heaving effect.

Flaws:

- We have to build a variety of communications. For example, ventilation, which an outdoor pool does not need. You will also need containers for overflow, drainage, etc.

- In a room where open water is constantly present, humidity increases. To prevent the appearance of mold and mildew, install high-quality waterproofing.

- If the pool is placed asymmetrically, the foundation is unnecessarily loaded. Concrete slabs can simply collapse.

- If the ground breaks below the level of the slabs, the foundation of the building may lose stability. The pool should not be part of the foundation, it should have its own foundation.

- When digging a pit, you can damage the walls of the house. There have been cases when houses simply “folded”.

The disadvantages are so serious that not every building with a basement will be safe and advisable to place a home pool.

Finishing work

After the rough work, finishing work begins. First you need to select the material. But before finishing begins, it is better to install an acrylic liner into the structure of the bowl, which prevents the structure from leaking during use. It is important that all walls and ceilings are waterproofed. This can be achieved through the use of waterproof plaster or other means.

In addition, ventilation is provided to remove moisture from the basement. A supply and exhaust system, which has an air recovery function, will reduce the humidity level in the room to a minimum.

Once these systems are installed, the bowl can be finished. This is the final stage, the quality of which will determine the evenness of the surface and the aesthetic appearance of the pool.

Types of pools

Both stationary and prefabricated pools are installed in the basement rooms. The choice of design depends on the stage at which the “reservoir” is installed.

Monolithic

This is a powerful stationary type design. Before its construction, a calculation is made of the bearing capacity of the foundation. The best option is an insulated Swedish stove that can withstand significant loads. To create such an object requires a lot of money and effort.

The bowl is finished in different ways, but with any solution, its installation requires special concrete for hydraulic structures. Construction can be entrusted to professionals, but then construction is more expensive.

Frame

Such pools are prefabricated industrial structures. It is based on metal pipes. The remaining elements are durable film and fasteners. Sizes and shape are at the consumer's choice. All designs are equipped with filters and pumps.

Frame pools can be ground-based (rod and sheet), for installation in a pit, small-sized and others. The downside is the fragility of the film. It can be cut or pierced with sharp objects. Plus - ease of installation.

Inflatable

This is the most affordable option for arranging a pool - installing an inflatable product made of durable three-layer polyvinyl chloride. They are filled with air or water. Polyester mesh can be used to strengthen the structure.

There are inflatable pools on sale that differ in the size and appearance of the bowls. There are products with stairs, roofs, slides, seats, air massage, etc.

Installation of equipment

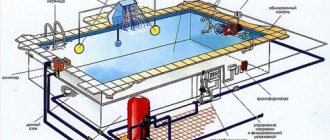

The equipment is installed according to a finished project. First of all, the equipment is assembled, all threaded and adhesive connections, couplings, taps and other important elements are checked. After the equipment is installed, it is necessary to fill in water and turn on the filters for washing.

If there are no leaks, we can conclude that the installation was completed correctly. Installing special equipment is a rather complicated operation, but you can do it yourself using the instructions. It is best to use the services of specialists to perform installation.

Preparatory stage

Frame and inflatable structures are assembled within a few hours and do not require additional materials - everything needed for assembly is sold complete with the pool. If a decision is made to build a monolithic structure, first create a project and prepare the necessary materials.

To build a swimming pool on the ground floor yourself, you will need special technical literature that regulates the requirements for the premises, materials, and equipment. After drawing up the project, they obtain the approval of experts and only after that work begins.

Creating a Project

At the beginning of the design, the features of the future structure are determined. They decide where to place the bowl, what its shape and size will be. Next, a static calculation is made, during which the possible loads and the desired safety factor are determined.

Stages of static calculation:

- Select materials for constructing the bowl.

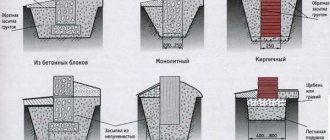

- The foundation is designed taking into account the settlement of the earth, the depth of its freezing and the presence of groundwater.

- The sections of structural elements are calculated.

- Carry out the drawing.

- They make an estimate.

At the design stage, the method of installing the pool is determined, waterproofing materials are selected, with which all joints and surfaces are treated.

Necessary equipment and materials

Pool bowls are made from different materials - stainless steel, polypropylene, fiberglass. Monolithic concrete is considered the best solution.

Advantages of hydraulic concrete:

- durability;

- thermal resistance;

- resistance to aggressive environments.

You can buy it or prepare it yourself from the following materials:

- binding component;

- filler;

- hydrophobic additives, for example “Ceresit” or others;

- seals.

Pool formwork is usually made of planks, plywood or other suitable wood. Plastic or metal copes with the task no worse.

When building a pool, it is better to immediately think about a filtration system, otherwise a musty “basement” smell will quickly appear in the room.

When creating a pool in the basement, you will need the following equipment:

- Filtering. A circular pump takes water from the bowl and sends it to a sand filter, where it is cleaned of large fractions. The filtration equipment includes: pumping station;

- skimmers (devices for collecting waste in water);

- equipment for adjusting water level;

- nozzles providing inflow/outflow of liquid.

Requirements for the basement floor

The basement floor in which the monolithic pool will be built must meet the general requirements for all premises with artificial reservoirs.

General requirements for premises:

- finishing must be completed by the start of work;

- availability of lighting, ventilation, air conditioning systems;

- The room temperature should not fall below + 15°C.

In addition to the general conditions, there are additional requirements specifically for the basement:

- minimum height – not less than 2.8 m;

- the area of the base of the basement should be equal to the area of the entire house;

- insulation of floors between the basement and the first floor to prevent condensation and increased humidity.

Despite the fact that the pool is being built inside the building, it is important that the soil on the site is dry and dense.

Conditions for constructing a pit:

- the bottom of the pit should exceed the groundwater level by 0.3 m;

- when determining the depth of the pit, in addition to the cross-section of the bowl, the thickness of the sand-crushed stone layer, hydro- and thermal insulation, and cement-sand mortar is also taken into account;

- The width of the pit is made 0.5-1 m larger than the dimensions of the pool.

Differences between a Russian bath and a sauna

In order to correctly draw up a high-quality project, take into account all the nuances, and equip a good, properly functioning room, you need to decide in advance what you want to have in your basement: a regular bathhouse or a sauna? Let's look at their differences:

- The operation of a sauna is characterized by dry steam obtained from heated elements. In a Russian bath, on the contrary, wet steam is used. The air humidity in a sauna does not exceed 7%, while in a bathhouse it can reach 60-70%;

- The sauna does not involve supplying water to the room - to get steam, it is enough to prepare a small amount of herbal infusions - to wet the stones or a bucket of liquid;

- The temperature of the sauna can reach 120°C, and the temperature of the bath not higher than 70°C;

- It is not difficult to build a sauna; it can be done in almost any room, provided that heat preservation and heat transfer are ensured. For a bathhouse, experts recommend building a separate building, with an individual water supply and drainage system.

Construction stages

When building a pool, it is important to consider the type of soil. If they are mobile - sand or sandy loam - the walls of the bowl are strengthened.

Work is carried out in a certain sequence:

- Marking the site and pit. These works are performed using a tape measure, level, poles and cord. First, the points at which the corners will be located are determined, then pegs are installed in the gaps - along the lines marked by the level. When marking the boundaries of the pit, take into account that between the walls of the building’s foundation and the bowl there should be 1.5-2 m, no less.

- Strengthening walls. The rabbeting method helps to strengthen the side edges of the bowl. This procedure is especially important on unstable soils. To complete it, you need a hand drill, concrete and reinforcement. 2.5-3 m long passages are drilled into the walls, reinforcement is placed in them and concrete is poured. This results in reliable reinforcement along the perimeter in the horizontal plane.

- Depreciation. The bottom and walls of the pit are first leveled with shovels and vibrating plates, then a layer of sand - 15 cm is poured into it. Having compacted the sand layer, crushed stone - 15 cm is poured into the pit and compacted.

- Waterproofing the bowl. Waterproofing is laid on top of the shock-absorbing cushion. Typically, bitumen-based coating mastics are used for this purpose.

- Walling. For this purpose, a variety of materials are used - concrete blocks, bricks, foundation wall blocks. At this stage, the walls are also waterproofed.

- Reinforcement. After the walls are erected, their rigidity, reliability and durability are increased using a steel frame. It is made of metal rods with a diameter of 10 mm and wire for the bundle. The rods can be connected in other ways, for example, by electric or gas welding.

- Pouring concrete. When doing the work yourself, first make formwork from boards, then prepare hydraulic concrete and pour it into the pit. Each layer of concrete is compacted to create a flat surface. If the work is carried out by specialists, at this stage they lay a concrete slab on the prepared bottom using special equipment.

- Installation of service systems. All equipment is installed in a technical niche constructed under the bottom of the bowl. It is sealed and closed with a hatch.

The room must be equipped with ventilation that controls air flow.

Ventilation, hydro- and sound insulation

Internal ventilation is always based on the action of physical laws - hot air rises and tends to exit through the ventilation hole, while cold air enters through the lower hole and fills the room. Therefore, the most optimal option is when the supply vent is located under the stove, and the exhaust vent is at the level of the second shelves. If additional heating of shower rooms is expected, as well as the presence of a swimming pool, then the ventilation system will be more complex.

To prevent the sauna from becoming a source of unwanted noise and to maintain a presentable appearance for a long time, it is better not to skimp on the quality of building materials for heat, hydro and sound insulation. If funds allow, it is better to take foil materials and carefully seal the joints with foil-based tape. It is important that the insulating materials do not touch the inner lining; to avoid this, transverse and longitudinal slats are used.

Pool finishing options

After installing the filters, finishing work begins. Their goal is not only to give surfaces special functionality, but also decorativeness. To perform the work, use a ladder and appropriate tools.

Finishing methods:

- Plastering and painting. This is the simplest and least presentable option.

- Ceramic tile. It looks more attractive than a painted surface. Porcelain tiles look no less beautiful.

- Mosaic. The most interesting finishing option. Mosaic surfaces reflect light, playing with it as the water oscillates.

- PVC film. A simple and inexpensive option. It is used only in small pools. The downside is fragility and fragility.

How to build saunas and baths in basements

The most popular materials for the construction of these premises are ready-made sandwich panels or frames made of beams. The second option is more popular, as it is up to 20-30% cheaper.

With a frame system, all elements are measured locally and one by one. First of all, the load-bearing beams are mounted, and then the horizontal crossbars are installed on them. External walls are covered with plywood or clapboard.

Finishing facilities

Everyone wants their home to be original, not like others, and decorated only with high-quality and natural materials. The same can be said about the sauna, which not only improves the health of the owners, but is also a room that you want to show off to friends and relatives. Therefore, it is important not only to design a functional steam room, but also to give it a presentable appearance.

Decorative wall cladding

Natural materials are used to decorate saunas. It can be deciduous trees and stone. The wood is not properly coated with varnish or paint, leaving it in its original form.

Important! The use of building materials containing pine needles, which release thick gluten and sticky resins when the temperature rises, is strictly prohibited.

Floors

Most often, during construction, a foundation is made, which is poured from above with a large amount of liquid concrete mortar. To prevent the floor from burning your feet, it is sheathed on top with boards or laid with regular tiles, on top of which boards or wooden pallets are placed.

Doors

When choosing doors, it is better to give preference to materials that are resistant to changes in temperature and humidity. The canvas should fit snugly against the walls and not contain metal elements, especially with regard to door handles. If they overheat, they simply cannot be used.

The most practical are wooden and glass doors or combinations thereof.

Lighting

It is the organization of lighting that can truly decorate a sauna and give it an individual style, creating a unique and, at the same time, cozy atmosphere for relaxation and rest. Multi-colored LEDs that illuminate the edges of the floor or provide diffused light under the indented slats will help create a bright room or plunge the space into intimate twilight.

The solution for arranging light in a sauna is not limited by anything except your imagination. But you need to carefully follow the wiring rules and provide protection for the wires to avoid damage and fire.

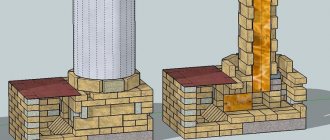

Stove and stove stones

The stove is the main element of the sauna. There is a wide range of these products on the modern market; these can be wall-mounted or floor-mounted devices.

Usually the body of the furnace is made of non-heating materials, but it is better to provide a fence for it. The parameters and size of the heating installation are selected taking into account the area and height of the steam room ceilings, taking into account efficiency, safety and with an emphasis on compactness.

Stones are placed in the oven: evenly, but with gaps, to ensure effective air circulation. The stones selected are resistant to temperature changes and have a high heat capacity.

To create a Russian bathhouse, the stove is made of brick. To do this, a foundation is first built at a short distance from the wall. Afterwards, a pit is dug, and crushed stone is poured into it and compacted well, after which the solution is poured. Before reaching the floor level, brick is laid and a sand cushion is installed. The stove is installed so that there is an air flow to it; a pipe is removed from it through a specially made hole in the base of the building.

Common mistakes

Construction of a swimming pool seems to be a simple process only at first glance. In fact, errors are possible at any stage, each of which can become an obstacle to the normal operation of the structure.

Mistakes when constructing a swimming pool on the ground floor:

- There are no openings for bookmarks. If you do not make holes for the embedded parts in advance, you will have to drill or chisel the concrete later. This can lead to cracks and weakening of the entire structure. The pipes are laid during reinforcement, immediately after the first layer has been laid. The openings must fully correspond to the dimensions of the mortgages.

- Concrete poured incorrectly. You cannot use concrete less durable than M350. Before pouring the mixture, check its quality, otherwise the bowl will simply fall apart. The bottom and sides are filled in one go.

- Cracks appeared after the formwork was removed. If the integrity of the hardened mixture is compromised, it means that the strength calculation was made incorrectly and the wrong diameter of the reinforcement was selected. If groundwater and surface water are not drained, cracking may also occur.

- There is no overflow tank. It should be positioned below the bowl to allow water to drain. Therefore, the house must have a basement. When designing a pool, it is presented as a technical room. Plastic containers for 2-5 tons of water help solve the problem.

The construction of a monolithic structure in the basement is a responsible undertaking that requires calculations and compliance with building codes. Any violation of the requirements for building structures and SNiP lead to serious consequences - from musty air to structural destruction.

Arrangement of the rest room

This room is no less important than the steam room itself. This is where intimate conversations take place, and the relaxation of steamed, heated owners takes place. The design of the room should be as comfortable and functional as possible. Usually, there are armchairs, a sofa or ottoman, a table, shelves, a kettle and a TV.

If the basement space allows, then the rest room is made large, where you can additionally place:

- billiards;

- large table for several guests;

- fireplace;

- a big sofa;

- bar;

- gym and other additional amenities.

Introduction

The best solution for equipping a bathhouse and a pond in the basement would be to plan such structures at the stage of developing a country house project. Since the construction of such facilities requires the presence of serious engineering communications - power supply, ventilation, sewerage.

white small insects in the apartment who are they

And if to install a bathhouse, in a modern configuration, you can get by with a powerful electrical cable and equipping a place for a shower stall (drain), then a swimming pool in the basement of a private house is a serious hydraulic structure that requires sufficient knowledge in this area, and most importantly - skill use this knowledge correctly in practice.

Construction of a bathhouse in a country house is the topic of the next article, and in this one, as you already understood from the title, the construction of a swimming pool in the basement will be discussed in detail. But since the construction of a steam room was mentioned above, I would like to offer developers one of the most profitable options - prefabricated panel structures (see photo).

Prefabricated bath model

The presented room (see photo) is equipped with an electric heater and automatic equipment for turning on and regulating the heating temperature. In addition to this design, you can install a shower cabin, equip it with a special pump (sololift) for forced drainage of waste water to the level of the central sewer system, and the bathhouse is ready.

Conclusion

If desired, from a lifeless basement or basement in a cottage, you can create an entire multifunctional floor where it will be possible to spend time comfortably.

Subject to all standards, careful design study and construction supervision, you can easily create a bathhouse or sauna in the basement of your house, equipped with a swimming pool, showers, relaxation areas and other necessary elements. Use high-quality materials, do not neglect safety precautions, and then the bathhouse will delight you for many years.

Did you find this article helpful? Please share it on social networks: Don't forget to bookmark the Nedvio website. We talk about construction, renovation, and country real estate in an interesting, useful and understandable way.