By power

In the marking of stoves of the “Koster” line

a numerical value is indicated indicating the maximum possible volume of the steam room for a given furnace, however, when calculating, it is necessary to take into account related factors and, as a consequence, correction factors.

Such as: 1. Quality of thermal insulation of the room. In the absence of proper reflective insulation, the actual cubic capacity must be multiplied by 1.5. 2. Material of the steam room. When calculating the volume of a room, for each square meter of surfaces made of brick, tile, concrete or glass, 1.2 m3 should be added to the volume. 3. Frequency of operation of the furnace. When operating the stove in the winter, it is necessary to multiply the resulting volume of the steam room by a factor of 1.5. According to the created microclimate. Most existing sauna stoves are divided into convection and inertial. Convection ovens quickly heat the air in the steam room, creating a sauna microclimate. Inertial stoves heat a large mass of stones with priority and release heat longer, creating a soft microclimate.

The lineup

The company producing Koster stoves is very young and so far there are few lines as such: only three, but they have a sufficient number of modifications, and the size range in two of them allows them to be used in both large and small steam rooms.

Basic line of Koster sauna stoves

This stove appeared first and it was this model that was discussed above. It is presented in five modifications, which are suitable for steam rooms with a volume of 4 to 28 cubic meters. Their technical characteristics are summarized in the table.

Technical characteristics of fireplace sauna stoves

Note! Depth indicated for model without remote tunnel. If you need an offset, add another 209 mm - this will be the depth of the Koster stove with an external combustion tunnel. The price is for the basic configuration - with a stem and a metal door.

Appearance of fireplace sauna stoves

The manufacturer offers the following options as options:

- Door with glass. Its weight is 1.5 kg, the door dimensions are 263*34*290 mm, the glass dimensions are 200*230 mm, the cost is about $40.

- Panoramic door with large glass (modification “Relax”). In this case, the door width is 440 mm, the weight is 9.5 kg (add to the original weight of the stove), the price is about $110. This door is different from those offered by other manufacturers - it is also extended upward. Therefore, even being at a distance of 1.5-2 meters from the stove, you can stand and admire the play of the flame.

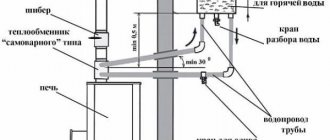

- Heat exchanger register (the letter “P” is added to the marking). The register is located in the front part of the firebox, the connection fittings are on the front surface. The maximum tank volume that can be connected to this register is 60 l.

- Samovar-type tank on a pipe. The volume of this tank is 50 liters, it boils in 50-60 minutes (through the register, the water takes twice as long to heat up). Therefore, to maintain a normal microclimate in the bathhouse, it is necessary to drain hot water in a timely manner to prevent boiling and the formation of wet steam.

How to connect a remote tank to a register

Bonfire-Grid

Mesh sauna stoves are popular because of their non-standard appearance - the body of the stove is lined with stones, which are held in place by the mesh. This solution also makes it possible to reduce hard radiation from the walls of a heated firebox to a minimum - it is “intercepted” by stones. And heated stones already transfer heat gently, in a range of thermal radiation that is pleasant for our body. But this solution also has disadvantages. Firstly, it takes two to three times longer to warm up the steam room. Secondly, the walls of the firebox covered with stones overheat and burn out faster.

Screen with holes for more active heating of stones and cooling of the firebox walls

Since 2013, these problems have been solved in Koster mesh sauna stoves: additional convective screens with perforations are installed around the firebox. The air rises along the wall of the firebox, cooling it. Through the holes in the screen, it partially exits into the heater, transferring heat from the walls to the stones. This speeds up the heating of the stones and eliminates the problem of overheating of the firebox walls.

Technical characteristics of fireplace stoves Koster-Setka

As an option, you can install a mesh module on the pipe and lay stones inside it. This is also an opportunity to shield the hard radiation from the chimney, as well as to remove more heat and speed up the heating of the steam room. Agree, the appearance of this model with a mesh on the pipe is more harmonious.

Appearance of the Koster-Grid stove for a bath

This line is equipped with either a standard door with glass or a panoramic one. It is also possible to install a heat exchanger.

Koster-PaRus

Many Russian bath lovers believe that good light steam can only be obtained from stones heated in a closed heater. In this case, the steam turns out to be really light and “dry” - very small droplets contain a minimum of moisture. The Koster-PaRus stove was created for fans of closed heaters. It is currently presented in a single modification - for steam rooms from 12 to 24 cubic meters, but there are three door options - simple metal, with regular and panoramic glass. An extension for the firebox from the adjacent room can also be installed.

Technical characteristics of the Bonfire sauna stove with a closed heater PaRus

Wood burning stoves "Koster" - an informed choice

When choosing wood-burning sauna stoves, a modern buyer, as a rule, does not experience difficulties in finding a model that is suitable in terms of power. Rather, he has the problem of choosing “his” option from many possible ones.

Most focus on criteria such as brand recognition, attractive design and, of course, cost. However, these criteria do not guarantee either the durability of the product or the creation of a comfortable microclimate in the steam room. At the same time, people try to purchase a stove for more than one year and expect to get maximum pleasure from the vaping process. Is not it?

Most focus on criteria such as brand recognition, attractive design and, of course, cost. However, these criteria do not guarantee either the durability of the product or the creation of a comfortable microclimate in the steam room. At the same time, people try to purchase a stove for more than one year and expect to get maximum pleasure from the vaping process. Is not it?

Materials

Today, most manufacturers use thick-walled structural or thin-walled stainless steel in the manufacture of their products. Each of these materials has both its strengths and disadvantages.

By developing and manufacturing modern sauna stoves, the specialists of Koster Group of Companies combined the most useful qualities of both types of steel in the production of fireboxes:

Low-alloy steel 09G2S with a thickness of 4 mm is characterized by high rigidity. Due to this, the risk of deformation of load-bearing walls is minimized. This is an excellent alternative for those who would like to purchase a cast iron sauna stove, which, as is known, is not subject to deformation.

High-alloy steel 08Х17Т 4 mm thick with a scaling temperature of over 850°C is 3 times more durable than structural steel.

Design features

Being specialists in our field, we know that when choosing a stove it is worth carefully studying not so much the features of its design, but the features of its construction. And it is this issue that we paid special attention to.

By increasing the height of the firebox and making it narrower, we were able to increase the area of contact of the flame with the walls of the firebox. Thanks to this, the air in the steam room heats up faster and more evenly.

In comparison with analogues, the height of the firebox manifold, in which the flame divider is located, has been significantly increased. This made it possible to solve the problem of incomplete combustion of wood and significantly increase efficiency, especially in comparison with the fireboxes of cast iron stoves, where wood combustion occurs less efficiently

The design of Koster wood-burning stoves uses a patented technical solution, thanks to which the user can switch the operating stove to combustion stabilization mode. This makes it possible to accomplish several tasks at once: increase the service life of the equipment and reduce the consumption of firewood.

Design Features

The main difference between Bonfire sauna stoves is immediately noticeable - it is the elongated upward shape of the firebox. If you look at its structure in cross-section, then the smoke collector also has an elongated shape, and its area is increased by 2.5 times compared to other structures. Another feature is that the divider is not located at the bottom of the collector, but almost in the middle.

What does this give? Due to the high and narrow firebox, as well as the fact that its lower part in the area of the grate has the shape of a trapezoid, the firewood burns evenly over the entire area of the stack, including from the sides. So there are no areas where firewood does not burn or burns worse.

Firebox for sauna stoves Fire in section

Also, the elongated design of the firebox allows you to increase the area of contact of the flame with the walls - during free combustion it stretches upward, and since the walls limit it on the sides, they heat up more actively. An extended collector serves the same purpose - to remove as much heat as possible from the smoke before it flies into the chimney.

Another feature of Koster stoves is the supply of secondary air to the upper part of the firebox for more complete combustion of wood. To do this, a high-alloy stainless steel plate is welded to the rear wall, with a hole in the lower part. The air passing through the grate is sucked into this gap and exits at the top of the firebox, causing the combustion of gases to activate. The second function of this plate is to protect the rear wall of the firebox from overheating (lining).

The next find is the nonlinear (concave) shape of the upper plate of the smoke collector, on which stones are also laid. The concave shape makes it possible to better transfer heat to them (larger contact area) and water evaporates better from such a surface (if it gets there by flowing from stones).

For a Russian steam room?

There is another interesting solution that allows you to avoid overheating of the steam room - a double-wall convection casing. Pay attention to its structure at the bottom of the firebox. There is an additional wall that separates the convection currents. Hotter air, coming in close proximity to the firebox wall, is supplied to the heater, accelerating the heating of the stones. Not so superheated air, separated from the firebox by a partition, goes directly into the steam room. Thus, the stones heat up faster, and the heat in the steam room is not felt so strongly.

Separation of convection flows in the Koster oven

To stabilize the temperature in the steam room and not to overheat it, the Koster sauna stove has a patented solution - perforation in the upper part of the door. When the temperature is actively set, the ash pan of the stove is pulled out, oxygen along with air enters directly into the wood burning zone. When the required temperature is reached, the ash pan is pushed in tightly, and air flows through the perforation of the door, entering only the upper part, and in limited quantities. At the same time, the firewood begins to smolder, releasing more flammable gases, which burn in the upper part of the firebox, that is, in the upper part the temperature remains high. In this mode, the lower one becomes colder, and heating of the steam room practically stops (the secondary convection flow, separated by a partition, has a relatively low temperature, which can no longer greatly affect the general background).

It is these findings that make it possible to use Koster metal stoves to create a microclimate in the steam room close to a Russian steam room - at a low air temperature of about 50-60°C, the humidity is raised to 70-80%.

But in order to feel good after a steam room, you need “light” finely dispersed steam, which is obtained from stones heated to very high temperatures (450-500°C and above). To solve this problem, the heater in Koster stoves does not have its own bottom and walls, as such. It is formed on one side by the walls of the firebox and smoke collector, and on the other it is limited by a plate. This allows you to better heat the stones even in an open heater, getting good steam.

What kind of steel is it made of?

In general, there are furnaces made of thin-walled stainless steel (2-2.5 mm) or structural steel with thicker walls (4 mm or more). Both of them have their advantages and disadvantages. Stainless steel does not burn through (if the seams were welded in a protective environment), and this is its undoubted advantage, but it is thin and “leads” when heated. The walls of the firebox bend, which can cause the seams to burst. Also, thin steel may not withstand the load from stones or from the chimney. Making thicker walls is unprofitable for economic reasons: the oven turns out to be too expensive. Structural steel is much cheaper, therefore thicker steel is used, it does not “lead”, but it burns out quite quickly, which is also not very good.

Combination firebox in a sauna stove

When developing the Koster stove, the advantages of both types of metals were taken into account and the firebox was made combined. Parts experiencing increased temperature loads are made of high-alloy stainless steel 08X17T with a thickness of 4 mm (a significant thickness that is rare). The vertical walls, which experience greater deformation loads (cooled by air flows), are made of low-alloy steel 09G2S. The thickness of these walls is also 4 mm. This steel has increased rigidity, it does not lead or “twist”.