Expanded clay concrete blocks are widely used in private construction, including in the construction of individual residential buildings, garages and other auxiliary buildings due to their low cost and good technical parameters. But the foundation made of expanded clay concrete blocks is often criticized by professional builders. What does this have to do with?

Basic requirements for laying walls

Buildings with a height of no more than four floors are erected from expanded clay concrete blocks.

To build a house with more floors, a metal or reinforced concrete frame is required. General recommendations and requirements for preparation and laying are as follows:

- the upper surface of the house foundation is leveled with cement mortar, about 30 mm thick;

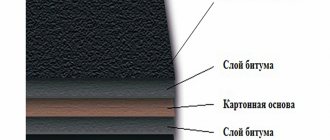

- cover the frozen solution with 2-3 layers of roofing material (waterproofing), coating them with bitumen mastic;

- always starts from the corner, building a row around the perimeter, after which the next row is laid, etc.;

- It is better to lay the internal walls at the same time as the external ones, paralleling the connection of the walls;

- The inner and outer walls are connected to each other by releasing every second block from the inner wall into the outer one. The release size should be equal to half the length of the block.

Having familiarized ourselves with the basic requirements, let’s move on to the technology of laying walls from building blocks.

Screw foundation

Features of laying walls from expanded clay concrete blocks

We are starting a series of videos about building a house

from expanded clay blocks. What types of work need to be carried out before

How we started building a residential building

in 2015, what was made and how.

Image of a helical foundation

The support of this foundation is helical pile structures. The foundation of the house is made of ceramic blocks. Pile-type foundations are distinguished by grillages. DIY foundation for a garage made of blocks. To construct it, wells of a given diameter are drilled. The purchased wells are reinforced and filled with concrete.

The base has a low installation price and is suitable for light buildings, for example, country houses. A foundation made of FBS blocks, the pros and cons of which should be carefully considered before. Therefore, it can be completely suitable for houses made of expanded clay block buildings on swampy soils. But there cannot be a basement in such a house.

Such foundations are used in the construction of light country houses.

Hydro- and thermal insulation

Regardless of the construction method, the foundation needs proper waterproofing. It consists of covering all the walls around the perimeter inside and outside with hydrophobic substances. This can be a coating - mineral or bitumen mastic, or insulating membranes: roofing felt or adhesive film.

The waterproofing design for each type of foundation is individual.

- Floor with thermal insulation layer.

- The foundation is monolithic.

- Horizontal waterproofing layer. It is applied to the sand and gravel bed before the pouring process. It consists of two layers of roofing felt glued together with bitumen mastic.

- A compacted sand and gravel base or concrete pad to be used when necessary on shifting ground.

- Thermal insulation board - polystyrene foam or polyurethane foam. It is used not only for thermal insulation, but also to protect the waterproofing film from damage during the pouring process.

- Vertical waterproofing.

Foundation insulation method 2

- House wall.

- Floor slab.

- Block foundation.

- Gutter made of waterproof cement.

- Horizontal waterproofing.

- Sand pillow.

- Drip pan for condensate drainage.

- Thermal insulation layer made of extruded polystyrene foam or mineral wool.

- Vertical external waterproofing. It consists of two layers of glued roofing material or a special polymer membrane. When laying it, part of the material should be folded onto the blocks of the upper platform.

- Insulation for the floor above the basement.

Slab foundation

Foundation made of FBS blocks (basics of construction)

Example of a slab base (photo)

This support for the building is quite reliable. It is used in climates where low temperatures prevail for most of the year. Since the slab base can withstand extreme cold, a house made of expanded clay blocks will protect the foundation base from hypothermia. Such a foundation is also used on unstable soils, since it:

- resistant to unstable soils;

- tolerates low temperatures;

- durable;

- durable

Its construction requires clear preparation procedures. Among them: the need to compact the soil, making a sand cushion, deepening the blocks and the operation of compacting concrete using vibration.

Advantages of expanded clay concrete

Expanded clay is obtained by heat treatment of low-melting grades of clay. It is as porous as gas silicate. This material has the following positive properties:

- Quite strong, but not suitable as a foundation for tall buildings.

- It has excellent soundproofing and thermal insulation characteristics.

- Resistant to changes in weather temperature and humidity levels.

- Non-flammable.

Expanded clay blocks are produced using the following methods:

- Monolithic production of walls by pouring.

- Preparation of blocks of various shapes.

For expanded clay mortar, make the following mixture: cement (1 part), sand (2 parts), expanded clay (3 parts). For the construction of a building, cement of grade M400, no less, is taken. Water is added to the solution while constantly stirring the mixture until the consistency of sour cream is obtained.

Columnar foundation

What foundation to make for a block house

Columnar - ordinary and cheap to manufacture

It is used for lightweight houses made of expanded clay concrete blocks on constantly freezing soils. Foundation for a one-story house made of blocks. Columns for the foundation base of a house are made of concrete, brick, expanded clay concrete blocks or foam blocks.

This support is sometimes combined with a reinforced concrete slab, which is installed on posts. How to make a foundation for a house from expanded clay concrete blocks. Various types of structures and methods of their installation. Foundation for a house made of expanded clay blocks: video instructions. The result is a columnar-slab base that can support the heaviest houses made of expanded clay concrete blocks, even on swampy soils.

Armopoyas

If a house is being built on unstable soils or on topography, then the prefabricated foundation needs additional reinforcement to minimize damage from shrinkage processes. An armored belt is a structure made of monolithic reinforced concrete with a thickness no more than the thickness of the walls and the same height (square in cross-section). For pouring, concrete grade from M150 is used.

It is most advisable to use a monolithic strip foundation for a house with 2 or more floors with interfloor floors made of reinforced concrete, but for low-rise construction such strength will be excessive. For a one-story house, a cheaper prefabricated foundation made from the same blocks is quite sufficient.

Expanded clay block foundation

The introduction of expanded clay concrete blocks as a foundation in the photo

A foundation made of expanded clay concrete blocks has a huge number of advantages. It is used not only for house construction. Which foundation is better for a house made of aerated concrete: options. It can also be used to build foundations. But such a foundation is suitable only for light buildings, for example, for garages, bathhouses and others. Advantages of expanded clay foundation:

- strength not inferior to concrete;

- can serve for a long time without changing under the influence of climate;

- quickly and easily erected;

it is waterproof.

Careful preparation

At the preparatory stage, you need to take care of everything in advance and calculate the base of the foundation. This point is necessary to calculate the consumption of materials.

It is equally important to calculate the load on the foundation so that the walls of the future house are firmly supported on it. Any foundation, no matter how strong it is, gives a certain settlement over time, so you need to calculate the foundation settlement at the preparatory stage, so you will know everything exactly about the design of the future foundation.

You also need to remember that expanded clay concrete blocks require careful waterproofing. A material saturated with ground moisture wastes its important advantages.

Selection of foundation

When choosing the type of foundation for a house made of expanded clay concrete blocks, it is necessary to take into account the depth of freezing of the ground and the topography of the site. It is also necessary to know the level of groundwater, the level of street noise and almost everything else.

This selection must be done especially painstakingly in areas with constantly frozen soils or on slopes. For walls made of gas silicate blocks, a special glue is used, which has excellent adhesion and thermal insulation properties. On this type of soil, it is unsafe to build houses from expanded clay concrete blocks, unless it is a slab one.

Due to the large area, the load on the soil in this case is distributed moderately along all fronts. The soil experiences virtually no pressure. Foundation made of FBS blocks, turnkey price in St. Petersburg. This makes it possible to erect any buildings on a slab foundation. Foundation for a house What kind of foundation is needed for a house made of walls made of aerated concrete blocks. But due to the size of the slab, this is not very comfortable to do, especially when building from blocks.

And, in general, it’s not worth chasing after far-fetched savings. It is better to entrust the construction of a house from expanded clay concrete blocks and the foundation for it to qualified specialists. They will select the type of foundation base appropriate to the area.

Construction technologies

So, depending on the type of construction of a house made of expanded clay concrete blocks, the foundation is selected.

Tape

The strip foundation can be either prefabricated or monolithic

It can be either prefabricated or monolithic. Monolithic has many advantages, since it minimizes the need to use special equipment. In this case, the width of the tape must be no less than the thickness of the wall panels to create a strong support and prevent displacement of the axis of the blocks and the base.

The material requirements are as follows:

- concrete grade B20-25;

- reinforcing bars A400;

- backfill made of medium sand;

- for tape with shallow or deep immersion, provide insulation materials.

Columnar base

It can be made of concrete blocks or be monolithic. A mandatory grillage is provided to ensure uniform distribution of the load on all elements.

Slab base

It is equipped with reinforced concrete monolithic slabs. For private buildings, slabs with a cross-section of up to 300 mm, class B20-25 concrete, and A400 reinforcement are used. Reinforcement frames are required, as is pouring in one go, which will increase the reliability of the entire structure.

Piles

To build a house from blocks with your own hands, it is better to choose bored piles

They can be screw or bored. To build a house from blocks with your own hands, it is better to choose bored piles, which increase the strength of the entire structure, but screw pile elements will reduce excavation work and deepen them much faster and easier. It is necessary to arrange a grillage, which is best made of reinforced concrete, but an ordinary metal one can also be used.

When choosing a foundation for a building made of blocks, it is necessary to clearly understand the characteristics and capabilities of the soil. Only with correct calculations will it be possible to avoid mistakes and make the foundation truly strong. Do not forget about insulating the underside of a house made of blocks if the choice fell on pile or slab foundations. Experts recommend choosing the latter option, but you can use strip types of foundations, provided the soil quality at the construction site is acceptable.

Types of expanded clay concrete blocks

Materials are produced in two ways:

- monolithic filling;

- bricks and blocks are made in various shapes.

For mortaring expanded clay blocks, materials are required in the following proportions:

- One part cement, two sand and three expanded clay. When adding water, the solution must be stirred until it has a homogeneous consistency, resembling sour cream.

- The concrete mixture must be prepared in small portions, immediately before use, since expanded clay tends to quickly absorb moisture, which significantly affects the quality.

- Stir the solution until the expanded clay granules are completely immersed in the mixture of sand and cement.

- To make bricks, choose small expanded clay granules.

- You can use a solution that hardens for about a month and no less.

- Expanded clay concrete blocks are suitable for various types of foundations, which are determined by the characteristics of the soil and climate of the area.

- It is necessary to identify groundwater and its level, the depth of soil freezing.

Return to contents

Purpose, types of foundation. Foundation construction technology.

Foundation for a house - choosing the type of foundation and material for it is an important task for a good builder. If the foundation for the house is not suitable, then problems will certainly arise during operation, which will require serious financial costs. In many ways, the type of foundation depends on the characteristics of the foundation soil, as well as on the material from which the house is built. Next, we consider what kind of foundation is needed for a house made of expanded clay concrete blocks.

Choosing the type of foundation.

Two characteristics of the wall material significantly affect the foundation - their mass and resistance to possible deformations. These characteristics of a house made of expanded clay concrete blocks are better than, for example, a brick house, but are inferior to a wooden house.

Before deciding on the type of foundation, you must consider the following characteristics:

– load on the foundation from the mass and distribution of the house structures. – soil strength at the site.

The load on the foundation depends not only on the material of the walls, but also on the number of floors being built. So for a one-story building it will be enough to provide one type of foundation, but for a two-story building it will be necessary to build a foundation of a more powerful structure. The strength, water saturation and heaving of the soil jointly influence the choice of the type of foundation with your own hands for a house made of blocks. The following recommendations can be given:

Construction of a house on coarse soil or sand of medium and coarse fraction. In this case, it is necessary to take into account that the soil is not too saturated with water (otherwise it is better to stay on piles). These foundations are non-heaving and have a fairly high load-bearing capacity. Construction on clay, loam, sandy loam and fine sand. Such soil has a much lower load-bearing capacity and is prone to heaving

When building a house here, it is important to pay attention to ensuring that the supports are laid at least to the depth of soil freezing. The groundwater level must be located at least 50 cm below the base of the building, otherwise dewatering and drainage will be required

Foundation construction technology.

The technology for building a foundation for a house depends on the choice of foundation type. Below we provide brief descriptions for each type of foundation.

Slab type foundation. Made from monolithic reinforced concrete. For private construction, the thickness of the base slab (excluding concrete preparation) will be 200-300 mm. For production, concrete of classes B20-B25 and reinforcement of class A400 are used. Reinforcement is performed with frames. Filling must be carried out in one step, which ensures compliance with all technology and reliability of the foundation design.

Strip foundation for a house. Can be manufactured in two ways: – prefabricated. – monolithic. Monolithic has much more advantages when building a private house, since it allows you to avoid the involvement of lifting and heavy equipment. The width of the tape is selected based on the thickness of the walls being built. It should ensure normal support of the enclosing structures, if possible without overhangs and displacement of the axes of walls and foundations. The following requirements for materials can be given: - concrete B20 - B25; - reinforcement A400; - sand for adding medium or coarse fractions. If you plan to install a shallow tape, you must provide insulation with expanded clay or extruded polystyrene foam.

Pile type of foundation. Here you can choose from two technologies: – drilled. – screw. When cutting supports of any type to ensure joint work, I provide a cane, which can be: – reinforced concrete; – metal; – wooden.

Columnar type of foundation. Just like the tape, it can be made from monolithic and precast concrete. A grillage is provided along the edge, which will ensure the joint operation of free-standing elements. This type of support is extremely rarely used for massive buildings; it is well suited for the construction of a small private house.

In conclusion of this brief review, we can recommend a slab or strip foundation for a house made of expanded clay concrete blocks.

Features of the material

Only two characteristics of the material from which the walls are made have a significant impact on foundations:

- weight;

- resistance to deformation.

According to these characteristics, a house made of expanded clay concrete blocks is better than a brick one, but is still inferior to wood. The following is discussed in more detail.

Resistance to deformation

Blocks are a piece of building material, so they are very unstable to base deformations. The danger is posed by uneven shrinkage, when one side or corner settles or rises more than the others.

If the foundation is not laid correctly, the blocks can cause shrinkage

In this case, the foundations become skewed, and inclined cracks run along the walls. To prevent the occurrence of such unpleasant phenomena, you need to correctly select the type of foundation, perform its calculations and strictly follow the construction technology with your own hands at the construction site.

Careful attention to each stage will ensure the reliability of the supporting part of the house made of expanded clay concrete blocks.

Mass and density

The density of the material is in the range of 500-1800 kg per m3. This is a fairly small mass, which is an undoubted advantage of wall structures. The fact is that the less the walls weigh, the less load falls on the foundation. At the same time, its required load-bearing capacity, financial costs for construction and labor intensity are reduced.

Table of characteristics of expanded clay concrete blocks

The blocks have holes that, without compromising thermal conductivity, reduce the final mass of the product. Due to the ability to retain heat, the thickness of the wall made from the material in question is needed less than for less thermally efficient products, which again reduces the load on the supporting part of the building.

For comparison, the masses of walls made of various materials are considered below. The values are given for a linear meter of a house wall within one floor (3 m high) for optimal thickness in terms of thermal performance indicators (on average). The normalized heat transfer resistance is multiplied by a factor of 0.63, which is permitted by regulatory documents.

- reinforced concrete without insulation 400 cm thick - 30 tons;

- ceramic brick 64 cm thick - 3.5 tons;

- expanded clay concrete blocks with a density of 1000 kg/m3 and a thickness of 65 cm - 1.95 tons;

- expanded clay concrete blocks with a density of 700 kg/m3 and a thickness of 40 cm - 0.85 tons;

- pine 30 cm thick - 0.5 tons.

From the list above you can see that the load depends on the density of the blocks. Compared to brick or reinforced concrete, expanded clay concrete clearly wins in terms of reducing the required load-bearing capacity of the foundation, which allows you to have more choice when designing and building with your own hands.

To make a more accurate load collection, you will need to perform a thermal engineering calculation of the wall thickness for the climatic conditions of a certain area and the selected grade of wall material.

Basic algorithm of actions

Most often, such blocks are used for laying prefabricated strip foundations. In this case, you need to carefully follow the following procedure:

- According to the initial design, a pit or trench is dug, and its length must necessarily be greater than the width of the blocks.

- The bottom of the pit is filled with sand and then thoroughly compacted.

- A special concrete pad is created a little higher.

- The blocks are laid according to a similar masonry principle. Start from the corners, do not forget about careful dressing. The solution is carefully poured into the resulting gaps between the blocks, leaving the necessary holes for future utilities.

- A so-called armored belt begins to form on top of the laid blocks - this is a durable layer of monolithic reinforced concrete that reliably connects all the tops together. It is designed to provide rigidity to the entire base.

- The outer side wall of the formed tape is tightly covered with waterproofing. Also, do not forget about the horizontal waterproofing layer; here it is simply necessary.

- If the design provides for the creation of a basement floor, floor beams are laid.

- At the end of all manipulations, the base is finally backfilled.

These are the steps that need to be performed by those who decide to lay the foundation themselves. At first glance, everything is extremely simple, but when it comes to practice, everything turns out completely differently.

DIY foundation

Before starting to build a house, you should complete the preparatory period: register ownership of the land on which the house will stand and examine the soil in this area. And depending on the properties of the soil, it will be possible to decide what kind of foundation we will build for our house with our own hands. The most common types of foundations are: strip foundation; pile foundation with and without grillage; monolithic slab foundation. Depending on how much money you are willing to invest, the type of soil on the construction site, and the weight of the structure of the future home, you can decide on the type of foundation. A do-it-yourself shallow strip foundation for a house is usually built on dense soil, with a fairly heavy structure of the future building. Do-it-yourself foundation: building from scratch! In the presence of loose, weak, swampy soil, when dense continental soil is located at a depth of up to two meters, it would be preferable to build a pile-type foundation. How to build a foundation with your own hands when the mainland soil is more than 2.5 meters away and the surface soil cannot support it? The best option in this case is to pour a monolithic slab foundation with your own hands as the foundation of the house. Swampy or loose soil is not able to support foundation strips or piles, but it can support a slab, since its support area is quite large. If we are building a foundation with our own hands, then we will need special equipment and the following tools: cord for marking; building level and preferably hydraulic level; several bayonet and shovel shovels (for yourself and assistants); hammer, hacksaw, axe, nails (for erecting formwork);

hook for tying with wire reinforcement. Do-it-yourself foundation: building from scratch! Most likely, you will need equipment: an excavator to dig a pit or special equipment to drill wells; vibrating platform, construction vibrator, concrete mixer, device for driving piles. Very often a crane is required, for example, if you decide to make a foundation from blocks yourself. You should rent the necessary equipment in advance and adjust the work schedule for building the foundation yourself so that there is no downtime. It is preferable to pour slab or strip foundations in one go. If part of the concrete mass “sets” before the pouring continues, then the joints of portions of concrete poured at different time intervals will be a “risk zone.” The strength of the foundation in such places will be a huge question mark - it will be a “weak link”. Piles can not be driven all at once, but in stages: one or two - three piles per day. It is clear that this will not affect the strength of the foundation in any way. What materials are needed to pour the foundation yourself?

Expanded clay concrete support

For the foundation of a block house, you can use expanded clay concrete porous building material. The budget option for constructing a support has a number of practical properties:

- characterized by increased wear resistance. The porous structure of the material is durable, which guarantees the durability and quality of the structure.

- excellent thermal insulation qualities of the building material. The design does not require additional insulation.

- Expanded clay concrete bricks retain their shape during temperature changes, which guarantees the integrity of the base.

- completely safe for humans, environmentally friendly.

- installation is carried out with your own hands, without the use of additional equipment.

Arranging a supporting structure from a porous block is a good solution not only for one-story buildings, but also for buildings with several floors. A block foundation requires effort and time to lay out. But its use will provide a residential building with a reliable and durable foundation. To build your country house using expanded clay concrete blocks, you should resolve the issue of arranging the foundation. The choice of a certain type of foundation is the key to the reliability of the entire construction.

Selection of foundation

When choosing the type of foundation for a house made of expanded clay concrete blocks, it is necessary to take into account the depth of freezing of the ground and the topography of the site. It is also necessary to know the level of groundwater, the level of street noise and almost everything else.

This selection must be done especially painstakingly in areas with constantly frozen soils or on slopes. For walls made of gas silicate blocks, a special glue is used, which has excellent adhesion and thermal insulation properties. On this type of soil, it is unsafe to build houses from expanded clay concrete blocks, unless it is a slab one.

Due to the large area, the load on the soil in this case is distributed moderately along all fronts. The soil experiences virtually no pressure. Foundation made of FBS blocks, turnkey price in St. Petersburg. This makes it possible to erect any buildings on a slab foundation. Foundation for a house What kind of foundation is needed for a house made of walls made of aerated concrete blocks. But due to the size of the slab, this is not very comfortable to do, especially when building from blocks.

And, in general, it’s not worth chasing after far-fetched savings. It is better to entrust the construction of a house from expanded clay concrete blocks and the foundation for it to qualified specialists. They will select the type of foundation base appropriate to the area.

Characteristics of expanded clay

Expanded clay block is the final product of processing low-melting clays by firing. As a result, a porous building material is formed, which has a number of unique properties that are in demand in the construction industry.

Technical qualities of the material

Expanded clay block is characterized by the following indicators:

- high strength – 50-150 kgf/cm²;

- good noise and heat insulation. Block walls made of expanded clay concrete do not require additional insulation;

- resistance to aggressive environmental influences;

- increased fire resistance and resistance to moisture.

The volumetric mass of the porous material is comparable to wood, for this reason the building can be erected on various types of foundations.

Expanded clay fractions

Loose expanded clay is divided into the following fractional types:

- expanded clay sand – fractions from 2-5 mm. It is used in construction work - laying a sand bed, for filling aquariums, for constructing drainage.

- crushed stone – large multi-faceted pebbles with sizes ranging from 0-5 mm, 5-20 mm, 20-40 mm, 40-70 mm, 40 – 200 mm. It is used in road construction, equipment for children's playgrounds, landscaping, and room decoration.

- gravel – oblong granules from 5 mm to 70 mm. Natural material is used to build foundations, backfill sites, make roofing materials, and build highways.

The raw materials have different sizes, which ensures wide application in various fields.

Foundation for a house made of expanded clay blocks

A porous, durable material obtained by firing low-melting clays is called expanded clay concrete blocks. It has a lot of advantages and is used not only for the construction of the structures themselves, but also for the construction of the foundation. Of course, one can argue for a long time about this; which foundation is better - from foam blocks, concrete, but in some cases, only an expanded clay block foundation can be completely justified.

Advantages of expanded clay foundation

- Due to their porosity, expanded clay concrete blocks have good strength and load resistance, which is in no way inferior to concrete;

- Such a base will serve for a long time in any climatic conditions, without changing under the influence of temperature changes and without losing its characteristics.

- The low weight of the blocks ensures quick and easy construction of the foundation.

- The uniqueness of the material lies in the fact that during its production it is possible to add various additives that increase the performance qualities of expanded clay concrete. For example, adding crushed granite makes it possible to use these blocks when building houses on acidic soils.

- The foundation of such blocks is moisture-proof. This design is superior to many others in its thermal insulation properties.

The foundation for a house made of expanded clay blocks can be built in different ways; it all depends on the depth of soil freezing, the groundwater level in a particular area:

- The shallow foundation of the building is suitable for stable soils that are not subject to shifts.

- Most often, unstable soil with a fairly high groundwater level is encountered. In such areas, more recessed structures should be used.

- Areas of permafrost, swampy soils, soils prone to heaving due to frost will not allow the use of expanded clay concrete foundations for a long time, therefore in such areas the foundation is built from other materials.

What kind of foundation can be made from expanded clay concrete?

The construction of a base from this material can be done in several ways;

- tape;

- screw;

- slab

Which one is better to choose depends again on the specific properties of the soil, as well as on the preferences of the owners. Tape is used when the level of adjacent waters is low; its technology is quite simple and allows you to complete the work in a minimum amount of time.

Features of the strip foundation are as follows:

- the depth of the structure must be greater than the soil freezing level;

- the base must be strengthened with reinforcement;

- Reliable fastening of the formwork is a mandatory work process.

A screw foundation is also made from expanded clay concrete blocks, the main element of which is piles. The groundwater level and soil composition are unimportant here. Everywhere, except rocks, a screw base can be used for construction.

A floating or slab foundation can be used even in permafrost conditions and on unstable soils. When constructing it, the following features should be taken into account:

- the design is made with shallow recess;

- the first stage of work is thorough compaction of the soil;

- the base is laid on a sand cushion or even on a concrete screed;

- the main slab is reinforced with a frame.

Sizes and cost of blocks

Expanded clay concrete blocks of different sizes are available for sale, so in each specific case the calculation of the foundation is carried out individually, taking into account its size, depth of the structure, and structure. There are blocks 590*400*200 or 590*290*200, as well as slabs of other sizes. They are equipped with special recesses for reinforcing elements, which are laid in the body of the foundation. Such a base will be the most durable and shear-resistant, which will prevent cracks and distortions from appearing.

If the future house will be built from brick, then the blocks should be chosen more massive and wider. For small wooden houses, standard blocks of small sizes are also quite suitable. The total cost of such a foundation will be low and will allow the owner of the future home to save significantly at the very initial stage of construction.

Technical specifications

Before considering all the advantages of expanded clay concrete blocks, let us dwell in more detail on its important technical characteristics.

First of all, when laying a block base, we are interested in density, thermal conductivity and moisture absorption.

- The density of expanded clay blocks varies from 500 kg/m3 to 1800 kg/m3. Expanded clay concrete material with a density of up to 1100 kg/m3 is structural - heat-insulating type, above - structural. This fact is due to the fact that when producing molds using large fractions, the final product is strong, but cold.

- Thermal conductivity coefficient is from 0.18 to 0.81–0.90 W/m°C.

- Frost resistance - class F25, F35, less often F50 and F75.

- Increased moisture absorption.

- Service life is 60 years and above.

- The weight of small-sized blocks is 10-25 kg, depending on the dimensions and density of expanded clay concrete. The standard size of small wall blocks is 40x20x20 cm (length, width, height).

- FBS size for small construction—(120-240)x(30-80)x60 cm

- Temperature changes do not affect expanded clay concrete; it does not expand or contract, which means that the geometry of the forms remains unchanged.

FBS made of slag concrete

Sand concrete foundation blocks are one of the cheapest building materials.

It must be remembered that dense slag concrete is made from coarse slag, and with a gradual increase in density, the ratio of fine and coarse slag will fall.

The popularity of cinder block foundations is associated with the advantages of the material, among which are:

- Good thermal insulation properties;

- Affordable price;

- The light weight of a cinder block foundation;

- Ease of transportation;

- High thermal conductivity;

- Large dimensions, allowing to reduce the time spent on laying sand concrete foundation blocks.

The unique properties of this building material prove that the choice made in favor of such blocks is the right choice, because sand concrete foundation blocks are in many ways superior to building foundations made using other materials.

Monolithic strip foundation

It is chosen by the vast majority of developers. Why him? Because the foam block (or other porous stone) has low bending resistance, and during seasonal soil movements there is a high risk that cracks will appear along the walls of a building that does not have a solid solid base. There are two types of such foundations: buried and shallow.

How to choose the right tape depth?

Textbooks and construction instructions offer formulas for calculating the correct laying of foundations, but all this information is rarely used in practice. It is more important for a private developer to understand the main reasons that have a decisive influence on the choice of the depth of a pit or trench for pouring concrete. - this is an indicator of how far the base of the base is located from the surface of the soil.

Types of foundations.

There is a widespread belief that the stability of the foundation directly depends on whether it is located above the freezing point of the soil or below it.

In fact, in most cases this factor is not so important. The opinion of experienced foremen is this: in most cases, for frame and block houses, a shallow monolithic tape (no more than 50 cm, optimally 40 cm) is quite sufficient, regardless of what the TPG is in the area

The classic calculation is as follows: a shallow one is one whose sole is located at a distance from the surface of the soil that is 1/3 of the freezing point.

There are rules, following which, you can independently determine how many centimeters will be enough at this particular construction site.

- if the soil is heaving (clay and loam) and groundwater comes close, then the developer is out of luck: he is faced with the most difficult option. The choice here is as follows: either a “floating” slab or a monolithic tape below the TPG;

- if the soil is heaving, but not waterlogged, the base can be installed at a depth of 1.7 m, even if the TPG is significantly lower. But the height of the tape or supports must be at least 80 cm;

- if the groundwater level and the TPG coincide, the base should be located 20 cm below the freezing point;

- if the soil is marshy or mobile (sandy), then screw piles are optimal.