The first frosts and the subsequent winter cold cause builders a number of inconveniences associated with concreting work. When water crystallizes, the concrete mixture loses its performance properties. Icy water reduces the strength characteristics of the monolith, causing the formation of cracks. However, pouring concrete in winter is still carried out according to special technology. It is successfully used in industrial and private construction. Let's analyze the winter specifics of concrete work.

We plan to carry out concrete work in winter - the main features

Winter is not the best time of year to carry out activities for pouring concrete for drilled injection piles, building foundations and the construction of solid structures. The problem with concreting is associated with the transformation of water into ice. Increasing in volume, it disrupts the hydration of cement, weakening molecular bonds. The performance properties of the concrete mass deteriorate. The reason is increased porosity and the formation of deep cracks.

The strength of the concrete mixture after pouring is determined by the reactions that occur:

- within 24 hours after concreting is completed, the massif sets. During this period, the solution hardens, passing from a liquid state to a hardened state. The strength of the array is not sufficient for operation;

- four weeks after pouring, the concrete mass finally hardens, acquiring operational strength. It is determined by the brand of Portland cement used, the recipe and weather conditions.

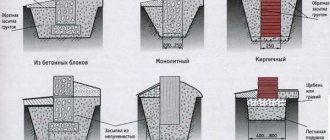

The foundation is the fundamental structure, the quality of which determines the geometric, technical and operational characteristics of the structure being built.

Developers do not always have time to complete the entire range of work before the onset of cold weather. They are interested in the answer to the question, to what temperature can concrete be poured in winter. The experience of professionals confirms the possibility of normal setting of the composition, as well as the acquisition of working strength at a minimum temperature of +4 ° C. As the temperature increases and high-quality cement is used, the hardening rate increases.

Planned hardening under normal hydration conditions occurs according to the following algorithm:

- a surface layer of sodium silicate is formed;

- hygroscopic cement absorbs water and binds ingredients;

- the water concentration decreases and the density of the outer layers increases;

- evaporation of the liquid stops and the hardness reaches its maximum.

When thinking about the temperature at which concrete freezes, it is worth remembering that hydration can occur at temperatures above zero degrees Celsius. The transformation of water into ice prevents the formation of molecular bonds. This feature makes certain adjustments to the concreting process.

However, due to the heating of the concrete mixture during hydration, it is possible to carry out concreting with a slight decrease in temperature. In this case, it is advisable to use heat-saving formwork or heat-insulating mats.

In case of insufficient strength gain before freezing, the quality of the concrete monolith will be very doubtful.

When carrying out concrete measures in winter, various technologies are used. They allow you to speed up setting and shift the threshold of water crystallization:

- modifiers are added that shift the temperature threshold for the transformation of water into ice. Builders calculate how much salt should be added to concrete in winter, as well as what the ratios of other ingredients should be;

- Heat the mixture using various methods. When giving preference to a specific method of heating the mixture, you should take into account the specifics of the construction activities being carried out, as well as the amount of upcoming expenses;

- improved quality cement is introduced. It acquires strength characteristics in a limited time and quickly absorbs the water contained in the solution.

Let us analyze the features of performing concrete work in winter temperatures.

What should you do if you have poured the foundation and are suddenly hit by frost?

We paid attention to how to pour, insulate and what to cover concrete after pouring in winter. However, it often happens that even in September night frosts can hit quite sharply and quite severely. What to do if something like this happened and you poured the foundation.

Ways to solve the situation:

- If you have added antifreeze to the concrete mixture, then you don’t have to worry, your work is not in danger.

- If you didn’t add it, then it’s best to insulate your fill for five days with a covering material so that all the necessary processes go through and the cement strengthens. After this, frosts are not terrible.

In general, winter construction is already considered weather conditions when the air temperature drops to plus five degrees. You can, of course, stop construction during this cold period of the year, but this can lead to losses such as time. Therefore, make your choice, build beautiful and reliable buildings and live with pleasure!

We use liquid concrete in winter - the advantages of technology

In winter conditions characterized by negative temperatures, performing concreting measures has its advantages:

- provides the ability to work on soils with a high sand content. Loose soil crumbles when soil is removed. Frozen and hard soil makes excavation and concreting easier;

- reduces the amount of money spent. Usually during the winter season there are various promotions and the price of building materials decreases. Seasonal discounts have a positive effect on cost reduction;

- allows to reduce the duration of concrete work. Unfavorable natural factors force builders to pour concrete faster, which has a positive effect on the overall duration of work.

It is pointless to argue with weather phenomena; you need to competently adapt to them.

When constructing a construction project in a harsh climate, winter pouring is inevitable, since it is the only option.

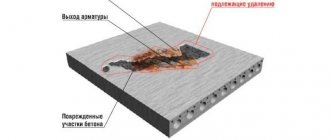

Possible consequences

In special frosty conditions, you must remember to follow all the rules for winter filling, otherwise irreversible consequences may occur, after which there can be no talk of any further operation of your facility. Therefore, you must strictly take into account all the standards and calculation data of this matter.

If you pour liquid into concrete during frost and do not do it correctly or with some, even minor, violations, then the thermal processes of hydration in the formwork, which proceed and are completed after about three to five days, may stop completely.

This leads to sad consequences; as a rule, the surface layer of your fill will be loose and crumbly. In this case, the work needs to be completely redone.

Is it possible to pour concrete in winter - the main difficulties

Some builders refuse to carry out work in winter, believing that it is better to continue after the weather warms up.

They give the following arguments:

- the purchase of building materials with anti-frost components will increase the estimated cost;

- the use of special technological techniques associated with heating will cause unexpected costs;

- short daylight hours in winter will cause additional costs for installing lighting sources;

- negative ambient temperature will require the implementation of measures for thermal insulation of living quarters for workers;

- the use of complex heating techniques will necessitate the use of additional equipment;

- with significant cooling of the air, a longer time is required to ensure strength properties;

- Unforeseen weather changes or disruption of technology can negatively affect the strength of the monolith.

Having assessed the risk factors, we can summarize that a violation of the structure of the monolith and an unforeseen increase in costs are possible.

The most economical is considered to be pouring concrete at sub-zero temperatures without heating, which predetermines the introduction of modifiers into the composition

Is it possible to concrete in cold weather?

First, let’s figure out whether it’s possible to concrete in cold weather. With low temperatures already falling below zero, you shouldn’t stop your work, that’s for sure. Just use concrete mortar with special frost-resistant additives, which are sold at any hardware store. And the next step, be sure to wrap the fill with a covering material - the simplest one, which can be branches or construction debris.

How does cement mortar behave in cold weather?

Let's see how frost affects concrete. In the usual classic version of concrete mortar, as a rule, all the main components are mixed with water, which is the main problem. The water freezes and destroys the formative integrity of the solution. Here the strength and, accordingly, the reliability of such a mixture are reduced to zero.

Therefore, during the pre-winter and winter period of construction of buildings, it is imperative to mix special plasticizers into the cement composition, which can easily eliminate such problems.

How to pour concrete in winter at home

To ensure normal hydration at low temperatures, the concrete solution should be heated using any of the available methods:

- heating water to 80 ⁰C and then introducing it into the solution;

- heating the filler used during kneading with a heat gun;

- increasing the temperature of the mixer tank using external sources.

The simplest option is to use preheated concrete mortar. This technique has proven itself positively under certain conditions:

- small volumes of poured mixture;

- performing filling on private objects;

- the first frosts with a slight decrease in temperature.

The introduction of additives is the simplest and cheapest method of concreting at sub-zero temperatures.

To ensure the desired result, you must follow the following recommendations:

- use high grade cement;

- use additives that shorten the hardening time;

- select the correct initial water temperature.

Carry out work according to the specified algorithm:

- Heat the process water and pour it into the concrete mixer container.

- Add the required filler according to the recipe.

- Fill in cement, which acts as a binding component.

- Mix by adding hot water until the mixture is as flexible as required.

The concreting process is completed by vibration compaction and protection against hypothermia using thermal insulation coatings.

Heating the mixture

There are several ways to heat concrete:

- Heating the concrete solution by mixing it in hot water (60 - 90 degrees). The liquid at elevated temperatures allows the concrete to overcome its strength limit during the cooling process. This method can be used if the frost is no more than 15 degrees.

- Internal heating is carried out by passing electric current through a welded reinforcement mesh, which strengthens the structure. In this case, the metal acts as an electrode.

- Another method involves pre-laying the heating cable. This is an effective but expensive technology that requires additional energy costs.

At very low temperatures, additional external heating of the poured foundation is recommended.

Is it possible to add salt to concrete in winter and use modifiers?

The temperature threshold for water crystallization is reduced by adding special additives. This allows for standard cement hydration to occur during cold winter conditions.

The preparation of mixtures with antifreeze additives is carried out in a special manner

Specialized stores offer various plasticizing substances, along with which the following available components are used in private housing construction:

- calcium salt of hydrochloric acid;

- potassium carbonate, known as potash;

- technical salt (sodium chloride);

- sodium nitrate.

Regular salt is popular among private developers, allowing it to partially reduce the crystallization threshold. However, its maintenance does not guarantee the preservation of the performance characteristics of concrete. The use of industrially produced additives is preferable.

The use of additives to increase frost resistance

The components contained in such additives can significantly change the properties of concrete. The purpose of each additive is to prepare the component composition for temperature changes. There are several types of additives that affect the level of frost resistance of the material.

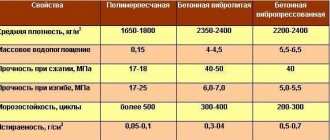

Superplasticizers contain components that increase the strength and water resistance of concrete. The use of such chemicals can reduce cement consumption by up to 20%. The “S-3” type from the Russian manufacturer is popular.

Hardening accelerators are used to reduce the setting time of the solution, but they also reduce the level of its plasticity. Therefore, together with accelerators, plasticity regulators are used, which extend the period of use of the finished mixture. Regulators based on calcium chloride, calcium sulfate and sodium chloride have proven themselves well. Anti-frost additives are also added to concrete when the temperature drops below -5ºC. They allow the properties of the material to be preserved longer. Widespread brands are MB 10-50C and MB 10-100C.

Modifiers are used to increase the strength level of concrete. They protect well against corrosion and improve resistance to sudden temperature changes. In cases where there is a need to improve several properties of a material at the same time, complex additives are used. They help improve frost resistance, reduce liquid consumption, and increase the speed of hardening.

Is it possible to pour concrete in winter using industrial technology?

At industrial facilities, when filling in the winter, various technological methods are used:

- insulation of formwork with special heat-insulating materials;

- connection of a current-carrying cable located in a flooded array;

- supplying voltage from the transformer to the electrodes inserted into the solution;

- local heating of the array using infrared radiation;

- induction heating of the mixture, converting the energy of the magnetic field into heat.

The choice of a specific method is made on the basis of calculations and requires special training.

Expert advice

In order for all work performed with concrete at low temperatures to give the desired result, you need to adhere to some recommendations that have been tested over the years. This is especially true in cases where a multi-story building is being built. Basic tips:

- The formwork must be prepared in the best possible way. All accumulated snow and ice must be removed from it, and the reinforcement frame and bottom must also be heated to a positive level. In this case, you can use special portable braziers or heat guns, the operation of which is provided by liquefied gas.

- In winter, it is much easier to make a strip foundation, since all work can be divided into several main stages. In addition, in local areas it is much easier to create optimal conditions for the solution to harden.

- If the customer wants builders to create a slab foundation, it will be almost impossible to do this. This is due to the fact that for concrete to harden normally, it is necessary to maintain a certain temperature, despite severe frosts.

- Craftsmen must adhere to a continuous installation method. The peculiarity of this procedure is that even if the foundation is poured in layers, then each subsequent ball must be laid before the previous one hardens.

- As practice shows, the best results during winter concreting can be achieved if you use several proven technologies at once.