When performing construction work, a concrete solution is used. This material is created on the basis of a binder component, sand and additives that promote strength and other performance properties. Due to the affordable price, reliability and ease of creating concrete, anyone can prepare it.

Characteristics of concrete

The characteristics of a building material are determined by such indicators as the proportions of concrete and its composition. They affect the quality of the final product and its class.

Class means a numerical coefficient of important parameters with a probability of 0.95. In the international classification, the letter B is indicated before the digital value that determines the permissible pressure on the material. The grade of concrete indicates maximum resistance to contraction and is designated by the letter M. Almost 45% of the final characteristics of the solution depend on it.

It is important to consider other factors, including:

- Quality of raw materials.

- Proportions.

- Cooking method.

So, if you produce material with the M400 grade in a manual concrete mixer, the output will be a B25 class product. When using industrial devices, the result is B35.

To convert a concrete grade into a class, you must be guided by the following classification:

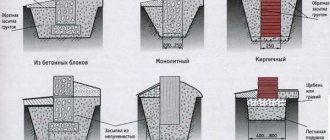

- M100 - belongs to class B7.5 and is intended for preparatory work when arranging the foundation.

- M150 - corresponds to B12.5. The material is in demand when installing screeds, floor coverings or small bases.

- M200 - class B15. It is in particular demand and is used in the organization of floors, foundations, concrete stairs, road and parking areas, etc.

- M250 (B20) - used for the construction of foundations, fences and stairs.

- M350 - belongs to class B25 and is a key solution for creating slabs, beams, pools and foundations.

- M400 - corresponds to class B30 and is developed for construction work in difficult conditions. In most cases, such material is used in the construction of bridges, financial institutions or other objects with high power requirements.

Waterproof

Before making concrete with your own hands, you need to study such a parameter as water resistance. It indicates the ability of concrete to withstand moisture and not deform.

Depending on the degree of moisture resistance, cellular products are divided into the following brands:

- W2.

- W4.

- W6.

- W8.

- W12.

There are concretes with a high degree of water resistance, which are used in difficult conditions and have the following advantages:

- They can be used when constructing buildings in an environment with close groundwater.

- They are resistant to temperature changes.

The level of moisture resistance is determined by the method of preparing the concrete mixture, the composition and the presence of special fillers. This indicator also depends on the internal structure of the concrete.

Frost resistance

The composition of concrete affects the degree of frost resistance of the finished product. This indicator refers to the number of defrosting and freezing cycles without visible defects, destruction and loss of strength. If the material is of high quality, its service life will exceed several decades. In the absence of quality control, products with little resistance to frost are put on sale.

The frost resistance value is indicated by the letter F, and then a numerical indicator is indicated - 50-1000, which reports the cycles.

Strength

Before mixing concrete, it is important to pay attention to such a characteristic as strength. It is measured in megapascals (MPa) and indicates the maximum pressure that a concrete product can withstand. Compressive strength is not a fixed parameter and can change as the binder additives are exposed to liquid.

Strength properties are displayed in a grade or class, but the exact value can only be determined a couple of weeks after pouring (in most cases, strength development takes about 28 days).

Such a term depends on several factors, including the temperature regime at which hardening occurs.

At subzero temperatures, the material freezes and cannot gain strength. To speed up the process it is heated. If concrete was laid in winter, but with the arrival of spring it began to thaw, the set of strength properties will be restored, but the characteristics of the product will deteriorate.

Under normal conditions, at positive temperatures, strength is gained more intensively. In just 7 days, the strength indicators will be 70%. However, the structure cannot be used for its intended purpose at this value, so it is not worth dismantling the formwork yet. Full strength gain is completed after 28 days.

As the temperature rises, the hardening process accelerates. In this case, it is necessary to take into account the moisture level of the material: if it dries quickly, the strength gain is suspended. Therefore, at enterprises the solution is treated with hot steam. When mixing concrete by hand, other methods of maintaining moisture are used, including covering the mixture with plastic or wet burlap.

When wondering how to prepare concrete for a foundation with your own hands, it is important to pay special attention to its strength properties. Leading manufacturers indicate strength in design documentation, which simplifies the process of choosing the appropriate option. But if you have doubts about the indicated values, you can independently determine the strength:

- Destructive method. Concrete products are placed on a flat surface, after which a special press begins to act on them. As a result, the compressive strength of concrete samples is determined.

- Non-destructive method. Provides mechanical impact on concrete using ultrasonic equipment, shock pulse or elastic rebound. A series of mathematical calculations are also performed to determine the strength properties.

Plastic

The plasticity of concrete refers to the specificity of its distribution over voids and surfaces. To determine mobility, a truncated cone is used, inside which the mixture is placed in 3 stages, acting on it with a reinforcing bar.

Then the cone is turned over with its wide base down and lifted back up. The solution will begin to spread over the surface, and the difference in height between the cones will indicate the settlement of the cone (OK).

A more complex but accurate technology involves analyzing the monolith. To carry out the procedure, you need to place the finished mixture in cubic molds and wait for it to harden. After 28 days, you need to evaluate the product.

Fillers - crushed stone and sand

The composition of concrete is determined by the functions and characteristics of concrete that are necessary during its operation. The most common are sand and crushed stone. They are subject to no less stringent requirements than the quality of cement. Sometimes pebbles are used, but only if they have sharp edges and not round ones. In the presence of broken lines, the adhesion of the aggregate to the solution is better, as a result, the strength of the concrete is much higher.

Sand

Construction sand can be river or quarry sand. River water is more expensive, but it is usually cleaner and has a more uniform structure. It is best used when preparing concrete for pouring foundations and screeds. For masonry or plastering, it is appropriate to use cheaper quarry sand.

In addition to its origin, sand is distinguished by fractions. For construction work, large or medium ones are used. Small and dusty ones are not suitable. The normal size of sand grains is from 1.5 mm to 5 mm. But optimally in solution it should be more homogeneous, with a difference in grain size of 1-2 mm.

The sand must be clean, preferably with the same grain sizes

The cleanliness of the sand is also important. It should definitely not contain any foreign organic inclusions - roots, stones, pieces of clay, etc. Even the dust content is standardized. For example, when mixing concrete for a foundation, the amount of contamination should not exceed 5%. This is determined empirically. 300 ml of sand is poured into a half-liter container, everything is filled with water. After a minute, when the grains of sand settle, the water is drained and refilled. This is repeated until it is transparent. After this, determine how much sand is left. If the difference is no more than 5%, the sand is clean and can be used when mixing concrete for the foundation.

For those jobs where the presence of clay or lime is only a plus - when laying or plastering - there is no need to take special care of the cleanliness of the sand. There should be no organic matter or stones, and the presence of clay or lime dust will only make the solution more plastic.

Crushed stone

For critical structures - floors and foundations - crushed crushed stone is used. It has sharp edges that adhere better to the mortar, giving the structure greater strength.

Crushed stone fractions are standard:

- extra small 3-10 mm;

- small 10-12 mm;

- average 20-40 mm;

- large 40-70 mm.

In the batch, crushed stone is used in several fractions - from small to coarse

Several different fractions are used simultaneously in concrete. The largest fragment should not exceed 1/3 the size of the smallest element of the structure being poured. Let me explain. If a reinforced foundation is being poured, then the structural element that is taken into account is the reinforcement. Find the two elements closest to each other. The largest stone should not be more than 1/3 of this distance. In the case of pouring a blind area, the smallest size is the thickness of the concrete layer. Choose crushed stone so that it is no more than a third of its thickness.

Fine crushed stone should be about 30%. The remaining volume is divided between medium and large in arbitrary proportions

Pay attention to the dustiness of the crushed stone. Lime dust is especially undesirable

If there is a lot of it, the crushed stone is washed, then dried, and only then poured into concrete.

Aggregate storage

It is clear that a construction site is not the cleanest and most organized place, and sand and crushed stone are often dumped directly onto the ground. In this case, when loading, you must ensure that no soil gets into the mix. Even a small amount will negatively affect the quality. Therefore, it is advisable to pour aggregates onto solid areas.

It is also necessary to protect them from precipitation. In concrete formulations, the number of components is given based on dry components. You learn to take into account the moisture content of components with experience. If you don’t have one, you have to take care of the condition and cover the sand and gravel from rain and dew.

Do-it-yourself concrete - main components

When choosing the composition of concrete for the foundation, proportions and ratios, it is necessary to prepare the following components:

- Cement mixture.

- Sand.

- Crushed stone.

- Water.

Cement

For novice developers who understand how to prepare concrete at home, it is important to correctly calculate the amount of binder - cement.

There are different types of cement mixtures available in the market including Portland cement, slag Portland cement, rapid setting compounds and others. Each option has its own properties, speed of strength gain and scope of application.

Traditional concrete composition and proportions include Portland cement due to its improved performance and availability. Available materials are divided into grades with the letter M and a numerical value that determines resistance to loads.

To make concrete with your own hands, it is customary to use the M400 brand - it has sufficient strength and reliability. Industrial production in Moscow uses Portland cement M500, and for the construction of foundations in difficult conditions, special compounds of a higher grade are used.

To prepare a concrete mixture, you need to know exact information about the brand and quality of the component used. It is also important to take into account such a property as freshness - the shelf life of a concrete product depends on it.

The fresh mixture is a crumbly dust with no compactions or lumps. If there are large elements in cement, it is better not to use it for construction work.

Sand

The concrete recipe for the foundation requires the presence of sand. There are different types of such a component, which differ in their composition and properties, and also determine the quality of the final product.

When figuring out how to make a concrete solution, you can choose any type of sand. The main thing is that they do not contain large amounts of dust, clay and large particles that worsen the properties of the mixture.

Experts recommend choosing sea or river sand, since these types do not contain dust, clay and organic compounds. As for raw materials mined in quarries, they can be quite dirty and require preliminary preparation with washing and settling.

This sand may also contain organic debris, including tree roots, leaves, bark and branches. If such particles end up in the concrete mixer, the concrete will be of poor quality and its strength will deteriorate.

An indicator such as sand moisture should be assessed. Even in dry material, up to 2% water can be present, and in wet material - up to 10%. In this case, the ratio of concrete for the foundation will be violated.

Crushed stone, gravel

When studying what a concrete mixture consists of, you need to pay attention to crushed stone and gravel. These rocks act as fillers and are responsible for the strength of concrete products. In most cases, crushed stone is used, which has different fractions and surfaces.

When preparing the composition, you cannot replace the filler with sea or river pebbles, since these components have a smooth polished surface and do not provide good adhesion to other components.

The proportions of the concrete solution affect the service life and reliability of the product. The permissible size of stones in crushed stones should not be more than 1/3 of the minimum thickness of the structure being built. The hollowness of the crushed stones or the amount of space between the stones is also taken into account.

To calculate this parameter, you need to take a bucket, place the filler there and gradually add liquid. The volume of water placed will indicate the void ratio. Therefore, experts calculate the proportions of concrete for the foundation in buckets.

To improve the process of filling voids with concrete mixture, it is recommended to combine different fractions of crushed stone. In addition to gravel and granite crushed stone, the following fillers can be added to the composition:

- Expanded clay.

- Blast furnace slag.

When creating lightweight concrete, wood shavings or expanded polystyrene granules are used.

Water

When starting to mix concrete, you need to take care of water. It is recommended to take drinking liquid that is used for household needs. It is prohibited to use water from questionable sources, waste water or swamp water. Depending on the ratio of components in concrete, its operational properties are determined.

When performing calculations, it is necessary to take into account the content of all moisture that is in the feedstock before mixing. If the composition includes blast furnace slag, it is important to determine what moisture content such material has, since “excess” water can worsen the characteristics of concrete.

The volume of liquid affects the mobility of the material. To create plastic concrete, it is necessary to adhere to proportions and not deviate from the given norm. Otherwise, the mixture will begin to separate and deform.

The degree of plasticity can be determined visually after the concrete has hardened. If it randomly slides off the bayonet shovel, this indicates good ductility. When sliding slowly, the mixture is said to be of little plasticity, and the solution held on the shovel by a tubercle is classified as non-plastic.

Supplements

To mix the solution and improve its quality properties, good proportions for concrete components include the presence of additives. They are intended to increase frost resistance and resistance to corrosion processes, reduce hardening time, change strength properties and other purposes.

Existing components are selected according to the following classification:

- Plasticizers - used to increase the strength and density of concrete.

- Air-entraining additives are used to obtain a porous structure, which increases the resistance to negative temperatures of reinforced concrete structures.

- Impurities to accelerate hardening - allow you to reduce the hardening time of the mixture. There are impurities with the opposite principle of action that slow down the setting process.

- Compaction additives - help increase durability and fill cavities between concrete grains.

- Corrosion inhibitors - can create an oxide film on the anode.

- Gas-forming elements - used in the production of gas blocks. Capable of increasing water resistance and reducing the intensity of delamination.

- Anti-frost - intended for construction work at temperatures down to -20°C.

When selecting suitable admixtures, it is necessary to consider the type of task they perform. Modern components are capable of:

- Improve the performance characteristics of concrete.

- Increase strength and resistance to moisture, corrosion or frost.

- Reduce the hardening period.

- Reduce component consumption.

- Influence mobility indicators.

How to choose the right materials?

Before combining all the ingredients for concrete in certain proportions, you need to select the necessary materials . Surely many people know that concrete structures (this also applies to the base) are made of different materials. These are cement, sand, and crushed stone.

All components must meet the prescribed quality criteria. The sand must be cleaned; it must not contain clay or silt impurities, even if their amount is minimal.

It is better when foundation building mixtures contain sand granules several millimeters in size. For example, the finest sand is used to prepare concrete type M200, and large grains of sand are included in the composition M350.

Sand is most often obtained naturally. It can be sea, quarry or river, and is often mined by crushing gravel using a special machine.

In the latter case, the material often contains gravel extracts.

Sea sand

The size of the building should guide the choice of crushed stone for the foundation. For more massive structures, builders often opt for the granite variety of crushed stone, and for small houses - limestone. It is significantly lighter and more affordable.

The middle option is considered to be crushed gravel; it is more affordable when compared with granite, but stronger when compared with limestone.

For the foundation, a cube-shaped fraction from 4 cm is often used, thanks to which it is possible to achieve excellent compaction.

The use of flat and angular elements is undesirable because they adversely affect the durability of the structure and the resistance of concrete structures to frost.

crushed gravel

There is more than one brand of cement on the market, but if builders are planning to carry out foundation work, then not every one will be suitable. In practice, grades 500 and 400 are often used; they have excellent resistance to cold and moisture, and this is very important if construction is carried out in Russia.

If the grade is below 400, the concrete is severely deformed during the shrinkage stage, so builders do not recommend using it.

It is also recommended to use exclusively “fresh” cement during the construction stage, all because this material is capable of changing its characteristics: after six months, up to half of its characteristics are lost.

Calculation of concrete composition by weight

When figuring out how to make strong concrete, you need to correctly calculate the composition, guided by the following information:

- Required brand of mixture.

- Required ductility.

- Brand of cement.

- Information about sand and crushed stone.

Developers use two methods of calculations, taking into account the following ratios:

- Volumetric.

- Weight.

To calculate the composition of a concrete mixture by weight, you need to use some formulas. When using Portland cement M400 and crushed stone with a medium fraction, first of all you need to find the ratio of water and cement (W/C). W/C - indicates the proportion of the weight of the liquid and the cement mixture that will be needed to obtain strength properties. Formulas or experiments are used to determine exact values.

If you have information about the brand of concrete and the brand of cement, you need to find the W/C. As an example, we can take the number 0.68.

Using the table, you need to determine the volume of liquid to create a mixture of medium plasticity when using crushed stone measuring 40 mm. The result will be 190 l/m³. Next you need to find the optimal amount of cement mixture per 1 m³ of concrete. To do this, 190 l/m³ is divided by 0.68, which will give an indicator of 279 kg of cement.

Purchasing from AlfaCem

Our company is a reputable supplier of building materials to the domestic market. Residents of the entire Central Federal District of the Russian Federation can order products for creating cement-sand mixtures of various types. All types of goods are supplied from the manufacturer. They are original and certified in accordance with current standards.

Leave applications on the website, or call us at the numbers in the “Contacts” section. Competent and responsible managers promptly respond to every request, helping to choose the best products with calculations that help clients save money. We have a strict privacy policy, often hold promotions and introduce discounts, and you can always leave your own reviews by telling other customers about aspects of the company's activities. Waiting for you!

Methods for mixing concrete

If you are interested in how to properly prepare concrete, you should study the following methods:

- Manual.

- Mechanized.

You can mix concrete in special equipment - mixers or concrete mixers.

Manual

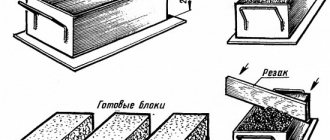

In private construction, it is customary to connect components manually, using the correct proportions of the concrete mixture. For kneading, prepare a container in which all components are mixed. You can use a tin trough or other suitable structure.

First you need to place sand in it, and pour cement mixture into the furrow in the central part. After thoroughly mixing the components, liquid is added to the solution and it is mixed again. Then crushed stone is added, mixing continues with periodic addition of water. Once a homogeneous consistency has appeared and the stones have been filled with solution, you can proceed to laying.

The key disadvantage of the manual method is its low speed. Any delays can lead to delamination of the material in the trough, as a result of which its properties will deteriorate. Therefore, experts recommend quickly placing the composition into the formwork, avoiding long pauses.

The best option for creating a mixture is to knead it in a concrete mixer. It allows you to obtain a homogeneous consistency of high quality.

Mixing in a concrete mixer

When preparing concrete with your own hands, proportions can be measured in buckets, and mixing can be done in a concrete mixer. The device produces a homogeneous emulsion with improved performance properties. Liquid and fillers are added to the creamy consistency.

The mechanical method prevents the problem of concrete delamination, and the material can remain in a rotating unit for up to 1 hour without losing its working qualities. But in order to preserve the positive properties of the material, it is better to place the concrete mixer at the construction site to avoid problems when delivering the solution to the site.

Expert advice

If we take into account the opinion of professionals, they advise doing foundation work exclusively in the summer months, thereby you will significantly reduce money and save time. To do similar work in winter, you will have to arm yourself not only with warm water, but also with professional additives.

The concrete itself, which will be poured into the formwork, will need to be heated. At sub-zero temperatures, water always freezes. If such a reaction occurs in the concrete solution, this will cause the water, in an altered state, to turn into ice and destroy the foundation.

Pouring the foundation

In addition, experts advise, for the sake of convenience, to keep the required portions of concrete in a bucket. For example, to prepare a solution you need to take a bucket of cement, crushed stone and 7 buckets of sand. If concrete is prepared following the correct ratio, it will have all the necessary characteristics.

Table: concrete made from cement M500

When creating concrete manually, the proportions with the M500 cement grade are calculated using the following table:

| Cement brand | M500 | |||||||

| Concrete grade | M150 | M250 | M350 | M450 | ||||

| Cement | kg | 1 | ||||||

| Water | ||||||||

| 0,5 | ||||||||

| Sand | ||||||||

| Crushed stone | 4,5 | 2,6 | 1,9 | 1,1 | ||||

| 6,6 | 4,5 | 3,6 | 2,5 | |||||

| Proportions (C/P/SH) | 1/ 4,5/6,6 | 1/ 2,6/4,5 | 1/1,9/3,6 | 1/1,1/2,5 | ||||