Until recently, heat loss through the foundation was not taken into account; it was simply compensated by increasing the heating intensity. However, the constant rise in energy prices forced a change in the approach to the problem of insulation. Nowadays, among thermal insulation methods, the first place in terms of quality and reliability is occupied by insulating the foundations of houses from the outside with penoplex foam.

General information about Penoplex insulation

This insulation is a domestic development. It is also produced for our conditions. This cannot but rejoice, since the material takes into account all the features of the domestic climate, which is far from mild.

The insulation is based on polystyrene foam, which at high temperatures is subjected to additional foaming - extruded. This operation allows you to significantly increase the already excellent performance characteristics.

The material is very popular not only among independent developers, but also among professional builders. Its main technical characteristics include:

- moisture resistance – no more than 0.5% of the total volume;

- guaranteed service life - more than 50 years;

- compression resistance – 27 tons per square meter;

- operating temperature range – from – 50 to + 75 C.

This information is not exhaustive, since the material also has many positive qualities. Full information can be obtained on the website of the material manufacturer.

Penoplex in packaging Source brus4you.ru

There are many varieties of this insulation on the market, but among them three main varieties can be distinguished:

- "Penoplex-45". This type of insulation has the highest density among all material lines. It is used for insulation of complex building structures that are subject to high loads. These could be airfields, various industrial structures or elements of highways.

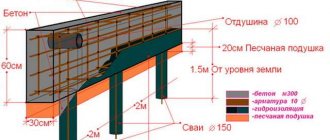

- "Penoplex-35". This type of material is often called “Penoplex Foundation”. They are used for insulating monolithic and pile-type foundations. It is also used to insulate the pile base. The material can be laid in both vertical and horizontal directions.

- "Standard". The most widely used type of material, made in the form of flat slabs. It is used for insulating a wide variety of objects, from utility networks and stone walls to insulating wooden floors.

All of the listed insulation modifications are produced in the tongue-and-groove form factor. This allows the elements to be installed as closely as possible to each other and to avoid the formation of gaps between them.

Solid insulation pad for pouring the base of the foundation Source ctkomplekt.ru

The method of cutting the material deserves a special mention. If a special tool is used for this, then professionals advise carrying out cutting work at medium speeds. This will prevent the material from melting and sticking to the cutting parts of the tool.

If you are interested in the question of how to insulate a house with Penoplex, then slabs of medium and smaller thickness will most likely be used. They cut perfectly with an ordinary stationery knife and are neatly broken along the cut line.

What is expanded polystyrene?

This is a snow-white foam material in the form of polystyrene balls, consisting of styrene, which forms its cellular structure, and a foaming agent - pentane. Both constituent components are hydrocarbon compounds obtained as by-products in oil and gas production cycles.

Characteristics of expanded polystyrene:

High heat-protective qualities, since the insulation has low thermal conductivity in the range of 0.029 - 0.037 W/(m•K).- Mechanical strength is ensured by the flexibility of the technological process, when it is possible to set a given strength for specific applications.

- It has special abilities to maintain stable dimensions at air temperatures up to + 80 C.

- Low water absorption - the insulation is not hygroscopic.

- High chemical resistance to salts and alkalis, but can easily be destroyed when treated with solvents.

- High resistance to atmospheric influences and aging processes.

- Low fire resistance - insulation is highly flammable. Modification of this material with fire retardants significantly reduces its flammability.

Choosing a method of insulation

Before deciding how to insulate the basement of a house from the outside with your own hands using Penoplex, you should decide on the method of insulation. There are several methods for carrying out insulation work. As a rule, in practice one of the following three types is used:

- Horizontal type insulation . It is widely used for insulating walls made in a monolithic manner. Shallow foundations of the strip type are no less often insulated. Well suited for laying under a foundation slab as it perfectly protects against freezing on soils prone to heaving.

Insulation areas Source fasad-exp.ru

- Vertical type insulation . With this method, external insulation of the foundation wall is performed. Using the vertical method, insulation of building plinths is also carried out. Fastening to the base is carried out using special mastic. Professionals recommend duplicating the fastening to mastic with plastic dowels.

- Insulation of the blind area . This method allows you to avoid deformation of the poured blind area under the influence of temperature fluctuations. To do this, first the floor pad is prepared according to the technology, then a layer of insulation is laid on it and the concrete mixture is poured.

Possible mistakes

Despite the fact that information about the choice of insulation and the technology for its installation on basement surfaces is publicly available in sufficient quantities on the Internet, in practice, contractors make a large number of mistakes that lead to deformation of not only the heat-protective layer, but also the structural elements of the building.

The biggest mistake that home craftsmen make is saving when choosing the thickness and density of Penoplex. The optimal thickness of base heat insulation sheets for the central regions of Russia is from 80 to 100 mm.

How to eliminate them?

Most errors made during the installation of thermal insulation cannot be corrected ; a complete rework of the base thermal protection system will be required. For example, if solutions not intended for this purpose were used as an adhesive or reinforcing mixture, for example, tile adhesive.

You also can’t save money by mixing glue with sand or adding cement to it for “strength.” It is no less dangerous to use cheap reinforced mesh or violate the technology of its installation. It is better if it is alkali-resistant, with a density of at least 140 g/m2.

A common cause of cracks in the thermal insulation of the base is when the reinforcing mesh is mounted directly on a layer of thermal insulation sheets. It needs to be deepened into the reinforcing layer so that it is 1/3 in the center of the layer. Another common mistake when reinforcing is connecting reinforced mesh sheets without an overlap of 10 cm .

Advantages of external insulation

If your house has not yet been insulated, then the answer to the question - is it necessary to insulate the foundation of the house from the outside with Penoplex - is obvious - it is absolutely necessary.

High-quality external insulation of the foundation will reliably protect it from the negative influences of the external environment and increase indoor comfort. In general, it is recommended to carry out such work at the stage of erecting the foundation of the building.

If we summarize the main advantages of external insulation of the foundation and basement of a building, they look like this:

- increased resistance to temperature changes;

The trench must be of sufficient width Source modernizacija.ru

- it becomes possible to maintain a constant temperature in the basement regardless of the time of year;

- a reliable barrier is created that prevents groundwater and rainwater from penetrating into the basement;

- The service life of the foundation increases significantly due to the reliable protection of concrete from the effects of low temperatures and moisture.

Thermal insulation of the foundation has another undeniable advantage - the ability to move the dew point. This is the moment when water vapor condenses into water. In winter, the difference in temperature inside and outside the room leads to the appearance of droplets of moisture. They gradually destroy the finish and infect the walls with fungi.

How to insulate the foundation of a wooden house

Many owners of wooden houses believe that to ensure favorable living conditions it is enough to insulate the walls and floors. However, this is not true, because serious heat loss can occur through a wooden floor - up to 20%. Therefore, thermal insulation of the foundation is mandatory, especially if the house is located in an area with harsh weather conditions.

Insulating the foundation of a wooden house from the outside will not only create favorable conditions indoors, but also prevent adverse effects on it. For this purpose, polystyrene foam and its varieties, as well as expanded clay, are usually used.

Stone finishing

Insulation of the foundation of PPS or EPS

Expanded polystyrene has excellent consumer properties, such as low thermal conductivity and moisture absorption, resistance to negative weather conditions, affordable cost, ease of installation, etc.

These and other characteristics have made this material one of the most relevant and in high demand among many consumers.

To insulate only the above-ground part of the foundation or plinth, a fairly simple installation is required. PPS sheets are simply attached to the surface using glue or special fasteners.

After this, cladding or plastering is performed. However, you should know that installing insulation does not mean complete waterproofing, so it should be carried out separately to avoid groundwater from penetrating under the floor.

At the summer cottage

In this case, it is necessary to completely waterproof the walls. For this purpose, a trench is dug around the wooden house, then the foundation is cleared of soil and debris. Next, EPS panels are attached to the surface, after which the whole thing is backfilled and compacted.

The insulated base can additionally be finished with brick or other types of cladding that can withstand adverse weather conditions.

Foundation insulation with expanded clay

Often a wooden house is insulated from the outside with expanded clay. However, it has increased moisture absorption.

To avoid the negative effects of this phenomenon, a trench is dug around the house and formwork with waterproofing is installed, after which the expanded clay itself is filled.

Blind area

This method is no less effective, but requires special attention and the need to adhere to all installation rules.

Calculation of the required material thickness and calculation of parameters

Of course, the answer to the question - how to properly insulate the foundation of a private house with Penoplex - is associated with certain calculations. The first thing that needs to be done is to determine the exact thickness of the material that is optimally suited to a specific climate zone.

Insulation at the construction stage Source rock-n-dom.ru

Firstly, this will make it possible to make the insulation of the highest quality possible, and secondly, you will not overpay for excess material.

Determining the optimal material thickness

When deciding what thickness of Penoplex to choose for insulating the foundation, first of all, you should pay attention to the data that the manufacturer indicates on the packaging. The prescribed parameters refer to the minimum recommended values for different climatic zones.

For example, in areas where sub-zero temperatures can reach thirty degrees or below, the minimum recommended thickness of the material is ten centimeters. As for the modification of the insulation itself, professionals recommend purchasing “Penoplex-45” or “Foundation”.

The form factor of such plates is sixty by one hundred and twenty centimeters. The weight of one slab does not exceed two and a half kilograms. The thickness of the material varies and is available in the range from two to ten centimeters.

Options

As mentioned above, the manufacturer puts general data on the minimum recommended thickness of the material on the packaging. However, these indicators are averaged, and in order to get the most accurate result it is necessary to perform simple calculations.

The insulation has been completed, but the final finishing has not been completed. Source www.penoplex.ru

See also: Catalog of companies that specialize in finishing materials and foundations.

They are performed using the following formula:

V=v1/a1+v2/a2

Wherein:

- a1 – thermal conductivity of the insulated material;

- a2 – thermal conductivity of insulation;

- V – regional resistance to heat transfer in a particular region;

- v1 – value indicating how thick the foundation is;

- v2 is a value indicating how thick the slab is.

Now all that remains is to look into the reference books and look up the values for the quantities “V”, as well as “a1”. It is necessary to find a value that corresponds to the value “v2”. To do this, a simple substitution of known data into the formula is done and simple mathematical calculations are performed.

The result must be rounded up. This will allow you to purchase with a small reserve, which will not be superfluous and will have little effect on the overall price of the insulation.

All calculations for the required amount of material are performed based on the area of the insulation. Penoplex slabs have a standard area of seventy-two hundredths of a square meter.

When thinking about how to insulate a house from the outside with Penoplex with your own hands, do not forget the advice of experts to do two-layer insulation. The second layer is applied to the first with a slight offset to cover the seams of the lower layer.

The most popular manufacturers, packaging price

In Russia there are about a hundred enterprises of varying capacities that produce polystyrene foam insulation boards.

Professionals, when purchasing base insulation in a retail chain, choose products from market leaders. This will serve as a guarantee of the quality and durability of the thermal insulation coating of the base.

List of popular polystyrene foam manufacturers.

TechnoNikol

Russian manufacturer, its facilities are located in 7 CIS countries and the EU. "TechnoNikol XPS" with a thermal conductivity of 0.028 W/(m*K) , is produced in packages of 4 slabs, dimensions 100x580x1180 mm, total area of 2.74 m2, packaging cost - 1200 rubles.

URSA

A product of a Spanish concern, production is also located in Russia in Serpukhov. “URSA XPS G4”, with a thermal conductivity of 0.030 W/(m*K), package of 4 slabs with dimensions 100x600x1180 mm, total area of 2.83 m2, packaging cost - 1500 rubles.

Penoplex

Produced by a company in St. Petersburg. “Penoplex Foundation”, with a thermal conductivity of 0.030 W/(m*K) , package of 4 slabs with dimensions 100x585x1185mm, total area of 2.77 m2, package cost 1540 rubles.

Theplex

Nizhny Novgorod plant are produced in the form of slabs. “Teplex 35”, with a thermal conductivity of 0.030 W/(m*K), a package of 4 slabs with dimensions 100x600x1200 mm, a total area of 2.88 m2, packaging cost - 1350 rubles.

Polyspen

The plant is located in Kirov. This is foamed polystyrene, which is produced by extrusion. “Polyspen 35 G4” has a thermal conductivity of 0.028 W/(m*K) , the package consists of 7 sheets measuring 50x600x1200mm, with a total area of 7 m2, the cost of packaging is 950 rubles.

Practical implementation of insulation work

Before insulating the facade of a house with Penoplex with your own hands, you need to carefully think through and prepare everything. Purchase insulation and consumables, select the appropriate tool.

Consumables and tools

Consumable materials and tools for carrying out insulation work are required:

- reinforcing mesh made of polymer materials or metal;

- primer with high penetrating ability;

- container for mixing mastic;

- stationery knife;

- brush for applying mastic;

- mastic for fastening insulation;

- polyurethane foam;

- mixer attachment for drill;

- perforator;

- plastic dowels for duplicating fastening on mastic;

- rule;

- construction trowel;

- level;

- insulation of the required thickness

- metal brush;

- putty knife.

Everything is ready to fill the blind area Source build-experts.ru

Fighting cold bridges

To avoid unwanted heat transfer in unintended directions, it is recommended to control the following nuances of foundation thermal insulation:

- The slab insulating the scaffold must be in contact with the vertical insulation of the foundation perimeter without a gap.

- When insulating the foundation base from the outside with penoplex, do not forget that there should be no gap left between this layer and the layer of external thermal insulation of the walls. When there are differences in the wall's topography, it is necessary to fill these gaps in geometry with horizontal sections of insulation.

Video description

Watch the video - insulating the foundation of a house and basement:

This is done as follows:

- At a distance of about twenty-five centimeters to the surface, a ten-centimeter sand bed is poured. Tamping is in progress.

- The bottom is covered with roofing felt and the overlapping sheets are coated with bitumen.

- Thermal insulation sheets are laid with the joints blown in with polyurethane foam.

- Further work on filling the blind area is carried out according to the generally accepted scheme.

- The base is covered according to personal preferences.

Glue, foam or dowels?

This question is very relevant for a correct understanding of the process of insulating the foundation and blind area of the house from the outside with polystyrene foam. Experts recommend using simultaneous fastening with glue and dowels for those areas of the surface that will later be finished with any facing materials. The glue creates a dense, without large voids, base for the insulation sheets; disc-shaped dowels make it possible to more securely fix the slabs on the facade. For underground sections of the wall (lower part of the plinth, foundation), the use of dowels is not considered mandatory, since the soil, backfilled after insulation and compacted, does not allow the heat insulation panels to move.

recommends this installation scheme.

The choice between cement-based adhesive mortar and foam adhesive is related both to the convenience and speed of work, and to the cost of the material. Cement-based adhesive compositions are applied to the surface of the slabs using a spatula and either leveled with its jagged edge or form “blots” with a more or less uniform arrangement. After this, the side of the sheet with the solution is pressed against the wall and held until initial setting. The hardening time before completing finishing work is 12...48 hours, before continuing to stick adjacent slabs - 5...10 minutes.

The diagram below shows options for applying adhesive composition to the surface of sheets.

Foam adhesive is applied according to the same principle, the main difference is that it cannot be spread over the surface with a spatula, since the foam is highly sticky and will not stick to polystyrene foam. Using a special gun, the adhesive foam is blown out in relatively thin strips, placing them in a zigzag or chaotic manner, but with the obligatory edging of the slab along the edges.

Important: with both adhesive options, it is necessary to limit the area of application so that the adhesive composition is located at least two to three centimeters from the edge. Otherwise, the foam or adhesive mixture will be squeezed out into the spaces between the sheets and make further work difficult.

The main stages of the process of insulating the foundation of an already built house are shown in the video.

Heat transfer resistance table

| City (region) | R - required heat transfer resistance m2×°K/W |

| Moscow | 3.28 |

| Krasnodar | 2.44 |

| Sochi | 1.79 |

| Rostov-on-Don | 2.75 |

| Saint Petersburg | 3.23 |

| Krasnoyarsk | 4.84 |

| Voronezh | 3.12 |

| Yakutsk | 5.28 |

| Irkutsk | 4.05 |

| Volgograd | 2.91 |

| Astrakhan | 2.76 |

| Ekaterinburg | 3.65 |

| Nizhny Novgorod | 3.36 |

| Vladivostok | 3.25 |

| Magadan | 4.33 |

| Chelyabinsk | 3.64 |

| Tver | 3.31 |

| Novosibirsk | 3.93 |

| Samara | 3.33 |

| Permian | 3.64 |

| Ufa | 3.48 |

| Kazan | 3.45 |

| Omsk | 3.82 |

Arrangement of waterproofing

Penoplex is a water-resistant material. But, if waterproofing is not carried out, moisture coming from below will accumulate in the cracks, destroying the structure of the base. You can avoid this in one of two ways:

- using bitumen mastic;

- pasting the foundation with rolled insulating material.

Mastic is used, both homemade and purchased. For the first option, machine oil is added to the melted bitumen to give better plasticity to the mass. For every 150 kg of dry bitumen, 50 liters of oil are added. If this is not done, in winter the mastic will crack, unable to withstand temperature changes.

Liquid waterproofing is applied to previously dried and leveled walls. Layer thickness - 2-4 mm. There should be no untreated areas or unfilled pores left on the surface. For greater reliability, roll waterproofing is laid on top. On stacks there is an overlap of at least 10 cm. Laying is done from bottom to top.

A gas burner is required for installation. The back side of each sheet is heated and quickly applied to the wall. Air bubbles are removed by smoothing. During the heating process, there must be at least 25 cm between the burner and the waterproofing. Otherwise, the material may catch fire. The joints are additionally coated with bitumen.

Finishing

Contact of insulation with open ground can lead to loss of consumer properties. To prevent this from happening, all surfaces are treated with plaster. An alternative is several layers of acrylic-based glue.

A fiberglass mesh for reinforcement is first attached to both the foundation and the plinth using a construction stapler. At the junction of the sheets there is an overlap of at least 10-15 cm.

Once the plaster or glue is completely dry, backfill the trench. For additional thermal insulation, replace part of the soil with expanded clay. Important: leave at least 30 cm to the surface for arranging the blind area.

Briefly about technology

In 1998, the Russian company PENOPLEX began production of thermal insulation boards from extruded polystyrene foam. A group of enterprises in the cities of Kirishi, Perm and Novosibirsk produces construction and decorative materials using Italian high-tech equipment under quality control by an accredited laboratory. Penoplex Foundation is an effective slab insulation material, widely used in our country for thermal insulation of capital structures in both private and industrial construction. Protecting bases from freezing increases energy savings by 20%.

Penoplex Foundation: sheetsSource vdom36.ru