Today, thanks to the abundance of special compounds for protecting wood, everything is much simpler. It is enough to use them according to the manufacturer's instructions, and you will get the desired result. We will tell you below how to protect the ends of a log frame for years and even decades.

Properly processed ends retain their appearance for decades

Why is it so important to properly process the ends?

The ends of the logs are one of the most vulnerable places in a log house. If they are not treated with a protective compound during construction, after 1-2 years they will become covered with cracks. These holes very soon become a source of proliferation of fungi, insects and bacteria. Moisture also gets into them. All these factors eventually destroy the log and the entire house.

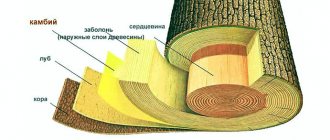

Cracks at the ends are formed due to wood shrinkage. This is the gradual evaporation of moisture from it, which comes out through the edges of the logs much faster. At this time, the middle is still moist. This discrepancy causes the ends to crack. Wood shrinkage can take from months to years depending on the surrounding climate. For example, in the southern regions it lasts about 1 year, and in the central and northern regions - from 1 to 3 years. The warmer the climate, the faster moisture evaporates.

By treating the ends of logs with a protective compound, we solve 2 problems. Firstly, we protect the tree from the penetration of fungal spores, moisture and insect larvae. Secondly, we let the wood “breathe” without interfering with the uniform evaporation of moisture. This helps reduce the number of cracks at the ends or avoid their occurrence altogether.

Wood with antiseptic properties

Typically, coniferous trees have such qualities - larch, pine, cedar, spruce.

Treatment of a log bathhouse indoors made from the listed options may not be applicable due to the resinous nature of their structure. It contains phytoncides, which themselves are natural septic tanks, and due to their action, wood is not susceptible to rot, fungus, or bark beetles. Some wood may not even be susceptible to fire.

However, there is also a pitfall in the resin content - bathhouses cannot be built from a large number of them, coniferous trees. At least steam rooms and saunas. Because resin tends to liquefy when heated and flow. It is clear that the walls will become simply inconvenient for bath use.

And the healing effect of the resin is very doubtful - it serves as a natural “plug” for tree wounds and will have the same effect on the lungs. If you use needles for a bath for medicinal purposes, then only as a decoction of needles or their extract, nothing more.

A comparison of resin content is given below:

| Wood | Larch | Pine | Cedar | Spruce |

| Degree of resin content | Very resinous | Moderately resinous | Very resinous | Low resinous |

| Presence of phytoncides | Big | Big | Big | Big |

| Making a bath | Not recommended for steam rooms. Perfect for the first crown | Not recommended for steam rooms | Not recommended for steam rooms | Suitable for the entire log house |

Chemical treatment

However, if the structure for the bathhouse is made of a different type of wood, then it makes sense to think about how to process it in this case. After all, a bathhouse is a structure where wood is not easily in contact with moisture, but also with hot steam, which has more penetrating properties than ordinary dampness.

In this regard, let’s consider what the progressive chemical industry offers today. So, the market offers three types of how to treat a log bathhouse:

- Washable.

- Difficult to wash out.

- Short term.

More details:

- The first option contains metal salts and is recommended for solving the question of how to treat the inside of a log bathhouse. But since the structure of such substances is susceptible to moisture, the decision to use them for washrooms will not be the best solution. Perfect for dressing rooms and rest rooms.

- The second option is well suited for the structure to be processed from the outside. Usually their composition contains oils and synthetics. Having applied them, we can say that treating a log bathhouse with an antiseptic of this type will be reliable protection against external manifestations.

- The third type of antiseptics is suitable for treating log buildings during assembly. They can also cover floor joists, ceilings and other bath structures. The chemicals contain not only components that prevent mold and rot, but also repels bark beetles or other parasites.

Do not forget that all these products are chemicals.

Therefore, their use should be done with caution, since a bathhouse is essentially a room with constant elevated temperature and steam. All containers containing protective compounds must be labeled “for saunas”

Also, when deciding how to treat a log bathhouse, you should take into account that all products should be purchased in specialized stores, and not in dubious retail outlets

All containers containing protective compounds must be marked “for saunas”. Also, when deciding the question of how to treat a log bathhouse, you should take into account that all products should be purchased in specialized stores, and not in dubious retail outlets.

How the ends are processed

Treatment of the ends of the log house with protective compounds takes place in 2 stages. The first begins immediately after construction. First, trimming is carried out - trimming the ends of the logs, which after the construction of the walls have different lengths. For crosscutting, use a gasoline or electric saw. After it, the ends of the logs should line up in an even vertical line.

After trimming, the ends are sanded. In this case, it is necessary to remove all surface irregularities and defects from them. For this, a belt sander with a coarse abrasive P40-60 is used. After all the ends have a clean, flat surface, they go over it with an ordinary grinder. Important: sanding should only be done in dry weather. If you work with a damp wood surface, fine lint will form on it. Because of this, it will be impossible to properly process the ends.

Only after sanding can you proceed to applying a protective composition. But first you need to make sure that the wood is dry. Air humidity should not be higher than 20%. Otherwise, the composition will not be absorbed well, and its consumption will be higher. The product must be applied with a paint brush; a roller cannot be used. Otherwise, the product will be distributed unevenly and may not get into some irregularities. Otherwise, when applying, you must follow the manufacturer's recommendations. It is necessary to process the ends of the log house, even if they are covered with siding or other decorative materials.

The second stage of processing the ends of the log house occurs after complete shrinkage of the wood. A special sealant or paint is applied to the ends. This is the finishing layer that will protect vulnerable areas from all adverse external factors.

Additional processing

A wooden house will last longer if, after shrinking the frame, you additionally cover the end cuts with a special sealant that provides reliable protection from moisture. For this type of work, specialized tools are used, which include Zobel, Kordin WV456, etc. Painting the ends will add aesthetics to the appearance of a log building if you choose a composition with a suitable color. When choosing wood protection products, it is better to give preference to environmentally friendly compounds.

Torvens end oil and its features

For primary processing of log ends there is Torvens oil. The service life of its coating reaches 10 years. This has been confirmed by climate tests. Among the composition features:

- Resistance to precipitation.

- Wide temperature range. From -50 °C to +80 °C.

- Protecting wood from moisture, ultraviolet radiation, fungi and mold.

- Creates a breathable film, allowing moisture from the wood to evaporate.

- Quick and easy to apply.

- The surface of the ends does not crack or peel after treatment.

Torvens oil is suitable for decks, timber and other outdoor wood parts. Moreover, it can be updated without cleaning the surface. It is based on modified linseed oil, wax and antiseptic additives.

An example of competent processing of the end when it did not crack due to shrinkage

Impregnation products

The use of impregnation for the ends can be carried out with various compositions that protect the wood and repel excessive moisture absorption:

- End protection with impregnants and septic tanks. These substances protect wood from mold, mildew and insects. Impregnants and septic substances are applied with a brush in two or three layers to the log, with intervals of 12 hours for drying.

- The sealant has a water-repellent property, keeping the logs from rotting and forming a protective film. It is recommended to apply this material in two layers.

- Machine oil is the most economical option for processing wood ends. The product must be used twice, every 10-12 hours.

- Paints diluted with a solvent will seal the timber from the penetration of insects or moisture, as well as prevent the appearance of fungus.

- The use of lime is the most ancient and well-known method of processing wood, protecting the wood from moisture and insects.

How to apply Torvens oil correctly

Before applying, the oil must be carefully applied with a brush for 3-5 minutes. This will give it a uniform consistency. Then you need to do the following:

- Apply the composition evenly with a soft-bristled paint brush. In this case, the ambient temperature should be from +5 ° C to +35 ° C, the weather and the tree itself should be dry.

- Leave the first layer to dry for 8 hours.

- Apply the next layer 16-24 hours after the first has dried.

Torvens end oil for initial application gives a consumption of 1 liter per 14 m2. During application of the second layer, the consumption will be 1 liter per 8 m2.

In what order to install a log bathhouse

It's no secret that the first crown of the house

or any other building - the most responsible. Since the dimensions of the lumber were known to me in advance, I precisely adjusted the layout of the future bathhouse and the size of the foundation to their length. Having accurately marked the first crown, it was enough in the future to use only a plumb line and a level so that the walls and corners of the bathhouse were vertical.

Log bathhouse. First crown

Before laying the first crown on the surface of the bathhouse foundation, I made waterproofing from two layers of RKP-350 roofing material.

Log bathhouse

, thanks to horizontal insulation, will not be exposed to ground moisture, which can rise through the foundation concrete due to capillary pores.

After the first crown, the rest are arranged. The entire frame made of timber

must be mounted along the crowns so that the lumber in the corners and other junctions is tied to each other.

How to connect beams in corners

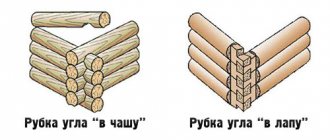

To connect the beams in the corners, I decided to use the simplest method, but quite sufficient for strength and heat protection - in a dressing with a root tenon (sometimes it is called a “warm corner”). It’s easier than not to tie the lumber together at all, installing them end-to-end, but then you would have to use staples to tie them together, and the corners of the bathhouse would be blown out.

Log bathhouse. Warm corner

All other methods that were in demand in the past - in a paw, in half a tree, in a cup, I immediately “rejected” as unreasonably complex. With modern means and methods for sealing joints, you can easily avoid unnecessary labor costs.

In order not to mark the configuration of the cutouts in the lumber for each corner separately, I simply made two cardboard templates, according to which I marked the ends. After this, making one or two cuts with a chainsaw and removing excess wood with a hammer and a wide chisel is a matter of a couple of minutes. The direction of the spike on each row must be changed. That is, if in an even row the tenon is on the right and the groove is on the left, in the odd row there should be a groove on the right and a tenon on the left. This bandage firmly holds the crowns together in height, preventing the frame from falling apart.

How to join a beam to a long wall

In some cases, it is necessary to make a T-shaped connection of the timber. This need arises when connecting an internal wall to an external one. I got three such connections for each crown.

It is better to make a T-shaped junction using a method that carpenters call a “dovetail” (in some sources this method is called a “frying pan connection”).

Log bathhouse. Dovetail connection

To do this, the end of the adjacent beam is cut out in a shape reminiscent of this very tail, and a corresponding notch is made in the long beam. After installing the unit, the connection must be wedged. For this, wedges made of dense, dry wood are used.

This type of connection provides sufficient strength and is completely airtight, since there are no through vertical joints.

How to connect crowns to tie a bathhouse frame

The connection of the crowns with each other must be carried out in order to ensure the strength of the structure of the bathhouse frame vertically. In other words, this is necessary so that the crowns do not move relative to each other. Previously, this operation was performed on wooden dowels - rods of round or square cross-section. They were driven into pre-drilled holes, connecting two or three adjacent crowns.

Not wanting to waste time preparing these dowels and drilling large diameter holes, I simply used 200 mm long nails. The nails are hammered very quickly, and if you deepen the head 3-5 cm into the upper beam, the nail will securely connect the two crowns, preventing them from moving.

To finish the nail and immerse it completely into the drilled hole, you need to use a hammer. If you don’t have it on hand, you can use an old, worn-out drill bit from a rotary hammer with a diameter of 10 mm.

Compositions

Many people will immediately answer that there is no need to treat it inside at all, because there is “chemistry” everywhere, and it is always harmful, especially in a bathhouse. If we understand by “chemistry” artificially obtained organic compounds, then yes, many of them will not bring anything good to living organisms if they get inside. But, excuse me, we ourselves also consist of organic compounds, and we eat them too. You just don't have to ask the question like that.

A steam room is a place where elevated temperatures make various substances more volatile. These are the smells of herbs, and resins in wood, and phenols in mineral wool... In general, if you smell the smell, it means something has warmed up and is “phoning.” It’s bad when paint or varnish, or PVC, or mineral wool, or sulfides in stones begin to “sink.” Therefore, they try not to put plastic in the steam room; for insulation they use only those heat insulators that do not release binding substances when heated (if mineral wool, then with a mark on the packaging “for saunas and baths”)...

IMPORTANT! They also refuse to use varnishes and paints based on organic solvents.

But the modern paint and varnish industry has already taken a technological step towards greater humanity and environmental friendliness. Now there are water-based varnishes and paints that practically do not smell when applied, and after drying they form a fairly durable polymer that does not smell of anything at all.

Therefore, the Finns, knowing perfectly well what temperature conditions they have in their steam rooms, make and sell compositions that have been tested and are considered safe. These are water-based acrylic coatings. Or they are impregnations made from completely safe oils - linseed, paraffin...

However, don’t even let the paint harm your health with its smell, it reacts quite poorly to moisture, tends to peel off, hang in rags... Therefore, if you paint the steam room in a bathhouse with anything, then only with special compounds that are suitable for bathrooms (also written on the packaging ). Such coatings are waterproof.

Lucky

After all, natural wood in a steam room is such a built-in standard. Therefore, somehow the thought does not arise about paint that will hide the texture of the wood. And there is no need - now you can tint the varnish with any color - be it green or pink.

Let’s think for a second about why we should even look for varnish for the steam room in the bathhouse. Wood that is heated and moistened undergoes deformation - it gains moisture, swells, then contracts in volume, and often cracks after this. And if it fails to dry properly, fungi and bacteria take advantage of this, converting the cellulose into rot.

So, coatings such as varnish are not so much for beauty, but for protection - from cracks and deformations, from mold.

You can protect the floor by using waterproof yacht varnish. Even though it contains polyurethane or urethane. The thing is that the temperature on the floor in the sauna is low - the Finns are required to have a 5-10 cm gap under the door to the steam room.

In a Russian steam room, if you don’t make special heated floors, it’s also not that high, it’s unlikely to be higher than 30 degrees. Therefore, yacht varnish will not hurt here either.

Waterproof, highly abrasion resistant varnish will make the floor more durable. Just don’t allow a problem like the one in the video below.

The walls can also be varnished, but this time it is safer.

ATTENTION! This can be any acrylic varnish that clearly states that it is intended for sauna walls.

Such varnishes are available from different manufacturers - both Russian and foreign. Teknos, Belinka, Tikkurila, Dulux have them, as well as ours - Neomid, Senezha, Rogneda, etc. If there is a certificate, it means the product is good.

Oils

When they talk about “oil for a steam room in a bath,” they mean impregnation for wood, but not drying oil. Compositions have long been developed that do not smell like drying oil. In particular, there is no smell from paraffin oil.

Treatment of the bathhouse inside the steam room with oils is usually limited to covering the shelves with them. This is done because it is the safest way for humans to protect the tree.

On sale you can find both liquid oil compositions and more solid varieties containing, in addition to oil, also beeswax. The latter are even better, considering that wood has been waxed for a long time, and not only for a beautiful shine, but also to increase its service life and protect it from all kinds of pests.