Designs of sauna stoves: general points and differences for different types

So what is a stove? This is a fire built inside a container. But combustion is an oxidation reaction of fuel, therefore, it cannot occur without oxygen. Therefore, we will call a furnace that container through which, at least temporarily, with the dampers open, flowing air moves.

Traction

This movement is called "traction" and it occurs when there are inlet and outlet openings.

Of course, such a definition suffers from incompleteness, because it does not apply to electric heaters. In them, heating occurs due to the passage of current through a material with high resistance. This releases heat.

But let's return to furnaces, where heat is released due to a chemical reaction. The art of the stove maker is to skillfully vary the amount of incoming air and the amount of firewood in the stack, in order to achieve their uniform burning and maximum complete combustion .

What happens if the combustion is still ongoing, but the air is blocked? Instead of carbon dioxide, a dangerous monoxide will begin to form - carbon . But why block the pipe if it is so dangerous? — The draft is shut off so as not to let the stove cool down when the wood burns out, because heat flies into the chimney along with the air.

So, we know about the role of air. Let's look at a diagram of the simplest draft furnace. What must be present in it? Three things:

- inlet (air vent or firebox door);

- firebox (aka firebox);

- outlet (chimney).

The first division of stoves can be carried out according to the presence or absence of a blower : without it they are called “stoves with a blind hearth”. In this case, air is supplied through the open firebox door. Here's what both look like in cross-section:

Kamenka

Now let’s ask ourselves: what do all sauna stoves have , but the stoves that heat houses are missing? Of course, this is a heater . All sauna stoves, even electric ones, have a container in which the stones are stored. The stones themselves are used as batteries - they accumulate heat. This is necessary so that the high temperature in the steam room lasts longer. Their other function is to create light steam , but in this capacity they are needed only in a Russian bath.

There are two classifications of heaters according to different criteria: one takes into account contact with fire in the firebox, the second - contact with air.

If there are gaps between the firebox and the heater through which the flames lick the stones, then this is a flow-through heater .

If the barrier is blind, then the heater is called blind .

When the container with stones is inside the stove, it is a closed heater .

And if the stones are in sight - open .

In this regard, furnaces are classified as follows:

Chimney installation

Wood-burning stoves are often used in saunas. The simplicity of the design makes it possible to assemble and install such a stove with your own hands. But it is very important to pay due attention to the installation of the chimney. Only with proper organization of the chimney can you be sure of fire safety.

Problems with chimneys of long-burning stoves arise due to their high efficiency. All the heat is transferred to the room, rather than going out into the chimney. In this case, the burnt gases condense on the inner walls of the pipe and flow down. This condensate, at the slightest cracks at the joints of pipes, can escape to their outer side, which leads to the appearance of an unpleasant odor and spoils the appearance of the device. To avoid such problems, at the design stage of houses and baths, all the features of the premises and the internal architecture of the space are taken into account to create the optimal shape and design of the chimney.

Furnace classifications

| Kamenka | Flow-through | Deaf |

| Open | "Black" batch oven | Continuous oven |

| Closed | Batch oven | Continuous or combined oven |

Let us explain: if the heater is running, then the poured water will spill into the firebox. Therefore, you have to wait until the wood burns out, then just supply water. Since combustion stops, the operation of the stove is called “periodic” . Accordingly, the continuous stove is not filled with water and the wood can burn throughout the bathing procedures .

On a note! Most often, metal stoves are permanent, and brick stoves are periodic, but there are exceptions. If a solid heater is made in a brick stove, then such a stove is called a combined stove.

Inertness of the material

So, the fire burns, the stones heat up, and what happens to the steam room? If we need to heat the stones to 300-400 degrees, can you imagine how much the air in the steam room can heat up during this time? And now we come to the next important point: the role of material in the design of sauna stoves, in particular steam room units .

Stoves are either brick or metal . There is no other option. The former are considered very inertial - it takes hours to heat them up, as well as to cool them down . The latter are able to heat up in half an hour and during the same time manage to overheat the steam room. sauna stoves !

When choosing a design, you determine for yourself how inertial its body should be. At your disposal are not only “clean” options: a purely brick, purely metal stove, but also combined ones . For example, you can increase the inertia of a metal stove either by using the internal lining of the firebox and heater, or by using an external sarcophagus casing. Moreover, the option with a casing and lining at the same time is not excluded).

Important! Answer the question, what is the optimal time for lighting the stove for you - it is this that determines the degree of inertia of the body.

Smoke

What happens when fuel burns? Heat is released and combustion products are formed - steam, gases and solids. We call the latter soot, soot , and all together - smoke . At the moment of leaving the furnace, this mixture is also heated to several hundred degrees. And if some heat-intensive obstacle , all this heat will simply fly away into the chimney to increase the greenhouse effect on our planet.

However, once upon a time, not only were there no obstacles, but there were no pipes either. Because they weren’t made from wood! Therefore, the first type of stove according to the method of removing smoke is chimneyless, “black” .

In its simplest version, it is a pile of stones placed in a vault over a fire . In the modern version, it is a brick hearth that keeps the same pile of stones from spreading. But the principle is the same: light a fire under the stones, wait for the wood to burn out, release the smoke outside through a window or door - and you can steam by pouring water on the heated stones.

Then a smoke collector - akin to a kitchen hood - also separated from the stove. A similar option can still be found in the bathhouse today.

Then the chimney pipe . And if it is simply inserted into the stove (into the firebox or heater - it doesn’t matter), then such a stove will be called direct-flow . Heat here is not taken from the furnace gases, so it has the lowest efficiency.

But heat is a pity, so the inventors’ idea went this way: what if we increase the path that the smoke travels inside the stove? smoke circulation system appeared , where smoke is forced to run with obstacles inside channels that lead it up and down, or horizontally to the right and left. The system is excellent for heat extraction, but it has its drawbacks - the channels, especially horizontal ones, must be cleaned regularly , otherwise there will be no draft.

An alternative to the smoke circulation system was the bell-type stove . It has no channels and is practically independent of traction. Hot furnace gases, leaving the firebox, end up under the hood, where they actively share heat with the furnace mass. New portions of hot furnace gases rise, displacing cooled ones down and into the chimney.

However, everything that has been said about the chimney primarily applies to brick stoves . It's rare to see a metal stove with smoke circulation. Usually they are primitive - direct-flow, except that they have flame dividers. And their sizes are much smaller than brick ones, there are no passages, and there is no heat-intensive material - where to take the heat?

The stove ends at the chimney. What remains optional is a tank or heat exchanger , which can also be indicated on the diagram of the sauna stove. But it is better to talk about this when analyzing specific structures, to which, in fact, we are moving on.

Principles of chimney installation

- “According to smoke” - the upper links of the pipes are put on the lower ones so that the smoke does not experience resistance from the joints as it moves. Such installation is acceptable for primitive furnaces and only if there is a special sump to collect condensate.

- “By condensate” is the optimal type of installation for long-burning furnaces. In this case, the upper section of the pipe is inserted into the lower one to allow condensate to flow down. This eliminates the possibility of condensation passing out. All liquid enters a special sump and burns in the oven.

Scheme of a stove for a brick bath

From the above it already follows that there are several basic diagrams of a brick kiln:

- direct flow;

- with smoke circulation;

- bell-shaped

However, each allows for many implementation options. In other words, the above diagrams clearly demonstrate the characteristic, but do not exhaust the possible.

Bath stove design: direct flow

Typically, in a brick kiln, the implementation of a direct-flow design is accompanied by a closed flow-through heater. In this case, there is no reason to fear that the furnace gases will not have time to cool sufficiently before leaving - their passage through the mass of stone filling is quite effective in removing heat.

By the way, the diagram shows that two types of bricks are used in the design of the sauna stove: red refractory and fireclay - they are shown in red and yellow. Please also note that there is a gap between them - this is an essential point.

The advantage of direct-flow can be considered its simplicity, including ease of maintenance. Of course, it is unlikely that you will be able to lay the stones perfectly the first time, but over time you will find their optimal number and location.

Designs of sauna stoves with smoke circulation

You already know the purpose of smoke circulation, but the difficulties associated with it do not yet. In general, everything in the oven is built on compromises. And this system is no exception. Let's start with the fact that horizontal channels are much better than vertical ones both in terms of heat distribution and the durability of the stove - there is no big difference in vertical temperatures, the stove does not crack. But with this arrangement there is another problem: the walls become overgrown with soot. Vertical ones overgrow more slowly, but here you need to clean them once a week, otherwise the draft decreases and the efficiency drops. Therefore, vertical channels turned out to be preferable.

The number of revolutions can vary from 1 to 12, but practice has shown that the optimal number of revolutions does not exceed 4 . As for their cross-section, it should not be too small and too large. In the first case there are more traps for soot, in the second there is ineffective heat extraction.

On a note! The inside of the channels must be as smooth as possible; they are specially cleaned of solution residues for this purpose. When laying, the most even geometry should face inward. The reason is that any roughness is a trap for soot.

Furnace structure in the bathhouse: bell-type

The design of a sauna stove may not contain channels. We have already shown you the structure of a simple bell-type furnace. Now a little more detail.

Its principle is simple: you need to build something like an inverted glass above the firebox, and make an exit to the chimney near its lower edge. This is a fairly clean design that suffers little from soot . The gases move as they want - the heated ones rise to the bottom of the glass, transferring heat to it, while they cool and tend downwards, they are replaced by new portions from the firebox.

Important! It is very easy to light such a stove even after a long break in operation.

However, it also has disadvantages:

- The upper part of the stove warms up well, and for good heating of the steam room it is necessary for the heat to come from below. This is treated with a two-hood system .

- For proper combustion you need skill - in an overheated furnace, gases stop flowing under the hood, it is easier for them to immediately escape into the chimney. It is treated by fine adjustment of the air entering the firebox.

Conclusion! Without experience, you can negate all the advantages of a bell-type stove.

With tank or coil

In an article devoted to a brick stove with a closed heater, we talked about how to correctly position the water tank in the stove structure in a bathhouse so that the water does not heat up too early, does not boil, increasing the humidity with heavy steam, and the tank is convenient to use in conditions of manual filling .

Here we just note that the coil inside the stove seems to us more optimal than the adjacent water tank. It is enough to maintain the angles of inclination of the pipes and the water in the system will flow only due to gravity and thermal convection.

In addition to the coil, a register of any other shape can be placed inside a brick oven. The location can be a firebox, a heater, or even a chimney.

Heat exchanger installation

The easiest way to install a heat exchanger in a bathhouse is when it comes complete with a purchased metal stove. You just need to carefully study the operating instructions and perform assembly in accordance with the diagram. All that remains is to connect to the system, this will be discussed below. Installing a water circuit into a flue or firebox of a brick kiln is another matter. Then the register must be made in advance from a thick-walled black pipe or stainless steel, and then built in in accordance with the furnace design.

On the Internet you can often read a recommendation that the area of the heat exchanger, that is, its surface, should be 1 m2. The statement is not entirely correct, because ovens are different, and calculating this indicator is quite difficult. In this case, it is better to make a coil according to the principle of analogy. That is, you need to find the technical specifications for a product from any manufacturer with the same power as yours, and take the specified heat exchange surface area.

Important. If you make a circuit with a small exchange surface, the water in it will constantly boil, which is unacceptable. “Overdoing” the size, on the contrary, can lead to a long warm-up period; as a result, by the time of washing, the water in the tank will remain cool.

As for chimney heat exchangers operating on the principle of a water economizer, such an element can either be purchased ready-made or welded from two pipes of different diameters. Remember, the longer the circuit, the more efficiently it will exchange heat with the chimney.

Metal sauna stove design

Metal stoves are more primitive than brick stoves for the following reasons: they are small in size, in fact it is a firebox with a closely spaced thin body, and besides, metal conducts heat well, but practically does not accumulate it. Complex structures have a place, but only in case of increasing the size, internal lining and other methods of increasing the inertia of the material.

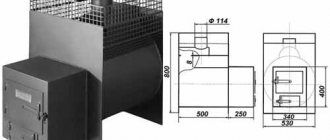

Therefore, the simplest metal heater will be a box with a grate inside, separating the ash pan from the firebox. The heater will be located above the firebox or to the side of it, and a water tank can also be located.

Below is an example of a fairly simple stove with an attempt to create smoke circulation and options for the location of the tank and heater, as well as a protective screen, the installation of which is clearly demonstrated in a separate publication:

Metal furnace with lined fuel core

Lining is the lining of the inside of the stove with fireclay or simply refractory bricks. At the same time, the inertia increases sharply, and with it the heating time. So, if you need to overheat the steam room in half an hour, the lining will be superfluous.

BUT! It has one important advantage: it increases the service life of the furnace, because its body is subjected to lower temperature loads. And this is in addition to the fact that such a stove retains heat longer.

We show the simplest diagram with a firebox lining and a closed heater:

Options for placing a water tank on a metal stove

You have already seen above that you can simply place the tank on top of the stove and everything will heat up. But you can do it differently.

Below are diagrams for combining a heater and a tank , from the simplest ones, where the bucket is buried in stones or the heater is placed in a separate container where stove gases enter, and the tank stands directly above the fire (the water will boil before the stones heat up) to variations on the topic of rational use of the top of the stove, where you can separate the space for the tank horizontally or vertically, or you can go around the heater on both sides, leaving an air pocket on one of the opposite sides, which, as they say, promotes heat exchange. Full information is provided in the corresponding article.

Options for the location of the tank and heater:

Yes, and of course, whenever there is a need for hot water, you can replace the tank with a heat exchanger of one type or another . If you are interested in learning more about this, read this article.

Metal heater made of pipe

On our website you can find material that tells you how to make such a heater. Here we will only present the diagrams themselves with some comments.

So, the owner has two options for a pipe stove:

- vertical;

- horizontal.

Usually they take a pipe of half a meter diameter. The figure shows that the pipe can be lined from the inside (or you can leave it as is, then it will burn out faster). The fireclay along the walls is shown in yellow.

The owner is also free to choose a stove with a blind hearth or ash pit. The difference between them was discussed above. But pay attention to the oven door with a blind bottom - in order not to keep it open, holes are drilled in it, which provide air flow if the pipe at the top is not blocked by a damper. If you lengthen the stove a little by using the blower, the draft will be regulated by opening the blower door . Then the holes become redundant.

The water tank is shown in both pictures, but is actually optional. Some make it lower by welding a metal box with a lid on the side of the stove - this is for ease of pouring in the absence of cold water supply in the bathhouse.

The horizontal stove has a completely different structure - it has an open . This is a welded basket for stones - you can’t get good steam with such a stove.

Yes, and in the picture we depicted the grate (under the flame) as recognizable, but in reality its grate is perpendicular to the direction you see here.

The water tank is welded to the back wall of the stove.

Features of operation

There are a number of conditions that are very important to observe when installing the stove. Neglecting these rules will make further operation of the fireplace stove difficult.

- The structure cannot be installed close to the wall. The required distance should be indicated in the instructions that come with the fireplace.

- There must be cladding on the surfaces of nearby walls. A ceramic stove is perfect for this.

- Do not install the structure on a bare floor. It is advisable to lay ceramic tiles or make a podium from bricks.

- The stoves weigh quite a lot, so additional racks should be installed to prevent the floor from sagging.

Useful video

Not just diagrams, but also a description of the advantages and disadvantages of vertical and horizontal structures (not necessarily made of pipes). Plus interesting life hacks.

Even more diagrams, even more explanations about them. However, the main concern of the author of the video is that you get a stove for a real Russian bath. So sauna lovers don’t have to watch it).

+++

We hope that you have received some kind of holistic understanding of what a sauna stove is. Other things can only be learned from practice and experiment. Good luck to you!

What to look for when purchasing

When purchasing a heating device, first of all, you need to pay attention to its power. This is a key characteristic that affects performance. To be sure, you can order a calculation of the power of a wood-burning stove for a bathhouse from specialists on the eve of purchase.

In addition, it is equally important to choose the right oven size. If the size of the stove is too large for the room, then it will overheat and fuel will be wasted. The choice of stoves is very large, so it is possible to select the optimal equipment for absolutely any type and size of premises.

Before choosing a stove, you need to find out the area of the potentially heated room and decide on the required set of technical characteristics. Using different models of stoves, it is possible to heat rooms with an area of 80-250 m2.

This type of units, in addition, has two varieties. The first is used exclusively for heating the room. The second model is more functional and, in addition to heating the air, provides the ability to cook food.

The simplest models are very affordable in cost. More complex models with advanced functionality vary in price and can be quite expensive. Therefore, you need to know which features are needed so as not to overpay for unused features.

Preparatory work

Work begins with preparing the construction site. If the stove is installed in the wall between the steam room and the dressing room, then part of the wall is cut out. When placed in a corner, the walls are protected with mineral thermal insulation, after which they are lined with red brick. When choosing a location, you should definitely consider how the chimney will be installed - perhaps its installation will be hampered by floor beams or rafters.

How to correctly calculate and install the foundation

You should be aware that even a small metal stove is an impressive structure, not to mention brick structures weighing hundreds of kilograms. Therefore, the first thing to do is to build a strong, reliable foundation.

To build the foundation:

- At the site where the structure is installed, a pit is dug with a depth of 0.5–0.6 m and dimensions that are 20–25 cm larger than the dimensions of the furnace.

- The bottom of the pit is covered with sand (a layer of 10–15 cm), after which it is watered and thoroughly compacted.

- After this, a cushion of crushed stone or granite screenings up to 20 cm thick is laid.

- To construct a reinforced concrete slab along the perimeter of the pit, plank formwork is constructed, inside which an armored belt is mounted at a height of 7–10 cm from the bottom.

It is best to equip the foundation of a steam room stove at the very first stages of building a bathhouse

- Concrete for the foundation is prepared by mixing 1 part of M-400 cement with 4 parts of crushed stone and 3 parts of sand. When using M-500 cement, the proportion of sand can be increased to 4 parts. There should be enough water so that the concrete laid in a slide does not spread and at the same time retains its plasticity. Immediately after preparation, the solution is poured into the formwork, being sure to compact it by vibration. The surface of the foundation is leveled according to the rule, after which it is covered with plastic film and left until the solution has completely set.

If you plan to install a metal stove with subsequent lining with red brick or stone, then the dimensions of the foundation must take into account the dimensions of the final structure.

Rules for preparing the solution

For laying a brick heater, you can use both factory mixtures and a simple clay-sand mortar. River sand and fatty clay are best suited for its preparation - it is more plastic, and during the drying process it forms a strong seam. To determine the amount of both components, an experiment is carried out. To do this, small parts of clay and sand are mixed in different proportions, after which balls with a diameter of about 5 cm are rolled out of the solution. Lumps of clay, dried for several minutes, are squeezed between two wooden planks, observing the beginning of cracking of their surface. The optimal composition is considered to be one in which the ball began to collapse only after it was compressed to 2/3 of its original size. If this happens earlier, then the amount of clay in the solution must be increased.

Not only ease of use, but also the strength of the entire structure depends on the quality of the clay mortar.

To obtain a high-quality solution, the clay is cleaned of impurities and thoroughly kneaded. After this, it is soaked in cold water for 24 hours.

Another way to determine the quality of the masonry mixture is to lower a wooden spatula into a bucket of mortar. The mixture should not drain immediately after removing the tool from the container - this indicates an increased sand content. If there is a lot of clay, the composition will spread unevenly over the surface of the blade, forming lumps. The optimal composition forms a layer 1.5–2 mm thick.

Cutting blanks

To build a metal furnace, a steel sheet with a thickness of at least 4 mm is used. To cut it with a grinder, you will need a lot of time and effort, in addition, you will have to spend more than one abrasive disc. If possible, it is better to cut the metal in advance using a gas cutter or plasma cutter. Even if you or someone you know does not have such equipment, do not despair. Now, any nearby enterprise or car service center will have everything you need, including a specialist who can help you.

It is best to use a special tool for cutting workpieces.