The technology for the production of concrete and mortars involves the use of crushed quicklime. During the processing process, almost all components of natural material are used, which makes its use profitable and preferable.

Products containing lime are durable, water-resistant and highly dense. The valuable qualities of quicklime raw materials make it possible to include the component in strengthening and stabilizing solutions used in road construction.

It is difficult to imagine the production of sand-lime bricks without lime. But the scope of application is not limited to the construction sector. The material is often used in fishing, poultry farming, and agriculture due to its purification and disinfection properties.

What is quicklime and its properties

Quicklime building lime is a white substance with a crystalline structure. Its formation occurs during the firing of chalk, dolomite, limestone and other minerals of the calcium-magnesium type. In this case, the proportion of impurities cannot be higher than 6-8%. In general, the formula of the compound can be represented as CaO, although it also contains magnesium oxides and other compounds.

The material is manufactured in accordance with the requirements of GOST 9179-77 under the name “Construction lime. Technical conditions". It is made from carbonate rocks using additives of a mineral nature: quartz sand, blast furnace or electrothermophosphorus slag, etc.

According to the requirements of the state standard, lime must be crushed to such a size that the residue after passing through sieve No. 02 and No. 008 is no higher than 1.5% and 15%, respectively.

Quicklime is classified as hazard class 2. Pure air-type lime can be of 1st, 2nd and 3rd grade, with impurities - 1st and 2nd grade. Hydrated lime has 1st and 2nd grades.

STRUCTURE

Calcium oxide is a white crystalline substance that crystallizes in a face-centered cubic crystal lattice, similar to sodium chloride. Point group: m3m (4/m 3 2/m) - hexoctahedral. Space group Fm3m (synthetic). Cubic system. Cell parameters a = 4.797Å. Unit cell volume V 110.38 ų (calculated from unit cell parameters).

Classification according to GOST

The classification of calcium oxide is carried out according to the content of the interstate standard GOST 9179-2018 (formerly 9179-77) “Building lime”. In accordance with paragraph 4 “Classification”, the substance, based on the conditions of its solidification, can be air or hydraulic.

Air, in turn, is divided into 3 more groups, differing from each other in the amount of calcium or magnesium oxide contained:

- Calcium - mostly consists of calcium oxides or hydroxides. There are no hydraulic or pozzolanic materials in it.

- Magnesium - has a similar composition with the difference that calcium oxides and hydroxides are replaced by magnesium oxides and hydroxides.

- Dolomite is a combined substance that contains calcium oxide with magnesium oxide or magnesium hydroxide. No foreign materials of hydraulic or pozzolanic nature are observed.

Hydraulic mixtures can be strongly or weakly hydraulic.

Other characteristics that characterize belonging to one of the varieties of quicklime include several more. First of all, the content of GOST emphasizes that division can be carried out according to the following criteria:

Based on the size of the fractions, quicklime can be lump (crushed) or powdered.

According to the speed of the reaction when water is added:

- Fast-extinguishing, a process that is completed within 7-10 minutes.

- Medium-extinguishing, its reaction lasts longer and can reach 22-27 minutes.

- Slowly extinguishing, having the longest chemical reaction time, more than 30 minutes.

Consumption

It will depend on where exactly the mixture will be used. To whitewash a room, you will need 0.5 liters of ready-made whitewash per square meter. If we are talking about fluff, then from a two-kilogram pack you can get six liters of whitewash, which will be enough to whiten about 12 square meters of surface. True, if you have to work with brickwork, then a larger quantity will be needed.

If we talk about ready-made lime dough, then its ratio will be such that three liters of liquid will be required per kilogram of dough.

If we are talking about quicklime, then first it must be slaked, and only then diluted with water. In its case, from one kilogram of quicklime you can get about ten liters of whitewash, ready for use.

"Household" classification

All the previously listed criteria affecting the classification of quicklime were based on the content of the above-mentioned state standard. They practically never occur in the life of an ordinary person, since they are aimed directly at the manufacturer of the product.

If we talk about classification based on what can be found in the windows of construction or garden stores, then the division will occur in a different way. According to quality characteristics, quicklime is divided into 3 grades:

- First.

- Second.

- Third.

Each of them differs in the amount of the above-mentioned impurities. You can determine whether you belong to a particular variety by the color of the substance. Snow-white is the first, white is the second, having a grayish tint is the third.

Another sign is the size of the fractions. Although the above-mentioned ITS describes the process of making the substance as proceeding through 3 cycles of crushing and subsequent grinding, lump quicklime (and slaked) lime can be found in stores. The division according to this criterion is carried out into 2 groups:

- Komovaya. Presented in the form of a mixture of stones of different grain sizes and sizes. They consist of calcium oxide, magnesium and additional components, which include calcium carbonate, aluminates and silicates. In addition, magnesium or potassium ferrite may be present in small quantities, formed as a result of heat treatment. Successfully used for the production of concrete. The nominal value of the strength of the resulting product is achieved due to the small amount of water required, which occurs due to the fine grinding of the material.

- Ground or fluff. It has the same chemical composition as lump. The difference between them lies in the physical form of the grains. In that case, the particles went through a full processing procedure: 3 crushing cycles, screening and grinding. Also, a distinctive feature of ground quicklime is the performance characteristics of the product. It is more durable, waterproof and hardens faster.

Healthy! To change the time it takes to harden, sulfuric acid, calcium chloride or gypsum are used.

The final feature that classifies quicklime is the scope of application (for domestic purposes). This criterion implies division into more than a dozen separate items. The most popular of them are considered to be the following compositions:

- Construction – used in the preparation of dry construction mixtures, added to large grades of concrete to improve quality characteristics.

- Hydraulic - also used for the preparation of concrete, but of low grades (low strength), intended primarily for use in areas with high humidity.

- Lump - primarily intended for the production of whitewash solutions.

- Garden - popular in agricultural work. It is used as a means to improve the beneficial qualities of soil and protect plants from harmful insects. Prevents rotting and stimulates the growth of garden plants.

- Sodium is the main consumer of the chemical and pharmaceutical industries.

- Chlorine is one of the main methods of disinfection and cleaning of household waste.

- Food – acts as a food additive E-529, which is part of a wide range of food products.

Important! When using lime as a soil fertilizer, it is not recommended to use it in combination with other types of additives.

Varieties

Construction lime is divided into two types: air and hydraulic. Air lime makes it possible to harden concrete under normal conditions, and hydraulic lime allows it to harden both in dry conditions and in an aqueous environment. Therefore, air lime is suitable for ground work, and hydraulic lime is suitable for the construction of bridge supports.

Based on the nuances of processing the burnt material, different types of lime are distinguished:

- Lump lime is made in the form of a mixture of pieces of different sizes. It consists mainly of calcium oxides (the predominant part) and magnesium. It may also contain aluminates, silicates and ferrites of magnesium or calcium, which are formed during firing, and calcium carbonate. It does not perform the function of an astringent ingredient.

- Ground lime is made by grinding lump lime, so their composition is almost identical. It is used in unslaked form. This avoids waste and speeds up hardening. Products made from it have excellent strength properties, they are waterproof and have a high density. To speed up the hardening process of the material, calcium chloride is added, and to slow down hardening, sulfuric acid or gypsum is added. This helps prevent cracks from appearing after drying. Ground lime is transported in sealed containers made of paper or metal. It can be stored for no more than 10-15 days in dry conditions.

- Hydrated lime is a highly dispersed dry compound formed when slaking lime. It contains calcium and magnesium hydroxides, calcium carbonate and other impurities.

- When liquid is added in a volume sufficient to transform the oxides into hydrates, a plastic mass is formed, which is called lime paste.

The most popular in use today are slaked and quicklime.

Quicklime production

In the past, limestone was heat treated to form lime. In recent years, this method has been used less and less because the reaction produces carbon dioxide. An alternative method is the thermal decomposition of calcium salts containing oxygen.

The first stage is limestone extraction, which is carried out in a quarry. First, the rock is crushed, sorted, and then fired. Firing is carried out in kilns, which can be rotary, shaft, floor or ring.

In most cases, shaft-type furnaces are used, which operate on gas, in a pour-over method or with remote fireboxes. The greatest savings come from devices that operate using the pouring method on anthracite or lean coal. The production volume using such furnaces is around 100 tons per day. Their disadvantage is the high degree of contamination with fuel ash.

You can get purer lime in a device with an external firebox, which runs on wood, brown coal or peat, or in a gas device. However, the power of such furnaces is much lower.

The highest quality is obtained from a substance processed in a rotary kiln, but such mechanisms are used quite rarely. Ring-type and floor-type furnaces have low power and require large volumes of fuel, which is why they are not installed at new enterprises.

Application of quicklime

Since time immemorial, quicklime has been actively used in many areas of human activity. Its use is known in construction, the food industry and many other areas.

Quicklime as a fireproof material

Among insignificant and cheap objects, fire-resistant material based on quicklime has become widespread. Compared to other refractories, quicklime has a significantly lower yield. cost, which allows it to be used in this capacity where the use of more expensive refractory materials is impossible or impractical.

Quicklime in the food industry

Quicklime has also become quite widespread in the food industry. It is found in products as food additive E-529. In this capacity, quicklime acts as an emulsifier, that is, it allows substances that are immiscible by nature, such as oil and water, to be mixed into a homogeneous mass.

Quicklime for painting

Painting with quicklime has its own nuances. A dense film after painting with quicklime appears only with a sufficient amount of moisture. That is why painting with this substance is carried out only in rainy and humid weather and on a not completely dry surface of the wall, floor or ceiling.

Quicklime in laboratories

In laboratory conditions, quicklime has also found its use. In small quantities, adding quicklime can significantly dry out substances that do not react with it.

Trial

Chemical studies and determination of physical and mechanical characteristics of potassium oxide are carried out according to the prescribed standards in GOST 9179 77. Lump material is shipped in bulk.

Lime in powder form is shipped in bulk or sorted into special containers. If the client agrees, the use of paper bags with four layers of paper is allowed.

To determine the average gross tare weight, twenty bags are weighed at the same time and selected at random. The resulting number is divided by 20.

It is allowed to deviate from the average values of bags of net lime from those indicated on the container. This number cannot exceed one thousand grams.

The manufacturer, at the same time with the details and information for shipment, must convey to each buyer a quality control passport, which must indicate:

- at what enterprise the product was manufactured;

- when the potassium oxide was shipped;

- party and passport number;

- weight of goods sold;

- when the extinguishing was carried out and at what temperature;

- how many minerals and other elements were added;

For each transported unit, a label is inserted, which states: the name of the company, the name of the product, its guaranteed type and grade, a description of the standard according to which the delivery is carried out.

If the material is shipped in paper containers, it must indicate:

- what is the name of the company;

- what is the name of the product, type and grade;

- description of the standards according to which the delivery is carried out.

in paper containers

by transport, preventing moisture from entering. Ingress of moisture is undesirable when storing materials.

Potassium oxide can be transported regardless of the type of covered transport in accordance with the standards for transporting such substances that apply to it.

How to properly apply lime to the soil

Is it necessary to lim the soil?

Lands with an acidic reaction must be subjected to liming. This procedure is necessary to make it easier for plants to absorb fertilizers, as well as to improve fertility. The fact is that acidic soil does not have the necessary microelements, and those that exist are in a form that the plant cannot absorb.

How to determine whether soil is acidic or not? You can contact specialists, or you can find out by looking at the plants that grow in your garden plot.

Horsetail, cornflower, heather, plantain, sedge, horse sorrel, and coltsfoot grow well in acidic soil. You can improve the soil by adding lime to it.

The soil is deoxidized as follows: in the fall, before digging begins, lime is sprinkled on the ground and dug up. But here, too, not everything is so simple. You need to know which crops like slightly acidic soils and which prefer alkaline soil.

Instead of lime, you can add chalk, ground limestone, dolomite flour or limestone tuff.

How to fertilize the soil with powdered lime? Quicklime must be quenched. You need to take 50 kg of product, dilute it with two buckets of water, quenching it. Quicklime cannot be fertilized. It will form into clumps and will not produce lime in the area.

If lime is stored outdoors, it has already been quenched by moisture from the atmosphere.

When digging in autumn or spring, powder must be added to the area. It should also be scattered under trees and shrubs when you loosen or dig up the soil around the trunks. Lime is added to strawberry beds a year after planting.

What rate to apply:

- For acidic and sandy soils - 300 g of lime per 1 sq. meter;

- For areas with acidic, clay soil - 500 g;

- If the degree of soil acidification is unknown, then apply half the norm, and then observe what herbs grow in the area.

If plantain or horsetail begins to grow rapidly, then the use of lime should be stopped. In the future, do not rush to add large doses of this substance. Excesses are just as harmful as deficits.

For the pond

If your site has a small pond with or without fish, it must be limed.

The fact is that a lot of dead plants, food residues, fish excrement, etc. accumulate in the water. Lime, on the contrary, is washed out over time. The procedure allows you to accelerate mineralization, eliminate the acid reaction, and enrich the water with calcium.

Other beneficial properties of quicklime:

- water disinfection;

- destruction of most parasites living on the bottom and in the water column;

- getting rid of weed fish (for example, rotans) in the fall (in the spring it will be possible to introduce new inhabitants into the reservoir).

- calcium entering the water promotes the formation of a healthy skeleton and normalizes the functioning of the neuromuscular system in fish.

Quicklime should only be applied to a damp bottom. It cannot be used on dry or frozen soil. Also remember that on a sandy bottom the effect of application will be minimal, but on a peat base it will be excellent!

Instructions for slaking lime

The lime slaking process can be organized at a construction site or at home. Depending on the type of raw material, the finished solution is:

- Quick-extinguishing (cooks in 10 minutes).

- Medium-extinguishing (extinguishing within 25 minutes).

- Slow-cooking (takes up to 1 hour to cook).

The duration of quenching is determined by the time from the beginning of adding water to the feedstock until the chemical composition of the finished product is completely stabilized.

Cancellation rules

The quenching process occurs according to the formula:

CaO + H2O = Ca(OH)2 + 65.1 kJ.

Lime powder is diluted in water, which reacts with calcium (or magnesium) oxide. Hydroxide is formed and a lot of heat is released, causing the water to become steam. Water vapor loosens the mixture, and instead of lumps, fine powder is formed.

Depending on the slaking period, lime is of the following types:

- quick-extinguishing (maximum 8 minutes);

- medium-extinguishing (maximum 25 minutes);

- slow-extinguishing (at least 25 minutes).

The duration of extinguishing is calculated from mixing with water until the temperature of the mixture stops increasing. Usually the specific time is indicated on the packaging.

Using slaking you can make hydrated lime (called fluff) or lime paste. In order for the fluff to come out, you need to pour 70-100% of its weight of water into the lime. It is usually made in factories, in special hydrators.

To make lime dough, liquid and powder must be taken in a ratio of 3-4:1. It is done mainly on a construction site. To make a plastic mass, it is kept for at least 2 weeks in a special pit.

Preparatory stage

For work, it is necessary to prepare raw materials and personal protective equipment from the negative effects of thermal steam - gloves, goggles, mask, clothing made of thick fabric.

The raw material should be quicklime, a deep wooden or metal container and a kneading device.

Also, to prepare a large volume of the mixture, you will need an earthen pit and a spacious box made of a wooden base, equipped with a drain window with a mesh filter.

Quenching process

To obtain high-quality hydrated lime, the following steps are performed:

- The raw materials are poured into the prepared container.

- Water is gradually added to the base in a 1:1 ratio and slowly stirred to activate the quenching process. This proportion is suitable for preparing fluff - a powdery mixture. To obtain lime dough or milk, 400 g of water must be added to 1 kg of raw materials.

- Stirring of the substance is carried out until the quenching reaction is completely completed.

- The freshly slaked solution is infused in a container for 40 hours until thickened, and used 30 days after preparation.

Cancellation in a wooden box

If a wooden box was used to prepare lime, the finished mixture is poured through a filter window into an earthen pit, covered with boards and infused for several days.

After the end of the period, the lime is covered with a sand layer 18 cm high and further infused for 2–3 weeks.

Where and how gardeners use fluff

Hydrated lime is used to increase soil fertility by liming, as well as to combat harmful insects and wild grasses.

Weed control

According to the observations of experienced gardeners, acidic soil is favorable for hard-to-eradicate wild plants such as woodlice, horse sorrel, wormwood, clover, horsetail and wheatgrass. Deoxidizing the soil will help get rid of them. At the end of the season, when digging before winter, 200 - 350 g of lime per square are added to the ground. With the onset of spring, these weeds will become smaller or disappear altogether.

Features of using lime simultaneously with fertilizers

Fluff is often used in conjunction with other fertilizers. However, there are a number of recommendations that need to be followed:

- Hydrated lime is not mixed with other carbonate rocks and their derivatives.

- The combined use of lime with humus and manure is not recommended, as this provokes the formation of compounds that are difficult to obtain for absorption by plants.

- It is permissible to mix ash, nitrogen, phosphorus and potassium mineral fertilizers that do not include calcium and magnesium with fluff.

The use of lime in the country helps to optimize the quality characteristics of the soil, allows you to effectively fight weeds and pests, thereby providing favorable conditions for the growth and development of crops. This is one of the widely available natural remedies that can be prepared even at home by extinguishing.

Areas of use

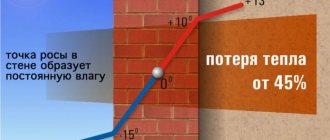

For many years, lime cement was produced from quicklime. It hardens well in the air, but absorbs a lot of moisture, which is why fungus appears on the walls. Therefore, now in the construction industry, quicklime is in much less demand than before. It is one of the components in the production of plaster materials, sand-lime bricks, slag concrete, paints, etc.

Lime can be worked with in winter, since slaking produces heat, which maintains the temperature of the mixture during the hardening period. You cannot use it for the production of cement for finishing fireplaces and stoves, because under the influence of temperature it emits carbon dioxide.

Another area of application of lime is agriculture and horticulture. It is well suited for treating plants against pests, whitewashing trees, and fertilizing acidic soils. Ground limestone is a raw material in the production of livestock feed and poultry feed.

Flue gases and wastewater are neutralized using quicklime. It is also used to paint various surfaces. The use of lime in the country and for vegetable gardens is very popular.

Quicklime is in demand even in the food industry. It is found in many products in the form of emulsifier E-529. It is an ingredient that helps to mix substances that are immiscible in nature (let's say water and oil).

Application of quicklime:

Cancelled and quicklime: the difference

Slaked and quicklime varieties are substances that differ in their chemical composition. Quicklime is calcium oxide, and slaked is its hydroxide, it is obtained as a result of quenching with water. By the way, during storage, quicklime gradually absorbs moisture from the air and slowly transforms into slaked lime.

The scope of their application also differs. Quicklime is a component of dry construction mixtures and is also used for the production of sand-lime bricks. Slaked lime is used in painting and plastering as a binder.

Quicklime has several advantages:

- does not generate waste during operation;

- low degree of liquid absorption;

- possibility of operation at sub-zero temperatures;

- high strength;

- wide range of uses.

Along with its advantages, the quicklime mixture also has a significant drawback - it is hazardous to health, is a caustic compound, and leads to burns of the skin and mucous membranes. Working with it requires caution, the room must be ventilated, and it is also advisable to use safety glasses, a respirator and gloves.

How to determine which lime is in front of you - slaked or not.

- This information must be indicated on the packaging.

- Mixtures can be distinguished by touch. When you touch the quicklime, you feel warmth, while slaked lime has a normal temperature.

- Quicklime is most often pebbles and lumps, and the slaked mixture is sold in powder form.

- You can check the composition using water. When liquid gets on quicklime, a reaction immediately begins, heat and gas are intensely released, and splashes fly in all directions.

Help with burns

A lime burn is a chemical damage to the skin that is fraught with the most unpleasant consequences. Quicklime is an alkali that emulsifies and dissolves sebum, penetrating into the deep layers of the epidermis. Externally, the burn looks like complex necrosis of off-white tissue with the formation of loose scabs. When it comes into contact with the skin and mucous membranes, the alkali penetrates in all directions, so the lesion is much larger than the area of contact with lime. Damaged tissues partially lose their ability to regenerate and wounds take a very long time to heal.

In case of injury, medical assistance should be provided immediately. It is necessary to promptly call a doctor, and while she is on her way to try to improve the victim’s condition. If slaked lime gets on your skin, you should rinse the affected areas with cold water for at least 15 minutes, and then treat with chamomile infusion or anti-inflammatory ointment.

But if a burn occurs with quicklime, then rinsing the skin with water is strictly prohibited, because this can aggravate the situation and cause irreparable damage to health. Most of the substance will come out along with tears, and its remnants should be removed with a cotton cloth and lubricated with oil or grease. By the way, this is the only type of chemical damage when their use is allowed. For any other types of damage, such reagents are strictly prohibited. The wound should be covered with a sterile cloth and then immediately taken to the hospital.

The situation is more complicated if lime gets into the eyes. It causes quite dangerous consequences, including partial or complete loss of vision. Small and medium fractions are not so dangerous; they can only cause conjunctivitis. Large parts literally stick to the mucous membrane of the eye and actually corrode them, penetrating inside and causing sharp pain, burning and spasm of the eyelids.

First aid includes:

- instillation of disodium salt, which binds metal ions;

- use of painkillers, including local ones.

For treatment, the eyelid is inverted, the lump of lime is removed mechanically, after which the patient is treated with antibiotics. The treatment period takes at least 2 weeks.

Pros and cons of the material

Advantages of quicklime over slaked lime:

- no waste;

- lower level of water absorption;

- possibility of working in winter;

- good level of strength;

- wide scope of application.

The main disadvantage of quicklime is its danger to human health. Therefore, you should act carefully so that particles do not get on the mucous membranes or into the lungs.

You need to work in a room that can be ventilated, and best of all, in an open space.

If it is not possible to ventilate the room, you should wear a respirator or a special bandage. And so as not to have to treat an eye burn, you must wear safety glasses when extinguishing the lime.

Security measures

When working with a duster, take all precautions to avoid burning your eyes and skin.

Before procedures with lime, you must wear protective glasses and gloves. When you extinguish the lime, move away from the extinguishing site so that the caustic fumes do not harm your health.

Dear friends, we tried to find everything you need to know about the use of fluff lime. If you have never used this component, then in the fall, following the rules, add it to the soil. If you have experience with this substance, tell us about it in the comments.

Precautionary measures

Lime belongs to toxicity class II, therefore, during any actions with this substance, it is necessary to take care of personal safety:

- To protect against the penetration of dust and fumes into the lungs, gauze bandages, a respirator or masks should be used.

- To avoid contact of the working solution with the skin, you need to wear gloves, a hat, glasses, closed clothing and shoes. If the liquid gets on the skin or mucous membranes, you need to rinse them well with water.

- Do not perform any manipulations with the chemical indoors; it is optimal to prepare the solution outdoors.

- During extinguishing, due to the violent reaction, keep a safe distance from the container.

- The chemical should be stored in a tightly closed bag in a dry place.

Facts to note

- Treatment should not be carried out more often than once every 4-5 years. On soils with an intensive type of agriculture, it is carried out once every 2-3 years, in accordance with the results of control measurements of pH in the areas.

- The use of lime is most rational on heavy (clay) soils, due to its high acidity and high density. The fact is that lime destroys the clay structure, making the soil looser and lighter.

- To neutralize excess acidity, lime can be fully replaced with ash from tree species. It just requires 3-4 times more ash compared to lime.

- Liming is best done in the fall. This will give time for calcium dissolved by rain to penetrate into the deep layers of fertile soil, it will have time to enter into all the necessary reactions with the formation of soluble and easily digestible minerals by plants, and possible excesses under the influence of winter cold will be neutralized.

- The appearance of mosses on the edges of fields, as well as wormwood and horsetails, indicates that it is time to liming the soil.