It seems impossible, but a 2 by 2 m bathhouse can be no less cozy and convenient to use than huge full-size complexes with a swimming pool and a relaxation room. If you don’t rush into building a sauna box for half of the site, but choose a successful project, then the construction and arrangement of a steam room from rounded logs will be more profitable, cheaper, even in comparison with a foam block or frame structure, and the level of comfort is approximately the same level or even higher.

Typical bath designs

Steam rooms and saunas have been built from logs since time immemorial, several hundred years. This simplifies the situation, since you can use experience and practical methods for arranging wooden bath boxes. The best bathhouse designs, simple and easy-to-manufacture options for bathhouse buildings have long migrated from the popular category to standard designs.

Projects of one-story baths

For a suburban area, cottage and home, the most practical options are most often chosen, those that require low costs and at the same time provide an acceptable level of amenities:

- Typical “trailer” project. The locker room and dressing room are made with a walk-through vestibule connecting the entrance to the room and the steam room;

- Single bathhouse near the house. Such projects are designed for one person;

- Bathhouse with living quarters on the second floor.

It is clear that most projects of small-sized steam rooms are designed for a maximum of two or three in one session. Such a bathhouse is traditionally built from a log next to the house, which has a shower and a place under a canopy for relaxation.

For your information! Experts call projects of small one-story log steam rooms “temporary buildings.” Often the premises of a small log bathhouse are placed on a removable foundation next to a construction site in the country.

You can put up a “temporary structure” on a country plot and use a small steam room - a log house - for an unlimited time, until the construction of a country house is completed, or the owners want to rebuild it according to the design of a 6x6 m bathhouse made of rounded logs.

Over time, the small-sized bathhouse will have to be dismantled and replaced with a more serious object. In practice, after 5-6 years, due to high humidity in the walls of the bathhouse, the logs of the lower crowns of the log house begin to rot.

Two-story house-bath

Choosing a two-story log building can be called the most compromise option, especially if there is not much space on the site for a full-fledged summer house and bathhouse, and there is no point in saving on arranging a steam room or living space. A country house needs comfort.

There are quite a lot of standard projects for a small two-story log bathhouse. All of them are more or less similar to each other in proportions and layout of the premises.

An example would be a project for a bathhouse with a balcony and a composite roof. This is the standard of a bathhouse complex with log walls; the remaining schemes will be variations and modifications of the standard solution.

For your information! All elements and details of the facade of the bathhouse according to the project are made of timber and cut logs. This ensures uniform shrinkage, good durability of the building and the absence of gaps on the front walls of the building.

Similar to the previous version of the bathhouse, a two-story “cube” made of logs with a summer terrace and an enlarged seating area on the second floor.

One of these projects for 6 by 6 log baths is presented below:

The first floor is allocated for the arrangement of a steam room, washing department and rest room. A basement is not built in the bathhouse complex.

According to the project, on the second floor there are living quarters, since the walls and ceilings are made of rounded logs, the building turns out to be much more durable than a timber or frame building.

A two-story bathhouse for this project costs just over 1,000 thousand rubles; for comparison, a one-story building 6x6 m without a residential module will cost a maximum of 970 thousand rubles.

Step by step process

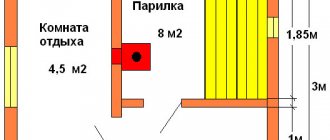

To begin with, you should pay attention to the fact that the structure itself will represent a separate steam room and a small relaxation room, which is often combined with a washroom. This is due to the fact that there is simply not enough space to organize other premises. That is why these types of premises are very often located next to the main building or a summer shower is installed nearby (see also the article “3x4 bathhouse - a small option for a summer residence”).

Plan for placing rooms in a small bathhouse

Base

- Since the structure is small in size, a pile foundation can be used for it.

- Supports are placed around the perimeter of the building and always at the site where the stove is installed.

- Some craftsmen advise making the base from a monolithic slab. It is also quite effective and simplifies the work process.

Another design option for similar buildings

- It is worth noting that a 2x4 bathhouse has dimensions that are characteristic of some types of ready-made concrete slabs. Therefore, if possible, you can use them.

- After completion of the work, it is necessary to waterproof the structure. It is made from mastic based on bitumen or roofing felt. This material is the most effective and has a low cost.

Advice! When creating a foundation, you need to take care in advance about organizing the drainage or drainage of water. The fact is that even in a small room moisture will accumulate, which must be removed so that it does not have prolonged contact with the surface.

Graphic representation of a pile foundation

Walls and roof

- Several methods can be used to make walls in a similar structure.

- The first of them involves the use of timber or rounded logs. They are laid one on one with their own hands, while creating corner connections with the rest. This way the structure will receive maximum strength and additional protection from the cold.

- The installation instructions also recommend using frame systems. For such buildings they are very effective and significantly reduce costs.

Timber structure

- Metal profiles or wooden beams can be used as supports. In this case, the lining is made from a regular metal profile, which is fixed with special fasteners.

- Several types of material are used for insulation. Professional craftsmen first advise fixing mineral wool or polystyrene foam. Then protect it from moisture with a film, and after that, you need to lay a reflective layer.

Frame manufacturing option

- At the final stage, the inside of the structure is sewn up and treated with a protective compound.

- It should be noted that the roof is also created using this principle. At the same time, its design should be single-pitched, since this will significantly reduce the cost of materials and manufacturing.

Correct formation of frame corners and walls

- The angle of inclination for such a roof must be selected in accordance with the selected coating. For metal tiles it will be at least 25 degrees, and when using roofing felt it can be reduced to 5 degrees. The remaining roofing coverings are in the region of 10-15 degrees.

- The roof is insulated according to the principle of walls using waterproofing and a reflective surface.

Advice! Professional craftsmen recommend using polyurethane foam for insulation. The fact is that it not only protects the building well from the effects of cold, but also tolerates even direct contact with water.

Wall cladding with wood and correct location of the stove for maximum space saving

Bake

Experienced bath attendants recommend installing small factory-made stoves in such rooms. Their price is not too high, and their small dimensions and workmanship are perfect for this situation.

Factory product with small dimensions

You can also use homemade devices, which are best made of metal. They are often combined so that it is possible to maintain the temperature due to the stones inside and at the same time it is able to heat the water.

Advice! Quite often, when installing a stove in a small bathhouse, craftsmen violate some fire safety rules to save space. It must be remembered that this is strictly prohibited, since the absence of even a small heat-resistant gasket between the stove and the wood can lead to a fire. In this case, everything should be checked several times.

An option for making your own metal stove for a bathhouse with small dimensions

Bathhouse 2 by 2

A miniature log building must be installed on a brick strip foundation or piles. According to a standard design, the height of the supports should be at least 60 cm.

This is the optimal size for lifting the bath box. In the typical version, the foundation blind area and the basement cladding are not done, so the first crowns of logs are simply raised higher above the ground to avoid soaking the walls of the bathhouse.

Structurally, the room is divided into two compartments. This is a classic bathhouse trailer project.

In the first compartment there is a locker room combined with a dressing room, in the second there is a washing room and a steam room. The surface of log walls must be insulated, covered with a vapor barrier and covered with clapboard.

Log house 3x3

Square proportions for a bath and steam room building are not the most successful of all possible. Even a small increase in size from 2x2 m to 3x3 m does not lead to fundamental changes in the arrangement of the bathhouse, but it gives a little more space.

The bathhouse turns out to be more spacious, there is space for installing a full-fledged stove in the dressing room. Instead of a fire-hazardous potbelly stove for a 3x3 m log bath, a firebox with a tunnel option for loading firewood from the dressing room is used.

For your information! In typical projects of a good level of development, a steam room made of logs is always equipped with an external firebox, and the stove itself should only be of industrial manufacture.

A clear inconvenience in the 2x2 m and 3x3 m projects was the combination of the steam room and washing compartment in one space. It means:

- The steam room is designed for one-time use; a maximum of several people can take a steam bath in one go;

- After heating the steam compartment, here we had to wash in the shower, then remove dirt and condensation from the walls and floor of the logs;

- After completing the procedures, the hot room is opened to ventilate and thoroughly dry all accumulated moisture.

In fact, the 2x2 m and 2x3 m bathhouse projects are sanitized versions of the old “black” steam rooms, in which the walls are made of antiseptic-impregnated logs, and a modern firebox is used instead of a smoking stove. There is little comfort and convenience, but according to the project, the bathhouse was conceived from the very beginning as an individual object.

Frame bathhouse “Luck” (2.5x4)

Dimensions - 2.5 x 4.0 m Internal dimensions - 2.3 x 1.9 Ceiling height - 2.0 m Area - 10 m2 Stove - Rainbow PB-11B or equivalent (firebox from a steam room) Water tank - 45 l . (stainless steel) Furnace heating time to 90-100 C - 45-60 minutes

Participates in the “Wooden painting as a gift” promotion More details here:

| Equipment | Standard 100 | Standard + | Standard | Economy + | Economy |

| Foundation | blocks 200x200x400 mm, | blocks 200x200x400 mm, | blocks 200x200x400 mm, | blocks 200x200x400 mm, | blocks 200x200x400 mm, |

| Base | timber 150x150 mm | timber 150x150 mm | timber 150x100 mm | timber 150x100 mm | timber 100x100 mm |

| Walls | frame made of timber 100x50 mm, - steam-waterproofing, aluminum foil, mineral wool, lining | frame made of timber 50x50 mm, - steam-waterproofing, aluminum foil, mineral wool, lining | frame made of timber 50x50 mm, - steam-waterproofing, aluminum foil, mineral wool, lining | frame made of timber 50x50 mm, - steam-waterproofing, aluminum foil, mineral wool, lining | frame made of timber 50x50 mm, - steam-waterproofing, aluminum foil, mineral wool, lining |

| Insulation | 100 mm Knauf or Rockwool throughout the entire bath | 50mm Knauf or Rockwool steam room only | 50mm Knauf or Rockwool steam room only | 50mm Knauf or Rockwool steam room only | 50mm Knauf or Rockwool steam room only |

| Floor | planed board 50x150 mm | planed board 50x150 mm | planed board 50x150 mm | planed board 50x150 mm | planed board 50x150 mm |

| Ceiling | similar to walls. | similar to walls. | similar to walls. | similar to walls. | similar to walls. |

| Rafters | timber 70x50 mm and 100x50 mm | timber 70x50 mm and 100x50 mm | timber 70x50 mm and 50x50 mm | timber 70x50 mm and 50x50 mm | timber 50x50 mm |

| Roof | metal tiles | galvanized corrugated sheet C10 | galvanized corrugated sheet C10 | galvanized corrugated sheet C10 | galvanized corrugated sheet C10 |

| Bake | Vesuvius | Rainbow | Rainbow | Rainbow | Rainbow |

| Hot water tank | On the pipe. 60 l. | Mounted. 50 l | Mounted. 50 l | Mounted. 50 l | Mounted. 50 l |

| Furnace arrangement | The walls around the stove are covered with heat-resistant Flamma panels. It is lined around the perimeter with red bricks with “vents”. On the floor there are fireproof bricks and fireproof cardboard. | The walls around the stove are covered with heat-resistant Flamma panels. On the floor there are fireproof bricks and fireproof cardboard. | The walls around the stove are covered with heat-resistant Flamma panels. On the floor there are fireproof bricks and fireproof cardboard. | The walls around the stove are covered with heat-resistant Flamma panels. On the floor there are fireproof bricks and fireproof cardboard. | The walls around the stove are covered with heat-resistant Flamma panels. On the floor there are fireproof bricks and fireproof cardboard. |

| Chimney | Double-circuit stainless steel sandwich. Including master flush and header. | Double-circuit stainless steel sandwich. Including master flush and header. | Double-circuit stainless steel sandwich. Including master flush and header. | Double-circuit stainless steel sandwich. Including master flush and header. | Double-circuit stainless steel/galvanized sandwich. Including master flush and header. |

| Chimney Arrangement | Through a factory passage unit with mandatory thermal insulation with basalt wool and basalt cardboard | Through a factory passage unit with mandatory thermal insulation with basalt wool and basalt cardboard | Through a factory passage unit with mandatory thermal insulation with basalt wool and basalt cardboard | Through a factory passage unit with mandatory thermal insulation with basalt wool and basalt cardboard | Through a factory passage unit with mandatory thermal insulation with basalt wool and basalt cardboard |

| Doors | aspen baths1700x700x50 mm | aspen baths1700x700x50 mm | aspen baths1700x700x50 mm | aspen baths1700x700x50 mm | aspen baths1700x700x50 mm |

| Window | 400x300 mm - 2 non-opening glasses. | 400x300 mm - 2 non-opening glasses. | 400x300 mm - 2 non-opening glasses. | 400x300 mm - 2 non-opening glasses. | 400x300 mm - 1 glass, non-opening. |

| Exterior finishing | imitation timber | imitation timber | lining | lining | lining |

| Interior decoration | Steam room - linden or aspen lining. The dressing room is made of pine paneling. | Steam room - linden or aspen lining. The dressing room is made of pine paneling. | Steam room - linden or aspen lining. The dressing room is made of pine paneling. | Aspen on the ceiling in the steam room. The rest is pine paneling | Pine lining. All over the bathhouse. |

| Canopy | 600 mm, aspen | 600 mm, aspen | 600 mm, aspen | 600 mm, aspen | 600 mm, Pine |

| Bench in the dressing room | 300 mm, pine | 300 mm, pine | 300 mm, pine | 300 mm, pine | 300 mm, pine |

| Electrics | Eat. | No | No | No | No |

| Stones for the stove | 60 kg Quartz, bunded | 60 kg Gabarro-Diabase | 60 kg Gabarro-Diabase | 60 kg Gabarro-Diabase | 60 kg Gabarro-Diabase |

| Canopy over the entrance | Eat | Eat | Eat | Eat | No |

| Insurance | Eat | Eat | Eat | Eat | No |

| Price | 230 000 | 170 000 | 160 000 | 145 000 | 137 000 |

Below is a photo report on the bathhouse assembly! We recommend viewing!

Have questions about price?

Call!

We can definitely come to an agreement!

3x4 log sauna project

Starting with a size of 3x4 m, you can add an additional washing room to your bathhouse project. For example, in the previous 3x3 m version, the comfort of using the steam room did not increase much; the room still remained a log house made of rounded logs, divided into two parts.

Now this is a full-fledged log bathhouse, which is easy to maintain hygiene and can accommodate everyone who wants to take a steam bath.

Conclusion

In the video presented in this article you will find additional information on this topic. Also, based on the text presented above, we can conclude that to create small baths you can use various installation methods and different building materials. However, the principle of maximum space saving remains unchanged in such buildings (also find out how a 2 by 3 bathhouse is built).

Did you like the article? Subscribe to our Yandex.Zen channel

Bathhouse project 4 by 8

In addition to bath and steam rooms, the building now includes additional rest rooms, terraces and service areas, for example, a kitchen and dining room. One of the classic designs of a luxury bathhouse is shown in the drawing below.

The layout of the bathhouse building looks unusual due to its elongated proportions, but it is thanks to the non-standard shape that the room wins in comparison with square and two-story boxes:

- According to the project, the building is divided into a recreation area and a bathhouse part. The covered extension can be used as a gazebo and a place to sit by the fireplace. Moreover, the entire complex is made of one material - logs and lining, which gives the impression of a single building;

- The entrance to the room is in the central part, and most of the canopy is protected from the wind by a decorative grille, protecting from wind and rain in inclement and cold weather.

Important! Unlike stone buildings, a heated log sauna will keep those under the canopy warm for a long time after completing the steaming procedures.

Subsequent versions of bath buildings are designed primarily taking into account the increase in the number of people visiting the steam room. If you increase the width of one of the walls to 4 m, the volume of the rooms will significantly expand and the level of comfort in the room will increase.

Bathhouse project made of 6x6 logs

The diagram below shows a typical version of a one-story hut made of rounded logs. Of all the projects for bathhouses made of 6x6 m logs, this one has the lowest construction cost with very good characteristics of the steam room and relaxation room.

According to the project, in a one-story building made of logs, out of a total area of 29 m2, almost 10 square meters are allocated for a shower room - 3.8 m2, a steam room - 5.8 m2. This is more than enough for a good country log bathhouse.

The rest of the territory - 10.3 m2 - is allocated for the rest room, 7.1 square meters for the terrace, 2.1 m2 - auxiliary rooms and a bathroom. Of all the one-story bathhouses assembled from logs, this project is distinguished by the most optimal planning of the premises.

The only drawback of the project is the lack of external wall cladding, which requires annual maintenance of the log crowns, sealing of cracks and removal of moss at the joints.

Bathhouse project 6 by 8

With an increase in usable area, the construction of logs becomes more and more reminiscent of a residential building project.

One of the popular options for a full-size log cottage - a bathhouse - is given below. The one-story building is planned with the so-called central or warm arrangement of living quarters.

The relaxation room is located in the center of the plan, which makes it possible to effectively use the heat dissipated through the partitions from the steam room and washing area.

As much as 15 m2 is allocated for the relaxation room, and 5 and 3.7 m2 for the steam room and sink, respectively. This project is well suited for a country house or winter cottage, for permanent residence even in the autumn-winter period.

For example, in a house made of logs, a universal stove is installed - a fireplace; it can be used both for its intended purpose, for the steam room, and for heating the rest room. Whereas in most other house designs combined with a bathhouse, a conventional tunnel firebox is installed with wood being loaded from the vestibule or hallway. The second feature of the building is the convenient location of the bathroom and shower compartment.

Bathhouse 6 by 9

Projects with log walls longer than 8 m can be safely classified as full-fledged residential buildings. An area of 50-54 m2 is enough to accommodate a bathhouse and several rooms inside.

Regardless of the size of the log house being built, the area of the steam room and washing compartment remains constant, they occupy 5 and 3.9 m2, respectively. All remaining 40-45 square meters of the bathhouse are allocated for recreation and living areas.

For example, in a bathhouse made of logs, according to the project, instead of the usual washing and shower compartment, a swimming pool can be installed, or a winter garden can be installed in the relaxation room. Buildings of this type can be easily distinguished from an ordinary bathhouse by the unusual shape of the roof; part of the roofing is made with a glass insert.

Bathhouse layout

If there are opportunities, a bathhouse complex can include a couple of floors, guest rooms with balconies, and billiard rooms with a swimming pool, and in the absence of these, they manage to enjoy the bathhouse in one room “for everything.” A typical bathhouse layout includes the following rooms:

- steam room;

- washing (soap);

- dressing room

Initially, in Rus' they made do with one room in which they both steamed and washed, but in today’s baths the steam room and washing room are separated. This is due both to the possibility of using various modes in the steam room, as well as to convenience and safety. Modern detergents are far from being so harmless as to risk using them at elevated temperatures.

The dimensions of a typical washing room with shelves and basins are also tied to the number of visitors - from 1.5 m² per person, that is, the washing room is half the size of the steam room. But given that today many people prefer to rinse under a shower head or install shower stalls, this room can be made smaller by adjusting it to the dimensions of the equipment. In this case, 1.8 × 1.8 m will be sufficient. However, possible does not mean necessary.

ZYBYFORUMHOUSE Member

Wet procedures are done in a soap bar. It is optimal to have the same number of beds in the soap room as in the steam room, according to the number of people steaming! Better yet, have a table in the middle where you can do massages and walk around! This is why you need a large soapy bowl, and keeping it warm during the procedures won’t hurt! Anyone who does not take this into account loses a lot! This is the main part of the sauna process, just like steaming! It's a shame that people have lost everything!

Not everyone can afford a full-fledged relaxation room in a bathhouse - for some, finances do not allow them to “go wild”, while for others, due to the size of the site, they only have room for the basic minimum. In these cases, the functions of the rest room are performed by the dressing room, which is also a locker room and vestibule. Naturally, the larger the room, the more comfortable you can stay in it, arranging a place for gatherings over a glass of whatever you like best. If you plan to relax after the bath in the house, and the dressing room has only direct functionality, a width of 1.2 m is enough to make it convenient to undress.