The products of fuel combustion in a stove or fireplace are removed from the room using a chimney. Chimneys have a complex structure. To obtain the necessary draft, you need not only to correctly calculate their height, carry out proper installation of the chimney, but also correctly organize thermal insulation. There is a wide selection of insulation materials for insulating pipes of all types of stoves and fireplaces.

Red fire brick chimney

Why is thermal insulation needed?

The role of the thermal insulation material is that, due to its poor thermal conductivity, the transfer of energy through the layer of material is difficult. Thus, you can not only preserve the heat that the fireplace produces, but also protect the structural elements of the house from high temperatures.

Chimney insulation serves several purposes.

- At the external location of the pipe, intense heat exchange occurs with the cold air of the street space. A huge part of the amount of heat is released into the atmosphere, but could be used to heat the room. If you reduce this share, you will achieve higher efficiency indicators. The solution to this issue will be insulation, which is applied on top of the walls of the chimney.

- Combustion products that are emitted through the chimney contain carbon dioxide and water vapor. The temperature of all this gas exceeds a hundred degrees. Upon contact with the chimney walls, which have cooled from the external environment, condensation forms on the surface of the latter. Acids, which are a combustion product, are mixed into it. The result is a chemically active environment, leading to the destruction of the walls. The appearance of condensation can only be avoided by increasing the temperature of the pipe itself, that is, by providing it with high-quality insulation.

- In places where the chimney pipe passes through the ceiling or roof, contact of materials necessarily occurs. In the case of wooden buildings, this situation is a fire hazard. But an additional function of insulation will be to protect the ceiling surfaces.

Corner placement option

Internal insulation of fireplaces implies the localization of energy inside the firebox for the purpose of its directed transmission. The fireplace should not emit heat in all directions, especially if it is installed near a wall. It should warm those sitting directly in front of the fireplace. Special reflectors for fireplaces are installed inside the firebox and serve as a screen from infrared radiation. As a result, all the heat escapes through the combustion hole into the room.

Reliable thermal insulation for stoves and fireplaces means protecting the walls of the building from the negative effects of temperature. When the fireplace is located close to the wall, a heat-protective layer is installed, since high temperatures can lead to destruction of the brickwork of the wall or fire if the building is wooden.

Classification

Cameras can work on:

But it will not be possible to assemble a gas unit at home, since it is dangerous and prohibited by law. The coal version can only operate with supercharging. But if there is such a forge, then it is easier to place a muffle in it rather than build a special furnace. The electric option will allow you to control the heating temperature and use a compact unit even in an apartment (the power of such devices is about 2.5 - 4 kW, so a regular outlet with grounding and a reliable wire will do).

There are different forms of ovens:

- Horizontal.

- Vertical (potted).

- Tubular.

- Bell bells.

The first option is the easiest to reproduce on your own.

Requirements for thermal insulation materials

At its core, a fireplace is the same stove with an open firebox and chimney, equipped with decorations. These products do not have any other design features, therefore the approach to their installation and equipment is the same. Thermal insulation, accordingly, is carried out separately for the firebox and for the chimney and must meet the following requirements:

- Low thermal conductivity

- Environmental friendliness

- High fire resistance

- Durability

- Maximum permissible heating temperature

The materials must retain the listed properties in full throughout their entire service life.

The main task of thermal insulation of fireplaces and stoves

The most important aspect in the operation of fireplaces and stoves is fire safety. This is exactly the case when the desire to save money or simple negligence together with ignorance can lead to big trouble. The main structural element responsible for safety is high-temperature thermal insulation.

Theoretically, you can do the installation yourself, but since we are talking about human lives, it is better to entrust this work to specialists. There are many companies on the construction services market that are capable of performing such a service efficiently, but the choice of contractor should also be approached with the utmost rigor - the company must have been on the market for a long time and have an excellent reputation. You shouldn’t involve migrant workers and coven workers; there will be no one to ask.

Overview of the thermal insulation materials market

The following will provide comparative characteristics of the materials available for free sale.

Rockwool Firebats

Due to its attractive price and high availability, it is the most popular product in the field of application in question. Composition: 100% stone (gabbro-basalt) wool. Available in two types: uncoated and with aluminum foil on one side. The maximum permissible temperature on the foil side is +500°C, on the cotton side +750°C. Slab size 1000*600*30 mm, density 100 kg/m3.

The thermal conductivity coefficient at +300°C is 0.088 W/m*K. The option without foil is not flammable, with foil the flammability class is G1. When choosing this material, it is very important to calculate the peak temperature of the firebox, since overheating may cause the foil to peel off and an unpleasant odor to spread throughout the room along with microparticles of cotton wool fibers. Insulator slabs are highly flexible and therefore are mounted in a rigid metal frame.

Vermiculite

A natural mineral from the hydromica group, the layered structure of which forms multi-colored threads when heated. Fire retardant materials are produced from it by pressing. In addition to fireboxes, it is used in the aviation and automotive industries, as well as in nuclear energy as a reflector and absorber of gamma radiation. The material is presented in two products on the market:

- VermixFireproof. Country of origin - Russia, thermal conductivity coefficient at +300°C - 0.18 W/m*K, plate size 600*600*30 mm, density 300 kg/m3, permissible temperature +800°C. Among the advantages are ease of processing and installation; a rigid frame is not required. There are also disadvantages - the material is afraid of moisture.

- Skamolex is a vermiculite thermal insulator imported from Denmark. It is a symbiosis of refractory and decorative panels with various design solutions. Thermal conductivity at +200°C is 0.16 W/m*K, plate size 1000*610*25 mm, density 600 kg/m3, peak temperature +1100°C. Advantages: does not require subsequent finishing treatment - according to the “set it and forget it” principle, used for lining fireboxes. The downside is the high cost; depending on the region of the Russian Federation, the price of a slab can be 5 times higher than a slab of the same area Vermix Ogneupor.

Based on calcium silicate

The next series of thermal insulators is calcium silicate - an inorganic substance in the form of a calcium salt and metasilicon acid. The mineral is presented on the market in the following versions:

- Silca 250km. Imported from Germany. Slabs measuring 1000*625*40 are designed for use in stoves, fireplaces and brick chimneys. Density 250 kg/m3, thermal conductivity coefficient 0.09 W/m*K at +200°C, application temperature +1100°C. The structure of the board is not fibrous, it can act as both an insulator and a facing material, and is absolutely harmless to human health. The installation features do not include a metal frame. Suitable for thermal insulation of wooden walls in places where the firebox is installed.

- Promasil 950 ks is another product from Germany with a size of 1000*500*30 mm and a density of 245 kg/m3. Peak load is 900°C, thermal conductivity at +200°C is 0.10 W/m*K, which is insignificantly inferior to the previous insulator at half the cost. It is easy to install without a frame, the manufacturer guarantees environmental safety. The material is relatively new, there are very few practical reviews on its use, and construction specialists are confused by the low price compared to analogues.

- Scamotec 225 - sample from Denmark. Slab size 1000*610*30 mm, thermal conductivity coefficient 0.08 at +200°C, maximum application temperature +1000°C, easy to install without a frame, harmless to health, combines thermal insulation and decorative qualities, it can be coated with any fire-resistant paint. The cost is in the middle price segment.

- Isolrath 1000. Country of origin: Austria. Size 1000*610*30 mm, density 240 kg/m3, thermal conductivity 0.06 W/m*K at +200°C. Operating temperature up to +900°C, a frame for installation is also not needed. The manufacturer guarantees environmental and fire safety against the backdrop of high structural strength. It also belongs to the middle price segment.

Furnace shielding

*

You can also provide protection from heat radiation with a screen around or near the stove. Insulation can be brick or metal.

Brick shielding

Bricks can be used to protect either one of the stove sides or all three - the sides and the back. In the latter case, essentially a brick casing is formed.

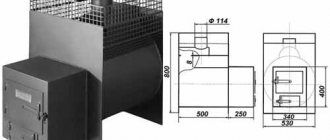

Bricks are placed maintaining a distance between the stove walls. Recommended distance is 5-10 cm. Approximate diagram of the protection device:

- ventilation gap – 5-10 cm;

- brick – 6-12 cm (depending on the format of the masonry);

- ventilation gap – 5-10 cm;

- bake.

Figure 6. Brick screening

Fireclay bricks are usually used as a screen. It is distinguished by optimal thermal characteristics. It is advisable to lay it in half a brick (12 cm), but if you increase the intervals between the walls and the stove, laying it in a quarter of a brick is allowed. Fireclay is placed on clay (or cement-clay) mortar or on a special heat-resistant masonry mixture.

Convection holes are formed at the bottom of the screen. Sometimes they are made in other areas of the shielding wall. To regulate air circulation, holes are made with doors.

Important! The brick must vertically overlap the stove by at least 20-30 cm

Metal shielding

*

This is the most popular option, characterized by availability and fast execution. There is a need for metal if factory furnaces are not initially equipped with thermal protection.

Most often, cast iron or steel sheets play the role of insulation in bathhouses. They are mounted around the hearth, maintaining a distance of 1-5 cm. If there is no thermal insulation of the factory stove in the bathhouse, the fireplace is equipped with either front or side sheets. The type of screen depends on the location and design of the furnace.

Figure 7. Metal furnace screen

Such shielding makes it possible to reduce the temperature of the stove surface to 100 degrees and below. This, in turn, makes it possible to reduce the standard distance between the heat source and the opposite wall by half - to half a meter.

Do not forget! The floor also needs protection. The larger the oven, the stronger the foundation should be. And if the floor is wooden, it is thermally insulated in the same way - using a heat insulator and an outer layer (metal, brick, tile)

What material is used

All building materials that provide insulation and are suitable for use in a fireplace can be divided into separate groups. These include stone fibers and silica, superisol, mineralite, gypsum fiber, supersil and vermiculite.

- Stone fibers are obtained by pressing crumbs of gabbrodolerite and limestone. The resulting fibrous structure is formed into plates. One side of the plate is covered with foil, which is capable of reflecting radiation, because this type of heat propagation accounts for about half of the total energy. Such foil can withstand temperatures of several thousand degrees. This material is quite durable and moisture resistant. Able to provide all possible assistance in maintaining the integrity of the structure in the event of a fire. The most popular fiber brands: PAROC FPS 17, TECHNO T80, Rockwool.

Rockwool brand insulation

- The technology for using silica involves melting alumina and quartz sand. The resulting glassy mass is blown into fiber form. Fiber is already a heat-insulating material, but for ease of use it is produced in the form of slabs or rolls. This substance is flexible, which makes it easy to insulate surfaces that are not perfectly flat.

- Products based on calcium silicate have good thermal insulation properties. Superizol is one of the representatives of this class. Its porous structure not only improves technical performance, but also facilitates easy processing. Super-insulated slabs are used to insulate fireplace casings and chimneys. They are mounted with glue or self-tapping screws. The operating temperature of the material should not exceed 1200 °C degrees.

- Vermiculite slabs represent a pressed grain structure of the substance. This is a fairly rigid structure, thanks to which the surface of the slab is ready for decoration. They have a relatively high density, but are easy to saw and process. Characterized by their durability. Buyers are showing increased interest in the Thermax, GRENAR-ISOL and Scamol brands.

Panels made of fire-resistant material Superizol

Thermal insulation not only improves the efficiency of the fireplace, but also provides fire protection. It is important that the material remains safe for humans when heated. The requirements for building insulating materials are technical performance, environmental friendliness and ease of processing.

- Supersil is a flexible material. It comes in the form of a silica fabric with a foil-like layer. But such production is expensive in terms of cost, which affects the final price of fabric rolls.

- Gypsum fiber sheets are produced by mixing cellulose with gypsum and then pressing them. A distinctive feature of such sheets is that they can be used as a building material. Gypsum fiber does not tolerate deformation, therefore it is used only for insulating the fireplace body, walls and floor.

Sound insulation: basalt slab for sound insulation

Noise is unpleasant acoustic waves, in the path of which you really want to put an obstacle that reflects or absorbs them. This definition does not only say that these waves themselves can propagate in two ways: through the air and through solid material. In the second case, we are talking about blows, say, from a hammer, which are carried along the walls and ceilings of the house.

In accordance with what kind of noise it is desirable to eliminate, strategies for its elimination are developed.

Rock wool Acoustic ultra-thin Rockwool 27 mm. Photo by Leroy Merlin

If it is vibration of a solid material, then vibration-damping materials, such as rubber, are used. If waves propagate through the air , then they are damped by materials with air voids.

Walls

First, determine from . If the window or door is poorly soundproofed, then soundproofing the walls will not help.

If it really is the walls, then usually a rather thin but effective layer of stone wool is used to soundproof them - 50 mm , its density ranges from 30 to 70 kg per cubic meter .

When it comes to frame construction, wool is installed in the partitions, and everything turns out to be quite simple. In the case of more massive walls - made of concrete, brick, wood - sound insulation will be attached according to the same principle as described above for external or internal insulation, but there are also more modern methods that save space and do not require a frame:

Door

entrance and doors . Both need sound insulation, especially when there are cavities inside them. In modern doors, such cavities inside frame-panel structures are filled with bars, bars with gaps, honeycomb material (with voids and stiffeners). In the cheapest option, it can also be cardboard filler.

Basalt slab in the entrance doors - what is it?

Well, to the ears of a person who is far from the construction site, it sounds quite brutal: “a basalt slab in the entrance doors.” What is it really? Just insulation inserted into the door with a dual function - both insulation and sound insulation. The mechanism of operation of both, we believe, is clear.

We have already written that the density of soundproofing slabs is up to 70 kg per cubic meter . The door might not be so tight - there is nowhere to fall, there is paneling on both sides. But it’s good if the mat is independent - it won’t settle.

A steel entrance door can be purchased with different configurations, including without filling . Then the buyer can independently fill the void with the same basalt insulation, and then cover it with plywood and some kind of finishing. Or you can get a door with the required filling and finishing right in the store.

Advantages and disadvantages

suitable for both entrance and interior doors , and can be much better than the same cellular and corrugated cardboard, and even polyurethane foamed inside.

Basalt wool 1000x500x50 mm. Photo Teplokontakt

Let us explain why. Foaming polyurethane will provide a good, continuous fill of voids in the door, but it will also become an obstacle if the owner wants to install multi-point locks, or if he needs to heat the door (for example, for painting with paint powder intended for baking). Regarding cardboard, we believe it is clear that it is not a sound insulator, but otherwise it does not interfere with installing anything in the door and is cheap.

The advantage of basalt wool in doors is that it can be cut, which allows you to bypass stiffeners, install multi-point locks, it is not afraid of heat, it can easily be replaced if necessary, it is a good insulator and a good sound insulator, its price is quite reasonable, the wool itself is durable , unlike polystyrene foam, penoplex and other flammable fillers, it does not burn,

In essence, we found quite a lot of advantages, but somehow we can’t even find the disadvantages of a basalt slab Well, except for one, albeit an important one: stone wool is afraid of moisture, it is very advisable to enclose it in a sealed bag made of a membrane film.

Ecowool or basalt insulation: which is better?

Let's say right away that in this context, when it comes to doors, it is not entirely appropriate to talk about what is better - ecowool or basalt insulation, because ecowool is not used to fill doors. In essence, of course, nothing prevents you from filling the cavities with it too, but it will only serve as insulation, and even manufacturers do not advertise it as a sound insulator.

If the question of comparing these two materials interests you in relation to the insulation of something else, then we recommend that you read the article on our website, which is dedicated to this topic.

Basalt slab or polystyrene foam - which is better for a door

But this comparison is quite appropriate. But as always, the answer will depend on the priorities you choose. Because the advantages in one do not cancel out the disadvantages in the other.

So, the main disadvantage of polystyrene foam is that it is a flammable material, when burned it releases harmful substances.

The main disadvantage of basalt wool is that it loses its thermal insulation properties when wet.

At the same time, basalt wool does not burn, and polystyrene foam is not afraid of water and does not lose any properties from it.

Insulation Penoplex, extruded polystyrene foam. Photo by Leroy Merlin

To answer the question of what is better for your door - a basalt slab or polystyrene foam, it is enough to weigh the fire safety (diffautomatic devices, RCDs in panels, etc.), as well as the likelihood of increased humidity in the room where it will be installed (humidity in the bathhouse). always elevated during procedures, even in the waiting room).

But for those who are guided primarily by the soundproofing characteristics of basalt wool and expanded polystyrene (foam or penoplex), the choice will definitely be in favor of basalt wool, because foam is not designed for sound absorption . Its performance is an order of magnitude lower than the sound insulation of mineral wool when it comes to sounds traveling through the air. It can partially dampen vibration.

However, there are better sound insulators than basalt wool, the only question is that this wool also works as a good heat insulator, that is, “two in one.”

Basalt slab for floor sound insulation

It is not always a task to insulate the floor with stone wool; sometimes it is needed solely to eliminate the transmission of sounds from the room to the outside and back.

The basalt slab for soundproofing the floor differs from the slabs described above for insulation. The material is, of course, the same. The density and differ .

Thermal insulation Rockwool Floor Butts. Photo by Maxidom

For sound insulation, slabs with a density of 50 to 80 kg per cubic meter . Their thickness is minimal - 50 mm and, if you find it, 30 mm is possible.

Such slabs are used as a layer, which will be covered with a concrete screed on top.

Carrying out work

The technology for thermal insulation of a fireplace consists of a step-by-step solution to certain problems.

Setting tasks and solving them

- The required amount of material is calculated. For more efficient use, take into account the cutting and processing ability of the insulation boards or fabric.

- If the fireplace is located at a distance not exceeding 50 cm from the wall, then sheets of insulating fiber are attached to its walls.

- The degree of insulation can be increased using a multilayer structure.

- The chimney is insulated, regardless of what material it is made of.

The characteristics of modern insulating materials will help answer the question, how to properly insulate a fireplace? To insulate walls, it is advisable to use slabs, one side of which is covered with foil. The foil creates a protective screen, and the effectiveness of such protection is quite high. A negative quality is the unaesthetic appearance of slabs made of insulating material.

In wooden buildings, it is recommended to use several layers of insulation. To do this, a lathing is made of metal slats into which gypsum fiber boards are inserted. A wooden sheathing is mounted on top to secure sheets of fire-resistant plasterboard. The outside surface must be finished with tiles or artificial stone.

Several technologies are used to perform chimney thermal insulation. One of them is making a sandwich pipe. A box is made of metal, which has a larger diameter compared to the diameter of the chimney pipe. Mineral wool is laid along the walls of the box. Then a pipe of smaller diameter is inserted inside. When manufacturing the structure, it is necessary to provide for the option of wrapping the pipe in parts.

The brick pipe is insulated with plaster, which is applied in several layers on all sides. After the fourth layer, the outside of the pipe is lined with mineral wool slabs. They are fastened with self-tapping screws with large washers. The outside must be made of brick; it will give an aesthetic appearance to the pipe and protect the material from precipitation.

Recommendations from experts on choosing insulation

There is a large selection of thermal insulating materials. The quality of insulation depends on its thermal conductivity and thickness. The thicker the insulation and the lower its thermal conductivity, the better it will insulate from unwanted heating or cooling. When choosing insulation, you need to pay attention to fire resistance, heat resistance, and the absence of toxic emissions when heated.

Kaolin wool has no competitors in terms of fire resistance. Even open fire doesn't kill her. The only drawback is the high price.

Basalt, mineral, glass wool are excellent thermal insulation materials. They are not flammable. Previously produced brands were not completely safe for humans. The complaints were caused by both the binder - phenol-formaldehyde resins, and crumbling solid fibers, the smallest particles of which could get into the respiratory tract. It is believed that modern production methods have completely solved the safety problems.

Advice! When laying insulation in several layers, it is necessary to lay the heat insulator overlapping, avoiding overlapping joints.

*

The safest materials: thermal insulation and folgoizol based on polyethylene foam. They have low thermal conductivity and are easy to use. Folgoizol reflects thermal radiation better, so it costs a little more. The ease of installation is due to the shape of the product. It is enough to simply put them on the insulated product and secure it firmly with aluminum tape. The disadvantage of the material is low heat resistance. Suitable for use at temperatures up to 170 °C. There is also no resistance to open fire.

How to do it yourself?

- First, the required number of thermal insulation boards is taken, which are cut to the size of the fireplace insert.

- After this, a special heat-resistant glue (mineral, cement-based) is applied, and the application should be carried out pointwise.

- When installing foil material, glue is applied to the non-foil part.

- After this, the slabs are mounted on the walls. Joints and other openings must be sealed with special heat-resistant aluminum tape, which can also be reinforced.

Fireproof wall coverings

To prevent spontaneous combustion of the walls adjacent to the furnaces, it is necessary to install special cladding made of non-combustible materials with thermal insulation properties.

Thermal insulation for furnaces in this case is carried out in two ways:

- For cladding, materials are used that have reflective properties and are resistant to high temperatures.

- The heat-insulating furnace casing is covered with a lining of heat-resistant tiles.

Good reflective qualities are shown by metal sheets covering non-flammable heat-insulating sheets. It is best to use stainless steel, since galvanized steel releases toxic substances when heated.

It is recommended to polish the outer surface of metal sheets, as this helps to better reflect thermal energy.

The following materials are used as thermal insulation:

- basalt cardboard;

- basalt wool;

- minerite;

- asbestos cardboard.

In accordance with SNiP 41-01-2003, installation of the casing is carried out in the following sequence:

- Installation of insulation with a ventilation gap of 2 to 3 cm. The thickness of the insulating material is no more than 2 cm and no less than 1 cm.

- Installation of metal sheet.

- Maintain a distance between the stove and the casing of at least 38 cm.

Ceramic bushings are used to attach materials to the wall: they allow the required gap to be maintained and are resistant to fire. If it is not possible to maintain the specified distance between the stove and the casing, then two layers of thermal insulation sheets should be used. For example, two sheets of mineralite are attached using ceramic bushings. The distance between them is 2-3 cm. The outer sheet is covered with stainless steel.

The design of a room or bathhouse does not always allow the installation of metal cladding. Often it will not fit into the interior of the room. In this case, you can resort to sheathing with heat-resistant tiles, which are attached using a special adhesive that is resistant to high temperatures. We list the suitable materials for cladding:

- terracotta tiles;

- porcelain stoneware;

- tiles;

- clinker tiles;

- Soapstone chlorite

When installing, follow the following rules:

- The ventilation gap between the wall and the fireproof sheet should be 2-3 cm.

- Fire-resistant tiles are attached to the installed sheet using special adhesive mixtures.

- The oven should be located no closer than 15 cm from the surface of the tile.

The following are suitable sheet fire-resistant materials for cladding with cladding:

- minerite;

- fireproof plasterboard containing fiberglass;

- glass-magnesium sheet.

The cladding will help not only to complement the design of the room and maintain a unified style, but also to reduce the permissible distance between the stove and the wall.

Insulation

Let's consider basalt fabric as insulation. What is it? As mentioned above, the minimum thickness of such a canvas should be at least 50 mm . Only in this case can we talk about any significant thermal insulation.

The structure of basalt wool insulation close-up. Photo by Leroy Merlin

Also, the density of building insulation materials varies greatly . The denser the insulation, the greater the load it can withstand. This quality is used to select different densities when insulating floors, walls, facades and roofs.

Floor slab under screed

Let's start the description of insulation with one of the densest - a basalt slab for the floor under the screed. From the name it is clear that it will have to withstand the weight of not only people and objects, but also concrete, which will lay a layer of screed on it.

of 125 or more kilograms per cubic meter are capable of this The upper limit is the highest density that the manufacturer has, but at the same time you need to focus on the construction calculations, which will include this material in the load on the foundation.

TechnoNIKOL stone wool for flooring. Photo by Leroy Merlin

As for the dimensions, the most important of them is thickness, but in order to select the desired thickness, you need to make a thermal calculation. It is either ordered from professionals, or calculated at your own risk and peril using online calculators on the Internet.

Insulation for the walls of the house inside

To begin with, apparently, we will have to clarify one point related to insulation.

It’s one thing when you have frame walls, and they have insulation between two layers of... well, let’s say, plywood. They have their own thermal engineering calculations, and this position of the insulation is quite acceptable in a residential building.

TechnoNIKOL insulation for walls 50 mm. 12 slabs 600x1200 mm. Photo by Leroy Merlin

It’s another matter when you have walls made of brick or concrete, for example, and you are thinking about using the same basalt insulation for the walls of the house inside. But the internal placement of insulation is done in extreme cases, and this must necessarily be preceded by a thermal engineering calculation.

What (in general terms) is this thermal calculation? Knowing the temperature inside the living space (this is important, because it is in the living room that the internal temperature is maintained at approximately the same level regardless of the temperature outside) and the characteristic frosts for a given area, the so-called “ dew point” is calculated.

The dew point depends on what materials and how thick the wall is made of each of them - each material has its own thermal conductivity. This is the condensation point for water vapor present in the air. And it ends up inside the wall material.

If the dew point hits the insulation, then this is very bad, because it means that it will get wet.

So, first the thermal engineering calculation, then the choice of basalt insulation of the required density and thickness.

In general, on sale you will find products from different companies, which are marked on the packaging as suitable for walls. The density of such insulation starts at 75 kg per cubic meter.

Dimensions

Everything here is quite simple: someone once introduced as a conditional standard the size of basalt insulation for walls: 60 cm wide and 120 cm long for one mat.

But in practice, such dimensions are not always observed by manufacturers..

Insulation TechnoNIKOL GreenGuard Universal 50 mm 8 plates 600x1200 mm. Photo by Leroy Merlin

It is known that the sheathing for insulation is made a couple of centimeters narrower than the width of the insulation. This is done so that during installation it shrinks a little, and then is independently held inside the sheathing due to the expansion forces of the material. Therefore, some manufacturers make the width 62 cm at once.

But this does not mean at all that another manufacturer’s basalt wool will not be, say, 59 cm . And this is not the only option. In general, the numbers revolve around 60 cm, plus or minus a few centimeters in both directions. The same goes for length.

Facade insulation

Facade basalt insulation differs in what technology you choose to attach it to the walls . Its density primarily depends on this.

Plate

In principle, when it comes to insulating a facade, the materials used for this are quite dense, which gives the necessary hardness and the ability to hold its shape when mounted vertically.

The density of basalt slabs for facades starts from 80 kg per cubic meter . However, there is one caveat. Still, insulated facades are different: in some cases, a ventilated façade is made on top of the insulation, that is, a decorative finish that is equipped with the possibility of free air flow, in others, plaster is placed directly on top of the insulation.

Facade basalt insulation Rockwool Rockfacade 1000x600x50mm. Photo by Maxidom

So, for ventilated facades, the recommended range of insulation density is 80-125 kg per cubic meter.

Fastening of basalt slabs on the outside of the house is carried out either with mechanical fasteners - the so-called “fungi”, that is, plastic dowels with a wide head, or with a special cement-based glue.

Facade insulation for plaster

But as for the basalt insulation of the facade for plaster , its density starts from 130 kg and up to 160 kg per cubic meter.

This density is needed so that the insulation board can easily bear the load of plaster.

For roofing

In the roof, firstly, the attic floor is insulated, and secondly, the roof. However, it is quite appropriate to call the insulation of the attic floor ceiling insulation. And here we will talk only about the roof.

Basalt roof insulation

Roofs can be flat or pitched. In cases where it is necessary to insulate a flat surface, basalt insulation for the roof is taken in the highest density, because it is usually also placed under the screed. Therefore, you can focus on the density that is taken for the floor, that is, starting from 125 kg per cubic meter.

Insulation Rockwool Standard 50 mm. Photo by Leroy Merlin

If the roof is pitched, that is, having an angle of inclination (on one, two sides, or many angles of inclination), then the basalt insulation for a roof of this type is selected of a completely different nature than for a flat one. It must be light, so its density does not exceed 55 kg per cubic meter. The initial density of basalt wool used for roof insulation starts at 25 kg per cubic meter .

There is also a third option, when the under-roof space is residential, that is, an attic. In this case, insulation is also carried out with rather loose insulation, but its minimum density is already 35 kg per cubic meter.

Installation

Let's briefly talk about how wooden houses and loggias are insulated.

Technology of insulating a wooden house with basalt slabs

There are slight differences in the technology of insulating a wooden house with basalt slabs, depending on which fastening method is chosen and what facade is supposed to be on top of the slabs - plaster or a ventilated facade.

We select the density according to the density figures given above for facades (taking into account the differences between ventilated facades and plaster).

There is one thing in common for attaching basalt insulation to a wooden wall - mechanical fastening using mushroom dowels is preferable to glue, because glue does not bond wood and insulation well.

Preparing wooden walls means removing the previous sheathing (if any), leveling, sealing cracks and removing dust and debris from the surface.

In order to avoid problems with water, the base is waterproofed - in any convenient way (roofing felt, mastic, etc.).

Use the guides to align the first row of slabs evenly. The guides are long bars of small cross-section (5 centimeters is enough).

First, about how to attach mats under plaster. The mats are attached end-to-end around the entire perimeter of the house. When the first bottom row of insulation is laid out and secured with “fungi”, proceed to the second row, but the joints should not be on top of each other, be sure to shift it by half the mat (bandaging).

And if there is a second layer of insulation, then it is made with a shift relative to the joints of the lower one, also by half the mat. These are measures against “cold bridges”.

After fixing the insulation, the surface is covered with a mesh, primed and decorative plaster can be applied.

Ventilated façade is lining, siding, etc. types of external cladding, under which a layer of insulation is hidden. In the case where just such a finish is intended, a sheathing is first fixed to the surface of the wall, into which insulation mats are inserted. It would be nice to protect them with a membrane that will unilaterally release water vapor from the insulation.

TechnoNIKOL insulation for siding 50 mm. 8 slabs 1200x600 mm. Photo by Leroy Merlin

Modern lathing no longer requires the creation of a counter-batten, but this also means that the mats inserted into it must be secured to the wall independently with all those “fungi” (they are also called “dish-shaped dowels”). five dowels per mat - in the corners and in the center.

When choosing a lathing, you should remember that the distance between the insulation and the finishing panel should be about 60 mm.

Why is a membrane needed? Stone wool loses its thermal insulation properties if it is moistened. Therefore, it must be protected from moisture. The good thing about the membrane is that it does not interfere with the evaporation of moisture from inside the cotton wool, but water from the outside does not penetrate into the cotton wool.

Insulation of walls with basalt slabs inside the loggia

In essence, we have already said above that for heated premises, internal insulation is done in exceptional cases, after carrying out the appropriate thermal calculations. If after this the decision to insulate the inside of the walls on the loggia with basalt slabs remains in force, then the sequence of actions should be as follows:

The surface of the wall is waterproofed, is attached to it , insulation mats are inserted into it using a spacer (that is, slightly squeezing the slabs into a space between the sheathing posts that is narrower than their width), everything is covered with film, is made , forming a ventilation gap of 40 mm, and on is attached to the counter-lattice .

Basalt wool. Photo by Leroy Merlin

In principle, nothing prevents you from using metal sheathing as for facades; in this case, the slabs will be end-to-end, but they will have to be secured to the wall with dowels. Then the technology is the same as described above for ventilated facades, only from the inside.

Protective screens for furnaces

The thermal insulation material used for stoves must not only prevent the possibility of fire, but also protect people from too harsh infrared radiation. Protective screens for fireplaces, as well as for sauna stoves, are ideally suited for these purposes. They can be made of metal or using brick or decorative stone.

The peculiarity of fireplace screens is that they are made exclusively of metal and can be built-in or mobile. Such designs prevent sparks and hot coals from entering the room, and also, when heated, contribute to the rapid and uniform heating of the air in the room. You can purchase a protective fence or make it yourself. Let's take a closer look at the features of furnace protective screens.

Brick protective screen

Along with insulation, the furnace is insulated using bricks. There are two options: constructing a protective wall and lining the furnace with bricks. In both cases, the brick is laid using an adhesive mixture or clay. The use of cement mortar is considered as a last resort. When lining the stove with brick, it is necessary to provide a gap of 3 to 10 cm, as well as ventilation holes at the bottom and top to ensure better convection and quick heating of the room.

How does a muffle furnace work? Main parts of the structure

The furnace design is a chamber (muffle) where the temperature is raised from 20 to 1150 °C. The heating element is a nichrome wire twisted into a spiral. Two layers of thermal insulation allow you to retain heat for a long time (the more reliable it is and the less heat loss, the higher the efficiency of the product). A layer of brick accumulates temperature. You can use refractory fireclay bricks, or asbestos (however, its use is increasingly rejected due to the harmful substances it releases when heated). The second layer is made of basalt fiber, or perlite.

All layers of the furnace are placed in a metal casing.

The process of heating the workpiece occurs not due to direct radiation from the spiral, not under the influence of open fire, but by heating the muffle array. An oven effect is created and uniform heating is ensured.

Homemade muffle stove in a metal case

As a housing for a stove, they often use housings from used equipment - an old oven, refrigerator, etc. If nothing suitable is found, they buy sheet metal and weld the housing from it.

The fact that the part is heated evenly, and without direct exposure to the infrared radiation of the spiral, gives:

- Melting of valuable metals without impurities.

- Obtaining an even surface shade for artistic ceramics.

- Possibility of drying conductive materials and much more.

Stainless steel casing

Thermal insulation of the furnace using stainless steel casing has several options. Based on orientation in space, front and side screens . The recommended distance from the oven to the screen is from 1 to 5 cm . Thanks to such structures, it is possible to reduce the intensity of thermal radiation from a metal furnace, since the outer surface of the protective screens warms up to 1000 C. In this case, it is possible to reduce the distance from the furnace to the wall to half a meter. Ease of installation and the presence of special legs that allow you to securely fasten the screens make their use especially attractive.

When is protection needed at all?

The need to install protective casings and screens does not always arise. If a fire-safe distance is maintained between the stove and the nearest flammable surface, additional protection is not needed. At this distance, the IR rays are scattered, weakened, and the amount of them that the wooden wall receives can no longer lead to damage.

It is believed that the safe distance from the wall to the brick stove (quarter-brick laying) is at least 0.32 m, from the wall to the metal stove (not lined) - at least 1 m. For a metal stove lined from the inside with brick or fireclay, the distance decreases to 0.7 m.

Thus, maintaining fire safety distances is more possible in large baths, where the issue of saving space is not relevant. In family steam rooms, where every centimeter of space counts, installing a stove 0.3-1 m from the nearest walls is impractical. In this case, the safety distances established by the standards must be reduced using screens and casings.

This article will tell you how to make a foundation for a stove.

For finishing walls under a boiler

If the walls of the boiler room are wooden, then they need to be pre-treated with fire retardants. The wall behind the boiler must be covered with sheet metal . The remaining area is finished with sheets of plasterboard or glass-magnesium. Then the surface is plastered or covered with ceramic tiles.

Basalt with cladding

Basalt facing slabs look aesthetically pleasing and provide good fire protection. In addition, this material gives off heat for a long time after heating. You can use this material to cover both a brick screen and the wall itself on top of insulating sheets.

Fire safety cannot be treated negligently - the consequences of carelessness can be tragic. The modern building materials market allows you to choose an option according to your means and taste, while providing reliable protection against fire.

Tips from the pros

In order to increase the fire safety of the ceiling that crosses the chimney or chimney, install a decompression chamber by installing a heat-insulating board in a horizontal position.

It is preferable to provide 2 fan grilles in the box : one for the purpose of cooling the decompression chamber, and through the other, warm air will be transmitted throughout the room. Sheets of plasterboard are attached to the iron guides using self-tapping screws: they will be the basis for the decorative finishing of the fireplace.

How to insulate a chimney

Having protected the walls from the hot fireplace insert, proceed to insulating the pipe. For this, one of the following materials is used:

Chimney insulation

- mineral wool is the most popular and sought-after material, which is convenient and inexpensive to work with;

- glass wool - its properties are similar to mineral wool, but it is more difficult to work with;

- brick - the use of whole and chipped specimens is allowed;

- slag slabs - designed for insulation in unstable climatic zones.

If the fireplace and chimney are made of brick, then insulation is carried out quickly and with little financial loss. To do this, the surface is plastered using a reinforcing mesh. At the junction of the pipe and the roof, reinforce it - lay an additional layer of brick. This completes the thermal insulation.

It is much more difficult to work with round pipes made of metal and ceramics. These materials overheat strongly during operation of the fireplace, and accidental touching them will inevitably lead to severe burns. Therefore, be sure to take care of insulating such pipes. This is necessary to reduce heat loss and maintain the integrity of the pipe for a long time.

Thermal insulation is carried out with non-flammable materials of dense structure. Mineral wool is ideal and is used to wrap the pipe as the first layer. The second layer of insulation is reinforced on top - stainless steel sheets. They are wrapped around the chimney and sealed. Instead of stainless steel, plaster can be used.

The above method of thermal insulation increases the efficiency of the chimney, increases the service life of the structure and prevents overheating of nearby surfaces. If all the work is done correctly, then re-installation will be required after about 15 years with intensive use of the fireplace.

Classification by composition

High temperature insulating materials are divided into the following types:

- Packed and filled: zirconium oxide, quartz sand, various mortars, kaolin. Used mainly in industry, labor-intensive to manufacture

- Fiber insulators: fire-resistant wool, felt, felt, are essentially mineral wool and its derivatives. They have the lowest thermal conductivity coefficient, are resistant to thermal shock, but can be susceptible to mechanical damage

- Solid materials: fire-resistant cardboard, fireclay bricks, fire-resistant ceramic slabs. Retains original shape and can bear mechanical loads

In everyday life, the fireboxes of stoves and fireplaces, as well as metal and asbestos-cement chimneys, are insulated mainly with mineral wool. Brick chimneys are insulated with solid materials with cladding, or simply plastered in three layers.

Heat resistant sealants

This type of sealing materials is produced on a silicate basis, which makes them stable at temperatures close to 1300-1500 °C. Some of them can even withstand temperatures of 1600 °C for a certain time.

In this case, they are dark gray or black in color and are called fire-resistant pipe sealants (the word “fire-resistant” is on the outside of the tube or package).

Some important rules when using heat-resistant sealants:

- Work with silicate sealing materials is carried out in the temperature range of +5 - +40 °C.

- The required sealing effect is achieved only in the case of rough and uneven surfaces. For this purpose, if necessary, the areas where the composition is applied are treated with abrasive materials.

- In addition, the surfaces should be degreased with acetone and then allowed to dry for 15-20 minutes.

- When the paste hardens in places where the sealant is applied, very strong and hard seams are obtained, so it is not recommended to use heat-resistant compounds for structures operating in vibration conditions.

- Traces of sealing material can be removed with a wet cloth or rag, but only before the material hardens. After hardening, this will require the use of mechanical force and some simple tools.

Video on the topic

The term “muffle furnace” itself means nothing to most people. No, this is not just another type of heating device that allows you to save on fuel. This is a device designed for firing ceramic products, smelting metals, cupellation, creating single crystals, etc. In medicine they are used to disinfect instruments.

Photo 1 Muffle furnace for firing

Despite its compact size, the household unit will cost 35-48 thousand rubles, which is quite expensive for the production of hand-made and ceramics. Therefore, many are searching for how to make a muffle furnace with their own hands. We suggest arming yourself with a number of tools, remembering your school physics course on thermodynamics and starting manufacturing.