A stove with a tank is the best option for a bathhouse.

Manufacturers offer a variety of models that differ in power, water tank volume and other parameters.

When choosing a suitable device, you should familiarize yourself with the design features and the principle of its operation.

And also consider different types and models.

On smartphones, you can scroll the table right/left ↔

| Place | Name | Price |

| TOP 7 best sauna stoves with a water tank | ||

| 1 | Harvia M3 SL | Find out the price |

| 2 | Harvia 20SL | Find out the price |

| 3 | Harvia Club Combi K15GS | Find out the price |

| 4 | Konvetika 12B | Find out the price |

| 5 | TMF Biryusa 2013 | Find out the price |

| 1 | Harvia Virta Combi HL90S | Find out the price |

| 2 | Harvia 20 ES Pro | Find out the price |

Who needs it?

The answer is obvious: for those who do not have a connection to the hot water supply network, and this, unfortunately, is not uncommon in our country. But in each specific case, hot water can be used for washing or for heating , or for both, therefore, for specific circumstances, stoves with different types .

In addition, in the steam room itself there is also a need for hot water - it is not good to apply cold water to the stones , because they cool sharply and may crack; then the temperature will go down, but until it rises again, that’s time. So, although small, a tank for hot water in a steam room is appropriate even if there are water supply networks.

IMPORTANT! The temperature of water that can be applied to the stones can be from 70 degrees.

Installation requirements

The thickness of the water layer in the heat exchanger should exceed 4 cm, since with a smaller thickness the water will boil.

The walls of the coil must be at least 5 mm, and if coal is used, even thicker. Failure to comply with the thickness can lead to burning of the walls.

Furnace construction process

Under no circumstances should the heat exchanger be mounted close to the firebox wall. Leave at least 2 cm. This space is necessary for thermal expansion of the coil.

Particular attention must be paid to the fire safety of the system. There must certainly be air gaps between the stove and the wooden partitions, since overheating of wooden structures is the first cause of fires

It is best to line it with brick or other fire-resistant materials.

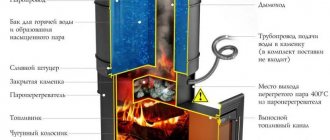

Operating principle

There's nothing complicated here. Water is one of the most heat-intensive substances , so it takes a lot of energy to heat it. We can take this energy either from the stove body or from the chimney.

Brick stove for a bath with a water tank

It is clear that inside the stove there is “working” heat, which is used to heat the steam room, but in the chimney it is already considered a loss , because the gases do not have time to cool down when passing through the pipe, and in this form they escape into the atmosphere.

It follows from this that the idea of purchasing a stove for a bath with a water tank can be useful for increasing the efficiency of the stove - for this you need to take a model with a tank on the chimney.

Installing a gas boiler in a bathhouse with your own hands

Before connecting the equipment, it is necessary to obtain the appropriate permits and approve the project with the authorities. Develop a gas supply project in a specialized service, and then send it and accompanying documents for approval, for example, to Gorgaz. You will need papers from the manufacturer: equipment data sheet, instructions, certificate of conformity.

Work with gas equipment is carried out by specialists in accordance with accepted rules and regulations: SNiP 42-01-2002 and II-35-76, set of rules: SP-41-104-2000. They provide a detailed description of how to properly perform this work, and what is strictly prohibited from doing. For example, the diameter of the chimney is selected in accordance with the power of the device using special formulas.

Wall-mounted gas boilers for heating water

Having received the necessary permits, you can begin work: install a gas pipeline and water supply, line the wall with fire-resistant material, make a hole for the chimney.

- Flush the device's pipe systems.

- Attach wall-mounted equipment to the slats.

- Make holes in the wall, secure the planks with anchors or self-tapping screws.

- Secure the boiler to the mounting strips.

- Attach taps and filters to the pipes;

- Connect the taps at the inlet and outlet;

- Install squeegees;

- Connect the heating system;

- Connect the squeegee to the heating;

- Connect the water supply;

- Connect the chimney.

A separate room is allocated for floor equipment. The walls and floor are covered with special fireproof materials. The unit is screwed to the floor. The rest of the connection diagram is identical to the wall-mounted version.

Kinds

Depending on the location of the tank relative to the furnace, they are divided into the following subtypes:

With mounting tank

Wood-burning stove Zhara-Malyutka 700PU. Dobrostal Photos

The most ancient method of heating: the oven was made in such a way that on its upper surface or even a special recess was made for a container of water.

The water warmed up well, located in a container directly above the firebox . And the heater was next door to it.

Today you have at your disposal many models of stoves that allow, if necessary, to install an upper tank, which, by the way, can most often be purchased from the manufacturer at the same time as the stove.

An example is the Zhara-Malyutka 700PU oven . It is equipped with a 50-liter water tank (there is a 30-liter option).

With mounted or attached

Sauna stove with water tank - a hinged type of tank

The location in this case is the same, but the fastening may be different . Such a tank receives heat from the side wall of the furnace. At the same time, manufacturers let the owner decide on which side of the stove the water tank will be located - this is essential for baths with a small steam room space.

The side tank can either be hung on special hooks , or simply placed on a pad - heat transfer will take place in any case, but not very much.

An example is Ermak stoves, which can be equipped with mounted tanks.

With built-in

It is difficult to classify such tanks as a separate type, because in practice it is still the same container located on the side, only without the possibility of removing it. Some manufacturers continue to make similar designs. As an example, let's take the Siberia stove , which is made by NMK.

Sauna stove with water tank Kastor - built-in tank

With external

Regardless of which room the hot water tank will be placed in, the design will be the same. If all previous tanks were in one way or another in direct contact with the furnace, then this type is located at a considerable distance, so heating is carried out using a heat exchanger.

You can read about the types of heat exchangers on our website in the article dedicated to them.

Most often, remote tanks are used to not only supply the washroom with hot water, but also to heat the room in which the tank is located. By the way, there are several options:

- some prefer to take the tank to the washing room ;

- others place it in the dressing room ;

- still others are left in the steam room ;

- the fourth are taken to the attic.

If the first three differ little from each other, then the last option has functional significance. You probably know that for gravitational pressure you need to raise the water tank as high as possible . If you just hang the tank on the wall, you are unlikely to be able to wash yourself in the shower. But if you lift the tank into the attic , then washing in the shower, which is usual for a city dweller, becomes quite possible.

ADVICE! The heat loss from an uninsulated tank in the attic will be too great. Therefore, such a tank is usually lined with one or another heat insulator, maybe even with foil.

There are many examples of remote tanks. Almost every manufacturer has them .

Wood-burning sauna stoves with a tank are a remote type of tank.

With a tank on the chimney

Sauna stove with a tank on the chimney.

We have already mentioned the advantages of such tanks above. Now it's time to clarify their design. The fact is that you always have a choice: attach to the chimney a full-fledged tank of tens of liters or a small one of 5-10 liters, which will serve as a heat exchanger , that is, transfer heat further to a large tank.

Both options increase the efficiency of the furnace, but there will still be some heat loss when transferred to a remote reservoir.

Making a potbelly stove

Initially, it is necessary to draw up a drawing diagram indicating all the dimensions of the parts and prepare the necessary tools for performing metal work (welding, grinder, pliers) and materials.

After cutting the metal, the following actions are performed:

The main elements are welded at right angles: the bottom and walls. Except for the front.

It is important to know! It is recommended to install the bottom of the heating structure at a distance of at least 30 cm from the floor level. Installed metal legs will help reduce the strong temperature effect on the floor covering

The furnace space is subject to zoning, namely, a grate or a sheet of metal is welded between the firebox and the ash pit, in which backlashes are drilled to remove ash.

- It is necessary to make an opening on the front wall to mount the doors. Now the front part can be welded to the remaining elements.

- Hinged hinges are added to the sides, after which the doors can be installed according to the location diagram.

A chimney pipe must be welded at the top of the stove structure. After completion of the work, all seams are cleaned and checked for defects. The next stage is the installation of the water jacket.

Pros and cons of different designs

Depending on the circumstances, individual advantages may outweigh the disadvantages. It is clear that if the tank is located on the stove or attached to the side , then three unpleasant things follow from this:

- Constant heating of water will lead to the formation of steam , but it will not be that steam heated over 100 degrees, which is called light - it is obtained only from overheated stones. And the usual heavy steam will pour out of the container, which makes it difficult to stay in the steam room.

- Using heated water for washing is problematic if the steam room is not combined with a steam room. You will have to carry hot water to the washroom and wash the way your ancestors washed).

- In tanks built on the side of the stove, heating occurs the worst, because the walls of the stove do not heat up as much as the top or chimney . Plus, over time, the wall of the tank itself will lose thermal conductivity due to scale, and the wall of the furnace will lose its thermal conductivity due to scale. Therefore, the water does not warm up well, remains cold at the bottom, and must be stirred manually.

such structures also have advantages they are easy to fill with water precisely because the container is not located high. But this is if there is no cold water supply either. Otherwise, the plus is leveled out.

By the way! The larger the contact area between the container with water and the oven, the faster the heating. But this is not always worth striving for - why do you need clouds of heavy steam in an unheated bathhouse?

Of course, you still have the opportunity to set up a shower from any tank. And, although stove makers do not recommend using a pump, the forced circulation of liquid in the system will calmly take water from either the manual or the attached tank. The main thing is not to forget to add more.

A pump is not needed only if gravitational and convection circulation between the heat exchanger and the remote tank is properly organized . (We recommend reading the article where the diagram is given.) But even here, if the remote reservoir is not located too high, you can only wash yourself with a hose. If you take it up into the attic, you may break the rule that says that the length of the connections should not exceed three meters . That is, everything is based on nuances and specific circumstances.

ourselves consider the optimal system to be one in which the tank is mounted on the chimney. Whether it will be a large tank or a heat exchanger depends on how you are more accustomed or comfortable to wash. Well, or whether there is a pump in the system or not.

Photo: samovar-type heat exchanger

However, the optimal system also has its drawbacks. In particular, traders admit that the connection between the tank and the pipe at the inlet below can suffer greatly from overheating, for example, in a situation where water is poured after the stove has been lit. Then the seam splits and needs to be welded. Another drawback is that the pipe burns out when the furnace heats up too much.

Pay attention to the dimensions of the filler hole . For some tanks it is large, it even has a hinged lid, while for others it is small and round. Still, you will have to fill tens of liters, and also wash the inside of the tank !

On a note! The stove should not be heated to the limit of its capabilities. This shortens the service life of the metal , which inevitably oxidizes and turns into scale, and then it crumbles and holes remain. The bottom piece of the chimney will also burn out if you heat it like this. If you don't want this, insert a piece of black structural steel pipe of the required diameter inside. It will take away some of the heat and add strength to the structure.

Useful video

This video explains in more detail about strengthening the chimney with pipe cutting:

You can learn more about the disadvantages of a hinged and chimney-mounted tank from the following videos:

https://youtu.be/S5TRvRjgmLs

Choosing boilers for the bathhouse

To maintain a stable, optimal hot water temperature, it is recommended to install equipment with cast iron heat exchangers. They heat up slowly, but maintain the desired temperature for a long time.

The following facts speak in favor of installing gas heating equipment in a bathhouse:

- Savings in fuel consumption and payment when compared with electric or solid fuel equipment.

- Environmentally friendly: no burning, no smell, no harmful emissions.

- Easy to install, configure, operate, repair.

- Electricity consumption is only 40 kW.

- Compactness.

- Simultaneous heating of the room and water.

Design and equipment of a specialized gas stove for a bath

Taking into account all these factors, we can conclude that installing a gas device is an economical and environmentally friendly solution. It is chosen taking into account the parameters of the bath and the functions it performs. A gas boiler for a bath is selected according to the following characteristics: thermal power, availability of automation, control equipment. When selecting equipment, you need to pay attention to its rated performance.

You will find detailed information about choosing a gas boiler for heating your home in our material.

Wall-mounted gas boilers for heating water

For a wooden bathhouse, you should not purchase wall-mounted equipment, only floor-mounted equipment. Since in this case the high temperature of combustion products is unacceptable. According to fire safety rules, gas boilers can be installed in a bathhouse whose room height is at least three meters. And the width of door and window openings is at least 80 cm.

If the boiler is installed individually for a bathhouse, then it is recommended to pay attention to the equipment of the latest models, which can operate on two energy sources. You can choose whether to use gas or wood. Vivid examples of such devices are: Teplodar, Uralochka, Sinara, Termofor.

Universal gas boilers for Termofor baths

Since modern equipment makes it possible to use any energy source, the choice of device depends less and less on their availability. Therefore, when buying a boiler, you should pay more attention to:

- total area of the steam room;

- quality and thickness of the furnace metal;

- heating speed and temperature;

- water tank volume;

- sizes and dimensions: pipes, stoves, tanks.

How to choose the optimal design

In essence, we have already answered this question in the previous chapter, but the answer referred to the specifics of a particular bath.

Let's look at the defining points again:

How to calculate the required volume of container? Assume that one washable item requires at least 10 liters of water.

How are adjacent rooms supposed to be heated? If there are no other options, you can use a remote tank for this purpose. It goes without saying that in this case it should not be thermally insulated. Another option is to use a furnace to heat the antifreeze in a separate heating system.

Are you ready to create forced circulation? If yes, then there are no obstacles to choosing any of the described designs. In this case, you will receive not only a shower, but also, if desired, heating through radiators. True, you will have to organize the system according to all the rules.

For example, do not forget about the need to install an expansion tank , which absorbs excess fluid in the system.

Heating system diagrams for the stove

Heating system diagrams for a furnace with a water circuit are divided into 3 types:

- Open;

- Closed;

- Combined.

An open system implements natural circulation of coolant in its operation - due to the difference in the densities of cold and hot water. It is constructed according to the classical principle - an accelerating vertical riser with a height of at least 2.5 meters rises from the furnace. An open type expansion tank is installed at the top point of the riser.

Scheme of an open heating system for a furnace with a water circuit

Next, the pipeline with a slope of at least 2 mm per 1 meter is directed to heating devices - radiators. Radiator piping is usually carried out using a single-pipe scheme, less often – using a two-pipe scheme. In this case, the diameter of the pipelines must be at least 32 mm, the diameter of the vertical accelerating manifold - from 50 mm. The recommended piping material is steel, and in the furnace piping area - only steel or copper.

A closed system involves the installation of mandatory elements - a circulation pump, a membrane expansion tank and a safety group. The safety group consists of a safety relief valve, a thermomanometer (or a simple pressure gauge), and an air vent.

Diagram of a closed furnace heating system with a water circuit

In addition, in a closed heating system it becomes possible to install a heat accumulator. This device qualitatively increases the overall efficiency of the system, equalizes the thermal regime, and accumulates heat during cyclic operation of the furnace.

In a closed system, it is also recommended that the furnace piping be made of steel or copper pipelines. Radiator piping is often made of polymers - stabilized polypropylene, metal-plastic. The diameter of the pipes is smaller than in a system with gravity circulation and is 20–25 mm. The radiators are connected using a single-pipe or two-pipe scheme.

Diagram of a combined furnace heating system with a water circuit

Such a system can operate both in the presence of electricity (closed circuit) and in its absence (open circuit). You can read more about this scheme here.

In all cases, heating systems are equipped with taps for draining the coolant, this is especially true for houses with intermittent occupancy. At sub-zero temperatures, it is recommended to drain the water. Another option is to use non-freezing liquids - antifreeze - as a coolant.

How to install a wood stove with a tank

If the stove is not homemade, then the details of its installation are described in the passport . Just in case, let us remind you that there is a significant difference between preparing to install a metal stove and laying brick.

Stove for a water bath: heat exchanger on a pipe

In the first case, a relatively light foundation is made, without a separate foundation , which is designed to ensure both stability and fire safety. These are 1-3 rows of bricks that are laid below the finished floor level.

refractory sheet is placed on top of the base , followed by an iron sheet that protrudes significantly in front of the firebox to avoid fire from flying sparks.

If the firebox is remote , then the duct is routed through the wall and must be thermally insulated. a gap is left between the channel and the wall , where a heat insulator is inserted (not any, but only one that can withstand very high temperatures). The wall itself is made of non-combustible material, for example, brick. Read more about remote fireboxes here; you may also need material about portals and fireplace stoves.

After installing the stove (see here and here), the chimney is installed. This is a separate topic. We are only interested in the case when the tank is located on the chimney. There is already a chimney pipe inside it , so it is simply placed on the outlet section of the pipe from the stove , and a regular chimney is mounted on top.

In other cases, the tank is either placed/hung on board, or pipes/hoses are attached heat exchanger a remote tank fixed in the washing room or dressing room.

Installing the tank should not cause much difficulty, especially when it is not a remote model. The hinged one, as the name suggests, is simply hung with hooks on the side of the stove , the mounted one is placed on top . The chimney tanks are simply placed on the outlet piece of pipe from the stove. For greater reliability, it is worthwhile to provide a stronger mount if you do not want to drop a tank weighing half a centner, or even more.

The remote tank may have loops for wall mounting : watch the short video where they are shown.

Making a steel stove-stove

The construction of a homemade sauna stove with a built-in heater and water tank is shown in the drawing. The design is quite simple - the body of the heat generator, made of an iron pipe, is divided into 4 compartments - an ash chamber, a firebox, a heater and a water heating tank. At the bottom of the firebox there are grates, between the remaining sections there are metal partitions crossed by a chimney.

The following materials will be used to manufacture the heater:

- pipe with a diameter of 400-500 mm;

- sheet metal 3 and 5 mm thick for partitions;

- fittings or corners for the grate;

- pipe Ø10-15 cm for the chimney.

Advice. For the body, it is advisable to find a thin-walled pipe (3-5 mm), since standard rolled metal with a wall thickness of 8-10 mm will be too heavy. The height of the stove can be adjusted due to the size of the heater, tank and firebox.

The procedure for assembling a heat generator with an integrated tank:

- Align the ends of the pipe with a grinder, cut openings for loading hatches and doors. Treat sharp edges.

- Place the cut pieces of metal on the doors - clean the edges, weld the handles and hinges.

- Make round partitions with holes for the flue. Make the firebox vault from 5 mm thick steel, the remaining covers from 3 mm sheets.

- Weld the grates from reinforcement Ø12-18 mm or angles No. 4-4.5.

- Mount all workpieces according to the drawing. Clean the welding seams and check for permeability using kerosene.

Equip the tank located on top with a convenient lid, cut a fitting into the bottom of the container and install a drain valve. It is better to reinforce the junction of the chimney and the firebox roof with stiffening ribs made of metal triangles, since this place burns out first. How to properly make such a stove, see the latest video:

Safe Operation

We have already mentioned the danger of the tank installed on the chimney overturning if it is not secured additionally.

It is equally important to observe the following rules for operating a water heating system:

IMPORTANT! Check the presence of water in the system before starting to light the stove. At least in this case, you can count on longer operation of the equipment.

In winter, the rule about draining water in the system becomes especially relevant:

DANGER! Drain the water before leaving to prevent it from freezing and bursting the pipes.

Well, don’t neglect the following advice:

ADVICE! Joints and connections are the most unreliable places in any structure, so they require good insulation and constant attention in the future.

Fight heavy steam by filling the tank half-full so that you can then add cold water to eliminate the steam.

Positive and negative qualities of metal sauna stoves

There cannot be a steam room without a stove, because it is it that heats the room and maintains the desired temperature. Nowadays you can find a wide range of different options. But it’s best to make the oven yourself.

The advantages of a metal device include:

- actions are carried out quickly, and at the same time not very expensive, this can be done autonomously with basic knowledge and experience;

- a significant part of the models are compact, so they are suitable for small saunas;

- rapid heating of the steam room to the required temperature, even in winter;

- the mechanism can last a long time, it all depends on the welding condition and the thickness of the metal;

- economical fuel consumption;

- easy to use, even a person who does not have the proper skills can handle it.

An iron stove has negative qualities, these are:

- low heat capacity, it is not enough to heat the rest room;

- excessively rapid cooling, so you need to heat it regularly;

- the walls heat up and nearby objects can catch fire.

It is not easy to determine which stove is best for a bath; there are a lot of design qualities.

How to install brick ovens with a water tank

Brick sauna stoves with a water tank can have different designs. The general thing is that the tank is located either above the firebox or on the side of it, next to the heater. a protrusion of appropriate size is made under the tank, which has a rectangular shape .

For independent work on the construction of a brick kiln, you need experience . The “recipe” may seem simple, but this simplicity is deceptive. Read more about brick kilns here.

It all starts with choosing a design , and there are quite a few of them. When the choice is made and the orders are found (for example, on the Internet), the number of bricks and the weight of the stove with all its components are calculated - the depth of the foundation depends on this parameter. If the weight of the finished stove is more than 700 kg (and it will definitely be more and do not forget to include a tank filled to the top with water), then a foundation is automatically required . Read about how foundations for furnaces are made on our website.

Having prepared the base, you can begin laying. But first you need to prepare the right solution .

IMPORTANT! Cement mortar is not used for laying stoves. Only clay and sand. There is also masonry without mortar.

First you need to soak the clay. To do this, take equal amounts of water and clay and mix them. After a couple of days, wipe the solution through a fine grid (3x3 mm is good). Then take the sand , sift it and add it to the mixture so that you get something like thick sour cream. The masonry mortar should be neither too fat nor too thin.

Alternatively, you can buy a ready-made clay-sand mixture in bags at a hardware store; just dilute it with water and you can lay the stove (follow the instructions on the bag).

The masonry itself follows the order of the chosen furnace design . You will need two types of bricks: regular solid and fireclay . To help those who decide to do it themselves, we have selected a video where the essential nuances are explained (the voice is boring, but you can be patient):

We also recommend useful materials about stoves:

- Installation in a steam room and a protective screen;

- Inexpensive;

- Which is better;

- With a steam generator.

***

Well, the topic is covered sufficiently fully so that you can decide on the choice of the right type of tank, its volume and location. Good luck with the installation!

Bottom line

To provide heating for a home, several options are usually considered. Popular gas or electric equipment runs on expensive energy resources. The most economical type is heating and cooking furnaces with a water circuit. They are easy to build yourself, which results in noticeable financial savings. This type of heating involves a combination of traditional brick construction and modern technology. As a result, the home receives the necessary warmth and comfort. In addition to brick ones, they often make metal stoves with a water circuit with their own hands. By ensuring proper maintenance of your heating system, you can guarantee a suitable microclimate in your home for many years.