For any admirer of good steam, the use of a stainless steel tank for a bath is considered an unrecognized standard, an indicator of a high-class heater and steam room in general. In addition, this concerns the appearance of the container and the safety of using the stove. The only worthy competitor to stainless steel water tanks are copper and brass soldered structures. They are rarely found on sale, at exorbitant prices, so most owners make do with alloy steel containers.

Rating of the best water tanks

There are several models of quality tanks available.

No. 5. Horizontal

The container is made of AISI 439 stainless steel. Its purpose is to store hot and cold water in baths and housing. At the top of the tank there is a filler hole, at the bottom and on the sides there are G3/4 pipes for supplying and draining liquid. The tank is hung on the wall using the mount included in the kit.

Horizontal

pros

- tightness;

- resistance to chemical and temperature influences;

- low deformation coefficient.

Minuses

There are no downsides to this model.

No. 4. Volcano

The rectangular tank is installed vertically. It is made of AISI 439 steel. Its purpose is to use it in conjunction with a heat exchanger, from which hot water flows into the container through natural circulation.

Volcano

pros

- good workmanship;

- budget cost.

Minuses

No. 3. MetalStroy

The tank is suitable for storing drinking water, organizing an autonomous hot water supply or installing a summer shower. The tank is made of AISI-430 steel with a thickness of 1 mm.

MetalStroy

pros

- high strength;

- hygiene;

- thick steel;

- light weight.

Minuses

The absence of nickel in steel makes it less resistant to corrosion, which shortens the service life of the product.

No. 2. Ferrum

A triangular-shaped container is mounted on the chimney. For connection it is equipped with elbows DU-115. Laser welding technology is used in manufacturing, which ensures the reliability of the seam.

Ferrum

pros

- excellent build quality;

- attractive design.

Minuses

high price.

No. 1. Teplodar Parus

The water in the tank built into the chimney (DN 115) heats up to 70...75 degrees. You can fill it through the hatch in the upper part. Steel thickness – 0.8 mm.

Teplodar Parus

pros

- long service life;

- high-quality performance.

Minuses

quite high price.

Table. Comparison of water tank models.

| Tank brand | Volume, l | Dimensions, cm | price, rub. |

| Horizontal | 60 | 48 x 30.5 x 48 | 2880 |

| Volcano | 60 | 33 x 50 x 50 | 3050 |

| Ferrus | 55 | 40 x 78 x 41 | 5120 |

| Teplodar Parus | 60 | 39 x 95 x 23 | 6500 |

| MetalStroy | 60 | 44 x 31 x 44 | 3400 |

Types of tanks

Water tanks of different configurations are installed. The method of heating water may also differ. When choosing a container, you should take into account all the nuances.

The purpose of the hot water tank in the bathhouse

Capacity

The volume of the installed tank depends on the number of people who can simultaneously be in the bathhouse and use hot water. On average, 10...20 liters of boiling water should be provided for each person (with a small reserve). Today, tanks with a volume of 50...100 liters are produced. As a rule, it is not advisable to install a tank with a capacity exceeding 100 liters.

The shape of the container can be any

Material

When choosing a container, you need to consider that it must be able to withstand high temperatures (up to 250 degrees) for a long time.

Metal tank for water in the bath

You should not try to save money and install tanks made of ferrous metals. This approach cannot be justified not from an aesthetic point of view, but mainly from practical reasons. Due to constant exposure to high temperatures, the metal will deform over time and traces of corrosion will appear on it. This significantly reduces the service life of the tanks and the quality of the water in them.

The most common tank option is stainless steel construction. The demand for such tanks is explained by their attractive appearance, durability, resistance to various types of external influences, high heating rate, ability to retain heat for a long time, relatively low weight, hygiene, high durability and ease of maintenance. The tank configuration may vary. But high-quality stainless steel costs a lot. And you need to take into account that today there are many counterfeit products on offer, which will soon rust.

Not so often, but there are tanks made of cast iron. They are not afraid of rust. However, it must be borne in mind that, despite the fact that the water in such structures will not cool quickly, it takes more time to heat it up. Due to the bulkiness of the tanks, you need to carefully consider their location. Today, not many companies produce cast iron tanks, and they are not very cheap.

Enameled containers can be used, but they are not the best option. Of course, such material does not corrode and is very hygienic.

But low resistance to mechanical damage over time will inevitably lead to the fact that the metal with a fairly thin coating will become chipped (as a result of not very careful handling) and these areas will rust. It will no longer be possible to fix the problem.

Location and design

Three methods are used to place the tank: traditional (directly near the firebox), on the chimney, and remotely. What is the difference?

Bath stove with tank

Tank built into the oven

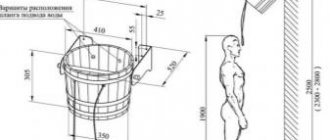

The reservoir can be located on the side or above the firebox. The water in it heats up quite quickly (exposed to open fire). To drain it, a ball valve is installed. Of course, this design does not involve pipeline laying work, which saves labor and material resources. However, using such a container is not very convenient; usually a tank of not very large capacity is installed, and its installation takes up useful space in the steam room, which usually is not very much. The best solution in small-sized baths is the top location of the tank. Since the metal will be in direct contact with the fire, the thickness of the tank walls must be at least 8 mm.

Water tank next to metal firebox

Reservoir on a pipe

If the ceiling height allows, you can install the tank on the chimney. Water is heated by hot gases passing through it. To simplify the installation process, it is possible to purchase a container with built-in chimney elbows. This tank can be fixed without much effort. By laying a pipeline from the tank, you can carry water to any point in the bathhouse, for which a pipe is connected to the bottom of the tank, ensuring the flow of liquid, for example, into the shower. Filling a tank installed in this way is not very easy due to the high location of the filler hole. It is best to use a hose lowered into a container for these purposes.

Reservoir on a pipe

Remote design

Thanks to the installation of a heat exchanger on the heater (on the chimney or directly on the stove) and natural convection, it is possible to place the tank in the washing compartment.

Water tank over brick firebox

The heat exchanger can be integrated into the oven (removable or non-removable), but you can easily install it yourself. It is a coil or container with a volume of several liters with pipes to create a circuit.

general information

Today there is a large assortment of sauna stoves with a water tank on the market. Models differ from each other in power level and design features. Some common features include the presence of a container for heating liquid and the possibility of firing with solid fuel, for example, wood, coal or peat.

Such equipment can be purchased in a store or assembled yourself, based on drawings and videos with master classes. Before you start making a heating device with your own hands, you need to familiarize yourself with the existing options for stoves, as well as study all the stages of construction.

In this video you will learn how a sauna stove with a water tank works:

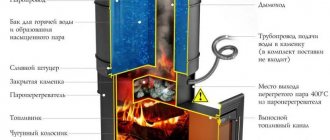

Design features

The main purpose of such devices is to heat the room for a specific period of time.

In order for the stove to have maximum heat transfer, it should be equipped with the following attributes:

- Heater - designed to maintain a stable temperature, which occurs due to large stones that absorb heat from burning fuel.

- The firebox is a place for storing firewood, and heat energy is released in it. Often a grate is placed in it so that the ash can fall down.

- Heat exchanger - helps heat the liquid during combustion.

- Ash pan is the area under the grate where combustion products collect.

- A water tank is a container into which moisture is poured.

See also: how to make a heat exchanger for a stove with your own hands.

The instructions in the picture will help you understand the drawing faster.

Most heating devices of this type operate on the following principle: solid fuel is placed in the firebox and set on fire, then the installation gradually heats up, its walls transfer heat to the air in the room, and the heat exchanger transfers heat to the water. The temperature in the steam room rises quite quickly, but it is worth noting that it does not last long. Therefore, you will have to periodically add firewood to the firebox.

Long-burning devices have an advantage over traditional stoves. They are distinguished by their ability to provide long-term heat transfer and do not require frequent addition of fuel. Such devices are perfect for heating private houses, because you will have to add firewood to the stove no more than once every 15-20 hours. These installations operate on a different principle, the peculiarity of which is the reverse direction of combustion (from top to bottom).

Step-by-step instructions for laying a brick stove:

Construction requirements

For assembly, it is better to choose a stove option that is easy to install and use, as well as economical, compact and attractive in appearance. It is recommended to use wood chips, dry branches and wood as solid fuel, which can usually be found in abundance in summer cottages.

Also, during manufacturing, it is necessary to take into account all the mandatory requirements that all sauna stoves must meet:

- high-strength coating and thick body walls;

- built-in heat exchange control mechanism;

- heat and steam generator, which will allow you to regulate the power of the system.

The stove must have a concrete base

. If these requirements are met, it will be possible to assemble a device capable of providing the room with the required level of heating.

It is also important not to forget about fire safety requirements:

- the furnace must have a solid foundation made of concrete or brick;

- the door wall is made of non-flammable metal;

- the device must have an even surface;

- the sides of the structure are located at a distance of at least half a meter from walls and flammable objects;

- the floor covering around the installation is fireproof;

- the gap between the door and the opposite wall is at least 50 cm.

It is worth noting that experienced bath attendants recommend using coal and peat briquettes for kindling. Firewood made from alder and birch wood is perfect, but only dry - this will speed up the process of heating the air in the room. It is better to avoid coniferous logs; during the combustion process they emit too much soot and soot, and this contributes to the rapid contamination of the insides of the stove and chimney.

DIY making

If you can’t buy a tank in a store, you can assemble it yourself. To do this, you need to prepare consumables and tools:

- grinder with discs;

- file, hammer, pliers;

- welding machine;

- shut-off valve with the ability to adjust the flow;

- stainless steel sheets;

- metal pipes.

Build process:

- Mark the main parts of the container body on the metal sheets. It's better to make it rectangular.

- Cut out parts of the body using a grinder.

- Connect the main parts and weld them.

- Cut a hole in the top through which fresh water will be poured.

- Make a hole in the bottom and secure the drain tap.

All that remains is to make hanging hooks on one of the walls of the stove, and labels for hanging on the tank itself.

Rules for soldering stainless steel at home

For soldering stainless steel at home, soldering or phosphoric acid and tin-based solders are used. The power of the soldering iron should not be less than 100W.

The work is carried out in several successive stages:

- Clean the edges of the workpieces using sandpaper or a fine-notched file.

- The edges are maintained: the surfaces to be joined are treated with flux and heated solder is applied with a soldering iron. If the tin does not stick, the procedure should be repeated.

- Go directly to soldering.

After the process is completed, the flux is washed off with water.

Let's talk about the rules of installation and operation

System calculation

If you decide to install the system yourself, you will have to make certain calculations. It will be difficult to absolutely accurately calculate the dimensions and volume of the system, and there is no urgent need for this.

For example, 5 kW is enough to heat a medium-sized room. This power can be provided by a heat exchanger with an area of 1 m². But the temperature in the furnace constantly fluctuates; when fully heated, 1 m² provides up to 9 kW, and when the furnace goes out, the power begins to drop rapidly and can drop by 5 to 10 times. Therefore, the area of the unit is taken with a significant margin, which makes it possible to equalize the heating of the liquid.

The configuration of the heat exchanger itself can be different; there is no consensus among experts. Some argue that stainless steel pipes are the best option, others prefer plates or manifolds consisting of 2 mating channels.

Connecting the system to the shower stall.

Tips for installation

If you decide to assemble the system yourself, then you should take into account several mandatory requirements.

- Tanks should be welded from metal with a thickness of at least 2.5 mm. The requirements for the upper, large tank are minimal; the main thing is that it does not rust or leak.

- The requirements for piping and the heat exchanger itself are somewhat higher; in the past, the most popular material for a heat exchanger was cast iron. Indeed, the material is very durable, does not corrode and holds the temperature for a long time. But cast iron also has serious disadvantages; it is heavy, which requires serious fastenings. And cast iron takes a long time to heat up.

- At this time, most experts prefer to assemble a system from stainless steel; its price is of course higher than that of cast iron or conventional steel grades that are susceptible to corrosion, but the savings here will cost more in the future. For the heat exchanger, stainless steel grades 08X17 (430) will be the most optimal; or 8-12Х18Н10 (304) they have optimal heat transfer parameters and meet all hygienic standards.

- As for the connecting pipes, naturally they should also be made of stainless steel. The drive pipe with cold water must initially, when leaving the large tank, fall slightly below the level of the heat exchanger; a drain valve is mounted at the lowest point and then rises at an angle of 2˚ to 5˚ to the entrance to the heat exchanger.

- The outlet pipe, through which hot water will flow into a large tank for a heated bath, must exit the heat exchanger, pass through the wall at an angle of at least 30˚ and connect to the tank.

Material for container

In the old days, the most popular material was cast iron. Of course, it will take a little longer to heat up, but the temperature will be maintained better. An important factor is the resistance of cast iron to corrosion and its long service life. But cast iron is a heavy material and such a container will need powerful support.

Cast iron stove with tank.

Ferrous metal is now practically not used for these purposes due to its tendency to corrosion and the high probability of deformation due to sudden temperature changes.

Stainless steel is deservedly considered a universal material. This metal is not afraid of corrosion and is relatively lightweight. In order to weld a large-capacity tank, a sheet 1.5 - 2 mm thick is enough. During temperature changes, such containers do not deform.

The video in this article shows the opinion of a specialist.

Assortment of tanks.

Hot water tank for a bathhouse - how to choose?

Everyone understands perfectly well the importance of hot water in a bathhouse. Without it, you can’t wash yourself or use the heater. A technological solution would be to install a heating boiler. But why take up extra space, for example, in a small bathhouse, if you can organize water heating in a regular tank using stove heating? And all you need to do is choose the right container for this.

To begin with, we note that all tanks differ in shape and capacity.

Design options

The sizes are clear. Now let's talk about the method of heating water. It depends on the design features of the containers and the method of their location. The main options include the following types:

- classic tanks built into the oven;

- containers on the pipe;

- remote tanks.

Built-in containers

The first option is considered a classic. The container is located on the side or above the stove. Heating occurs as it heats up, and there is a ball valve on the tank for draining. On the one hand, they are quite convenient and do not require additional work to remove pipes or arrange places for fastening. But stoves with such tanks are large in size, and in some bathhouses that do not stand out in size, their installation will involve the loss of precious meters. In such cases, it is necessary to choose a sauna stove with a tank located on top. In this design, it will not block the passage.

Remote structures

Such tanks are more often used in saunas,

What should the tank be made of?

Of course, the most common option in all forms is stainless steel. There is several indisputable evidence for this: they are not subject to corrosion, the water in them warms up faster, and due to the special properties of the metal, it cools down more slowly. Stainless steel does not deform from high temperatures, is lightweight and always looks attractive, complementing the design of the interior space.

To save money, many people still use metal tanks. But they are impractical neither from an aesthetic point of view nor from a practical point of view. And if the unsightly appearance can be hidden behind the brickwork, then it is impossible to cope with the rust that appears over the years inside the container. And constant heating deforms the metal. And if people who have had such tanks for a relatively long time can still be understood, then it is impossible to understand the complexity of the thinking of those who install metal tanks in a newly built bathhouse. Moreover, many do not even try to hide them with partitions, leaving them outside for everyone to see.

You can also find cast iron tanks on sale. Thick metal that has a certain structure does not rust, but the water in it takes a long time to warm up, but also cools down slowly. Cast iron tanks are heavy; it is better not to place them on a small stove, but to place them on the side.

In addition to capacity, you also need to choose a tank based on its design features. Conventional stainless steel containers, powered by furnace heating, are produced in rectangular, square and semicircular shapes. Depending on the free space and taking into account whether the foundation will be poured under the stove, the type of tank is selected. Also, do not forget about the free space. They need to be positioned in such a way that they do not restrict the space. So that when washing you do not get scalded by accidentally touching it.

In winter, after washing is completed, the tanks are completely emptied. Once frozen, water will tear apart any metal. Do not fire stoves with an empty tank. High temperatures deform the container, and all protection will peel off from the enamel surface.

proekt-banya.ru>

Enameled

Enameled samovar type tank

Also a good option for making tanks. This material is also not susceptible to corrosion, provided proper handling is taken into account. If, due to an accidental impact, a layer of enamel breaks off from the surface, then rust may appear in this place. This can be corrected if you paint the area with heat-resistant paint in time.

The specifics of the material must be taken into account, and before making a tank for a bath, you should think about this method of arrangement so as not to accidentally damage it.

How to install and connect correctly?

During the process of installing and connecting a tank in a bathhouse, one of the main priorities is deciding how the water in the tank will be heated. The water in the tank can be heated either from the heat of the stove in the steam room, or using a heating element. The main factor here is the number of people visiting the steam room and their need for hot water. The thickness of the tank will also affect the rate at which the water heats up.

Connection diagrams for the water tank may vary. If there is running water in the premises, it is necessary to use a closed water supply system. For this purpose, it is most advisable to use a stove that has a coil, which, in turn, will be connected to a water reservoir and heat the liquid. The container itself can be mounted on the wall. Sometimes tanks are mounted directly above the furnaces, but with this installation option it is best to use lighter and smaller structures. For containers that have a water circuit, stainless steel or galvanized sheet is often used.

You need to connect according to the following instructions:

- The tank itself should be installed in the steam room and connected to the pipes using a coil.

- To achieve good circulation, it is worth connecting the upper part of the tank with the upper outlet of the coil, and the lower part of the tank, respectively, with the lower one. For this reason, cold water will enter from below, and hot water will be discharged from above.

- At the point where cold water will enter the tank, a safety and check valve is used.

- Then you need to set the threshold pressure for the valves at which they will operate. The drawings are presented below.

Thanks to this principle of operation, the liquid in the container will be heated using a coil. And after it is used, the tank will be filled with cold water again.

Welding stages

At the initial stage of welding, boards must be placed under the corners of the sheet, which will serve as the bottom.

It is important that the thickness of the substrate is the same. This will give an even plane along the entire length and in the corners of the structure. During the welding process, it is necessary to constantly check that the sides do not extend beyond the base. You can immediately grab all sides together, then weld them to the base.

The sheets should fit tightly to each other. The next stage is the final welding of the seams. Welding can be done inside the tank or outside.

There should be no lack of penetration. Self-welding takes about 7-8 working hours.

It is recommended to make the structure rigid. To do this, use squares inside the tank and on the outside. To drain the water, a pipe with a control valve is welded into the lower part.

You definitely need to put aside your laziness and check the structure for leaks . After completing the work, you should prepare a chalk solution and apply it to the seams from the inside.

When it dries, use a cloth soaked in kerosene to go along the seams of the tank from the outside. Purpose: identifying “lack of penetration” clogged with slag. It only takes a few minutes to control.

If the liquid does not appear, then everything is fine. If stains appear, the problem area should be boiled again. It is best to check and re-weld immediately before painting.

Installation can be done on pre-laid bricks, but it is better to use a stand. Next, fill the tank with water and observe for several days: no liquid appears on the walls of the structure.

Remote with heat exchanger

Heating water in a bathhouse using a heat exchanger is highly efficient. This method is used in boiler houses of any size. The heat exchanger is located in the furnace flame. Water circulates through it; this heating of water is the most effective of all possible. The only thing that limits the use of this system for baths is its complexity and the resulting high cost.

Advantages

A remote tank for hot water in a bathhouse is placed in any convenient place. Heat is transferred to it through circulation pipes if a stove or boiler is used. Remote tanks are also ideal for electric heaters.

Compared to a tank directly on the stove, heat is transferred to a remote tank in a more complex way. The length of the pipes can be several meters. Of course, this causes additional heat loss, but also provides many advantages:

- If the tank is remote, then a highly efficient heat exchanger is necessarily used to heat the water;

- The installation location can be any; large volume containers can be installed;

- It is convenient to install at a height, for example, in the attic of a bathhouse for a ceiling shower.

conclusions

All methods of heating water in a bath described in this article are widely used. They are structurally thought out, safe and comfortable. It is only necessary to ensure their high-quality implementation. Like any other water systems, sauna water heaters must be sealed.

The tank for heating water in the bathhouse is installed in one copy. Using one tank with a large capacity, which is designed with a margin, is more profitable than several smaller tanks. In the construction of a bathhouse, we recommend that you read other articles on our website.

Why stainless steel: key advantages of the material

The modern market offers a wide range of water tanks made of cast iron, stainless steel and enameled material. As practice shows, stainless steel is the most popular among bathhouse owners, which is due to the competent and acceptable ratio of operational and technical characteristics and cost indicators.

Stainless steel is characterized by excellent thermal conductivity, withstands temperature changes and objectively lasts longer than various ferrous metals.

Examples of stainless steel tanks

Stainless Steel Oven Mounting Tank

Stainless steel tank

Stainless steel containers

A logical question arises here: which of the existing brands of stainless steel is better suited for the manufacture of the container in question, intended for use in a bathhouse? Firstly, this is brand 08Х17 (430), secondly, 8-12Х18Н10 (304). The mentioned materials, among other things, are used for the production of tableware and are characterized by high resistance to high temperatures, are completely hygienic, do not rust or deform during use. In addition, such materials are unpretentious and extremely easy to maintain.

Composition and mechanical properties of different grades of stainless steel

To summarize the above, we can highlight 3 main advantages of water tanks made of stainless steel:

- the products do not require additional protection from high air humidity and can easily withstand operation in conditions typical for a steam room;

- Stainless steel has high thermal conductivity, which makes it possible to obtain hot water in the shortest possible time;

- Stainless steel tanks do not deform due to sudden temperature changes, or these deformations are insignificant.

Anti-corrosion treatment

For metal tanks, corrosion is the main problem. The key solution is stainless steel, but for now, the price for it remains 10 times higher than usual (in terms of weight). In reality, a stainless steel tank costs not 10 times more than a regular steel tank, but much less. This happens because the thickness of the walls of the stainless steel tank is made smaller. There is no reserve required for thinning due to corrosion.

Anti-corrosion treatment of tanks is carried out in the factory. Technologies in this area do not stand still and are constantly being improved. Zinc has the strongest adhesion to steel. Various protective layers are applied on top of it.

There are two popular options for anti-corrosion protection. This is either paint for a hot water tank in a bathhouse, or glassy enamel, which is applied at high temperature. Enameled tanks are better protected from corrosion and high temperatures than painted ones.

The general technology for their manufacture is the same as for conventional enamel cookware. Glass-based food grade enamel is used for tanks and utensils, without the addition of lead.

Information. In some cases, they carry out independent anti-corrosion treatment of tanks. All homemade structures need it (with the exception of stainless steel). You need to use only specially developed compounds and apply them to a clean and grease-free surface.

Mounted

This design option is hung on a standard metal sauna stove. The presence of metal walls of the furnace is mandatory, since heat is transferred through one of them to the water in the tank. This design is not widely used due to low efficiency, but its main advantage is maximum simplicity.

A hanging tank for a bathhouse is usually made of thin stainless steel. It is placed outside the stove and located in a visible place in the bathhouse. Stainless steel is not only an ideal material for water tanks, but also has a beautiful appearance.

When you need the simplest tank for hot water in a bathhouse, wall-mounted installation is best. With it, you don’t even need to do pipe routing. The tank is delivered completely ready.

The bath tap for hot water is also included with the tank upon purchase. The spigot is located at the center of the lowest point, and the bottom is usually flat or has a conical stamping.

The inconvenience of this location of the tap is the small distance from the floor. In addition, the stove is often placed in the corner of the bathhouse. One side of it is occupied by the door, and the other by the tank. Thus, it turns out that the tap is in a very inconvenient place. This problem is solved by installing a pump.

Information. For a wall-mounted tank, the sauna stove should be standard. This is either a ready-made structure, or a home-made one, but having at least one flat metal wall of the appropriate size for the tank.

Wall-mounted tanks have either a removable lid or a filler neck with a diameter of at least 10 cm. A filler neck is much more common. It makes cleaning and processing the internal space somewhat more difficult, but makes the structure more durable.

The cheapest designs of hanging tanks are welded from sheet steel and galvanized. The service life of such structures is short. Stainless steel thin-walled structures are gaining popularity.

Due to their small wall thickness, they are affordable. Steel enameled tanks are rarely used as hinged tanks on the stove.

What designs can be used

You can place the tank in the bathhouse in different ways. The main types used are:

Built-in design. In this case, the chimney pipe runs inside the tank. This structure is considered stationary, non-removable and is installed during the manufacture of the chimney. The tank can be made in the form of a pipe (cylindrical version) or have a rectangular cross-section

It is important to securely seal the bottom entrance of the pipe to prevent water from leaking out of the tank. To use water, outlets are made from the tank directly into the shower stall or intermediate tank

Given the elevated location of such a tank, water flows by gravity.

The device of a heater with a tank on the chimney

- Hanging structure. Such a system is removable, i.e. installed on an existing chimney. The tank is placed close to the chimney pipe and securely attached to the column. Such containers can be purchased or made by yourself. This design is typical when a gutter is formed on the back wall, repeating the shape and diameter of the chimney, which makes it possible to bring the surfaces as close as possible and ensure high-quality heating.

Design of a hanging tank for a bath

- Remote design. In principle, the water container itself can be placed in any convenient place (for example, in a shower). In this case, the energy of the chimney heats the coolant, which is sent to heat the water container. When such a heat exchanger is mounted on a bath pipe, the installation height of the tank must be selected so as to ensure gravity flow of the coolant according to the laws of physics, i.e. the warm flow rushes upward, and the cooled flow – downward. This design provides for the presence of additional elements in the form of a heat exchanger, but it also allows you to place the tank itself in the right place.

Water circulation diagram with a remote design of the tank and stove in the bathhouse

Depending on the design, the tank can be placed at different height levels. 3 options can be implemented:

- At the stove level: the base of the tank is placed on the top of the stove, which means no additional brackets are required. The main disadvantage is that the height does not allow gravity flow of water for showering. In this case, it is scooped by hand.

Tanks at furnace level

- On the chimney column. This design is located at a certain height, which eliminates the previous drawback. Mounting the tank requires special brackets, and the weight of the structure is limited.

- Attic level. Here there is a reliable support for the tank in the form of a ceiling. The problem arises in a cold attic, where you will have to think about external thermal insulation.

Diagram of installing a water tank on a chimney at the attic level

When calculating the parameter, they usually proceed from the following requirement: 10 liters per person for a bath procedure and 5 liters per person when taking a shower. In addition, a reserve should be created for unforeseen circumstances.

There are various forms of water tanks for a bath on a chimney

The dimensions of the container also depend on the design and dimensions of the chimney. The most common type is a sauna tank with a 115 mm pipe. Naturally, a bath tank for a 150 mm pipe is made of a larger diameter, regardless of the need.

The choice of volume of a metal water tank depends on the number of family members

Formula for determining the volume of a cylindrical tank

Built-in tank, remote tank or tank on a pipe?

Bath tanks come in various types. The most famous are built-in, remote and on a pipe. Each of them has its own advantages and disadvantages. Compare and evaluate which one is right for your bath.

Advantages of a tank that is built into the oven

Once upon a time, water tanks for the bath were always built into the stove - so that the entire lower part of the boiler was in the upper part of the firebox - the hottest. In this case, the bottom of the tank is in direct contact with the stove fire. Water from this container can either be drawn directly or removed through a special built-in tap.

Remote sauna tank: main advantages and disadvantages

Thanks to the excellent ability to install a special heat exchanger in the oven, the tank does not need to be tied to a specific place - it can even be installed in a washing room. According to all known laws of physics, cold water will fall into the heat exchanger, and hot water will rise back.

Sauna tank on a pipe

Of course, it also happens that the sauna is used not for a couple of hours at all, but for the whole day - for example, when washing, but time has already passed since the fire. Then the best option is a sauna tank on a pipe, where the water will be constantly heated to the required temperature. This is on the pipe through which smoke comes out of the furnace - and its temperature can reach 500 degrees. Such tanks can be quite large, since the heating area of the pipe is very large, and the water will heat up evenly and quickly.

There is also another advantage of this design - in this bathhouse, smoke leakage through a crack in the pipe is absolutely impossible, since the tank in this case serves as a full-fledged fuse.

Metal

Made of metal

In their own way, such tanks are good, but they still have more disadvantages. The main advantage in choosing such a material is its low cost. The thermal conductivity of the metal is good, so the water will warm up quickly.

If you decide to install a metal tank, then be prepared for constant maintenance. After each washing procedure, it must be completely drained and wiped dry to prevent corrosion, which will directly affect the purity of the water.

All the details and nuances

Depending on the purposes for which you will use the room, how many people will relax there, the choice of construction method will vary. If you plan to build an entire complex, then most likely you will have to be patient.

Building a sauna tank with your own hands or calling a construction company for help is a matter of your choice, but its presence will significantly simplify some processes.

Previously, the container was placed directly in the stove or above it. Since the slab itself is made of brick, stone or metal, the structure is truly strong and durable. Today there are many options for replacement. As an alternative to this, you may be offered:

- Remote

- Mounted

- Heated by heat exchanger

Those structures and tanks that have the ability to be transported are much more practical and can be easily moved to other rooms.

Recently, the production of this type of product has become more in demand. The latest generation technologies allow you to choose from a number of tanks with any parameters and efficiency, at a price that suits you.

The main purpose of such tanks is for greater release of light and soft steam, as well as water supply in the shower or other amenities. The volume of the container and its dimensions will depend on how great the need for water is. For 3 people, 50 liters is quite enough, 80 liters or more for noisy companies, or if the bathhouse is heated several times a day.

Good functioning is also influenced by factors such as the density or thickness of the metal. A stainless steel water container is very practical and maintains optimal temperature conditions well. It’s not worth saving on such a device, and you need to understand that high-quality material will cost much more.

The choice of tank plays a big role; during the combustion process, the temperature reaches 400 degrees; if the installation is attached to a chimney, then this level of steam goes beyond such a building and can be called a classic option, since it has become widely used in the last ten years. Choose a manufacturer responsibly and try to purchase only high-quality certified products.

Materials

When choosing a tank for a bathhouse or when making it yourself, an unmistakable choice of the material for its manufacture is extremely important. The heating time of the liquid, the period of its cooling and the duration of operation of the device itself will depend on this. Among the most widely used materials, cast iron, stainless steel and enameled steel are widely used.

Previously, only cast iron tanks were used for hot water tanks. Cast iron containers have been tested by time and have a number of positive aspects. In particular, a cast iron tank will keep the water hot for a long time. There is no corrosion on them and the water in this tank will always be clean. This material is very resistant to temperature changes. And finally, the shelf life of a cast iron tank is very long, since this material is not susceptible to corrosion. Currently, not many manufacturers are engaged in the manufacture of cast iron tanks. But it is quite possible to buy a used tank at a lower price. In this case, you will need to process it and give it a pleasant appearance.

One of the disadvantages is the rather long time it takes to heat the water in the tank. Cast iron tanks are heavy and sometimes need to be installed on a special foundation. If the tank is located above the stove, its fastening requires additional reinforcement. Making such a tank yourself will also be a very problematic undertaking.

Stainless steel containers are now used quite often. This material replaced cast iron tanks. The owners of the baths appreciated their high positive qualities. Such tanks do not require additional protection from high humidity. The water in a stainless steel tank heats up in an extremely short period of time. Stainless steel has good resistance to sudden temperature changes and, accordingly, does not rust, as its name already implies. The only downside that can be noted is that the water in it cools down quickly.

Tanks made of enameled steel are also a popular option for this design. A special enamel coating on such tanks reliably protects them from corrosion. The main thing is to prevent damage to the enamel, otherwise the tank may begin to rust. Although damaging the enamel layer is quite problematic, since such a coating is resistant to various types of damage. If necessary, a tank made of this material can be very easily cleaned. Enamel of various colors is available on the market.

For cold water, separate tanks are now rarely used, since it most often enters the room through the water supply. But if there is a need to install a container for cold water, then there is much less hassle with it than with a tank for hot water, since there are no particularly strict requirements for it. You can even use wooden containers, such as an oak barrel. Plastic containers for cold water are also popular. But such containers cannot be placed in a steam room, much less near a stove, because plastic is sensitive to high temperatures and can become deformed when heated. You can also make such a tank yourself.