Construction of a bathhouse on a personal plot is not a quick process; the stages of construction work must have time intervals between each other. It is difficult to give a clear answer to the question of when is the best time to start construction. However, there are general recommendations that you should heed before starting work.

The regions of Russia have different weather conditions and temperature conditions, which make their own adjustments to the work process.

The choice of which materials are best to build from depends on the financial capabilities and features of the construction of a particular type of bathhouse.

Which one is better to build a bathhouse?

There are a large number of subtypes of baths, each of which has its own special requirements for construction, maintenance, temperature conditions, ventilation and other subtleties. There is no consensus on which bathhouse is better.

You need to start building a bathhouse based on your own preferences.

In white

White baths were built more often as public ones, especially after the decree of Peter the Great.

They were intended for a large number of people and were easier to use. In a white bathhouse, the stove is more complex and requires the construction of a chimney.

Compared to a black sauna, it is more complex to construct. It is easier to heat such a sauna than a black sauna - there is no need to keep it free of smoke.

It is completely free of soot and soot, since the products of fuel combustion exit through the chimney. At the same time, they require ventilation to prevent the formation of mold and mildew. It usually separates a steam room and a washing room.

In black

In Rus', black baths were installed, in which both a steam room and a washing room were combined. In appearance it was (and remains) a small hut with a complete absence of a chimney.

Its advantages are that such a bathhouse is cheaper to build; there is no need to build a chimney in compliance with all fire safety rules.

Log walls retain heat for a long time and warm up quickly, which allows you to save on firewood and preparation time. Soot that accumulates on the ceiling and walls absorbs unpleasant odors and has a disinfecting effect.

Hammam

A Turkish bath or hammam has certain requirements during construction. It occupies quite a large area. The hammam can be attached to the main building.

The room itself must be at least 2.5 meters high. The ceiling should be dome-shaped to allow condensation to flow evenly onto the walls. A so-called heated floor is required - a floor equipped with water heating or electric heating.

In a Turkish bath, at least two rooms are required - the bath itself and the technical room. Steam generators are located in the technical room, which serve to maintain the humidity level. If desired, an aroma generator is also placed there.

No wood materials are used in the construction of the hammam. Foam blocks, brick are used, for interior decoration - stone, marble, tiles.

It is believed that building a Turkish bath for your own use is very expensive and not very justified.

Sauna

The good thing about a sauna is that it can be attached to a bathroom, and it is not demanding on the size of the room.

It is not necessary to build a separate building for the sauna. Most often, the sauna is a separate cabin, so work can begin at any season.

An electric stove with a thermostat installed inside the sauna is used as a heat source. To finish the floor, tiles are used, on top of which you can use a wooden board-flooring.

The peculiarity of the sauna is that it is essentially only a steam room - the washing process is carried out in a shower stall or in a separate washing room.

4 mistake - lack of fire safety

The sauna stove is heated all year round and therefore it is very important to think about fire safety. It is necessary that the chimney in the place where it passes through the roof is protected by a metal box. It must be taken into account that there must be at least 38 centimeters from the chimney to the wooden parts. The brick for the chimney must be of high quality without cracks, chips, or cracks. It is important that the pipe in the attic is whitewashed. If cracks form, it will be clearly visible on the white pipe.

For the stove, red, well-burnt brick without cracks or defects is selected, which produces a ringing sound when tapped. Bricks for the stove of the same size and height are laid immediately on a dry surface, so you can get a uniform seam no larger than 5 mm in size. The size of the seam is very important; the thicker it is, the worse the oven will behave when heating and cooling. Read more about the brick oven.

What material to build from?

The choice of material for building a bathhouse is no less important than the design.

You need to proceed from the expected material costs, the type of bathhouse, its location on the site, its size and purpose.

timber

Construction from timber is a fairly economical and to some extent classic option. From timber you can build a bathhouse in white and black.

You need to pay attention to the material itself - there should be no large cracks on it, the surface should be smooth and even, without a large number of knots.

The wood must be free of traces of insects. Color gives information about the quality of the material - the presence of a bluish tint indicates the presence of fungus or mold.

The roof for a timber bathhouse is preferably gable, with strong rafters. Ventilation is required, otherwise the appearance of fungus and mold is guaranteed. You can use special impregnations, but they will reduce the health properties of the bath.

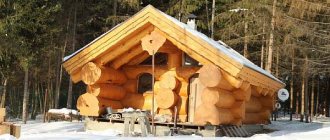

Log

A log bathhouse can be built in either black or white.

The first thing you should pay attention to is the material. It must withstand high temperatures and high humidity. There are many types of wood from which log houses are built.

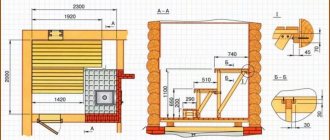

A log bathhouse needs a good foundation, the type of which depends on the soil. On heaving soil, the best option would be a shallow foundation.

For a large bathhouse, a strip foundation is optimal. It is deepened depending on the level of soil freezing and laid with waterproofing material. A columnar foundation is suitable for small baths.

Logs for construction are used to be as equal in diameter as possible. The best option would be a diameter of 25 cm. Thicker logs are placed at the bottom of the walls, and thinner ones at the top.

The walls, just like in a timber bathhouse, are caulked, and as the logs dry out and the gap between them increases, they are treated with dry moss or tow.

Brick

A brick bathhouse is more expensive, but at the same time more durable than a wooden one. A brick bathhouse can only be “white” - brick tends to become damp and deteriorate, so it needs good ventilation. The walls of such a bathhouse are lined with clapboard with an insulating layer.

The foundation is built from stone or brick. Construction from reinforced concrete is allowed, but this type is expensive. The brick used is red or silicate, the main masonry is one and a half to two bricks, the partitions are half.

Laying the walls starts from the corners. The first row is laid across, the subsequent rows are laid with lightweight masonry of several half-brick walls. The openings between the walls are filled with light slag or a mixture of sawdust.

When building a brick bath, more attention is paid to waterproofing and thermal insulation.

Foam blocks

Foam blocks retain heat better than bricks, are not subject to rotting, and do not lose their strength at high temperatures. When choosing blocks, you should pay attention to a water-resistant primer.

When building a bathhouse from foam blocks, a high-quality foundation is required. The material for it is concrete with a reinforcement frame. When laying, a sewerage system is provided.

During the construction of walls, you should monitor the thickness of the seams.

The first row of foam blocks is fixed with cement-sand mortar, the subsequent rows with special glue.

From the inside, a bathhouse made of foam blocks needs to be insulated. The insulating material can be foil insulation, mineral wool, jute felt, which are laid on the sheathing.

Internal cladding is carried out with clapboard or ceramic tiles.

From foam blocks you can build a sauna, white bath and hammam.

Common questions and answers

How much more expensive is pine than larch?

The price difference is approximately 70-80%.

What is the service life of the breed if it is used in a bathhouse?

More than a dozen years, for sure. In general, larch buildings can last 200-300 years.

What difficulties can you encounter when processing the material (other than hardness)?

Due to the abundance of resin, the tool blades become heavily oiled, so they have to be cleaned frequently.

Can a bark beetle live in larch?

This happens, but extremely rarely. Insects do not like the breed because of its resinous content.

Is it necessary to varnish the larch paneling inside the bathhouse?

This is not necessary; minimal impregnation with a protective composition is sufficient.

What wood is suitable for building a bathhouse?

The variety of wood for building a bathhouse is great. An undeniable advantage of a wooden bathhouse is the microclimate created in the building. Resin aromas have a healing effect.

In general, the material must withstand high temperatures and high humidity. Northern wood species are well suited for this purpose - cedar, oak, larch, pine.

Alder, aspen, and linden are less commonly used. It is recommended to combine several tree species.

For the ceiling and floor, it is better to use non-resinous rocks, so that in conditions of elevated temperatures, hot resin does not fall on the skin with condensation from the ceiling.

Oak

Oak is the strongest and most durable wood. At the same time, the price is high, and an oak bathhouse as a whole will be expensive. Oak is well suited for laying the first rows of a log house - they will withstand the pressure of subsequent rows.

Another option for using oak wood would be interior decoration - the material is resistant to mold and fungal infections.

Pine and cedar

Pine has become widespread in the construction of log houses. Pine scaffolding is easy to process, soft and light. Not very suitable for lower levels, as it will shrink greatly under the pressure of the upper ones.

Needs additional treatment to prevent moisture and rotting. It is recommended that the interior decoration of a pine bath be done with hardwood.

A frame made from Siberian pine, or cedar, will be expensive in price, but light and durable. Cedar makes good interior decoration.

You can lay out the upper links of the bathhouse from cedar - it is light in structure, the wood will not shrink strongly to the lower levels.

Larch

Larch is difficult to process, but at the same time it is durable and costs less than oak or cedar. There is no need for impregnation against insects and fungal infections. It does not have the best thermal insulation properties.

Spruce

Spruce logs have almost the same qualities as pine logs. When heated, resin secretions give off a pleasant odor.

The high content of resins in wood can cause allergic reactions and a suffocating odor.

Spruce is an economical material for construction.

Linden

Linden scaffolding does not shrink when dried and does not require waiting after construction.

At the same time, the log house is short-lived and requires additional financial and time costs for maintenance, such as: treatment against mold, impregnation of wood against insects, and thorough drying of the bath after use.

Aspen

Aspen, as recommended by many builders, is a good combination of price and quality.

Aspen wood does not “lead”, it does not crack and almost does not shrink. It does not contain resins, so it can be used on floors and ceilings. It tolerates dampness and high temperatures better than linden.

Professional opinion

“We are building baths, and larch is one of the most popular materials at the moment. There is nothing surprising about this: it is strong, durable, and smells very nice. We ourselves recommend her if they ask us to recommend a material that will last for decades.”

Alexey Poilov, builder, author of the video blog “Siberian Terem”“I have an old bathhouse on my site, which is probably 30 years old. I didn’t want to build a new one from scratch, I decided to update what I have. I thought for a long time about how. As a result, I came to the idea of lining the inside of the bathhouse with larch planks and making the floor from the same material. I worked on my own, and it was sometimes difficult - the rock is very hard. But I’m one hundred percent satisfied with the result - I got exactly what I wanted. The first thing that catches your eye is the aroma. It is indescribable - as if I found myself in a coniferous forest. Plus strength - nothing cracks from water and steam, moisture is not absorbed.”

Alexey Permyakov, author of a life blog on YouTube

“Larch wood is perhaps the best solution for a bathhouse. After all, it practically does not absorb water. I personally observed such a case. Boards of this type were stacked in a rather damp room. It so happened that the roof leaked at night and moisture got on them. It wasn't absorbed at all! It spread across the boards and that’s it. I think any additional comments here are absolutely unnecessary.”

Features of building a bathhouse in different seasons

It is better to choose wood for a bathhouse if it is cut in winter - during this period all growth processes slow down, insects die, and the wood is resistant to rotting. This wood is more durable due to the reduced amount of starch and moisture.

Construction of a log house in spring and autumn is considered the most unsuccessful. Wood swells, picks up moisture, and after drying it begins to crack.

Such a log house will shrink very strongly and may “lead.” In the fall, only the foundation should be laid.

In winter, it is not recommended to work in severe frosts, since the wood dries out excessively and becomes very fragile. The optimal temperature for working in low humidity is minus 13 degrees.

For many, summer is the best period for construction. At the same time, rain and hot weather have a bad effect on the tree. In addition, in the summer, construction companies have a lot of work, and prices for transportation and delivery rise.

When should you purchase a plot of land with a turnkey timber bathhouse?

The most rational time period for purchasing a plot of land with a bathhouse is autumn. There are several reasons for this:

In autumn, land prices drop. This means that having a large selection, you can purchase the plot you like at a significant discount. Or you can buy a larger plot of land or with better characteristics for the money you have.

There is time to put the bathhouse in order. If you purchase a plot traditionally - in the spring - there is simply no time to calmly look around and see all the shortcomings and imperfections in the bathhouse. This is understandable - the sowing, fish, mushroom, and harvesting seasons begin. Or simply don’t feel like doing anything. Except, of course, sunbathing and swimming in the nearest body of water. By purchasing a bathhouse in the fall, you get time for a leisurely review and high-quality, leisurely repairs. This means that defects (if any) will be eliminated efficiently, and there will be no need to return to the issue of repairing the bathhouse.

Columnar foundation and its practical advantages Ready-made transportable baths are the best solution for country house construction

Stages of work

Preparing the foundation, pouring it

It is recommended to pour the foundation in late autumn. Depending on the size and soil, different types of foundations are used.

On heaving soil, the best option would be a shallow foundation.

If the bathhouse is planned to be large, then it is better to choose a strip foundation.

A columnar foundation is suitable for small baths.

Preparing timber

Winter is the best time to prepare timber if construction will be carried out immediately. If the construction of the log house will be carried out in the summer, the material should be prepared in late spring and early summer.

In winter, timber is prepared for subsequent assembly. The logs are cut, debarked - removing the bark, and the logs are hewn. You can purchase pre-prepared material.

Assembling a log house

If weather conditions permit, the collection of logs should begin in winter. Work is allowed at temperatures down to minus 25 degrees. Assembly in summer is carried out on cloudy, cool days, and the wood is stored under a canopy.

When can you caulk a log house?

There are subtleties in caulking a log house. The work needs to be thought through and started at the assembly stage.

The insulation is laid on the timber with a small margin so that its ends hang down. Subsequently, the insulation will be compacted under the weight of the timber, but additional caulking will be required.

After the winter construction of the log house, caulking can begin three months after completion of the assembly. During this time, the building will shrink.

The same applies to summer assembly - it is not recommended to caulk the log house immediately after finishing the work; postpone it until spring.

Installation or laying of a furnace

It is carried out after caulking, but is designed at the stage of laying the foundation.

When is it profitable to start making a turnkey timber bathhouse?

In the first case, the most rational time to start purchasing is winter. Surprised? And there is nothing to be surprised about. See for yourself. The most rational time to build turnkey timber baths is the end of spring - the beginning of summer. Accordingly, the project, approvals and the log house itself must be ready by this date. Design (even using a ready-made project) requires at least a month or two. The design work itself will take much less time. But it’s unlikely that you will be the designers’ only customers. If so, you will be put in a queue. Don’t forget that various types of approvals also take time. The funny thing is that designers consider the most difficult coordination to be coordination with the customer - loaded with many options and their own ideas about beauty and practicality. Customers have difficulty listening to proposals from designers and builders. With even greater difficulty, customers agree to changes that are technologically necessary, but do not affect their souls. After completing the project, time is needed to set the task for production workers and produce the required amount of profiled timber. We shouldn't forget about that. That timber (especially laminated veneer lumber) is made to the specific dimensions of a particular bathhouse, and if so, the construction of timber bathhouses does not have interchangeable elements and parts. Adding up the time intervals necessary for the implementation of the plan called “turnkey timber bathhouse” makes it possible to conclude that the bathhouse must be ordered no later than 4-5 months before the planned installation date

Final interior finishing work

For a building assembled in winter, in summer interior finishing is carried out - paneling (if required), installation of shelves, design of the dressing room - and completion of construction. Doors, windows are installed, and exterior finishing is carried out.

In the case of summer harvesting of the log house, it is recommended to postpone the final finishing work until next year.

Building a technically competent and safe bathhouse is a long process.

In the fall, only laying the foundation is recommended; the construction itself is carried out in winter or summer. Insulation is carried out after the frame shrinks, which takes at least 3 months. In general, the construction of a bathhouse can take a year, sometimes longer depending on weather conditions.