Wood is the best material for building a Russian steam room. It can be used not only for the construction of structures, but also for interior decoration.

Wood for baths has unique performance characteristics: it is environmentally friendly, practical and durable.

However, when choosing a suitable material, it is worth understanding that not all existing types of wood are used to build a bathhouse.

Advantages of a wooden bath

Private baths are built from almost any available material: brick, wood concrete and aerated concrete blocks, natural and artificial stone, wood.

Many developers prefer brick buildings, considering them more durable, strong and wear-resistant. However, a wooden bathhouse is absolutely not inferior to its brick counterparts in terms of operational parameters.

Advantages of a wooden building:

- Low thermal conductivity of the material, which ensures the maintenance of a comfortable indoor microclimate.

- Economical fuel consumption for heating wooden structures.

- Safety, environmental friendliness and availability of the material.

- Relatively low cash costs for maintaining the building.

- High heat accumulation for a long period.

Which one is better to make floors from?

It is best to make the floors in the bathhouse from larch wood. This is the best option, because the temperature near the floor is always low, so there is no risk of resin release there. And if water pours onto the floor, then larch will withstand such an attack better than other species. However, this does not eliminate the need for thoroughly drying the bath. Because larch (and many other species) behaves well with constant contact with water, but water-air is still fraught with decay for it.

BY THE WAY! It is not necessary to make the floors of the entire bathhouse from expensive larch; you can limit yourself to only the steam room and washing room.

In other rooms, much less moisture gets on the floor and you can use a standard floorboard, for example, spruce or pine . See also the article: What is the best material to make a steam room floor from: tips, instructions, diagrams and videos.

Types of wood for building a bathhouse

When choosing a building material, it is recommended to adhere to simple rules: the raw material must be easy to machine, resistant to overheating and deformation, and have a long service life.

What kind of wood to build a bathhouse from? For these purposes it is better to use a log house:

- from deciduous trees - linden, aspen, alder, oak;

- from coniferous species - pine, spruce, cedar and fir.

The distinctive characteristics of such materials include the absence of unpleasant odors, toxic substances and low thermal conductivity. The main requirements that wood for baths and saunas must meet are strength, wear resistance, environmental friendliness, and inertness to high humidity and temperature changes.

Useful video

A very interesting video in which wood moisture tests are carried out and the results are unexpected not only for us, but also for the experimenters themselves . We cannot agree with the authors of the video that reducing moisture during impregnation does not matter. Has for the wood itself, its service life.

***

We advise everyone who is busy building or improving their bathhouse to subscribe to our Telegram channel - this way you will always be aware of new materials appearing on the site, and we try to make them as informative and useful as possible.

Coniferous wood for the construction of a bathhouse

The material has excellent performance characteristics that allow the construction of high-quality and durable buildings. To decide which wood is best to build a bathhouse from, you need to consider in detail all the pros and cons of the presented materials.

Pine

A pine bathhouse is the most popular option for private developers. This is largely due to the availability and ease of processing of the material. In addition, pine logs are resistant to deformation and drying out.

The disadvantages of wood include the high concentration of resin released when it is overheated. But after just a few years of operation of the structure, the volume of resinous emissions sharply decreases or stops altogether.

Under the influence of high humidity, pine is prone to rotting, darkening and mold. Therefore, it is important to ensure the preservation of its original appearance by treating the surface with antiseptic compounds.

Larch

Wood for a bath of this type is durable, wear-resistant, practical and durable. During use, larch acquires the necessary hardness, similar to that of an oak log.

In addition, wood is resistant to mold and damage by harmful microorganisms. When heated, it has a beneficial effect on the human body and practically does not release resinous compounds.

The only drawback of larch is its high cost.

Spruce

In terms of its operational parameters, spruce is practically not inferior to pine. A cheap and easily processed material that can maintain the original whiteness of the fibers throughout its entire service life.

This is a budget option for those who want a simple and environmentally friendly building that does not require additional treatment with antiseptics.

The disadvantage of spruce is the ability to release large amounts of resin.

Cedar and fir

Cedar and fir wood are expensive materials that are not yet in sufficient demand on the domestic market. Despite this, cedar and fir have many advantages: they are resistant to shrinkage, cracking and mold. In addition, wood contains beneficial phytoncides and oils that are released into the air when heated.

With the right approach, you can build a beautiful and high-quality bathhouse from fir and cedar that will last for decades.

How to choose the right logs for a log house?

It is worth knowing that in winter the trees “sleep” and there is no sap flow in them. Wood from winter trees is strong and dry. In the summer, the trees are filled with sap, so the logs often crack when they dry out. Every crack opens the way for rot, moisture and insects.

Log sellers are well aware of these nuances. When people buy a log house in the summer, sellers try to prove that it is from “winter” trees. More often than not, this is not the case. Wood storage is too expensive. If we are really talking about a “winter” forest, then the logs can be stored in the open air, which destroys all the advantages of such wood. The conclusion is simple: you can choose good logs, but you need to do it in winter. The best time to buy a log house is from late October to March.

The quality of the log is also affected by where the trees grow. Strong and dense products are obtained from trees that grow at higher elevations and in sandy soil. If the trees grew in a swampy or low-lying area, the wood will be of lower quality. It is loose and “watery”.

Log houses are often sold in sets. This includes windows, ceilings, doors and other structures. On the one hand, this is convenient, since everything fits together. But on the other hand, the kits may be too overpriced.

It is worth noting that it is better to purchase a log house directly from the manufacturer. It is always better to avoid intermediaries. Unfortunately, there are too many of them on the market. By using the services of intermediaries, you greatly overpay. The cost of the log house includes the seller’s salary, advertising costs, etc.

It is more profitable to buy a log house without additional goods. Often low-quality lumber, made from a different type of wood, is sold together with a log house. When ordering a log house, you should ask the seller what is included in the basic kit.

Deciduous wood for the construction of a bathhouse

Deciduous tree species are no less in demand for assembling a log house for a private bath. They can be used not only for the construction of structures, but also for interior decoration.

Oak

To build a strong and durable bathhouse, experts recommend choosing oak - one of the most wear-resistant and hard types of wood, which is designed for use in conditions of high humidity.

The disadvantages of the material include high cost, complexity of technical processing, significant weight and the need to build a reinforced base. Therefore, a steam room made of oak is built less often than from other species.

Aspen

Soft wood, which is characterized by its low cost, ease of processing, attractive appearance and low thermal conductivity. Therefore, an aspen bathhouse does not require frequent repairs. This is explained by the material’s resistance to rotting and deformation during prolonged exposure to high humidity. Do not forget that aspen is not capable of releasing resins when heated.

Linden

Another representative of deciduous species is linden. This material is quite in demand for the construction of baths. It is light and easy to process, resistant to deformation and shrinkage. In addition, linden has low thermal conductivity. This ensures quick heating of the linden bath and preservation of thermal energy for a long time.

Among the disadvantages of the material are high cost, short service life, loose structure, susceptibility to rot and mold. For this reason, the linden bathhouse requires careful ventilation and drying.

Alder

White, black and Siberian alder are used to build bathhouses. In terms of performance characteristics, it is similar to pine - it is resistant to shrinkage, deformation and rotting.

The main disadvantage of the material is its ability to darken in the open air. To solve this problem, an alder structure can be painted with decorative paint.

An equally significant disadvantage of lumber is its fragility and the presence of defects: knots, wormholes and cracks. This material can be used in a steam room to decorate walls and ceilings.

Windows and doors

A double-glazed window in a bathhouse is a necessary thing, but you shouldn’t put it in a plastic frame. Because plastic in a bathhouse is not only a source of harmful substances released when heated. When heated, it also increases in size, and when strongly cooled, it can crack. Of course, this can be compensated for by various additives to PVC, but then you need to be confident in the manufacturer.

We believe that the best option for a bathhouse is wood for both windows and doors. And for entrance doors as well. Because iron doors in a bathhouse in winter are a source of condensation.

But windows and doors have one feature that does not go well with wood - it swells when absorbing moisture, after which the window or door may not fit into the opening. When dry, of course, the dimensions are restored, but cracking is possible.

What wood is best to use for a bathhouse when choosing windows and doors? With minimal change in dimensions when moistened and dried. linden plays this role but our study of reference data showed that aspen is even better in this regard.

But the Finns have long switched to thermal wood, which they use for door frames and window frames. Since heat-treated wood dries down to 6%, it is no longer able to absorb moisture and change dimensions. A very valuable property precisely for those items that are now being discussed. So, if possible, we recommend paying attention to thermal wood.

Another interesting observation made when studying the properties of cedar pine is that its coefficients of change in linear dimensions are even smaller than those of linden and aspen. Therefore, it is also a candidate material for windows and doors.

More materials about windows and doors: Windows for saunas and baths, Doors for baths.

Properties of spruce logs

Practical and economical for construction, this breed is quite widespread. To the east of the Urals grows Siberian spruce, to the west - European spruce, which practically do not differ in quality. The cut wood has a pinkish or yellowish tint and exhibits annual rings of varying thickness.

- Quite durable, soft wood with low weight;

- Good heat saving properties;

- Durability of structures;

- Releases a pleasant and distinctive resinous odor when heated.

Disadvantages of spruce logs:

- Quite significant shrinkage, which over time can provoke the appearance of deep cracks;

- The trunks are not as straight as those of pine;

- Many branches and twigs;

- Abundant content of resins that are released to the surface for a long time.

Comparative analysis

The thermal conductivity of the materials is approximately the same. In spruce, due to the higher air content in the wood, this figure is slightly higher. But pine walls can be much thicker, since the diameter of the tree trunks of this species is larger.

The durability indicators of spruce are lower due to high moisture absorption, which can provoke the occurrence of fungi, mold, and rotting. The resin content in its wood is lower, and, accordingly, their release into the atmosphere is also lower.

On a note! The evenness and smoothness of the trunks greatly simplifies the processing of pine. The difficulty of working with spruce is due to the knotty nature of the species, but this is compensated by the high decorative qualities of the log house.

Both types of wood darken in approximately the same time, but pine untreated with special compounds gradually acquires a more intense brownish-red hue. This problem can be solved by installing decorative cladding or using special impregnations.

Important! Wood treatment compositions must be safe for health, not melt when heated, and not emit odors or toxic substances!

The ability of spruce to absorb and remove moisture outside causes greater “dryness” of bathhouse structures than those made of pine, which is at the same time subject to “blueing.”

The price of both types of wood is approximately the same, and they can be easily combined provided that healthy raw materials are chosen and the logs are prepared correctly. For example, pine is the optimal material for constructing lower crowns exposed to strong humidity, and spruce is ideal for constructing the upper part of walls, since it has high heat-saving and decorative qualities.

Selection of materials for different rooms

The microclimate of different rooms in the bathhouse is not the same, so you need to choose the material for the cladding, taking this circumstance into account.

Waiting room

The temperature in the rest room does not rise to critical levels and the humidity in this room is low. Therefore, any type of wood is suitable for finishing the dressing room.

Here you can save money by using low-price material:

Pine . This wood has a beautiful pattern and a pleasant shade, so it can be used to create coziness. The shade of pine wood is light pinkish, and becomes deeper over time. Scandinavian pine is particularly durable, although its cost is much higher than domestic ones.

Spruce . Linings and boards made from this wood undergo heat treatment during production, which gives them moisture resistance and strength. Spruce exudes a subtle, pleasant aroma and does not emit a lot of resin, like pine.

Washing

The washing room is most often located in front of the steam room, so it has a comfortable temperature. But it contains high humidity, so the materials are subject to special requirements regarding moisture resistance.

Often the walls are sheathed with larch - a stable, moisture-resistant material that dries quickly and does not deform.

Steam room

This is the most problematic place in the bathhouse. Because of the high temperature, you shouldn’t use conifers there, and because of the high humidity, deciduous trees will rot there, but if you don’t take too much care of them.

The best materials for a steam room:

Alder

Its cognac aroma and noble shade will delight you with its aesthetics and impeccable operation. Over time, the aroma becomes even more noble, and the shade also pleases with its nobility. But it will be difficult to buy smooth alder cladding, and it will cost a lot.

Linden

It has an excellent aroma, but its white surface forces you to handle it very carefully, not to pollute it, for example, with brooms and various infusions, essential oils - it is very easy to stain it, but it is difficult to wash it. Linden is chosen by connoisseurs of its subtle healing aroma and very careful bath attendants and steamers. Linden is an excellent option for those who like fairly high vaping temperatures, since its surface is not able to heat up.

Aspen

Ideal for the steam room, although it has a slightly bitter aroma. Aspen has long been considered the material that drives away illness and disease, as well as bad thoughts. This is a real healing tree.

Ash

Sometimes the finishing of the bathhouse is made of ash. The material looks expensive and noble, the texture is dense and beautiful.

Larch

An excellent option for finishing a steam room. But processing it is difficult, the structure easily splits. But it contains gum, thanks to which the lining is maximally resistant to humidity and has high thermal insulation parameters for the room.

Cedar

It is distinguished by soft and ductile wood, can be processed with ease, and is extremely beautiful. The high value of cedar is its special smell and amazing effect on the body.

Advice! For additional strength, the wood used for steam rooms and washing rooms can be heat treated. The material prepared in this way is more resistant to a humid environment, resistant to fungal diseases and takes on a chocolate-brown hue.

Technological features

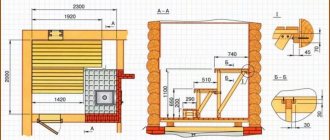

Bath floor: which boards to use is only the first question. The next task is to choose its design. In practice, 2 options are used:

- Leaking variety. In it, the boards are laid with a gap through which free flow of water from the floor surface is ensured. This lattice system is considered traditional for a Russian bath. The drainage in such a design is produced directly into the ground under the bathhouse or collected underground by a drainage system and then discharged into special collectors outside the building.

- Leak-proof design. In this case, the boards fit tightly to each other, and additional waterproofing is provided to prevent water from seeping through the flooring. For such a system, tongue and groove boards are most suitable. The water drains through special drain holes, and the floor itself is made with a slope in the direction of these holes.

Thus, the question of how to lay the floor in a bathhouse from boards is decided taking into account the choice of design. In other words, the boards can be installed with a gap of 2-5 mm or fitted closely, sealing the joints.

Structurally, both options differ precisely in the way the boards are placed. The structure of the wooden floor itself is similar. Its installation is carried out in the following order:

- Leveling and compacting the soil. Backfill the cushion with sand and crushed stone with a compaction 10-12 cm thick.

- Laying roofing felt waterproofing.

- Installation of logs from wooden beams measuring at least 40x40 cm. The installation step is 40-65 cm, depending on the size of the room. Installation is carried out with the formation of a slope towards the drain holes.

- Laying or backfilling thermal insulation between joists. Expanded clay is usually used for this purpose, but mineral wool also works well. Do not use foam that can release harmful substances when heated. Then another layer of waterproofing and a vapor barrier with a foil layer are laid (for the steam room).

- After completing the formation of the base of the floor, rough flooring from boards can be applied, which increases the strength of the structure. However, this element is optional. In principle, the finishing board covering can also be attached directly to the joists.

The floor in a bathhouse made of boards has long been considered a traditional design. If all work is carried out correctly and protective measures are taken, it can last a long time even in extreme steam room conditions.

It is important to choose the right type of wood and carry out the necessary preparatory work