The chimney is considered one of the most complex roof components in terms of design. The product must be sealed using a modern, reliable chimney seal. To isolate smoke exhaust channels, asbestos, roofing felt, cement and bitumen solutions are used. But more and more dacha owners prefer the elastic “Master Flash”.

What to consider during work?

Finishing smoke exhaust ducts involves creating a flashing or apron from rectangular sheets of metal. The width of the products is 40 cm, and the length corresponds to the size of the pipe. The plates need to be bent, focusing on the angle of movement of the smoke. To calculate the length of the finish, it is worth considering:

- chimney size;

- the angle that the slope has;

- type of roofing.

Tiled roofs or structures covered with corrugated sheeting are connected using the standing seam technique. Pitched roof structures require a special “side” made of wooden beams, which prevents exposure to weather factors.

Possible problems with poor-quality sealing of the roof passage

Corrugated sheeting is a high-quality roofing material that has a complex layered structure. The following layers are applied to the outer steel sheet base:

- zinc;

- additional anti-corrosion;

- primers;

- polymer (polyester);

- installation protection.

And on the inside, galvanization, primer and corrosion protection are also applied. Thanks to this structure, corrugated sheeting has excellent load-bearing capacity, protection from rust, fire and rot. The building material retains its properties over a wide temperature range.

It is customary to create various openings on the roofs of houses for ventilation and smoke escape. This naturally leads to damage to the waterproofing and other protective layers. Therefore, sealing the joints between the pipe and the roof surface is of great importance. This process must be carried out correctly, otherwise problems may arise:

- Leak. When the pipe is routed through the roof, the presence of uninsulated cracks leads to the penetration of water into the house, living quarters, dampness of the walls, including load-bearing ones, the appearance of mold, etc.

- Destruction of rafters. The roof structure consists of wooden rafters. Moisture entering through the joints contributes to the rotting of the wood and the destruction of the entire structure.

- Corrugated sheeting corrosion. Although the roofing material is protected by anti-corrosion layers, the internal protection is weaker than the outer layer. Corrosion gradually destroys corrugated sheeting, reducing its protective characteristics and attractive appearance.

- Reduced roof insulation level. When water penetrates into the layers of thermal insulation, the latter lose their ability to retain heat and protect from external cold. The insulator loses about 50% of its ability to effectively retain warm air in residential areas.

To be sure of the quality of your roof, you should seal the joints in a high-quality manner. Various sealing methods have now been developed that allow high-quality waterproofing of the gaps between the pipe and the flooring.

Traditional sealing materials

When purchasing a chimney lining, you should focus on the type of material from which the chimney is made. Experts advise working:

- roofing bricks. Durable boards are resistant to temperature fluctuations and the influence of aggressive environments. Solid bricks are laid on a cement mass, and the seams are treated with grout;

- clinker tiles. The tiles are lightweight, which is ideal for tall chimney structures;

- plaster. The inexpensive cost of the mixture makes it accessible for construction work on a small budget. The loose texture of the composition requires reinforcement with a cement screed or cement-lime paste. Additionally, the applied and dried mass is coated with silicone compounds;

- slabs made of cement fibers. Small plates are characterized by strength, resistance to ultraviolet radiation and climate change. Eco-friendly, non-flammable material with a smooth or structured texture due to its low weight is easy to install;

- slate. The natural material is suitable for cladding the roof or chimney. In addition to sealing, rectangular, flake or octagonal panels create an attractive pipe decor.

When choosing the type of material for self-sealing, give preference to steel sheets - they are characterized by strength, ductility and ease of use.

Features of making a steel apron

A steel apron is applied to a plank roofing deck covered with liquid or sheet roofing felt. Measures to organize compaction include:

- bending the edges of the apron onto the walls of the chimney structure;

- laying timber sheathing at the beginning and end of the pipe;

- placing tiles on top of the sheathing;

- cutting a groove on the wall of the pipe - the upper part of the apron is placed in it;

- fastening steel frame elements to pipe walls. They start working from below;

- filling the grooves with the upper part of the apron with roofing silicone or a special sealant.

It is recommended to seal the roof hole when installing a chimney.

Roll insulation

To seal large-diameter and square-shaped pipes, roll insulation reinforced with aluminum strip is produced. It has its own installation nuances:

- the material must be cut 30 cm larger than the diameter of the chimney in order to secure it with an overlap;

- when gluing the insulation, it is necessary to bend it so that the edge extends onto the chimney to a height of about 5 cm;

- After finishing the formation of the edges of the rolled insulation, it is necessary to secure it with a special silicone glue. The fasteners are reinforced with small screws.

After fixing the insulation, it can be painted in the color of the roofing sheet. The speed of construction is ensured by innovative material - “Master Flash”. Special penetrations made of elastic rubber are characterized by a long service life and resistance to aggressive environments.

Waterproofing a square chimney pipe

From a technological point of view, for the correct organization of work with your own hands, what is important is not the nature of the roofing material - metal tiles, ondulin, but the cross-section of the chimney - rectangular or round.

Waterproofing the chimney is carried out together with laying a waterproofing membrane on the roof.

- The film web in this area is cut so that the material overlaps the chimney. The film is glued to the walls of the chimney using polymer-bitumen mastic.

- A layer of bitumen mastic is again applied over the tightly pressed edges of the membrane. This waterproofing is already quite reliable, but is not very durable.

- A sheathing under the apron is fixed on top of the membrane - the second waterproofing element on the roof. The distance between the wall and the slats is 5–10 cm. It is recommended to treat the bars with fire retardants.

- An apron is installed around the chimney, starting from the bottom element. The apron is located 10–15 cm above the roof and covers an area of 20–30 cm around the perimeter of the chimney. Fastening - dowel-nails in increments of 15–20 cm.

- The joints between the elements and the chimney are treated with heat-resistant sealant.

- Then the roofing material is laid over the lower apron. Roof elements made of metal tiles or ondulin are laid end-to-end, making sure that the gaps are as small as possible.

If we are talking about a roof made of corrugated sheets, then a hole is formed in the sheet under the chimney with dimensions 1.5–2 cm smaller than the parameters of the chimney. Cuts are made in the corners of the hole, and the edges of the sheet are carefully folded back. At the stage of laying the roofing, this fragment is put on the chimney and the bent edges are aligned, trying to reduce the joints to a minimum. For waterproofing, a special device is used, such as bitumen waterproofing tape, or roofing felt and water-repellent sealant.

- A metal upper apron, similar to the lower one, is mounted on top of the roof made of corrugated sheets, metal tiles and other materials. You can use adhesive materials like Wakaflex, Master Flash, Onduflesh, etc.

In the photo you can see the installation of an apron around the stove chimney on the roof.

Waterproofing of a round chimney

This need arose due to the widespread use of sandwich pipes, which are very practical and more affordable. It’s even easier to do it yourself, since here the waterproofing is provided by a special device - pipe penetration.

The penetration looks like a box made of steel or aluminum with a cap made of polymer material.

- A wooden sheathing is installed around the chimney, just as was done in the previous case. Roofing material is laid.

- A hole with the required diameter is cut out in the flexible polymer part of the penetration. The device is put on the pipe and pressed against the roofing material.

- The joints are treated with a special heat-resistant sealant. The penetration is secured with self-tapping screws to the sheathing in increments of 7–10 cm.

The video discusses the waterproofing of round and rectangular pipes.

"Master Flash" - a new word in chimney sealing

“Master Flash” is an elastic seal that seals the joints of the chimney and roofing material. It is a rigid base made of silicone or rubber with rings of different diameters in the upper part. To strengthen the product, an aluminum gasket is used.

Difference between rubber and silicone materials

The chimney cover has the shape of a cone and an angle of inclination depending on the roof slope. Cones with an angle of 90º are used for flat roofs. The pitched roof covering is sealed with a roof with the rings protruding at 45-30º. Silicone or EDPM rubber is used to make the seal. The raw materials differ in their qualities:

- Silicone cones are more elastic. When exposed to temperatures up to 315 ºС, they are destroyed under the influence of ultraviolet radiation;

- rubber melts at temperatures above 185 ºС, but is resistant to ultraviolet radiation.

The cost of the “Master Flash” design is affected by the material and diameter of the product.

Material advantages

The modern design for sealing the chimney has a number of advantages:

- elasticity, which ensures a tight fit of the pipe to the material;

- resistance to temperature changes, which is especially good in regions with harsh climates;

- fire resistance (preservation of its qualities at temperatures of 185 – 315 ºС depending on the type of material);

- long service life - about 30 years;

- does not require special skills, effort or specific tools for installation;

- can be installed at any time of the year.

The use of the Master Flash sealing structure eliminates the need for additional use of sealing materials.

Tips on how to choose

Heating equipment and chimneys are a very important and unsafe part of the home’s engineering. The life and health of residents depends on their serviceability. Therefore, it is not worth saving on heat-resistant sealants. It is best to buy materials from well-known brands and in large stores with a receipt.

Silicone is expensive and is sometimes counterfeited. If you purchased several bottles, you can squeeze out a little polymer from one, wait for it to cure and set it on fire. Silicone is difficult to burn and will produce a mixture of black and white soot (hydrocarbons and silicon oxide). A fake (most often acrylic polymers and PVC are used) will burn and release black soot.

It is also worth mentioning that heat-resistant sealants for stoves and chimneys are sold in tubes for a construction gun. If sellers recommend polymer in regular tubes, know that most often this is a sealant for cars, it contains acid and is completely unsuitable for heating equipment and chimneys, so before purchasing, carefully read the labels on the packaging.

When choosing, be sure to read the label. The operating temperature must correspond to the operating conditions; this is the most important criterion for choosing a heat-resistant sealant for a chimney. The sealant must be neutral, not acidic.

Popular brands

Popular brands of heat-resistant sealants are the Baltic Penosil (silicate, 1500 °C), the Belgian company Makroflex (silicone, 260 °C), the Belgian brand SOUDAL C (silicate, 1500 °C), Kraftool (silicate, 1500 °C), the domestic “Moment” Germent" (silicone). You can also mention affordable brands of silicate compounds BAUMASTER and TITAN (Selena Group).

approximate price

Below is information on how much the most common brands of heat-resistant polymers cost. Silicone polymers are much cheaper than silicate ones.

Installation Features

A modern type of seal does not require specific knowledge in the field of construction; it is enough to follow the installation instructions:

- The top of the rubber cone should be 20% smaller than the diameter of the pipe, so if there is excess, it needs to be trimmed (for convenience, you can use scissors with a hooked end);

- Installation is carried out by pulling the structure onto the pipe. To make it easier to move along the chimney, it is recommended to moisten the cone with water or lubricate it with soap. You should pull while holding the top to avoid deformation of the base.

- The base, reinforced with aluminum sheet, is inserted under the nearby edge of the roofing to prevent moisture from entering the structure;

- The junction of the upper edge of the rubber cone with the pipe must be thoroughly coated with sealing compounds for additional strengthening. Instead, you can use a metal clamp.

For additional fixation of the structure, you can screw the base to the roof, using rubber washers to seal the holes. After installation, the device remains movable, which gives an advantage when the pipe expands during the heating process.

When is it necessary to seal a stainless steel chimney?

It is imperative to seal the joints between the pipes at the chimney assembly stage. This needs to be done for several reasons:

- Smoke will enter the room or attic through the cracks. The combustion products it contains can cause poisoning to people in the house.

- If the system is not sealed, cold air will be able to penetrate inside the pipe (the problem is especially acute in winter). This, in turn, will lead to the appearance of condensation, which can destroy even stainless steel.

- Smoke entering through cracks can cause a fire.

Sealing may also be required during operation. If the method or material for sealing was chosen incorrectly, the work was performed poorly or not at all, then over time the chimney will need to be repaired and sealed.

Selecting a seal

To choose the right modern roofing seal for the Master Flash chimney, you must be guided by the following data:

- To seal a chimney located on a pitched roof with a slope of 10-45 degrees and covered with roofing steel, bitumen shingles, and plastic, sealing structures with a flexible square or round base are used.

- in the case of a roof slope from 45 to 60 degrees, seals with a reinforcing strip of aluminum are used.

- if the roof slope is more than 60 degrees, “Master Flash” models with an increased base area are installed. Such structures are also mounted on roofs covered with slate or tiles.

- When installing, it is worth considering the physical properties of silicone and rubber. Silicone structures are completely resistant to any changes in temperature, unlike ethyl-propylene rubber, which has an upper limit of tolerance to high temperatures of +140 degrees.

For cases where it is not possible to put a sealing structure on top of the chimney, models with a side lock have been developed. Roofing using Master Flush seal around the chimney provides reliable protection against water leakage into the pipe openings. It is possible to install modern insulating material yourself, without the involvement of specialists.

Can it be sealed with cement?

Previously, cement was used for sealing due to the lack of other materials and solutions. Currently, cement is used only to seal cracks in the roof where the chimney exits. Yes, and then only in cases where the house is covered with slate. To ensure good performance, asbestos is added to cement.

It is better not to use cement to seal joints along the entire length of the chimney. Due to temperature changes, it can crack and quickly lose its properties. It is better to give preference to modern materials that are designed specifically for sealing chimneys and use at high temperatures.

We use sealant for threaded connections

The simplest way is to use thread sealant, which is sold in tubes of various capacities and does not require additional preparation for use. This is a substance that is applied directly to the pipe threads or to the winding (additional fibrous material, such as linen).

It fills well all the formed internal cavities and, after drying, forms a barrier to leaks. The main disadvantage is that subsequent analysis is not expected. If the joint still needs to be disassembled, then when reconnecting it, it will need to be cleaned and resealed. Technically, this is not difficult to implement, but it takes time and having the appropriate components on hand.

Sealants that are applied directly to the surface are also called plumbing glue, despite the fact that its adhesive properties are not very pronounced. The winding version is considered more reliable, since the fibers swell over time and completely close the gaps.

Watch the video: methods of sealing threads

How to seal plumbing threads: flax, fum tape, thread, anaerobic sealant

Watch this video on YouTube

Preparation of pipe surfaces for sealing: washing, degreasing, drying. The cleaner they are, the more reliable the adhesion to the metal will be. Applying material to the thread at the site of the future connection. It must be continuous and performed immediately before assembly. A pause that is too long can negatively affect the quality of the joint. Different manufacturers have their own time settings, and you need to familiarize yourself with them in advance.

It is important to apply a sufficient volume of anaerobic so that it can fill the entire internal space (glue the threads to each other). Reliable connection pulling

Of course, manual force will not be enough, and in all situations you need to use wrenches. Excess sealant can be removed from the pipe immediately. Waiting for the specified time necessary for hardening and gaining the desired properties. Information is indicated on the packaging, and, as a rule, basic polymerization requires 15-30 minutes. Complete hardening and set of operational properties takes several hours. After this, tightening the nut is not allowed, since any displacement will affect the sealing parameters.

The entire cycle of applying an anaerobic sealant to threaded connections takes little time and is suitable for independent use at home. The nozzle on the tubes simplifies the task and avoids contamination.

A specially developed classification determines not only the operating temperature (for heating and hot water supply) and the permissible pipe diameter, but also the force that must be applied to separate the joint - weak, medium or large. The latter type is recommended for use on pipes with a diameter greater than 2.5 inches and the use of preheating during dismantling.

Overview of species

For a profiled sheet, depending on the type of its profile, a different seal is required. It is worth clarifying that any sealing materials under the ridge are moisture-resistant, fireproof and noise-reducing. Each type of seal has its own characteristics.

Universal

The universal option is used most often due to its affordable prices and ease of use. This seal is made from a synthetic substance based on polyurethane.

With the right size, the universal type can create low air resistance, which will be an excellent solution for insulated roofs.

Profiled

The profile version of the insulation is good only if the profile is at least 5 centimeters high. To create a seal, polyurethane foam is also used, but only modified. The strength of this material is higher. The profiled look is distinguished by precise shapes. It also has special holes that allow air to pass through.

Self-expanding

Self-expanding sealing tapes have appeared recently and are quite expensive. Their distinctive property is that during the process of attaching them to the ridge, their dimensions increase. This way, all gaps remain well filled. Self-adhesive tape applied to one side makes installation of such a seal extremely simple. This insulation is made from compressed polyurethane foam impregnated with a solution of polyacrylates.

Equipment

To seal the roof of a chimney on the roof, using the flush master itself is not enough. In addition to it, as already mentioned, the kit includes a special amplifier frame for the base. Also, some manufacturers of chimney passages through the roof equip their product with individual fasteners. As a rule, they are not included in the price.

Description

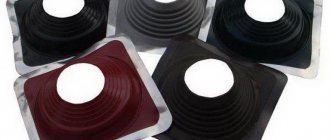

Roof chimney seal.

Universal silicone seals (Master-flash) are designed to seal the hole in the roof where the chimney passes and ventilation.

Roof seals are made of aluminum and special silicone. For installation on profile surfaces (tiles, ondulin, corrugated sheets, etc.), the silicone skirt ensures a tight fit to the roof surface. A flexible aluminum base (size 600x600) helps to repeat the shape of the profile, and silicone sealant, applied during installation, ensures good sealing.

Due to their universal design, flexible seals are mounted on roofs with any angle of inclination. The seal is intended for installation on insulated pipes with an outer diameter of 180 mm or more. The main colors of the seals are red, chocolate, black, gray, green.