A phenomenon such as convection, translated from Latin, means “transfer”. When there is a temperature difference between two bodies, heat is transferred from the hot body to the colder one. One of the places where you can observe such laws of physics is a bathhouse.

For many years, the sauna has been considered one of the most popular relaxation areas. In order for this wonderful place to perform its functions to the maximum and efficiently, it is important that in the steam room:

- the air heated up quickly and evenly, without drying out;

- the room warmed up well below and above;

- the steam was hot and light.

This is the only way to feel all the invigorating and healing power of the bath.

Basic requirements for sauna stoves

Since a sauna heater is a structure that bears a significant functional load, it is subject to serious requirements:

- Greater heating capacity so that the air temperature under the ceiling reaches 95°C, and near the floor – at least 45°C. At the same time, the stove should allow you to change the temperature to the desired parameters and be an economical device.

- Compactness, thanks to which people can comfortably perform water procedures, move freely, and avoid accidentally touching hot surfaces.

- A sufficient volume of heated water in accordance with the number of members in the family and the average consumption per person is approximately 15 liters.

- High tightness of all elements so that gas and smoke do not penetrate into the premises.

- A thoughtful design to ensure long-term preservation of the heat that is accumulated by the stones.

Taking into account all the requirements, the choice of a finished stove or its construction is carried out with a creative approach to the process. Indeed, thanks to the efforts of engineers, heaters of different sizes and designs have been developed.

One of the stove size options Source kamin.website

Top 3. TMF Skoroparka 2012 Inox Lumina

Rating (2021): 4.55

Convenient maintenance The design of the oven allows easy access to all its internal parts, so there will be no problems with cleaning and maintenance.

- Characteristics

Average price: 24,500 rub.

- Heated volume (cub.m): 18

- Dimensions (D/W/H): 92/51/71 cm

- Construction: floor

- Weight (kg): 76

Any heater, especially one powered by wood, will sooner or later require maintenance. It is necessary to clean and maintain the device in order for it to work for a long time. This is often not easy to do, but not in this case. Here the manufacturer took care of convenience, making the design such that you can easily access all internal parts. This is a heater, but a closed type. However, it can be used without the top cover. The body is collapsible, divided into three parts. The firebox is removed separately, and a spacious box is used to receive ash.

Advantages and disadvantages

- Easy maintenance

- Spacious ash drawer

- Can be used as a closed heater

- Very large firebox window

- Not the highest performance for its size

- Difficult manipulations when changing the burner

Types of construction

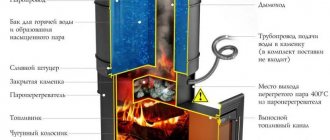

Some owners of private residential buildings believe that a heater is a stove made of stones. This is a wrong opinion because they are present in the design only in a certain place. Special stones are loaded into the stove so that they heat up, and when water hits them, steam is formed.

Heaters are usually built from bricks. Metal is also used. Steel options are sold ready-made. They are also manufactured according to individual drawings. Less time is spent on equipping bathhouses with metal models. Most often, the steel version is purchased ready-made and installed in the desired location.

On a note! The metal model is a sauna stove, the dimensions of which are usually smaller than the dimensions of a brick heater.

Options for metal and brick sauna stoves Source obustroeno.com

Pros and cons of a metal stove

A metal heater is made by welding. In its design, above the firebox, just like in a brick stove, there is a container for laying stones. Cast iron is not used in production, as it cracks when exposed to water. The advantages of a metal heating device include:

- a large number of ready-made options;

- low weight, usually not exceeding 50 kg;

- quick warm-up, which is usually completed in a maximum of one hour.

The disadvantages of a metal bath heating device include the possibility of installation in a building with an area of no more than 25 m2. The disadvantage is also the uneven heating of the bath, an increased level of fire hazard, and rapid cooling upon completion of the combustion process.

Advantages and disadvantages of a brick stove

A brick-built heater in a bathhouse is the most popular type of heating structure. It is chosen by all those who like to take a steam bath in accordance with Russian traditions.

Brick sauna stove Source ad-cd.net

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

The advantages of brick construction include:

- high degree of fire safety;

- maintaining heat for a long time;

- easy operation, since there is no need to add firewood during washing;

- ability to heat a large sauna;

- no contact of the special stones used with combustion products;

- uniform heating of the room.

The disadvantages of such a heater include the large size and weight of the structure. Therefore, a brick foundation for the stove must be created, and the need arises for choosing the right location for the heating device. It is determined during the design of the bath.

The downside is also the pre-heating of the heating device, which can last, for example, 5 hours. In addition, brick structures are difficult to clean and construction cannot be completed without special skills. Therefore, most people turn to specialists for help.

Professionally installed brick stove Source blogspot.com

Top 2. Vesuvius LEGEND

Rating (2021): 4.79

The most reliable stove A completely cast iron heater that is not afraid of the highest temperatures. The most reliable and durable design.

- Characteristics

Average price: 43,500 rub.

- Country Russia

- Heated volume (cub.m): 18

- Dimensions (D/W/H): 70/56/69 cm

- Construction: floor

- Weight (kg): 90

Cast iron is a derivative of iron. The material is durable and has good thermal conductivity. It retains the accumulated heat for a long time, so it is ideal for the production of stoves. But it has disadvantages, such as high cost, heavy weight and low aesthetic appeal. It is because of these shortcomings that cast iron is increasingly being replaced by ordinary metal and steel. But there are stoves that are still produced using old technologies. One of them is now in front of us. A real work of art by blacksmiths. The vat is made of cast iron, so it will never burn out or be warped by high temperatures. True, and the price is appropriate. But such a stove is unlikely to have to be changed even after ten years.

Advantages and disadvantages

- Cast iron boiler

- Openwork forged firebox

- High strength

- Small ash box

- High price

Stoves with open and closed heaters

Sauna stoves come with open and closed heaters. The first option is mainly used in small buildings. An open-type oven can heat a small steam room in a short period of time. However, after water gets on special stones, the heating device quickly cools.

Stoves with a closed heater are equipped with a steam door, which is located at the level of special stones. In such models, it is in the closed position when fuel combustion occurs. The door is opened if it is necessary to speed up the heating process of the room and increase the amount of steam in it. Models with a closed heater are always heated several hours before using the sauna. Such devices are able to retain heat for 2 days.

There are also stove options with both a closed and open heater. Source teplozhar.ru

Model ratings

The main purpose of heaters is to heat the bath room and create a comfortable microclimate in it. But the models may differ in shape, appearance, and characteristics. Therefore, it is worth considering the best units, selected based on ratings and customer reviews.

The best wood-burning stove for a sauna

The Vesuvius Skif 22 model is popular among consumers. From the main characteristics:

- power - 22 kW;

- unit dimensions (width, height) - 560x740 mm;

- built-in “clean glass” system, so virtually no soot settles on the heater.

Vesuvius Skif 22 is a popular stove model.

Price - from 17 thousand rubles.

A good model is “Kastor KARHU”. The outer body and door are made of steel alloy. From the characteristics:

- weight - from 30 kg;

- Sauna volume (cub.m.): 8 – 40

Kastor KARHU is a popular stove model.

The cost of equipment is from 43,000 rubles.

“Sauna stove GFS-ZK in mesh 18” is a cast iron unit. Key equipment indicators:

- The volume of the steam room is 18 m³;

- Efficiency - up to 87%;

- Recommended weight of stones: 140 kg

Hephaestus GFS-ZK in grid 18 - cast iron stove for a bath.

Price - 56 thousand rubles.

The best electric stove for a sauna

A good device is the Mini Cirrus Rock 2 CRR2-30NS-P. Among the main equipment indicators:

- weight of stones - 46 kg;

- sauna volume - 2-4 cubic meters;

- power - 3 kW;

The unit is equipped with a remote control, the price of the device is from 34 thousand rubles.

A good model, according to consumer reviews, is Harvia Vega Pro BC-165. Main characteristics:

- power - 17 kW;

- weight - 15 kg;

- dimensions - 435x640 mm.

The cost of the unit is about 50 thousand rubles.

Harvia Vega Pro BC165 is a stylish and efficient electric oven.

A reliable model is the Harvia Cilindro PC70F electric oven with a built-in remote control. The characteristics include:

- dimensions - 360x930 mm;

- power - 7 kW.

You can purchase the design from 37 thousand rubles.

Harvia Delta D36E is popular. From the characteristics:

- power 3.6 kW;

- dimensions - 340x635 mm;

- weight - 8 kg.

Harvia Delta D36 is a compact electric heater.

Price - 19 thousand rubles.

Best steel stove

The Kalita Druzhina model has positive reviews. The volume of the combustion chamber is about 40 liters. The unit is designed for bath rooms up to 16-18 cubic meters.

Advantages:

- laconic style;

- ease of use;

- light weight (can be easily moved around the territory).

However, the working surface does not allow the device to be used in a large room. The model hums when wood is actively burning.

From a pro's point of view

Cast iron wood burning units are chosen from the following: Harvia, Kastor, Hephaestus, IKI, Feringer

From a hobbyist's point of view

Users like the following cast iron bath models - “Hephaestus”, Harvia, Koster.

From the point of view of undemanding vapers

Undemanding or inexperienced steamers prefer cast iron wood-burning structures Hephaestus, Feringer, IKI From steel units - Harvia, Helo

Electric oven Harvia Vega Compact BC35 Steel, built-in remote control included

The best sauna stove with a water tank

There is no universal model. According to user surveys and calculations using a separate method, the Harvia 20 RS PRO was recognized as the best stove with a water tank. This is a compact, simple, easy-to-use model. It is no worse in build quality and features than other premium analogues.

The loading of stones inside reaches 40 kg. The unit has a built-in heat exchanger. The chimney is made as a labyrinth, which increases efficiency.

The best stove for a bath with a heat exchanger

The unit from the economy class line is “TERMOFOR VITRIVIA”. The package includes a heat exchanger.

The model is distinguished by its complete set and low price. Creates a moderate indoor climate. The water does not boil, but remains hot for a long time.

The disadvantage is that the stones heat up slowly.

Stove location

The heating device is placed in the bathhouse in such a way that the structure can heat all rooms of the building. Usually the front wall of the heater with the combustion door and ash pan is located in the dressing room.

The choice of a finished device or the calculation of a stove for a bath during design is carried out taking into account the area of the steam room. If no more than 2 m2 is required to place a heating device, it is often installed in a specially created niche.

Heater stove in a specially prepared niche Source sdelaikamin.ru

This arrangement makes it possible not to expose the front wall of the device with the combustion door and ash pan to the dressing room. In this case, the stove will have to be heated from the steam room. This option is used when it is necessary to reduce heat losses and there is no need to heat other rooms in the bathhouse.

Brick stove foundation

In order to safely use a heating brick structure in a bathhouse for a long time, a foundation for the stove is always created first. It must be carried out in the form of a separate structure if the weight of the heater is more than 700 kg. In this case, the distance between the foundation of the bathhouse and the stove should be at least 0.5 m.

To avoid mistakes, it is better to entrust the construction to a master from a specialized company. Typically, specialists perform work in the following sequence:

- Dig a pit with a depth below the freezing point of the soil, but not less than 50-70 cm.

When determining the width and length of the pit, the size of the sauna stove is taken into account. The pit around the perimeter is 10-15 cm wider than the heater. The increased size of the pit allows for free installation of the formwork.

Pit for the foundation of the stove Source sdelaikamin.ru

- Pour sand into the bottom of the hole.

The sand cushion is watered to compact the layer. Then sand is added so that its thickness at the bottom of the pit is 15 cm.

- Pour broken bricks onto a compacted sand layer. Stones are also used.

The second layer is also compacted. To eliminate the free space between the stones, sand is used, which is compacted with water. Typically the thickness of the 2nd compacted layer is 25 cm.

- Fill in crushed stone and compact the third layer.

- Install the formwork.

4 cm thick boards are used for the box. When determining its internal dimensions, the width and length of the furnace foundation are taken into account. The upper edge of the wooden box is placed at the level of the subfloor of the bathhouse. The formwork is securely fixed in the pit.

- Install the reinforcement frame inside the box.

The distance between it and the formwork walls is usually 5 cm.

- Concreting is carried out.

The poured solution is compacted using steel reinforcement. A wooden block is rarely used. The concrete surface that has not yet hardened is leveled along the edge of the formwork.

Poured and leveled foundation Source fishki.net

After the solution has cured, the formwork is removed. The concrete surface is covered with tar in two layers. Then the free space between the concreted area and the walls of the pit is filled with gravel or sand. Then the foundation for the sauna stove is covered with polyethylene. It is left in this state for a week.

More information

You may also find the following materials about stoves useful:

- Inexpensive;

- Installation;

- Installation of metal;

- Installation in a steam room;

- Cast iron with closed heater;

- The best are cast iron.

***

Well, we dare to hope that through joint efforts we will find the objectively best stoves for a Russian bath and help everyone who is still deciding on their choice.

Masonry stove-stove

As soon as the foundation for the stove in the bathhouse gains strength within 21 days, masonry work begins using smooth fired bricks without cracks or chips. It is recommended to give preference to ceramic refractory blocks when constructing the external contour of the heating device.

When installing the firebox, only Sh5 fireclay bricks are used. This material is, if necessary, cut to the required dimensions. It can cool down quickly. At the same time, fireclay does not accumulate heat. That is why it is not used for laying the stove itself.

On a note! To avoid mistakes, many stove makers first lay the bricks dry with small gaps. Professionals also use different types of special mortar for the construction of the combustion zone and external masonry.

The masonry process itself is a complex stage in the construction of a stove. To perform it correctly, a large number of subtleties must be observed. Therefore, the work is trusted only to experienced stove makers.

Features of the firebox and ash pan

During the construction of the stove, it is important to correctly determine the size of the combustion zone, taking into account various nuances. Be sure to take into account the need to install a collector for heating water and the type of fuel used.

The depth of the firebox is determined individually. If this size is 80 cm, then 55 cm of this is used for loading standard length firewood, and 25 cm is used for the water heating system. The width of the combustion zone can be 40 cm, and the height – 35 cm. A firebox of such dimensions allows you to load 8-10 standard logs at a time.

Fuel combustion products are removed from the sauna stove through the ash pan. The blower also allows you to collect ash. In addition, air necessary for the combustion process enters the combustion zone through them. To regulate the rate of fuel combustion, an ash pan or a special valve is used. If it is necessary to quickly heat the bath rooms, it is recommended to completely open the air passage.

Briefly about the main thing

Before calculating a stove for a bath, you need to decide on the type of structure. After all, it can be with an open or closed heater, completely metal or lined with refractory bricks. In this case, it is necessary to provide for high thermal performance, tightness and long-term heat retention by the stove.

Metal heaters are available for purchase in finished form. They weigh less than brick ovens. At the same time, steel structures heat up faster, but they heat the bath unevenly. Brick heaters are built on a foundation.

Regardless of the type, the stove in the bathhouse must provide heating to all rooms. Its design includes a firebox and an ash pan. Often the wall with their doors is located in the dressing room.

Ratings 0

Top 1. Harvia M2

Rating (2021): 4.87

Best value for money High-quality closed-type heater with a long service life and easy operation.

- Characteristics

Average price: 24,800 rub.

- Country: Finland

- Heated volume (cub.m): 13

- Dimensions (D/W/H): 71/39/43 cm

- Construction: floor

- Weight (kg): 54

In the modern world, everything is possible. Even a Russian sauna with a Finnish heater. Harvia M2 is the best stove in terms of price-quality ratio. It is very reliable and will last for many years, which more than compensates for its not-so-low price tag. The design is thought out to the smallest detail, although some users have problems with the ash pan. However, this is a matter of habit and does not affect the technical parameters in any way. Otherwise, an excellent iron stove with a wall thickness of up to 8 millimeters. The firebox is equipped with a panoramic door, so you can also enjoy the beauty of an open flame. And the rear exit of the chimney will not interfere with the supply of steam, spraying the stones.

Advantages and disadvantages

- Robust design

- Thoughtful form factor

- Laconic but stylish design

- Rear chimney outlet

- Not the most convenient ash drawer

- Relatively high price

See also:

- 12 best brands of sauna stoves

to the beginning of the rating