The starting material for the construction of Turkish baths (hamams) are structural, heat-insulating panels . There are two types of rigid foam polystyrene " LUX ELEMENTS " Germany - there are NO other analogues, extruded polystyrene "WEDI, RUS PANEL, A-PANEL..." Germany, Italy, Russia.. They are similar in their physical properties, they differ in the country of origin and the manufacturer , and accordingly the pricing policy.

Based on extensive experience in the construction of Turkish baths (hamams), our installation teams prefer to work with panels made of foamed polystyrene “LUX ELEMENTS” - the properties of the material allow us to create more correct and even geometry, complex surfaces, without unnecessary leveling layers.

What is a hammam and where did this phenomenon come into our lives?

The origin of this bath is not Turkish, but ancient Roman - from the Roman thermal baths. Steam from boiling water outside the room was supplied to holes in the walls, and the stove heated the underground floor on poles. But in Turkey, baths became truly widespread because the Prophet Mohammed declared that the cleanliness of a Muslim’s body is half of his faith, and declared regular visits to the hammam obligatory. The first Russian hammam was incredibly luxuriously built in Tsarskoe Selo according to the design of Ippolit Monighetti.

Sketch by architect Ippolit Monighetti “Turkish Bath”

In Europe, hammams originated in the 19th century and were considered a panacea even for asthma and cholera. They are traditionally spacious and luxurious; marble and mosaics are used for decoration. They have certain architectural principles, in particular - a domed vault, so that water does not collect in the corners and does not drip on vacationers.

Hammam dome in mosaic

Design and differences from a steam bath and sauna

Hammam is a very special pleasure. Despite the fact that it, like any bathhouse, uses the influence of temperature on a person, the principles of this influence are very different.

Sauna

In the sauna, the temperature can reach up to 1200 with almost very low air humidity. This is a huge burden on the heart, sweating is difficult, but the most important thing in any bath is cleansing the body of waste and toxins through the skin through sweating. But a sauna requires the least space, it does not require a swimming pool and can be installed even in a city apartment.

Sauna in the apartment

Russian steam bath

Much better parameters for health - a combination of temperature and humidity - are maintained in a Russian bath. But even there there are extreme values. At such temperatures and humidity, the heart and blood vessels also do not feel the best. Instant cooling in the font saves. But if you do not have a very hardy heart, it is also better to avoid a steam bath.

Russian steam bath with shelf, heater and fragrant herbs

Turkish hammam

In a Turkish bath there is almost one hundred percent humidity, and the temperature of the air, stone floors and benches does not exceed the very 400 to which the human body temperature rises to the maximum in the bath. It lasts much longer and is better tolerated and is accessible even to children, heart patients and hypertensive patients. You will lose no less fluid and cleanse your body no worse than in other types of baths. You will put in less effort for this - you don’t have to wave a broom, endure the heat, run out and dive into an icy plunge pool. You can easily communicate while steaming, which is practically impossible in a sauna and steam bath. In addition, there is an advantage purely for women: the hammam is much healthier for the face, since it does not cause such a blow to the facial vessels and saturates the face with moisture.

A huge public hammam awaits visitors

But building a hammam is a rather labor-intensive undertaking. It is lined with quite expensive materials - up to marble, mosaic and smalt, it is necessary to provide heating for beds and floors, it requires complex electrical equipment and consumes a lot of electricity for heating. In order to build a hammam at a reasonable cost, you must have a number of special knowledge. In addition, many modern materials are good substitutes for traditional and expensive ones. So building a hammam with your own hands is quite possible.

Examples of private small hammams (photo gallery)

Tiny hammam with a drain in the center of the floor

Hammam illuminated in the form of a “starry sky”

Luxurious marble hammam

Hammam with one bench and a kurna

Stepped mosaic benches

Hammam of a floor structure to save space

Mosaic hammam with corner benches

Hammam with lighting and rounded lines

Oriental hammam with gilding and dome

Hammam in blue glass mosaic

Hammam in simple tiles

Necessary tools and materials, drawings

Layout plan of rooms and elements of the hammam health complex

Hammam designs can be different, involving the use of various construction and finishing materials. But there are only two technological solutions for the construction of these premises:

- multi-layer (traditional);

- lightweight (panel).

Multilayer method

The first option involves performing a complex of construction works on heat, steam and waterproofing. The pie in the direction from the wall to the room looks like this:

- plaster;

- insulation;

- reinforcing mesh;

- metal-plastic pipes;

- facing material.

The total thickness of the layers is 8–10 cm. The advantages of this construction method include uniform heating of the walls and the ability to install heavy vertical marble finishing elements. This is the most suitable option for building a hammam in a separate building, an extension to a residential building, or in a basement.

Lightweight method

A lightweight method of installation consists of gluing pre-leveled walls with reinforced polystyrene foam panels. This is a new building material, characterized by low thermal conductivity, high strength and tightness. The most popular panels are Wedi, Do it, Luxelements. This construction method is optimal for installing a hammam in an apartment in an apartment building, in fitness centers and spa salons.

The small size of the steam room is not a reason to abandon the stages of designing, performing calculations and drawing up drawings. Keep in mind that a hammam is a room with a high level of humidity that requires high-quality hydro- and vapor barrier. When designing your Turkish bath, you can rely on standard designs and drawings.

Layout plan for ventilation, heating circuits, steam and water supply

Room requirements and choice of materials

The project should include a ventilation and air drying system

Regardless of where the hammam will be located, in a building specially built for this purpose or in an existing premises, a number of rules are observed:

- ceiling height - 250–260 cm;

- minimum number of rooms: steam room, shower, for relaxation, storage of technical equipment and equipment maintenance;

- ceilings and walls must withstand significant weight loads;

- ventilation and sewerage are required;

- the ceiling should be domed.

The choice of materials depends on the method of building a hammam with your own hands: traditional or lightweight. Free-standing buildings are erected from brick, foam, gas or cinder blocks. A good choice is wood concrete. These building stones are made from sawdust concrete, which has low thermal conductivity. The construction of walls made of wood concrete makes it possible to save on insulation.

The following materials are used for interior decoration:

- natural marble;

- smalt;

- ceramic tiles.

You can make patterns of any complexity from mosaics and combine them with natural marble cladding

Mineral wool and polystyrene foam act as thermal insulators for walls and ceilings. When choosing thermal insulation panels, it is recommended to pay attention to domestic developments - the Deluxe and Teplofom brands. These products are made from extruded polystyrene (EPS) reinforced with fiberglass mesh. The main difference between these materials is the composition of the polymer-cement layer necessary to fix the reinforcing mesh. The technical specifications are largely identical.

Technical equipment

To install water heating, you will need metal-plastic pipes with fittings. In addition to them, you will need:

- a collector or comb to create a heating circuit;

- circulation pump;

- metal mesh for reinforcement;

- concrete for screed;

- plaster mortar.

Electric heating is carried out using cables laid in the walls, ceiling, and sun loungers. The system is equipped with a thermostat that allows you to set the required temperature. This is a more economical method of heating surfaces than water heating. But more expensive during the operation of the premises due to high electricity tariffs. However, it is advantageous in that it does not require maintenance.

If the hammam will receive visitors on a regular basis, it must be kept heated all the time. This will eliminate the intense formation of condensation and will save energy resources required for heating the screed and finishing materials.

Tools

To perform construction and finishing work you will need a set of tools.

- concrete mixer;

- perforator;

- screwdriver;

- Bulgarian;

- tile cutter;

- set of spatulas;

- metalworking tools;

- stepladders or platforms;

- tools for performing electrical installation work.

Preparing for construction

If you build a Turkish bath as a separate building, then the costs of its operation will be prohibitively high. To warm up a stone building, even a well-insulated one, before visiting in winter, you need to warm it up for several days. Therefore, we use one of the premises of our country house or even a large apartment to equip a Turkish bath. It will only need to be rebuilt taking into account the bathing requirements. The sequence of preparatory steps will be as follows.

Summation of requirements

This includes making a preliminary decision: what kind of benches you want and how many, what ceiling height, what kind of scent system, music accompaniment, and so on.

Choosing a room for the future hammam

The number of benches, the presence of a massage table, and the height of the ceilings depend on the room. You need to decide how many people your hammam will accommodate at the same time. The hammam must have a domed ceiling, so the top point of the ceiling should be about 2.7 meters high.

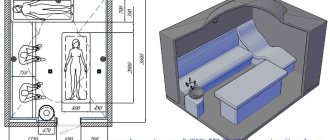

Scheme of a small hammam in 3DMax

At least one full bench for lying 0.6x2 meters is required. If it is possible to squeeze a massage table into the hammam, which is called “chebek” in Turkish, with a free area around it for the massage therapist, then it will be absolutely wonderful; but this is optional. Instead of a massage table, it is better to place another bench.

Optimal hydro- and thermal insulation materials

An excellent modern choice is elements-panels made of Wedi or Lux Element's rigid foam polystyrene made in Germany - lightweight, durable, reinforced with fiberglass mesh, with cement-based waterproofing on both sides.

Sectional view of Lux Element's panel

They are fire resistant, can withstand high temperatures, do not emit harmful substances and are extremely durable. In addition, they hold heavy finishing materials very well: stone, porcelain tiles, tiles, mosaics. No plaster or drywall can compare. The dome can be formed from ready-made dome-shaped panels.

Scheme for insulating a hammam with Lux Element's panels

From the same material you can select ready-made benches and massage tables of almost any configuration.

Choosing finishing materials

The design and price of your hammam largely depend on them. There are quite a few options, they differ in installation complexity and price.

Important! The hammam is always finished with moisture-resistant and heat-resistant material with high structural strength. The tree is inappropriate in it.

Marble is an ideal material for a hammam. But it is very expensive and difficult to install yourself.

Marble bench, marble type – CREMA VALENCIA

Onyx is a very beautiful semi-precious and translucent stone that creates an amber atmosphere. Even more expensive than marble.

Onyx with mosaic

Porcelain tile is an amazingly beautiful and durable material; it perfectly imitates marble and semi-precious onyx.

Finishing the hammam with onyx porcelain stoneware, onyx mosaic

A very interesting, but labor-intensive option is loose mosaic made of smalt. You can show your artistic talents and lay out a lot of panels on the walls and benches, but the construction time for the hammam will be very long.

Loose smalt mosaic

We chose adhesive-based mosaics - this is a quite reasonable compromise in terms of price and quality, besides, it is beautiful and allows you to create smoothly curved surfaces. such a mosaic can be made of natural stone, glass, ceramics. We liked the glass one better.

Finishing mosaic Caramelle mosaic naturelle

Which lamps are better?

This is done in advance for the same reason: it determines the design features. Lamps can be ceiling and wall, on the ceiling - low-voltage halogen or LED spotlights, on the walls - special sconces. LED strips are available. The safest fiber optic lighting is most welcome. With its help, for example, you can create a “starry sky” on the ceiling of the hammam.

Hammam lamp W-071C (brass)

Choosing a heating method for sun loungers, floors and walls. You can choose either electric or water, but the second will be more economical and safer.

Heating of the lounger, walls and floor with hot water pipes

Selecting or designing an equipment room

The technical room will contain an external steam generator, a heating device (for example, an electric or gas boiler for heating water or thermostats for “warm floors” in seats, floors and walls) and lighting system transformers. It’s good if this room is above the ceiling or under the floor of the hammam.

Layout of the steam generator for the hammam in the adjacent room

Steam generator power calculation

The power of the steam generator also depends on the size of the hammam. At your dacha, you are usually limited by the power of your electrical connection. There is a dependence: for a 2x3 meter hammam you need a steam generator with a capacity of at least 9 kilowatts, and if the hammam on the metro is longer and wider, then there are already two steam generators with a total capacity of at least 18 kilowatts. That's a lot. It is also necessary to calculate - if this particular heating method is chosen - the power of electric heating devices. For hard water, the steam generator is connected through a special filter, or a water softening unit is installed in the system before it.

Helo steam generator for hammam

Identifying and resolving power supply issues

The hammam will require higher power supply than the power supply at home; you need to take care of this in advance.

Identifying and resolving water supply issues

It is necessary to think over the water supply and sewage system of the hammam. Under no circumstances should its drain be connected to a common septic tank; it will simply choke due to burst bath discharges. You need to dig a separate drain hole.

Thinking through the ventilation system

If necessary, it must be forced, using fans, to remove excess steam so that it does not fall into condensation on the walls. If desired, you can also design an aromatization system if you do not like the smell of pure water vapor.

Fan for hammam

Drawing up a drawing

And only after all this can you begin to draw up or adjust a drawing that satisfies the room and the desired qualities of the future hammam, drawn up taking into account SNIPs and GOSTs, with visualization and specifications.

Drawing of our future hammam with visualization and specifications

Then we draw up a specification of materials and check the construction estimate. Considering that we already have the premises, there will be no costs for building a foundation, walls and roof.

Examples of drawings of small home hammams built into existing premises (photo gallery)

Scheme of a free-standing hammam with two sunbeds

Diagram of the Malsi hammam, side view

Diagram of the Malsi hammam, top view

Diagram of the Millennium hammam, side view

Diagram of the Millennium hammam, top view

Drawing of a large hammam with a relaxation room

Drawing of a small hammam with an angular outline

Detailed drawing of the hammam

Diagram of a hammam with sunbeds at an angle

Approximate estimate (based on the cost of a real triangular hammam measuring 2.81 by 2.42 m, height 2.5 m) for self-building

Thermal insulation and other materials:

| Position | Material | Specification | Quantity | Price | Sum | Notes |

| 1 | RPG panels - extruded polystyrene foam and branded components | Set | 1 piece | 63590 | 63590 | For installation of walls, ceilings, floors |

| 2 | Waterproofing | Set | 2 pieces | 3600 | 7200 | For waterproofing walls, ceilings, floors |

| 3 | Panel adhesive, polyurethane foam, mesh | Set | 1 piece | 5000 | 5000 | For installation of walls, ceilings, floors |

| 5 | Fastening and consumables | Set | 1 piece | 4500 | 4500 | |

| Total | 80290 | |||||

Purchase of equipment:

| Position | Name | Specification | Price, rub) | Amount (RUB) |

| 1 | Steam generator (we chose Harvia HGX-90) | 1 piece | 37300 | 37300 |

| 2 | Automatic drain valve for auto cleaning | 1 piece | 10500 | 10500 |

| 3 | Harvia steam room aroma | 5 liters | 2600 | 2600 |

| 4 | Flavor supply device | 1 piece | 10200 | 10200 |

| 5 | Audio speakers Harvia | 1 pair | 6000 | 6000 |

| 6 | Door ALDO matte 190x70 cm | 1 piece | 19500 | 19500 |

| 7 | Brass taps | 2 pieces | 3500 | 7000 |

| 8 | Moisture-resistant spotlights | 3 pieces | 1500 | 4500 |

| 9 | Polystyrene kurna | 1 piece | 15000 | 15000 |

| 10 | Polystyrene lounger | 2 pieces | 12000 | 24000 |

| 11 | Plumbing part (water heated floors and sunbeds, manifold, fittings, etc.) | Set | 11000 | 11000 |

| 12 | Electrical part | Set | 3500 | 3500 |

| 13 | Ventilation part | Set | 4500 | 4500 |

| 14 | Copper steam line with fittings and drainage | 3 linear meters | 550 | 1650 |

| 15 | Drain ladder with water seal | 1 piece | 1600 | 1600 |

| Total | 158850 | |||

Finishing and facing materials:

| Position | Name | Specification | Price | Amount (RUB) | Notes |

| 1 | Mosaic | 34.3 m2 | 712 rubles per m2 | 24446 | On the sunbeds, walls, ceiling, kurna |

| 2 | Mosaic (or tiles, choose mosaic) | 3.5 m2 | 712 rubles per m2 | 2470 | On the floor |

| 3 | Adhesives, mixtures, grouts | Set | 11000 | 11000 | Consumables for finishing work, approximate amount for this volume |

| Total | 37916 | ||||

The total amount is about two hundred thousand rubles, which is not that much for such an ambitious project as a home hammam.

Functions of hammam sun loungers

A stone-based lounger or a special table has the following functions:

- when heated, the stone can warm up joints or muscles well;

- on a sunbed you can take special foam treatments typical for a hammam;

- Stone loungers are also used as massage beds, which is especially important after preheated muscles.

To make it convenient for a massage therapist to work, the optimal height of the lounger is 80-90 centimeters .

Optimal temperature indicators

The human body temperature in any environment is no more than 400. This is achieved by the fact that when the ambient temperature rises, a person sweats and releases excess heat with moisture into the surrounding air. This is the basis for the effect of any bath; they differ in the ratio of temperature and air humidity.

The best state of health at a certain combination of humidity and temperature is graphically expressed by homeothermal curves: below the first curve is the optimal combination of temperature up to 900 and humidity up to 80%. It is the combination of temperature of about 40% and almost one hundred percent humidity that gives hammams.

Homeothermal curves - theoretical dependences of relative humidity on temperature

Features of using the hammam

- After completing all the work, you need to let your hammam stand for a couple of weeks, slightly maintaining the heating of the surfaces. This is done to ensure that all solutions and adhesives dry completely.

- The first start-up should be long and gradual, with a slow increase in heating temperature. This is done to prevent thermal expansion from causing the surfaces to crack. This is especially dangerous for all-stone and all-marble surfaces.

- During short breaks in the hammam operation, all heating should not be turned off. If the break is expected to be long, you need to leave the heating on the benches and massage table.

- It is necessary to keep the hammam clean and frequently clean it with special detergents for marble, tiles, and glass.

- If the water is hard, you need to remove scale from the steam generator tank on heating elements using a solvent according to the instructions, depending on the hardness at certain intervals: the harder the water, the more often. In addition, the steam generator must self-clean every few hours: drain water from the tank and add new water.

- During steaming, the ventilation hole should be kept slightly open, since the air exchange you need is equal to 4-6 volumes of your hammam per hour.

If you follow these simple rules, your hammam will serve you for a long time and will not cause any problems.

Design features of sun loungers and seats

To relax in the hammam they use:

- massage tables;

- seats;

- sunbeds;

- domes.

Production is carried out on the basis of polystyrene foam, which has different densities. At the same time, seats and loungers differ from each other in shape and purpose. Each model can be made wall-mounted, adjusted in height, set a certain slope or planting depth. All this can be adjusted either during individual production or installation. To handle corners or trim the body, you will need a carpenter's tool. In this regard, polystyrene, regardless of density, lends itself well to drilling .

Features of polystyrene for structures

You can purchase chairs or loungers of standard sizes and shapes, or order them according to your individual wishes.

And to give them the required density, it is best to use the densest material. Then the product is covered with glass mesh, after which it is treated with a waterproofing polymer-cement composition. Such models do not have voids and have a filled structure.

In order to increase adhesion, the surface of sun loungers and seats is treated with reinforcing acrylic, which provides excellent adhesion to any tile mixture and various cement-based solutions. After this treatment, the structures have a hard surface and can be further coated.

For the manufacture of tables, seats and loungers for the hammam, polystyrene foam is used for the following reasons:

- zero moisture permeability;

- ease;

- vapor permeability;

- long service life.

Errors in finishing hamam beds

When producing a hammam, finishing is very important, and it is no less important than the frame and the equipment itself. Many people do not pay special attention to the material used to make benches and sun loungers, believing that the most important thing is to correctly place the heating elements. But there is a difference, and sometimes a very significant one.

Thus, mosaic is not capable of heat transfer compared to properly selected natural stone. Therefore, if you have chosen mosaic as the key finishing material for cladding the structure, then it is recommended that all horizontal elements be made from solid real stone . This applies primarily to seats and sunbeds.