We can say with confidence that clay was the very first to be used in construction. This material turned out to be so good that it is still used today. Clay is often used with various additives, such as sawdust. Its ability to harden has made it an ideal material for a wide variety of construction applications. It is used to create load-bearing structures; mortars for laying bricks are made on its basis, as well as to create an insulating composition by adding sawdust. Clay with sawdust is an environmentally friendly and economical insulation for the home, which you can make with your own hands.

Features of building materials

A simple and inexpensive composition is most often used as insulation for home buildings - ordinary clay with sawdust. You can easily prepare it yourself.

In nature, clay layers are formed as a result of the breakdown of rocks. With an abundance of moisture, dry powdery clay is transformed into plastic clay. The latter contains minerals from the kaolinite group, which directly affects the physical properties of the manufactured building mixtures.

After thoroughly mixing the clay with the liquid, a dough-like mass is formed, which has unique properties. It can take on all sorts of shapes and also retain them after drying. Together with sawdust, this material is best suited for thermal insulation of ceilings and walls. This is a great way to insulate a small structure.

After mixing clay with water, taken in certain proportions, a dough-like mass is formed, which has unique properties Source hydrotechnics.ru

Economical thermal insulation

The cost of building your own home (not to mention purchasing a plot for it) can put a dent in almost any budget. Therefore, in private construction, preference is often given to more economical options for materials.

The cost of modern insulation makes you think about how to save on this expense item when building a house. The simplest sawdust can be used for thermal insulation of a house, while the cost of this material will be minimal. You can purchase them at a very low price at any sawmill.

It is necessary to treat them with special compounds that can prevent this. In addition, it is also necessary to ensure their protection from rodents and fire. You can mix sawdust with clay, lime or cement. As a result, you will have insulation ready for use. It can be used to insulate roofs, floors and walls.

Advantages and disadvantages

Today, the popularity of environmentally friendly construction, which is safe for the natural environment and does not require the use of artificial building materials, is rapidly growing. Clay is an accessible, inexpensive raw material; the use of sawdust is an opportunity to use wood without waste. Wood particles have minimal thermal conductivity, so they retain heat for a long time.

Clay with sawdust is most valued for:

- fire safety;

- environmental friendliness;

- resistance to weather changes;

- long service life;

- sound insulation properties;

- maintainability;

- no need to install a vapor barrier;

- relative cheapness;

- the ability to independently insulate the building.

Like any building material, clay with sawdust has some disadvantages:

- high susceptibility to chemical corrosion;

- if the technological process is disrupted, the slabs acquire an irregular shape;

- the use of clay insulation is allowed only inside the building: when moistened, the thermal insulation properties of the material are reduced, although they are restored immediately after drying;

- it is usually necessary to apply a thick layer of the mixture; the supporting structure of the building cannot always withstand it;

- Clay products containing limestone are often covered with swelling.

Attention! Sawdust is a material that belongs to the group of highly flammable materials. The fire-resistant clay layer practically does not reduce the possibility of a fire. When thermally insulating surfaces with clay and sawdust, it is important to monitor the electrical wiring. It is also advisable to place it in special protective boxes.

Insulation made from clay and sawdust is completely harmless to a person living in a building insulated with such material Source stroyfora.ru

Adobe as insulation

Another interesting option for using clay is adobe. Previously, it served as the main structural material for the construction of walls, but today it is used only as insulation.

Here the filler is no longer sawdust, but straw. Again, an environmentally friendly product with excellent thermal insulation properties and, again, the purchase of which will not ruin your budget.

To acquire adobe, you only need to have a wooden mold and the desire to work. Kneading (clay and straw are kneaded with feet) is usually done right next to the clay quarry, where the resulting mass is filled into molds, and the blocks dry there.

The whole process is quite labor-intensive, but if this point doesn’t bother you, you can get a material with a thermal conductivity of 0.1 W/m°C, and this is already a pretty good indicator.

Criterias of choice

It is possible to provide high-quality thermal insulation for a room if you choose the right insulation materials. Clay resembles ordinary plasticine - it is plastic. For construction work, it is best to use red clay: it is more pliable, hardens faster, and absorbs less liquid. If such material is not available, you can use other varieties (for example, white). This will not affect the final result, but the finished surface will subsequently have to be looked after more carefully.

Red clay is best suited for insulation work because it has high plasticity and minimally absorbs moisture Source kamtehnopark.ru

Insulation technique

Making high-quality insulation in ordinary home conditions is not at all difficult. When dried, it perfectly retains its original shape; after application and hardening, it only slightly decreases in volume. Having absorbed a certain amount of moisture, such insulating material no longer allows liquid to pass through.

When insulating a home with clay and sawdust, it is important to consider the following points:

- A cracking test is performed to test the available clay materials. Using samples of raw materials, balls and cakes are made, dried in the open air, and then tested for drop. High-quality specimens should not crack or split.

- This insulation is dried under natural conditions. It is most relevant for buildings in the southern regions, where it is very hot in the summer. This is due to the following fact: the heat-insulating material made of clay with sawdust does not heat up very much, as a result of which the room remains cool inside.

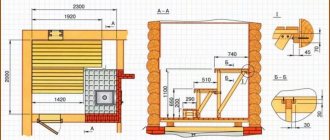

- To make slabs, you need a container with sides: clay, wood particles and water, taken in a ratio of 1:1:5, are mixed in it. You will also need many wooden molds for pouring the prepared solution.

- On the eve of laying the mixture, all forms should be moistened and sprinkled with cement. Subsequently, this will make it easy to remove the dried product from the container.

- After hardening, the slabs are carefully removed from the molds and laid out in the open air to dry. It is advisable that this be a shaded place.

The drying period of products largely depends on the level of humidity and air temperature, and is 7-14 days. During the drying process, 15% of the total weight is lost.

The use of natural materials is the cheapest and most environmentally friendly option for organizing home insulation Source store.building-tech.org

Video description

We insulate the ceiling with clay and sawdust - environmentally friendly, economical and effective.

Wall insulation

In order to properly insulate the walls of a house, it is necessary to make heat-insulating blocks in advance. As soon as the insulation products are ready, they need to be secured to the walls using reliable wooden lathing. Then all joints should be rubbed with the remaining clay mixture.

After manufacturing, the blocks are stacked in a dry, ventilated area, then attached to the walls using the same mortar or anchor nails Source i.ytimg.com

Finishing

It is possible to level uneven insulation boards with a special plaster - wood concrete. In its manufacture, clay with sawdust, as well as lime and water are used.

Plastering the walls is carried out in two layers (after the base has completely dried):

- Chernova. The solution is applied with a spatula (thickness - 3 mm), then leveled as much as possible.

- Similar grouting, but without the use of sawdust.

If all work is carried out in accordance with regulatory requirements, the created thermal insulation will last for many years.

For finishing walls, the same compositions are used as for filling, only more suitable proportions are selected Source pro-uteplenie.ru

Preparatory work

How to insulate a ceiling with sawdust in a private house? Whatever method is chosen, preliminary preparation of the wooden base is required. Initially, the elements on the ceiling are processed. As a rule, during construction they use material that has already undergone appropriate processing. However, in some cases this procedure is skipped. Then you need to do it yourself.

The treatment is carried out with special protective compounds. It is carried out in several stages, since comprehensive protection is required. Initially, wooden parts are coated with antiseptic compounds designed to protect against rotting and insect damage. Next, fire-bioprotective agents are used, which increase the material’s resistance to fire and exposure to elevated temperatures. The next stage is treatment with water repellents. They prevent previously applied compounds from being washed out of the wood structure, help remove excess moisture from the material, and protect against water penetration.

For processing, it is recommended to choose drugs from the same brand. Some manufacturers offer products that perform several functions at once, for example, protect against fire and high temperatures, prevent rotting and insect damage. The bathhouse must be treated with special products that are resistant to high humidity and high temperature.

After processing and drying of wooden structures and ceilings, the substrate is laid.

Initially, all gaps and cracks should be sealed. To do this, use polyurethane foam and acrylic sealant. Large cracks are treated with foam. Gaps and joints are sealed with sealant. It is allowed to use bitumen mastic, but not for finishing the ceiling of a bathhouse. This is due to the low resistance of the material to high temperatures.

You need to seal not only the holes in the wooden ceiling, but also in the roof itself. This increases the thermal insulation properties and eliminates the impact of external factors on the internal elements of the roof.

After drying the sealant and foam and removing excess material, the substrate is laid. It is necessary to protect the interior space of a private house from the penetration of dust from sawdust, and serves as a vapor barrier between the ceiling and sawdust insulation. The substrate must be vapor-permeable, since warm air and steam rise up. If it does not pass through the ceiling and further into the space under the roof, condensation will form. This will lead to gradual rotting, the formation of mold and fungi.

An excellent and inexpensive option is to lay cardboard. It can be any type of material. The main condition is that the cardboard must be dry. The sheets are laid directly on the ceiling, with an overlap of 15-20 cm on each other. If the cardboard is thin, then it should be placed in 2-3 layers. The joints are fastened with staples. The perimeter of the junction of cardboard and walls is treated with polyurethane foam or sealant.

PVC film is often used as a backing. It is also laid with an overlap of 10-15 cm, and additionally secured with staples using a stapler. The edges of the film around the perimeter should extend onto the walls/roof by 10-15 cm.