Insulation of a bathhouse between the crowns refers to external thermal insulation, internal insulation of a bathhouse: floor, walls, ceiling, attic floor (if there is one) and roof - a separate article is devoted. And this is very important for a log bathhouse, since such bathhouses, as a rule, are not insulated from the inside. The choice of material is quite difficult: there are a huge number of different products of both natural and artificial origin.

Therefore, in search of an answer to the question: “which inter-crown insulation is better for a bathhouse?” many spend a lot of time and effort.

Inter-crown insulation of a log house, moss and jute

Since the very beginning of existence, humanity has been building wooden houses, using various techniques developed through trial and error over many centuries.

During this time, technology has advanced, new methods of wood processing have appeared, modern machines have appeared that make it possible to give building materials almost any shape, dry the wood efficiently and impregnate it with various antiseptic materials - that is, do everything to ensure that the future house lasts a long time and brings a minimum of trouble to its happy owner . And, of course, it was beautiful, modern and environmentally friendly. It is difficult to imagine something more popular, time-tested in wooden construction than the classic log house. In houses made from logs or beams it is always cozy, easy to breathe and a special, indescribable comfort is felt, however, even in a beautiful wooden house in winter it can be completely cool if you do not take the insulation of the walls very seriously. When assembling a log house, be it from timber or logs, the question usually arises, what material is best to use for inter-crown insulation?

Different insulation materials are used, these are flax batting and linen felt, tape tow, various moss (for example, sphagnum or cuckoo flax), jute tape. Some extreme sports enthusiasts even try to insulate with polyurethane foam and a lining for laminate parquet, folded several times. But, of course, we will not consider such clinical cases, but will try to understand the pros and cons of the two most popular materials for laying logs - moss and jute. What's better?

How much material will be needed?

It is impossible to accurately derive a formula by which you can calculate the amount of material for sealing cracks.

Natural material, be it jute or moss, is highly compacted and compressed when processing cracks. So its consumption can be quite large. First of all, material consumption depends on the methods of processing logs and cutting grooves.

In any case, you need to buy material for caulking with a large supply - it will not go to waste and will be useful for a repeat procedure. As for industrial sealants, as a rule, the manufacturer indicates a method for calculating the approximate number of packages.

How should you caulk a log house?

A number of requirements apply to materials for insulation: it must be resistant to sudden changes in temperature and moisture, prevent heat loss, not be toxic and not lose its properties for many years. There are several types of materials used for these purposes.

A material with a long history, it has unique properties: it provides good thermal insulation, has a long service life and has an antibacterial effect. However, it must be selected very carefully: moss that is too wet causes the timber to rot, and moss that is too dry causes it to break and crumble. The cost of moss is higher than other materials; it is quite difficult to install. Therefore, experts recommend caulking the log house with tow mixed in equal parts with moss. Before laying in the cracks, the moss must first be wetted and slightly dried in air.

Being an environmentally friendly insulation material, jute is characterized by high strength, good thermal insulation properties and natural composition. It practically does not absorb moisture, thereby extending the service life of the log house. There are several varieties of it:

- Jute tow. Rigid insulation of low density, they will have to be caulked several times.

- Jute felt. Dense and flexible eco-material, which must first be treated against parasitic insects and rotting.

- Flax-jute. Non-woven fabric that looks like flax wool. Flax-jute is resistant to mold, parasites and rot, and also removes excess moisture from the room.

Lnovatin

Tape natural insulation, which is made from flax fibers and has good thermal insulation properties. At high humidity it absorbs water, and at low humidity it returns it, thereby preventing the logs from rotting. However, it quickly becomes infested with insects, and its service life is only 3 years. It must be treated with special solutions against parasites before installation.

Tow

The most inexpensive and popular environmentally friendly material for sealing seams. Insulating a log house with tow makes it very warm. But its main drawback is its fragility. During the shrinkage of a wooden house, the tow begins to rot, becoming dust. The maximum period of its use is 3 years. After this time, it needs to be changed and the log house must be re-caulked with tow, which is quite problematic and time-consuming.

Sealant

Modern sealants make it possible to quickly and easily insulate a house or bathhouse. They are usually used in tandem with natural inter-crown seals (jute or flax). The sealant applies smoothly and neatly, providing an aesthetically pleasing appearance to the wooden structure. However, it is only suitable for log houses made of rounded logs and is applicable only after shrinkage has completed. After coating the cracks with sealant, re-caulking is not required.

How to caulk a log house correctly?

Caulking the cracks of a wooden house or bathhouse is a rather painstaking process. First, inter-crown insulation is laid between the logs during construction. After the wood shrinks (after about a year), gaps form and the procedure must be repeated. The timber finally dries out 3-5 years after construction, during which time the final caulking is carried out. In this way, maximum thermal insulation of the building is achieved.

You can caulk a log house with natural insulation after shrinkage at any time of the year. The exception is when working with sealant: seams can only be sealed at temperatures above 0 degrees, otherwise the composition will not dry out.

There are two ways to insulate cracks:

- To the set. This technology is used when working with large gaps: the sealant is twisted into a ball and, gradually unwinding it, is hammered into the space between the logs. When filling large voids, it is necessary to twist the loop or turn the rope. You should start laying out loops from the top of the gap and gradually work your way down.

- Stretch. This method is suitable for closing small cracks: a strand is formed from the insulation, placed across the log and pushed inside the hole so that the material protrudes by about 5 cm. Thin rolls are formed from the protruding part and hammered inside.

For caulking, a wooden tool is more often used, since it is more gentle and causes less damage to the timber. When choosing tools, you should pay attention to their hardness - they should be made of softer rocks than walls. It is necessary to caulk the log house not only from the outside, but also from the inside. This process is carried out in a circle from the bottom up, since if you caulk each wall separately, the structure may warp. Particular care must be taken to fill the cracks at the corners of the log house, where the most noticeable gaps form.

Caulking log houses is a long and labor-intensive process that requires certain knowledge and experience. For this reason, it is worth entrusting this work to professionals. has been engaged in the construction of turnkey wooden buildings in Moscow, the Moscow region and the Central region of Russia for more than 15 years. Our team consists of 40 teams of experienced specialists with at least 7 years of experience. From us you can order a log house based on a ready-made project from the catalog, or create an individual project to suit your taste. You can get expert advice, calculate an estimate and place an order by calling 8(495)128-21-53, or request a call back on the website.

Varieties of jute

1. Jute tow. The long, almost unprocessed stems of the plant are used for caulking between the crowns of log houses and other seams that need insulation.

Article on the topic: Interskol mini-wash how to draw water from a container

2. Jute felt. It is not used in its pure form due to its strong hardness and brittleness after deep processing. A little flax is added to the composition of felt, which gives it greater strength and elasticity.

3. Flax-jute. Mixing two plants in equal proportions creates a very reliable and durable material that is perfect for bathhouses made of laminated or profiled timber, as well as rounded logs.

It, like felt, is produced in the form of strips, so it is not very convenient to use for log houses made from solid logs. Tow is a coarse fiber obtained from waste bast crops. Tow for a bath comes in the following types:

- Construction is flax fiber with a length of 30 - 40 cm, produced mainly from hemp;

- Linen tow is a type of tow similar to construction, but differs in the material used. Please note: flax tow has the lowest thermal conductivity. With 50% moisture, it absorbs only 8%, when the figure for other representatives is 13%.

- Ribbon is linen ribbons of various widths. Note: the advantages remain with the tape type, since the longitudinal structure of the fiber is preserved during production, which allows you to manipulate the thickness and width of the compacted seam.

- Jute tow is an analogue of flax and is made from the jute bush.

General characteristics: high environmental performance, water resistance, thermal insulation, sound insulation, moisture resistance.

Which bath insulation should you prefer?

In order to determine what is better for a bath - moss or tow, it is necessary to consider and compare the characteristics of these representatives. The advantages of moss are obvious: it does not rot, it is available and its price is low, however, the big disadvantage is that it dries out and subsequently begins to blow out of the cracks, so in areas where strong winds are normal, you will have to constantly caulk it. When laying a log house, moss requires a lot of effort and a lot of time. Other modern materials allow this work to be completed in a shorter period of time, so focus on the financial indicator and the allotted time for work. Please note that if the log house is built from wood chopped with an ax, you can use moss as insulation. Give preference to jute or linen tow. It must be remembered that some types of flax tow absorb moisture abundantly, which over time causes rotting. However, they still have a common drawback - they are a favorite food for rodents and flying animals (moths, birds), but moss is still less interesting for them.

Article on the topic: How to melt butter in a steam bath

How to get moss on your own?

If you want the insulation to be “homemade”, and if buying moss for a bathhouse is too expensive for you, then these instructions and assembly tips will help you in this matter:

- Moss grows in the forest, so go there when the snow melts.

- Use bags for laying, however, do not compact the moss too much.

- Choose clean places where there are fewer knots and cones, then the moss will be clean.

- Choose a plant 15 - 20 cm long, it is less problematic when composing.

- Make about 25 bags (standard sizes).

- After compiling the moss, do not lay, for example, a log house on top of it, it will begin to compact, and an unpleasant odor is guaranteed.

- After returning, put the plant you collected in one place - in a pile. Choose a shady place so that it does not have time to dry out under the scorching sun.

- Do not delay the work until later, since the moss will subsequently become unusable; immediately upon arrival, begin assembling the frame and laying the moss.

- Pour water over the collected material and knock it down. This way it will be cleaned, and the bumps and twigs will fly out of it.

Note: When making moss, do not use additional tools; it is malleable, so you can easily handle it with your hands.

How to lay moss correctly?

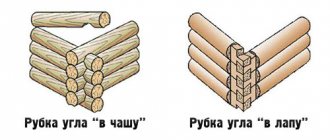

If it is dry, then compact it in a barrel and fill it with 20 - 30 liters of water. Leave for half an hour, drain the water, and squeeze out the moss. Remember - dry moss does not allow itself to be manipulated, so pre-soaking the material will allow it to become more pliable. Take the moss that is ready for laying and spread it across the log without compacting it. Please note that the sealant must lie evenly. Make sure that the width of the display is 200 - 250 mm, and the thickness is 40 - 50 mm. Laying in the bowl is made with a thickness of 4 - 5 cm, and protrusion beyond its limits is 5 - 10 cm.

Article on the topic: When can you take a bath after appendicitis?

Lift one end of the log and place it on the bowl, then lift the other end, about 50 - 60 cm higher from the place of laying, so as not to move the moss, release it into the opposite bowl. Tap the entire surface with the headstock. Take a construction stapler and secure the laid out material every 30 - 40 cm.

Tow is less problematic to work with, since the finished canvas does not require additional time for cleaning and even laying on the deck. It differs only in the installation methods. If the timber is for a bathhouse, profiled, glued, then we lay the insulation without bends. We don't use a stapler. If it is an ordinary log, profiled with natural moisture, then the material must be folded once with a lock. Make sure that the canvas does not extend beyond the edge of the end. If the bathhouse is built from a wild log house, a fire monitor structure, or from a milled log, lay the tow in two layers. Use a stapler to secure the fabric.

Attention! Crumpling the canvas is prohibited, as this leads to poor shrinkage and subsequent damage to the wood.

Log caulking technology

Caulking is one of the stages of the construction process by which gaps and crevices are filled with a special material to prevent contact between the inside of the room and the outside environment. Types: stretched and set. The goal of the work is to fill the visible cracks tightly, without gaps. Progress:

- Select a specific area as the primary task.

- If the material is in the deck (it has just been insulated), the protruding part is pushed into the gap.

- Take the caulk in one hand and insert the tool into the crack.

- After it stops falling into the gap, proceed to tapping it with a mallet.

- Next, compact the next section on the same log, and so on along the entire length in a circular direction.

- After the external caulking of the bathhouse, proceed to the internal filling.

- Remember! One log needs to be compacted, both on one side and on the other.

- After 12 months the process must be repeated.

Article on the topic: What does it mean to brew in a water bath

So, the job was successful, so given that the bathhouse is under constant influence of temperature factors, it must be caulked periodically. With annual care it will last for a long time. Thus, a detailed description of the types of seals for a bath, as well as the process of sealing and its further maintenance, will help you carry out the work yourself.

Types of inter-crown insulation made of flax

1. Tow. Tow made from flax, produced in a gentle manner, is a loose insulation tape that is perfect for all types of log houses.

2. Linen wool. The second name of this modern material is “Euroleen”. Made on modern equipment, flax batting is interwoven flax fibers. For strength, the resulting fabric can be stitched with threads.

Another natural inter-crown insulation, consisting of fibers from a plant of the linden family. Natural jute is becoming increasingly widespread due to the following advantages:

Tow

Tow is an inexpensive insulation material consisting of natural plant fibers, mainly flax. Although it may also contain jute. Therefore, it is not easy to say something specific about this type of insulation; it all depends on the materials from which it consists. Tow has a cotton wool-like, soft structure, perfect for caulking. For the initial insulation of the log house, i.e. Laying insulating material between the crowns produces tow in the form of a tape.

Flax tow does not have the best characteristics; it is afraid of moisture due to the low lignin content in the fibers of flax plants. Therefore, it is better to use it for insulating log houses made of timber or rounded logs, because they contain a small percentage of moisture. In its structure, linen tow in the form of a ribbon is soft, light and quite easy to work with.

Ribbon tow made from flax and jute includes the properties of these two natural plants. It has the good heat-insulating properties of jute and the soft structure of flax. The highest quality insulation is considered to be one in which the flax content is less than 20%.

Tow, jute and moss are good natural insulation materials. If you use them wisely, for example, using moss or jute rather than tow for a bathhouse and logs of natural moisture, then high-quality and durable insulation of the log house will be ensured.

Materials unsuitable for insulation

Option #1 - mineral wool

Ordinary mineral wool also cannot serve as a heat insulator for timber in any way - its threads have moisture absorption close to zero. All the moisture in this material is retained by the tension of the fibers and does not disappear anywhere. In addition, this material allows heat to pass through and even creates a dew point when lighting a bath. And yet, unscrupulous builders sometimes manage to use it.

Option #2 - isover

As for Izover, which has recently become incredibly popular, in those places between the rims where there is no gap, it is compressed almost 100%, and here its heat transfer is somewhat less than that of other material under the same conditions. But in the gaps, Izover is a little fluffy and copes quite well with its functions as a heat insulator. On the other hand, Izover’s ability to absorb and remove moisture is almost the same as that of many other inter-crown insulation materials, but this material does not burn, does not rot, does not need to be caulked, and over time it does not crumble like dust. Unpleasant dust can be eliminated with a sealed finish.

So, let's summarize. This is what Izover is preferred by many as an interventional insulation:

- Doesn't burn, doesn't rot;

- Convenient to use;

- It compresses well and leaves no gaps;

- Birds don't like it;

- Does not require additional caulking.

But this fashionable material also has a significant drawback: it is not very environmentally friendly, and when slightly torn, it emits caustic and allergic dust. It also quickly accumulates moisture... And many lazy builders convince future owners of bathhouses to use this inter-crown insulation - after all, it’s much easier for them to work: it cuts easily, just rolling out over the log, construction goes quickly and costs are less. That is why, despite advertising from neighbors, not many people want to install Izover in the walls of bathhouses - especially those who saw it in use: even with dry timber, the insulation turned out to be 2/3 wet.

Also, similar synthetic materials often serve as a dangerous source of phenol. So, let’s conclude: mineral wool in a compressed state does not remove moisture at all, and Izover, if not covered with a vapor barrier, completely turns into a sponge. The decision is yours.

Option #3 - polyurethane foam

Polyurethane foam is also used as inter-crown insulation. It is valued for the following properties:

- Fast technological installation.

- Good adhesion, thanks to which the timber sticks tightly together. When drying, it will not twist, and the steam room will not warp.

- Foam seals corners in a log house much better than moss or tow.

- Hardened one-component foam is not flammable and does not emit toxins, which, however, multi-component foam cannot boast of.

- The process of caulking after foaming is quite simple.

But with all its advantages, foam as an interventional insulation does not please with the following qualities:

- It is not elastic, which is why microcracks may appear over time (and wood, like any living material, can slightly change its volume).

- In winter it does not tolerate the cold well - it crumbles.

- Less resistant to ultraviolet radiation. Over time, it turns to stone and discolors from the sun.

- Not environmentally friendly enough.

And, let us note that polyurethane foam is used relatively little today as inter-crown insulation, and therefore many other negative consequences of such insulation are not yet known. But the foam itself is also used as inter-crown insulation in the following alternative:

- Option #1. The beams are laid half a meter apart, and after construction is completed they are foamed. This way it supposedly dries faster, and then the remaining wide gap can be foamed. Fast, airtight and no caulking required. From the inside of the bathhouse, the cracks are caulked with linen rope.

- Option #2. Before using the foam, allow the bathhouse to sit completely on the tow. After all, the settlement of the building occurs due to the shrinkage of the timber itself - and this is at least a year and a half. After that, a 5-centimeter gap is punched in the tow and the groove is foamed, and finally, the seams are protected with sealant.

As for the choice of foam brand, “Macroflex Pro” is so far most suitable for this purpose. In a word, there is a lot of material, and, as they say, as many people as there are so many opinions. There are also bathhouse owners who built their steam rooms ten years ago and are quite satisfied with Izover as a sealant. They claim that after rains the timber will be wet in place of the insulation, regardless of the type of insulation: it is moss or a modern material. And the main advantages become the decisive factor: they are cheap and easy to build. It’s just important not to take the cheapest Izover (also called Chinese) - you can really get poisoned from it.

Video description

The correct use of seam sealants is shown in this video:

But the first caulk is not the only one, especially when it comes to natural insulation. The logs in a wooden frame shift and rub against each other; this period can take up to 3 years, during which the walls will have to be additionally caulked. But even after shrinking, the insulation can fall out and become unusable, so it needs to be replaced as it wears out. The tools for re-caulking a log house are the same as for the first one.

Repeated caulking occurs as many times as necessary. This is a targeted procedure that corrects the situation only in the place where new cracks have appeared. It is advisable to perform it in the fall before the rains begin. Even if the shrinkage should have ended long ago, you need to inspect the house annually and update the caulk.

What to put between the crowns?

To create a gasket between the crowns of a log house, there are many insulating materials. But not all of them are ideal for these purposes. First, you need to safely cross out synthetic and artificial materials from the list of candidates for inter-crown insulation. They will cope with the thermal insulation task well, but the price of their work will be damaged crowns of the log house. Artificial materials allow air to pass through well only when they are in a fluffy form, and when they are compressed by logs, they cannot do this, which will negatively affect the wood; it may begin to rot.

There is another drawback to these insulation materials - they are made from non-ecological components. And it seems to me that many people choose wood for construction in order to be closer to everything that is clean, safe and natural. The use of artificial, synthetic insulation will disrupt the entire beneficial microclimate of the room. It is for these reasons that I do not recommend focusing your attention on these insulating materials.

And it is advisable to lay insulation between the crowns from natural materials, which consist of fibers of natural plants. They also have good thermal insulation characteristics, but they are in perfect harmony with the wood and do not cause any harm to it. Among such materials are:

- Moss.

- Jute.

- Tow.

Many builders cannot make the final choice of insulation, deciding which of these three materials is better.

Moss can safely be called the best insulation material. Even with the advent and development of technology, they have not yet been able to invent and create insulation that is superior to moss, unless they came close to its characteristics by producing jute insulation. There are more than a hundred varieties of moss, but only brown and white moss have shown excellent results in construction. They practically do not differ in their properties, they only have differences in appearance. White moss consists of small light green fibers. It does not have a root system, despite this it grows well. White moss produces a very valuable product - peat. Brown moss consists of longer and tougher fibers that are greenish on top and brown on the bottom. Its stems resemble flax in appearance, which is why its second name is cuckoo flax.

Specific answers from a log cabin expert:

1) Which moss is best to use for assembling a log house from logs and timber? The best two types are sphagnum and cuckoo flax.

2) Which moss is better to buy for a wooden frame - red, brown or white? For a log house, it is best to buy “cuckoo flax” moss, and for a bathhouse, white marsh moss “sphagnum” is better.

3) What kind of moss is best to choose for a wooden bath? As already mentioned, “cuckoo flax” moss is well suited for a wooden log bathhouse.

4) Is it possible to use moss to caulk a bath? For caulking, it is better to buy long-fiber moss “cuckoo flax”.

5) Is bog moss or bog moss best used for laying chopped logs in a log house? In this case, it is better to choose swamp moss.

Jute fiber

Mechanically combed stems of jute hemp Jute Tassa produce a tough and at the same time durable fiber, which is used not only as a sealant on the walls of the bathhouse, it is an ideal material for containers and technical fabrics. Jute is produced in the form of coils, ribbons, and ropes, which allows you to caulk cracks on the walls of a bathhouse many times faster than using tow and moss.

Technical jute has only two disadvantages:

- High hygroscopicity;

- Susceptibility to rotting when soaked for a long time.

Jute for a bathhouse is interesting because during the shrinkage process it ideally fills the inter-crown space, especially if the log house is built from chopped logs. In this case, you only need to caulk with jute fiber and rope.

If, according to the project, the bathhouse building is planned to be covered with decorative finishing, the jute rope will simply rot in a couple of years. The tapes are laid to seal the crowns of the new log house; the rope is good for finishing the open surfaces of the walls of the bathhouse.

In fact, jute occupies an intermediate position between dense and hard moss and soft flax tow.

Video description

This video describes the correct caulking of a wooden log house:

Before caulking the timber, the cracks must be cleaned of dust and dirt, treated with antiseptics and anti-rot solutions. Work begins with the lower crown on the outside - the junction of the first and second logs. Then you need to go around the house in a circle, sealing the same lower crown. The next stage is to repeat the procedure from the inside. Only after this can you move on to the next crown. If flax or jute is used, they can be fixed with a construction stapler.

Stretch

Stretch caulk is a way to seal small and narrow cracks. These occur between loosely fitted logs of a log house. A caulking chisel with a flat and not sharp blade is used.

The tool needs to be chosen correctly Source remontnik.ru

The tow for the log house is distributed into two long strips for each crack. One, 9-10 cm wide, is stretched along the crack and hammered into it. The edge of the strip is left hanging freely. A second ribbon of fiber is woven into it and a roll is formed. The resulting structure is driven inside the gap so that it completely occupies the space.

The method is suitable for all types of natural and artificial fibers, but is not suitable for caulking with moss. Narrow cracks are completely sealed, but in wide cracks the caulking will not hold. The effectiveness of the work is checked simply - you need to pull on any part of the fiber. It should not be removed from the slot with normal force.

Hand-cut sauna caulk

When building a hand-cut sauna, it will not be possible to do without caulk. This is a very important stage of construction. There are many options for choosing crown gap sealants, the most popular are moss, jute, tow and flax wool. Recently, sealants made from sheep's wool have become in great demand.

A brief overview of popular materials for caulking hand-cut baths

If the choice is made in favor of moss (and this is the material our ancestors used), then it must be dried very carefully to avoid rotting of the logs. But you cannot overdry the moss, as it may crumble. Here we must follow the rule of the “golden mean”. It should be noted that moss is rarely used today, as more convenient to use materials with better performance characteristics have appeared.

When using seals based on felt and tow, it is necessary to impregnate the material with formaldehyde or other anti-moth compound before starting work. Otherwise, the material may be completely eaten by moths. After treatment, the sealant must be thoroughly dried and only then can it be used.

Linen wool and jute are the most popular materials today. Valuable features of jute: very high strength and lack of hygroscopicity. In climatic zones with high humidity, jute is indispensable, as it always remains dry. Linen batting is a tape product, which simplifies its installation and subsequent operation.

of seals based on sheep wool , all of them are completely environmentally friendly, and their characteristics deserve the highest praise. But there is one “but”: they are very expensive.

Practical recommendations for choosing a sealant

- To achieve maximum efficiency , it is necessary to choose all-natural seals. For example, natural jute contains a natural antiseptic - lignin. Lignin is a resin that protects the seal and the log surface in contact with the jute from rotting. The drying speed of jute is very high, and this is a very important quality for a sealant.

- High-quality insulation should not have foreign impurities. Even impurities or shedding of the product that are imperceptible at first glance indicate that the product is of poor quality and made from waste. Such a sealant has already completely lost its value (or will lose it very soon) and is not worth using for caulking.

- The worst property of insulation is the accumulation of moisture throughout its entire thickness. This leads to rotting of the walls of the hand-cut bathhouse.

If you do not understand the quality and features of seals, you can focus on their cost. If the price is very low, it means that its quality and properties leave much to be desired. Opt for a different material. Better yet, listen to the advice of professionals and do not try to save as much as possible, because the saying: “The miser pays twice” has been tested many times in practice by many developers.

Plant fibers or tape material

Plant fibers are often more affordable in terms of cost, but they require more installation time.

Plant fibers are more environmentally friendly, but have a shorter service life compared to synthetic materials.

Reference. A separate article is devoted to foil materials used as insulation for ceilings and walls.

Eco-insulation materials

These invisible and at the same time irreplaceable helpers for creating home comfort are:

- synthetic (mineral-based, with two types of pores);

- natural (rope jute, moss, flax, hemp).

Synthesized insulation materials, despite the rapid technological development, are still not able to satisfy all the requirements for quality and durability. It is often their fault that the walls of houses “sink” and rot. This problem especially concerns buildings made of rounded logs, which are deprived of their protective coating during the production process and are therefore more susceptible to constant contact with moisture.

Types of natural interventional and artificial insulation

There are different ways to maintain a comfortable temperature inside a log house or bathhouse. However, no matter what type of wooden house is preferred by the owner, inter-crown insulation naturally helps to maintain heat in it.

Materials with these characteristics include:

- ribbon linen;

- moss;

- rope jute;

- hemp;

- tow.

The general properties of natural insulation materials are:

- low thermal conductivity;

- antifungal properties;

- bactericidal.

Each of the listed materials also has its own unique properties, which attracts an equal number of consumers.

What qualities should a sealant have?

The main function of the inter-crown seal is heat insulation ,

which means that the material used for this purpose must have a low thermal conductivity coefficient.

Secondly, since wood is a “living” material that reacts to changes in environmental conditions, the gasket between the crowns is designed to prevent the appearance of blown gaps, and for this purpose it must be sufficiently dense and elastic

. Thirdly, it is required

to be resistant to rotting,

the process of which threatens to destroy not only the material filling the cracks, but also the wooden walls themselves, as well as

the ability to give and absorb moisture, adapting to changes in the humidity regime both outside and inside the room.

The next condition for the effectiveness of interventional insulation is non-susceptibility to biological damage

from insects, rodents and birds and, finally,

environmental friendliness,

that is, safety for human health.

About choosing insulation for a log bathhouse

Traditionally, a truly Russian bathhouse should be built only from larch, pine or spruce wood that grew far in the north. And no matter how precisely the beams or logs for its walls are adjusted to each other manually or in production, it is impossible to do without the use of insulating materials. Thanks to them, the bathhouse will quickly warm up to the desired temperature and retain heat inside the steam room for a long time. It is recommended to use only natural inter-crown insulation in the process of laying a log house.

Despite the wide variety of modern synthetic materials for insulation, none of them has such unique properties as plant fibers. In addition to being unconditionally natural and, accordingly, environmentally friendly, such insulation materials themselves are durable and help extend the service life of construction wood. By regulating the level of humidity, they prevent rot, which is the main enemy of wooden buildings.

Neither wool fiber, nor batting and padding polyester, nor sealants, nor thermal insulation tapes can provide that amazing microclimate of a wooden bathhouse, for which log houses made of timber and logs are especially valued today. Only moss, flax and jute as inter-crown insulation ideally correspond to the image and spirit of a truly Russian bathhouse.

Moss insulation

Moss has always been used in Rus' as a sealant for wooden log houses. And not only because its habitats, damp forests and swamps, occupy a significant part of the country’s territory. The unique qualities of this plant are valued: it does not rot at all and does not allow organic bodies and objects to decompose in the dampness of swamps.

Dismantling the log cabins of centuries-old wooden buildings, insulated from roof to floor only with layers of moss, one can observe perfectly preserved wood at the junction of the crowns. And the excellent heat-insulating properties of this plant have been tested by Siberian snowstorms and frosts. And a better alternative for sealing the frame of a wooden bathhouse has not yet been found.

Not every type of moss is used in construction. The so-called red moss copes best with the task of insulation. The biological name of this plant is cuckoo flax; it grows in the wetlands of the northern territories. It is less widespread in nature than white sphagnum moss, which is also used for thermal insulation of log houses.

Qualities that allow mosses to be considered the best inter-crown insulation:

- pronounced bactericidal properties that prevent the development of mold and rot;

- the strength and elasticity of plant fibers that form a well-retaining heat-retaining layer;

- vapor and gas permeability, allowing you to maintain a healthy microclimate indoors made of logs or timber;

- the ability to absorb excess moisture, promoting rapid drying of wood;

- natural environmental safety.

Compared to cuckoo flax, sphagnum is less durable. And although it is more convenient and preferable to use red moss for laying a bathhouse in a log house, white moss always turns out to be more accessible.

Jute insulation

The use of jute spacers between the crowns of the bathhouse frame is possible in the absence of moss.

This insulation is no less environmentally friendly, it prevents rotting due to the lignin content in its fibers, but is inferior to moss in terms of thermal insulation properties. But it is easier to install and visually more aesthetic. As a result of special processing, insulating materials are obtained from the annual jute plant: tow, felt and flax-jute. Long fibers of tow are suitable for compacting crowns during manual felling and as caulking. And tapes of felt and linen-jute, uniform in density and layer thickness, are convenient for insulating walls made of timber and rounded logs.

The disadvantages of this material include its ability to cake over time and its high cost.

Linen insulation

Flax has been used as a natural heat-insulating material in the construction of wooden baths for as long as moss. Today, tow and flax wool (eurolin) are made from it. Both types of insulation are durable and environmentally friendly, their density allows you to reliably isolate the inter-crown space of any type of log house from heat loss.

Ordinary tow, packaged in bales, is used to caulk cracks, and for laying in log houses, material is used in the form of a tape. Flax batting, which is also a tape made from weaves of flax fibers, has good thermal insulation properties, is cheaper than jute and more accessible than moss. But the hygroscopicity (ability to absorb moisture) of the material is much worse.

In order for the Russian bathhouse to be hot, but “breathable”, and the steam in it to be not just light, but healthy, by purchasing a beam or log of excellent quality, you should not skimp on inter-crown insulation. Its naturalness and optimal hygroscopicity will provide for many years maximum comfort, a charge of vigor and pleasure with every visit to a warm and cozy wooden bathhouse in any season.

Where can I buy this material?

Our company sells high-quality and very warm interventional materials for wooden baths made of timber and logs, both in cash and by bank transfer. Call and check the availability of materials in a warehouse in Moscow and a warehouse in the Moscow region.

Our company specializes in the supply of natural spacer materials and natural materials for caulking - caulking works.

The store and wholesale warehouse of our company in Moscow is located here...

Is it possible, using modern tape insulation, to do without secondary caulking?

No you can not. Despite the high surface density and uniform thickness of the insulation layer along its entire length, when settling a house, linen and jute fabric still shrinks up to 5–6% in its height, which is 10–15 cm per floor. This means that the resulting cracks will have to be sealed. This can only be avoided in the case of a building made of laminated veneer lumber, and not at all because of the special properties of the insulation, but only because such buildings themselves are practically not susceptible to sedimentary processes and lose only 1–1.5 cm of height per two floors .

Performance characteristics

High-quality insulation, which is laid between the crowns of logs or beams, must meet high standards of quality and safety of use. Therefore, the main performance characteristics of the material include:

- High elasticity and density, maintaining properties throughout the entire period of operation. Thanks to its elasticity, the insulation is able to take the desired shape, and its density is able to fill existing gaps between the crowns.

- Low thermal conductivity for effective protection of walls from heat loss.

- High moisture and vapor permeability.

- Resistance to mold, fungi and harmful microorganisms that arise when exposed to increased moisture and heat.

- Resistant to ultraviolet exposure and adverse weather conditions.