It’s hard to imagine a traditional bath without hot steam, a fragrant broom and a warm shower after bath procedures. To organize hot water supply in a bathhouse, the main heat source is often used - an electric or wood-burning stove.

An alternative option is a water tank for a bathhouse, which is mounted on a heating boiler or stove. Read more about how to wisely choose a device of suitable volume and configuration for a private sauna or bathhouse.

What is the design

- The principle of operation is that from a large tank to a small one, cold water flows through the drive pipe, is heated in the small tank, which is called a heat exchanger, and returns through the outlet pipe to the main tank, already heated.

- If the drive and outlet pipes are positioned at the correct angle, then the water will successfully circulate by gravity thanks to natural physical laws. But in order to avoid the formation of air pockets in the system and ensure faster and more uniform heating of the water, the tank for the heat exchanger in the bathhouse is equipped with an electric pump for forced circulation of liquid in the system.

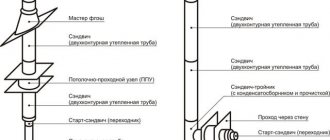

- The heat exchanger can be located directly next to the firebox itself, in which case it is installed at the stage of construction of the furnace inside the structure. Or it may have the so-called samovar operating principle, when a small tank is mounted around a metal chimney for a bathhouse directly next to the firebox.

- But regardless of the location of the tank, professionals prefer systems in which the liquid circulates freely, without additional pressure.

Let's talk about the rules of installation and operation

System calculation

If you decide to install the system yourself, you will have to make certain calculations. It will be difficult to absolutely accurately calculate the dimensions and volume of the system, and there is no urgent need for this.

For example, 5 kW is enough to heat a medium-sized room. This power can be provided by a heat exchanger with an area of 1 m². But the temperature in the furnace constantly fluctuates; when fully heated, 1 m² provides up to 9 kW, and when the furnace goes out, the power begins to drop rapidly and can drop by 5 to 10 times. Therefore, the area of the unit is taken with a significant margin, which makes it possible to equalize the heating of the liquid.

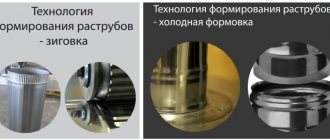

The configuration of the heat exchanger itself can be different; there is no consensus among experts. Some argue that stainless steel pipes are the best option, others prefer plates or manifolds consisting of 2 mating channels.

Connecting the system to the shower stall.

Tips for installation

If you decide to assemble the system yourself, then you should take into account several mandatory requirements.

- Tanks should be welded from metal with a thickness of at least 2.5 mm. The requirements for the upper, large tank are minimal; the main thing is that it does not rust or leak.

- The requirements for piping and the heat exchanger itself are somewhat higher; in the past, the most popular material for a heat exchanger was cast iron. Indeed, the material is very durable, does not corrode and holds the temperature for a long time. But cast iron also has serious disadvantages; it is heavy, which requires serious fastenings. And cast iron takes a long time to heat up.

- At this time, most experts prefer to assemble a system from stainless steel; its price is of course higher than that of cast iron or conventional steel grades that are susceptible to corrosion, but the savings here will cost more in the future. For the heat exchanger, stainless steel grades 08X17 (430) will be the most optimal; or 8-12Х18Н10 (304) they have optimal heat transfer parameters and meet all hygienic standards.

- As for the connecting pipes, naturally they should also be made of stainless steel. The drive pipe with cold water must initially, when leaving the large tank, fall slightly below the level of the heat exchanger; a drain valve is mounted at the lowest point and then rises at an angle of 2˚ to 5˚ to the entrance to the heat exchanger.

- The outlet pipe, through which hot water will flow into a large tank for a heated bath, must exit the heat exchanger, pass through the wall at an angle of at least 30˚ and connect to the tank.

Tank on a pipe for a bath: types, principle of operation, dimensions and installation

Hello, dear guest!

Sit back and forget about your pressing problems for a moment. The topic of today’s article is one of the favorite vacation spots of Russian people. A place where people have long washed themselves, treated illnesses, met with friends, and simply hid for a while from life’s hardships.

Have you already guessed what I mean? Right! Today we will talk about the Russian bathhouse. About a classic bathhouse, but made in modern solutions, comfortable and safe. We will take a detailed look at the tank on a bath pipe, find out why it is needed, in which cases this option for heating water is optimal, and find out the dangers of choosing the wrong bath containers.

Why do you need a tank on a pipe?

Strong hot steam, invigorating tart aroma of wood, birch and juniper brooms, the special spirit of a Russian bath... Not a single sauna with scalding air can replace real light steam! Even in our time, a bathhouse is a favorite place to relax for a person tired of the everyday hustle and bustle. And no entertainment and shopping centers will replace it.

And now I’ll add a little horror to the beautiful picture.

Imagine - you have decided to build or renovate a bathhouse. And so, the walls are covered with new lining, fresh brooms are waiting for hot steam, and the simplest thing remains - to buy a tank for the sauna stove. It would seem, what could be simpler?

Modern stores are overflowing with bath accessories and there are a great variety of containers for heating water. Most are tanks for sauna stoves of various shapes, shiny, smooth to the touch, with high-quality and beautiful welds. It would seem, what else is needed?

Now let's take a closer look at the material of manufacture.

note

In 80% of cases it is stainless steel with the incomprehensible name AISI430. And few people know that the stainless steel in this AISI is only a shiny surface and a little chrome. And a sheet of such material burns out under the influence of direct fire in 3-4 months. It’s no wonder that the manufacturer’s warranty for such tanks is no more than 3 months. Moreover, the sheet thickness is rarely more than one and a half millimeters.

And this is where the fun begins. Imagine, you bought a tank for 10, 15, or even 30 thousand rubles and happily installed it on the stove in the bathhouse. And six months later a hole burned in the bottom. Scary?

So I'm scared.

But there is a great way to avoid all such troubles, even using products made from Chinese stainless steel. And one of them is installing a water tank directly on the sauna pipe.

The principle of operation of a tank on a pipe

The first Russian baths were heated “black”; smoke filled the room, leaving traces of soot and soot on the walls. This technology has long been a thing of the past; modern stoves are equipped with chimneys.

Vapors and gases leaving the stove through the chimney heat it up greatly. And this temperature can be used to heat water.

To do this, a tank is installed on the pipe. It encircles the pipe and the water in it is heated by hot gases. This solves two problems at once - heating water and thermal insulation of pipes.

Pros and cons of this design

The main advantages of installing a sauna tank on a pipe:

- The reservoir can be placed along the entire length of the pipe, which allows you to obtain a large volume of hot water. At the same time, increasing the volume of the container will not affect the heating time;

- The temperature of the gases in the pipe is high (up to 500 degrees), so heating is carried out quickly and evenly;

- Installing the tank is easy to do with your own hands;

- Hot smoke is not just discharged into the street, but heats the water, so the efficiency of the stove increases;

- The service life of the chimney increases;

- The water maintains its temperature for a long time while the pipe cools;

- No additional heating elements are required;

- The samovar tank can be installed not in the steam room itself, but at the attic level. In this case, hoses are connected to the heat exchanger to input cold water and output hot water.

Design disadvantages:

- Large tanks are difficult to install due to weight. If it is necessary to install a large container, it is necessary to use a fastening system, and the load should not fall on the stove, but on the walls or foundation;

- The water temperature cannot be controlled;

- The liquid boils away faster;

- The design is not suitable for every chimney. For example, if the pipe in the bathhouse is brick or asbestos, you will have to choose another option;

- If the heat exchanger is located high, it is difficult to fill it with water.

Types of factory tanks and average prices

Factory tanks have different configurations. Main parameters:

- Type of material;

- Design;

The most common materials are galvanized, steel, stainless steel, less common are products made of cast iron.

The most popular factory shape is a rectangle and a cylinder with a circular cross-section.

Average cost of a rectangular tank with a volume of 50 liters:

- Steel - 1000 rubles;

- Galvanizing - 1500-2000 rubles;

- Stainless steel - from 3000 rubles.

How to choose?

To begin with, you need to decide where the tank will be located - directly above the pipe, or it will be a remote structure located in the attic.

Installing a container in the attic is convenient, but not always possible - it all depends on the design of the roof and the possibility of supplying and discharging water.

Calculating the volume

The required volume of liquid is calculated from the norm of 15-20 liters per person plus 10-15 liters in reserve. For example, if a family of 2 people periodically washes in a bathhouse, then a tank of 50 liters will be enough. A family of 4 people will need a capacity of 80-100 liters.

Type of material

Pros and cons of steel, cast iron, stainless steel:

Cast iron containers are heavy, they are inconvenient to install, the water in them heats up slowly, but remains hot for a long time;

Containers made from it last longer than steel ones, but over time they rust and burn out;

Due to their high thermal conductivity, steel tanks heat up quickly and cool down just as quickly. The main advantage is the price, the main disadvantage is the low service life;

They combine all the advantages of iron products with high corrosion resistance.

Enameled products are found in stores. They are more durable than uncoated steel tanks, but are susceptible to chips, in place of which pockets of corrosion form.

Note!

Construction work does not only involve the construction of a furnace or heating device. The drawing and layout of the foundation also require attention.

Remember to be safe and remember that large amounts of hot equipment and improper handling can cause burns and injuries. The overall atmosphere and interior of the room can be affected by the design of walls, benches, stoves, and finishing with clinker tiles.

If you have a real desire to build a bathhouse, then carefully consider everything, from laying the foundation to door and window frames and tanks for heating the liquid. Monitor how conscientiously the work will be completed and control the processes.

Watching our video will not replace consultation with a specialist, but will help convey a lot of useful information. Ready-made projects or proposals will greatly simplify the task of arrangement.

How to properly install and connect the tank

Depending on the conditions in the bathhouse, the connection diagrams for the container may be different. For example, if water supply is installed in the washing room, i.e. water will be supplied under constant pressure, then a closed water supply system is needed.

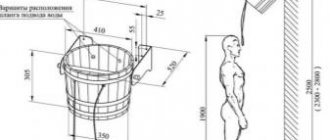

The photo shows an example of installing a tank in a washing room.

In this case, the ideal option is a stove with a coil inside, which is connected to the tank. You can, of course, implement another method - hang the container on the stove itself. For this, the simplest design of a tank of 50-120 liters is suitable, which you can weld yourself, in which case the price of the product will be determined solely by the cost of the material.

If the connection was made correctly, then the water heating circuit looks like this - the water is heated in the register and, according to the law of physics, rises. There it gradually cools down and goes back into the register. Thus, natural circulation is obtained.

Connection instructions are as follows:

- The container is installed in the steam room of the bath under the ceilings and connected to the coil using pipes.

- For normal circulation, the upper outlet of the tank must be connected to the upper outlet of the coil, and the lower outlet must be connected to the outlet from below. Thus, hot water is discharged from above, and cold water will flow from below.

- At the entrance of cold water, check valves and safety valves are installed, the latter is also called a blast valve.

- Then the threshold pressure is set according to the instructions of the storage tank, at which the safety valve is activated.

This system will work as follows:

- A filled tank is heated through a coil and when hot water is drained, it will automatically begin to be filled through the cold inlet.

- If hot water is not used, the pressure in the tank will increase as it heats up. When the critical point is reached, the explosive will go off and release the pressure.

If the system is implemented correctly, then the hot water in the bathhouse will be in the quantity required, and at the same time the pressure will be sufficient to wash comfortably.

How does the system work?

Heat from the stove is transferred to the register or water jacket of the heat exchanger, which leads to an increase in the temperature of the coolant. Since the water in the tank has a lower temperature, pressure is created that promotes gravity flow of the liquid. Thus, hot water enters the tank, and cold water enters the heat exchanger through a pipeline, where it is heated (from the bottom point of the tank, water should be supplied to the bottom point of the heat exchanger, and from the top point of the heat exchanger, water should accordingly go to the top point of the tank). The minimum pipe diameter is 3/4 inch. The process continues until the temperature in the oven drops.

Important! The tank must be higher than the heat exchanger, otherwise water circulation will not be ensured.

Without installing a pump, the total length of the pipes between the heat exchanger and the remote tank should not be more than 3 m. There is also a nuance in the principle of the pipeline design. It is necessary to create a slope to ensure natural circulation of the coolant: the pipes connecting the heat exchanger to the tank must have a slope of at least 25...30 degrees, and those delivering water from the heat exchanger to the tank must have a slope of at least 250 degrees.

Installing a heat exchanger allows you not only to do without a water heater in the tank, but also to transfer heat to all rooms.

The heat exchanger must be chosen wisely. It should not reduce the performance of the heater by taking away a significant amount of heat from it. The maximum that it can take is 10% of the generated thermal energy.

If it is not possible to organize the movement of water by gravity, you can supplement the system with a circulation pump. This will increase its effectiveness. It will be possible to increase the length of the pipeline and reduce the slope. But the operation of this equipment is only possible from a 220 V electrical network.

Circulation pump pressure calculator

Go to calculations

Important! When operating water supply systems, remember that it is forbidden to heat the heater if the tank is empty. Otherwise, the welds may come apart. We also must not forget that in winter, water must be removed from the system (if the bathhouse is not heated), since when it freezes it can break the structure.

Since when installing water supply in a bathhouse it is often impossible to do without a circulation pump, which ensures the movement of liquid in a closed circuit, 5 of the best models are offered.

Boiler for a bath

Boilers are effective in regions where there is no firewood. Gas and solid fuel options are popular. It is better to prefer solid fuels on peat. Unlike coal, they do not pollute the surrounding area.

There are two options with boilers. Either connect the tank to the heat exchanger in the bathhouse (the heat exchanger is placed in the combustion chamber of the boiler), or install the tank on the boiler itself.

Information. Unlike stoves, boilers are not assembled from bricks, but are purchased ready-made. The design with a heat exchanger has maximum efficiency; by the way, it can be implemented without a ready-made expensive boiler. This is discussed below.

You can use homemade boilers for a bath from a pipe, but this requires good quality welding work, which is the main difficulty. A common option is to manufacture the boiler and tank from large-diameter stainless pipes.

Wood-burning sauna boilers with a tank are produced ready-made. Structurally, they are designed in the same way as a regular sauna stove and differ in size. Their water capacity is usually larger, and the area for installing stones for soaring is smaller.

Anti-corrosion treatment

For metal tanks, corrosion is the main problem. The key solution is stainless steel, but for now, the price for it remains 10 times higher than usual (in terms of weight). In reality, a stainless steel tank costs not 10 times more than a regular steel tank, but much less. This happens because the thickness of the walls of the stainless steel tank is made smaller. There is no reserve required for thinning due to corrosion.

Anti-corrosion treatment of tanks is carried out in the factory. Technologies in this area do not stand still and are constantly being improved. Zinc has the strongest adhesion to steel. Various protective layers are applied on top of it.

There are two popular options for anti-corrosion protection. This is either paint for a hot water tank in a bathhouse, or glassy enamel, which is applied at high temperature. Enameled tanks are better protected from corrosion and high temperatures than painted ones.

The general technology for their manufacture is the same as for conventional enamel cookware. Glass-based food grade enamel is used for tanks and utensils, without the addition of lead.

Information. In some cases, they carry out independent anti-corrosion treatment of tanks. All homemade structures need it (with the exception of stainless steel). You need to use only specially developed compounds and apply them to a clean and grease-free surface.

Advantages and disadvantages of samovar systems

A sauna tank on a pipe is called a samovar. It is an integral part of the chimney pipe elbow. Its location is very convenient, the water heating process occurs much faster and more uniformly than with other locations. The design itself is very compact.

The negative aspects of samovar systems include the fact that filling the tank with water is not very convenient. But this issue is easily resolved if the top of the tank is in the attic and a water tap is connected to it.

Important. It is very dangerous to make mistakes in designing the volume of the container, since you can end up with very frequent boiling of water.

The material for making samovar containers is usually stainless steel. The possibility of corrosion over time when using other materials is detrimental to the normal operation of the bathhouse, therefore the decision to install a stainless steel container is the right decision.

Among other things, the high thermal conductivity of stainless steel guarantees fairly rapid heating of the water in the samovar tank, and the strength of this material allows you not to be afraid of deformation of the device due to temperature changes.

Why stainless steel: key advantages of the material

The modern market offers a wide range of water tanks made of cast iron, stainless steel and enameled material. As practice shows, stainless steel is the most popular among bathhouse owners, which is due to the competent and acceptable ratio of operational and technical characteristics and cost indicators.

Stainless steel is characterized by excellent thermal conductivity, withstands temperature changes and objectively lasts longer than various ferrous metals.

Examples of stainless steel tanks

Stainless Steel Oven Mounting Tank

Stainless steel tank

Stainless steel containers

A logical question arises here: which of the existing brands of stainless steel is better suited for the manufacture of the container in question, intended for use in a bathhouse? Firstly, this is brand 08Х17 (430), secondly, 8-12Х18Н10 (304). The mentioned materials, among other things, are used for the production of tableware and are characterized by high resistance to high temperatures, are completely hygienic, do not rust or deform during use. In addition, such materials are unpretentious and extremely easy to maintain.

Composition and mechanical properties of different grades of stainless steel

To summarize the above, we can highlight 3 main advantages of water tanks made of stainless steel:

- the products do not require additional protection from high air humidity and can easily withstand operation in conditions typical for a steam room;

- Stainless steel has high thermal conductivity, which makes it possible to obtain hot water in the shortest possible time;

- Stainless steel tanks do not deform due to sudden temperature changes, or these deformations are insignificant.

Mounted

This design option is hung on a standard metal sauna stove. The presence of metal walls of the furnace is mandatory, since heat is transferred through one of them to the water in the tank. This design is not widely used due to low efficiency, but its main advantage is maximum simplicity.

A hanging tank for a bathhouse is usually made of thin stainless steel. It is placed outside the stove and located in a visible place in the bathhouse. Stainless steel is not only an ideal material for water tanks, but also has a beautiful appearance.

When you need the simplest tank for hot water in a bathhouse, wall-mounted installation is best. With it, you don’t even need to do pipe routing. The tank is delivered completely ready.

The bath tap for hot water is also included with the tank upon purchase. The spigot is located at the center of the lowest point, and the bottom is usually flat or has a conical stamping.

The inconvenience of this location of the tap is the small distance from the floor. In addition, the stove is often placed in the corner of the bathhouse. One side of it is occupied by the door, and the other by the tank. Thus, it turns out that the tap is in a very inconvenient place. This problem is solved by installing a pump.

Information. For a wall-mounted tank, the sauna stove should be standard. This is either a ready-made structure, or a home-made one, but having at least one flat metal wall of the appropriate size for the tank.

Wall-mounted tanks have either a removable lid or a filler neck with a diameter of at least 10 cm. A filler neck is much more common. It makes cleaning and processing the internal space somewhat more difficult, but makes the structure more durable.

The cheapest designs of hanging tanks are welded from sheet steel and galvanized. The service life of such structures is short. Stainless steel thin-walled structures are gaining popularity.

Due to their small wall thickness, they are affordable. Steel enameled tanks are rarely used as hinged tanks on the stove.

Why do you need a water tank in a bathhouse?

As for the traditional Russian bathhouse, it always had two containers with water. The first is for hot water. The second is for cold. It is believed that the comfort of spending time in the bathhouse depends on the first tank of water.

Here, it is worth clarifying that one adult needs up to 25 liters of water. This must be taken into account when purchasing a container.

Another feature of the tank is the saving of electricity required to heat the liquid. And probably the main advantage is the increase in humidity in the room.

Based on the above, we can conclude that the volume of the container depends on the number of people for whom it is designed. If the sauna is for two, then a tank with a capacity of up to 50 liters will be enough. If there are more than two people, then a 100-liter tank will come in handy.

Types of tanks

All tanks are divided into types according to two criteria: installation method and material of manufacture. According to the installation method, tanks are:

- built-in;

- remote;

- samovar type (mounted on a chimney).

According to the material of manufacture:

- cast iron;

- stainless steel;

- made of enameled steel.

Each type has models that differ in shape, volume, and wall thickness. Most containers are equipped with standard taps and have shower outlets, but there are also those from which water is drawn through the top using a ladle. In order not to make a mistake when choosing, you should familiarize yourself in detail with the advantages and disadvantages of all these types.

Built-in tanks

Built-in tanks

The most economical and convenient option. The tank is installed during the laying of the furnace. Its lower part is located inside the firebox, due to which the water is heated directly by the flame. Hot water is drawn through the top using a ladle or using a built-in tap.

Brick oven with water tank

Due to direct contact with fire, the walls and bottom of the container must be as thick as possible, therefore the most preferred material for such a tank is cast iron with a thickness of 5 mm. Stainless steel tanks with wall thicknesses of 1 and 1.5 mm are considered no less popular. Enameled steel containers are not suitable for this installation method. Cast iron tanks are bowl shaped, stainless steel tanks are usually cube or cylinder shaped.

Cast iron water tanks

Advantages of built-in tanks:

- water heats up quickly;

- the water temperature is maintained for a long time;

- free space is saved since the tank does not protrude beyond the stove;

- easy installation.

Flaws:

- the heat transfer of the furnace decreases, since the main part of the heat is spent on heating water;

- the dimensions of the tank are limited by the size of the furnace;

- the tank must have thick walls, which increases its weight and cost.

Metal tanks for sauna stoves

This method is convenient in cases where no more than 4 people are steaming in the bathhouse at the same time, or people wash separately. For example, if 3-4 people take turns steaming in a bathhouse, this takes quite a lot of time, and accordingly, it will take longer to maintain the water temperature by adding firewood. The built-in tank allows you to save on fuel while remaining hot for a very long time. But for large companies, this option is not the most optimal, since it does not provide the required amount of water.

Remote tanks

Remote tanks

The remote tank is located at a distance from the firebox and is connected by pipes to a heat exchanger built into the furnace. Without this, its operation is impossible. Most often, such a tank is installed in a washing room or mounted on the wall of a steam room next to the stove, if its dimensions are larger than the area of the firebox. When choosing a location for a container, it is necessary to take into account that the length of the pipes should not exceed 2.5-3 m. Remote tanks can be made of stainless steel or enameled, cylindrical, rectangular or even triangular in shape - for installation in the corner of the room.

Triangular shaped water tank

Advantages:

- the tank is installed where it is more convenient;

- Large containers can be used;

- there is no direct contact with fire, so the tank can be enameled and with thinner walls.

If 6-8 people regularly steam in a sauna, a remote tank is an excellent option.

Flaws:

- without maintaining a fire in the firebox, the water quickly cools;

- the oven cannot be used without water in the circuit;

- more complex installation compared to a built-in tank.

Remote tank connection diagram

Tank on a pipe or “Samovar” design

This option involves installing a tank around a chimney, and in some models the pipe is located outside the tank, in others - inside.

Hot water tank on a pipe

Design option for a water tank on a pipe

In height, the tank can occupy the space from the stove to the ceiling, partially extend into the attic, or be attached only to a small section of the chimney above the stove. The most convenient container shape is cylindrical, but there are many models with rectangular, triangular and oval sections. Heating of water is carried out using smoke passing through a pipe, which has a very high temperature.

Oval shaped water tank

Advantages:

- fast and uniform heating of water;

- does not reduce the heat output of the furnace;

- space saving;

- you can install a container of any volume;

- the water stays hot for a long time.

This tank is suitable for any bathhouse and any number of people. It all depends on the size of the container.

Stoves with water tanks on a pipe

Flaws:

- installation complexity;

- increased soot deposition on the walls of the chimney.

When installing the tank, it is necessary to select the correct fastening elements in order to securely fix the tank in a vertical position. In addition, you will need to install pipes for supplying cold water and discharging hot water, and install a faucet.

Samovar type tank

Tank on the chimney

Installing a cold water tank

An individual water supply system with a storage tank is convenient to use and simple to install. Water is pumped from the well or it is filled in manually. But the latter option is considered “Spartan” and modern technologies make it possible to move away from this method of collecting water, especially since pumps are relatively inexpensive, and water is pumped into storage tanks.

A little about pumps

Submersible pump for water intake.

The work usually uses silent submersible pumps or installations with a hydraulic tank. It would be good if there is a small space in the bathhouse for installing such a station. This could be a basement, a shed built on the side, or a place in the bathhouse separated by a partition. In some options, you can even refuse to install a tank if the pumping station reservoir has a sufficient supply.

By type, pumps are distinguished by their power characteristics and noise ranges. It is clear that the quieter it works, the more complex the mechanism and the more expensive the device itself. But for a bath these are not regulatory indicators. For one-time water intake, the cheapest pump is suitable. But such devices only pump water from wells located nearby, with a high surface of water in them. The main thing is that the height between the level in the reservoir and the installation site of the water tank does not exceed 7 meters, but in reality this rarely occurs. If only the bathhouse is made on two floors.

Methods for installing storage tanks

The complexity of the water supply wiring depends on the location of the water tank in the bathhouse. It needs to be chosen so that you don’t have to pull the supply from one end of the room to the other. In any case, a bathhouse is a low-rise building, so you will have to choose the storage location from two options: lower and upper.

Bottom position of the tank

Such tanks are installed in the basement.

They already have a built-in water supply system. In this scheme, it is installed at the level of the bathhouse foundation. The tank is buried in the ground, and water is collected by installing an additional pump. Year-round use of the bathhouse requires insulation of the tank and laying it at a level below freezing of the soil. In the summer version, it is installed in the basement at a distance of 0.5 meters from the ground.

This arrangement of the tank also works on a pneumatic water supply circuit. The pump forces liquid into the reservoir, displacing air. When the balance is exceeded in favor of the liquid, due to its physical properties, the latter will begin to displace water to the outlet: taps and watering cans. But such a scheme is rarely resorted to, due to the unreliability of its operation. Typically, additional units are used to supply water: pumps and blowers. But this also entails increased costs, not to mention the installation, connection and supply work.

Upper diagram

An example of a top drive location. This is not recommended. It is better to secure it on a more stable platform.

Due to simpler installation, no need for central water supply to the bathhouse and installation of additional devices, the option with an overhead tank is used more often. According to the name, the tank is mounted at the maximum height, from the point of supply: watering cans and taps. This could be a roof, a special overpass, or a place inside the bathhouse. The water supply is carried out due to the difference in height. That is, by placing the tank in the attic, there is no need for any blowers, the water will flow by gravity to the taps. Like the lower installation option, this arrangement requires insulation if the bathhouse is used all year round.

The disadvantage of this method is considered to be low pressure, but to rinse after a steam room, you do not need high pressure. Raising it a little will allow the tank to be positioned. Increasing the pressure is achieved by setting it at a higher point. For example, for 0.1 atmospheres, a height above the level of the taps of 1 meter is sufficient, and for 0.5 atmospheres, the storage tank is installed at a height of 3–5 m. This is quite sufficient for bath procedures and technically feasible. Also, when installing a roofing system for a bathhouse, a place for the tank is provided in advance.

How to install a simple drive

As it turned out, these include tanks mounted at the top point. This means that first we select a container or make it from stainless metal according to the required dimensions. The tank installation process is as follows:

- In the intended location, the floor beams are first strengthened;

- the tank is installed and attached to the base in any way convenient for you;

- The valve and all outlets are installed.

How to install the valve?

An example of an installed storage unit in the wash compartment.

This process needs to be described in more detail. It is necessary to mark a point from the top edge of the tank, 7–8 cm away from it. A hole is cut here to fit the size of the valve. The tail part with a plastic float is inserted inside and secured to the tank with a bolted connection. To prevent water from escaping at the valve entry point, rubber gaskets are made on both sides, and the connection point is coated

adhesives and sealants. The seat is tightened, and a supply pipe of the appropriate diameter is connected to the shank. It is better to lay it to the tank in the ceiling space of the bathhouse, so that there are no pipes in the attic that interfere with movement. Now, when water is drawn in, the float will block the inlet, thereby stopping the flow until space is freed up.

Next we do the overflow. It is placed 2–3 cm below the valve entry point. A hole is drilled and the pipe is fixed in this place, similar to the installation of the valve. The outlet is discharged into the sewer. The outlet location is made at a level above 3 cm, from the bottom of the tank. So that water is not completely taken out of it. All outlets are sealed with gaskets and treated with hermetic compounds.

Plastic container for storage. Very convenient containers. The outlet and inlet valve are already installed in this model.

The tank is installed. If necessary, it is insulated by covering it with a special box. If possible, all protruding sections of pipes are fixed on the walls so that there is not a single freely hanging hose. The operation of the system is checked by starting the water. If any shortcomings are identified, it is better to eliminate them at the stage of installing the drive.

The upper location of the water tank is convenient when planning the construction of a bathhouse roof with a veranda. You can set aside a small space in advance and securely hide the drive, making all the necessary connections.

proekt-banya.ru>

Which material to choose?

Cast iron tanks

Cast iron tanks

The popularity of cast iron tanks has decreased markedly with the advent of stainless steel tanks. However, in most old baths you can see just such tanks, traditionally bowl-shaped, built into the stove. Large tanks were additionally secured with metal chains suspended from the ceiling beams to reduce the load on the stove.

Water boiler suspended on chains in a black bathhouse

Advantages of cast iron:

- very durable material;

- has the ability to retain heat for a long time;

- not subject to corrosion;

- resistant to high temperatures;

- easy to clean from dirt.

Flaws:

- weighs a lot;

- takes a long time to warm up.

Enameled tanks

Enameled tanks

Enameled steel containers are excellent as remote tanks. In the absence of direct contact with fire and careful handling, they are very durable. There are models for installation on a pipe, mostly rectangular in shape

The most important thing when installing and operating enameled tanks is to avoid mechanical damage. In places where the enamel is chipped, unprotected metal begins to rust very quickly

Minor damage can be repaired with special paint, but if the chips are large, the tank will have to be replaced.

Advantages:

- relatively light weight;

- aesthetic appearance;

- ease of care.

The only disadvantages of enameled products include low resistance to mechanical damage.

Stainless steel tanks

Stainless steel tank

The most popular type of sauna tanks. Due to the variety of models, such tanks can be mounted in any of the described ways - built into stoves, mounted on a wall or around a chimney. The main thing here is to choose the right wall thickness and container volume.

Stainless steel tanks of various shapes and sizes

Advantages:

- long service life;

- resistance to deformation and corrosion;

- light weight;

- variety of models in shape and size;

- hygiene;

- heat resistance;

- high thermal conductivity;

- attractive appearance.

Open stainless steel tank in a bathhouse

Flaws:

- high price;

- cool quickly.

DIY sauna tank

Types of tanks

Water tanks of different configurations are installed. The method of heating water may also differ. When choosing a container, you should take into account all the nuances.

The purpose of the hot water tank in the bathhouse

Capacity

The volume of the installed tank depends on the number of people who can simultaneously be in the bathhouse and use hot water. On average, 10...20 liters of boiling water should be provided for each person (with a small reserve). Today, tanks with a volume of 50...100 liters are produced. As a rule, it is not advisable to install a tank with a capacity exceeding 100 liters.

The shape of the container can be any

Material

When choosing a container, you need to consider that it must be able to withstand high temperatures (up to 250 degrees) for a long time.

Metal tank for water in the bath

You should not try to save money and install tanks made of ferrous metals. This approach cannot be justified not from an aesthetic point of view, but mainly from practical reasons. Due to constant exposure to high temperatures, the metal will deform over time and traces of corrosion will appear on it. This significantly reduces the service life of the tanks and the quality of the water in them.

The most common tank option is stainless steel construction. The demand for such tanks is explained by their attractive appearance, durability, resistance to various types of external influences, high heating rate, ability to retain heat for a long time, relatively low weight, hygiene, high durability and ease of maintenance. The tank configuration may vary. But high-quality stainless steel costs a lot. And you need to take into account that today there are many counterfeit products on offer, which will soon rust.

Not so often, but there are tanks made of cast iron. They are not afraid of rust. However, it must be borne in mind that, despite the fact that the water in such structures will not cool quickly, it takes more time to heat it up. Due to the bulkiness of the tanks, you need to carefully consider their location. Today, not many companies produce cast iron tanks, and they are not very cheap.

Enameled containers can be used, but they are not the best option. Of course, such material does not corrode and is very hygienic.

But low resistance to mechanical damage over time will inevitably lead to the fact that the metal with a fairly thin coating will become chipped (as a result of not very careful handling) and these areas will rust. It will no longer be possible to fix the problem.

Location and design

Three methods are used to place the tank: traditional (directly near the firebox), on the chimney, and remotely. What is the difference?

Bath stove with tank

Tank built into the oven

The reservoir can be located on the side or above the firebox. The water in it heats up quite quickly (exposed to open fire). To drain it, a ball valve is installed. Of course, this design does not involve pipeline laying work, which saves labor and material resources. However, using such a container is not very convenient; usually a tank of not very large capacity is installed, and its installation takes up useful space in the steam room, which usually is not very much. The best solution in small-sized baths is the top location of the tank. Since the metal will be in direct contact with the fire, the thickness of the tank walls must be at least 8 mm.

Water tank next to metal firebox

Reservoir on a pipe

If the ceiling height allows, you can install the tank on the chimney. Water is heated by hot gases passing through it. To simplify the installation process, it is possible to purchase a container with built-in chimney elbows. This tank can be fixed without much effort. By laying a pipeline from the tank, you can carry water to any point in the bathhouse, for which a pipe is connected to the bottom of the tank, ensuring the flow of liquid, for example, into the shower. Filling a tank installed in this way is not very easy due to the high location of the filler hole. It is best to use a hose lowered into a container for these purposes.

Reservoir on a pipe

Remote design

Thanks to the installation of a heat exchanger on the heater (on the chimney or directly on the stove) and natural convection, it is possible to place the tank in the washing compartment.

Water tank over brick firebox

The heat exchanger can be integrated into the oven (removable or non-removable), but you can easily install it yourself. It is a coil or container with a volume of several liters with pipes to create a circuit.

Heat exchanger on pipe

Heat exchanger for pipe

The temperature of the gas leaving the sauna stove is quite high, so it is advisable to use it. Accordingly, the heat exchangers, which will be discussed further, are attached only to the single-wall metal pipe of the furnace.

Heat exchangers for chimneys are also called samovar. The water in them heats up evenly and quickly enough, circulation occurs very quickly, and fuel savings are achieved. Additionally, such heat exchangers are a kind of fuses that prevent any leakage of smoke from the chimney into the room.

The heat exchanger and pipe are joined using heat-resistant sealant (up to 1000 degrees) and clamps. The pipes are connected using the technology discussed above.

Connecting the heat exchanger on the pipe

It is not necessary to make such a heat exchanger yourself; the cost of factory-made products is presented in table form.

Technical characteristics and prices of heat exchangers

Chimney diameter 105 mm Chimney diameter 115 mm Chimney diameter 130 mm Price, rub. 279028905290

| Volume, l | 8 | 8 | 20 |

| Steel | Stainless steel – 0.5 mm on the sides and 0.8 mm on the bottom/top | Stainless steel 0.5 and 0.8 mm | Stainless steel 0.5 and 0.8 mm |

| Weight, kg | 2,5 | 2,5 | 4,5 |

| Height, mm | 500 | 600 | 665 |

| Fittings | 3/4″ x 2 | 3/4″ x 2 | 3/4″ x 2 |

Remote large capacity

The water tank for the bathhouse is remote; if a large container is used, it is installed on the floor. For baths with several sinks and showers, a pump must be installed.

It creates the required pressure, which makes it possible to use any modern plumbing fixtures, spray showers, hydromassage cabins and much more.

When installing the pump, care must be taken to ensure that it does not cause excessive noise.

It is reduced by the use of plastic pipeline fittings and the pipes themselves.

Also, the pump installation should be carried out outside the bathhouse.

Nowadays pipes are inexpensive, and you can make an elbow for the pump in any convenient place, for example, in a plumbing hatch, next to the water meter or in the utility room of the bathhouse.

The “water tank with heat exchanger” type arrangement for a bathhouse is suitable for heating the largest volumes of water. The tank capacity can exceed hundreds of liters. In other heating systems, such options are difficult to implement.

Information. All pipes, connecting fittings and pump must be heat-resistant (if plastic is used). For metal, ordinary ½ or ¼ inch steel pipes are optimal.

And a little about scale in boilers

If a summer house or cottage with a bathhouse is located in a region with hard tap water, scale will form in the boilers. It is deposited in the place of extreme temperature heating, reduces the rate of heating of water, and significantly reduces the conductivity of heat in the pipes. Scale from hard water constantly builds up in an uneven layer and has a high coefficient of heat resistance.

The appearance of scale inside the pipes reduces the strength of the samovar sections of the chimney, reduces the service life of the entire structure, and deteriorates the samovar-type heat exchanger. If pipes and boilers are not cleaned of scale in a timely manner, water floods the fuel compartment of the stove.

Recipes for folk remedies against scale

- Baking soda. In the tank, bring the water to a boil, pour a pack of soda into it. Then let the water cool and bring it to a boil again. Drain the water and soda, fill the tank with clean water, pour half a glass of vinegar essence into it. Bring to a boil, leave to cool. Bring to a boil again and pour out after half an hour. The influence of soda and acid loosens the scale; it is removed with a hard sponge or brush.

- Lemon acid. Not sparing the bags of lemon, pour it into a tank of cold water, then bring to a boil. Let it sit for a while, drain the water with citric acid, fill the tank with clean water, and bring to a boil. The acid breaks down all the scale deposits, the tank is rinsed with clean water. The method is cheap, fast-acting, but has a significant drawback: the acid, acting on scale, affects the metal material, its surface will be rough, and fresh scale will quickly appear again. It will become more and more difficult to clean the boilers with lemon each time.

- Vinegar. Pour a glass of vinegar into the filled tank and boil for 20 minutes. The acid acts effectively, its disadvantage is the residual odor. You need to clean the boiler with the windows open, then rinse the system thoroughly and ventilate the room for a long time.

Today, all methods of heating water in home baths are widely used. The designs of the various systems are well thought out, easy to use and safe.

It is important to fulfill all installation conditions efficiently.

Cast iron, steel or stainless steel?

Quite a lot depends on the material from which the tank is made - both the rate of heating and cooling of water, and the durability of the tank itself.

Cast iron: hot water all day long

For a long time, the tank in the bathhouse was made of heavy cast iron - the water took a long time to heat up, a lot of firewood was consumed, but it was hot until the evening and the whole family could wash all day. In addition, cast iron is not afraid of either corrosion or high temperatures. But its considerable weight is, of course, an obvious drawback.

Stainless steel sauna tanks: lightweight and durable

But today, a stainless steel sauna tank is becoming increasingly popular - there is no need to isolate moisture from it, it has excellent thermal conductivity, and the deformation coefficient due to sudden temperature fluctuations is negligible and cannot be compared with the properties of ferrous metals.

The best brands for such tanks are 8-12X18H10 (304) and 08X17 (430), which are also used for making dishes. They are resistant to even extreme temperatures, hygienic and do not corrode or deform.

Such bath tanks are made from durable and thin stainless steel sheets, into which special ball valves are installed to enter and supply water. Caring for such tanks is extremely simple.

Enameled tanks - good if handled with care

Enameled tanks will also get rid of unpleasant rust. Their only drawback is possible chips, which will lead to corrosion. But they can be treated with special heat-resistant paint - unless the tank itself is inserted into the oven.

Materials

When choosing a tank for a bathhouse or when making it yourself, an unmistakable choice of the material for its manufacture is extremely important. The heating time of the liquid, the period of its cooling and the duration of operation of the device itself will depend on this. Among the most widely used materials, cast iron, stainless steel and enameled steel are widely used.

Previously, only cast iron tanks were used for hot water tanks. Cast iron containers have been tested by time and have a number of positive aspects. In particular, a cast iron tank will keep the water hot for a long time. There is no corrosion on them and the water in this tank will always be clean. This material is very resistant to temperature changes. And finally, the shelf life of a cast iron tank is very long, since this material is not susceptible to corrosion. Currently, not many manufacturers are engaged in the manufacture of cast iron tanks. But it is quite possible to buy a used tank at a lower price. In this case, you will need to process it and give it a pleasant appearance.

One of the disadvantages is the rather long time it takes to heat the water in the tank. Cast iron tanks are heavy and sometimes need to be installed on a special foundation. If the tank is located above the stove, its fastening requires additional reinforcement. Making such a tank yourself will also be a very problematic undertaking.

Stainless steel containers are now used quite often. This material replaced cast iron tanks. The owners of the baths appreciated their high positive qualities. Such tanks do not require additional protection from high humidity. The water in a stainless steel tank heats up in an extremely short period of time. Stainless steel has good resistance to sudden temperature changes and, accordingly, does not rust, as its name already implies. The only downside that can be noted is that the water in it cools down quickly.

Tanks made of enameled steel are also a popular option for this design. A special enamel coating on such tanks reliably protects them from corrosion. The main thing is to prevent damage to the enamel, otherwise the tank may begin to rust. Although damaging the enamel layer is quite problematic, since such a coating is resistant to various types of damage. If necessary, a tank made of this material can be very easily cleaned. Enamel of various colors is available on the market.

For cold water, separate tanks are now rarely used, since it most often enters the room through the water supply. But if there is a need to install a container for cold water, then there is much less hassle with it than with a tank for hot water, since there are no particularly strict requirements for it. You can even use wooden containers, such as an oak barrel. Plastic containers for cold water are also popular. But such containers cannot be placed in a steam room, much less near a stove, because plastic is sensitive to high temperatures and can become deformed when heated. You can also make such a tank yourself.

Water bath containers: how not to make a mistake when choosing

The main elements of a bathhouse, if you intend to get maximum pleasure from the process, are a stove and a water tank. To ensure that everything related to the water tank in the bathhouse is done correctly, we will dwell on the main issues that may arise when setting up a steam room yourself.

The main questions that arise when choosing an element such as a tank for a bath are:

- Its parameters

- Which type should I choose: remote, built into the oven, on a pipe?

- What should it be made of: steel, stainless steel, cast iron?

Tank parameters

If you are used to doing everything with your own hands, then, of course, you will try to make a sauna tank yourself.

However, you should first think about what type of container is suitable for your steam room, what principle of water heating will be used, what material to make the tank from, so that later you do not have to invest money in re-equipment again. So, you must decide whether you will heat the stove in a sauna or simply heat the water using the heating element built into the tank. And in order to understand what is more profitable for you, heating a stove or using an electrically heated container, estimate how many people will steam at the same time. Another important factor is the volume of water that needs to be heated and the allowable time for heating to the required temperature.

Let’s say that if you want to steam alone, a person is unlikely to need more than fifty liters of hot water. But to please the whole family or group of friends, you need to install a water heating tank with a capacity of seventy or more liters.

Also pay attention to the thickness of the tank wall. It is this parameter that determines how evenly the water in it will be heated and how long its temperature will remain. But remember that the thickness of the tank wall directly affects its price and weight.

In any case, a stainless steel bath tank with a volume of up to fifty liters should have a wall thickness of 0.8-1 mm. For containers of larger volume, a wall thickness of 1.5 mm is desirable.

Advice from the master!

And do not forget that no matter what material the tank in the bathhouse is made of, you need to equip it with the optimal number of outlets and make an inlet for water. When choosing a tank in a store, ordering it in a workshop, or preparing to brew a canister for a sauna yourself, take into account all the parameters mentioned, and the process of washing in a sauna will be a complete pleasure for you.

Return to content

Types of heat exchangers for sauna stoves

Structurally, the heat exchanger can be a coil or a tank with a maximum volume of 5 liters and two pipes for connecting a water tank/radiator.

According to the mounting method, heat exchangers are divided into two types:

- internal. Such products are fixed on one of the side walls of the furnace or mounted on its bottom. It is also possible to install a water jacket, which literally encircles the fuel chamber from the inside or is located in the space between the stove casing and the walls of the firebox;

- external. Heat exchangers of this type are fixed to the chimney or attached to the wall of the furnace.

Prices for different types of heat exchangers

Internal type heat exchangers have the best heat saving indicators. The water in them will heat up until the stove cools down completely down to its last brick or stone.

The fastest heating of water is provided by internal heat exchangers and external ones installed on the chimney. At the same time, the first products often imply the need to make design changes/additions to the sauna stove, while the second cannot be called a decoration for the steam room (a wide tank does not fit well into the interior).

Example of an internal steel heat exchanger in a brick kiln

If we compare products in terms of ease of installation, the palm is occupied by heat exchangers that are hung on the outer walls of the furnace. Such products have a long service life and do not spoil the appearance of the stove, but the water in them takes longer to heat up and cools much faster.

DIY making

If you can’t buy a tank in a store, you can assemble it yourself. To do this, you need to prepare consumables and tools:

- grinder with discs;

- file, hammer, pliers;

- welding machine;

- shut-off valve with the ability to adjust the flow;

- stainless steel sheets;

- metal pipes.

Build process:

- Mark the main parts of the container body on the metal sheets. It's better to make it rectangular.

- Cut out parts of the body using a grinder.

- Connect the main parts and weld them.

- Cut a hole in the top through which fresh water will be poured.

- Make a hole in the bottom and secure the drain tap.

All that remains is to make hanging hooks on one of the walls of the stove, and labels for hanging on the tank itself.

Other nuances of choosing a tank

Capacity volume

Many people are interested in how much water needs to be heated for a bath. The calculation is made depending on the number of users. The norm for one person is about 8-10 liters; for steaming brooms you may need the same amount. If the shower is powered from the reservoir, the consumption increases even more. Factory models of containers have an average volume of 50 to 80 liters, products with built-in tanks - about 22-30 liters. When making a tank with their own hands, craftsmen are guided by the rule “the bigger the better,” but, obviously, it is impossible to endlessly increase the useful volume, because water also weighs something (there may be problems with reliable fixation), and it will heat up more slowly.

A constructive solution when the tank on the pipe plays the role of cutting

Material of manufacture

Naturally, metal is used. In artisanal conditions, craftsmen use sheets of black steel (which is easy to weld) about 3-5 mm thick. The more massive the walls of a homemade tank, the longer it will last and the more reliable the weld will be. Industrial products are usually made from stainless steel. Since there is no need to worry about corrosion and burnout, the wall thickness of a medium-sized stainless steel tank is usually in the range of 0.8-1 mm, which has a positive effect on the rate of heating of water. As the volume of the tank increases, the thickness of the metal also increases, which can reach one and a half millimeters. Sometimes branded tanks are made of cast iron - a durable, and most importantly, heat-intensive material, although expensive and heavy. You can also find factory-made steel containers, the bodies of which are coated with heat-resistant paint. This is a completely working option, but such tanks must be handled very carefully so as not to damage the coating.

Sources

- https://oboiman.ru/inside/bak-dla-vody-v-banu-varianty-samovarnogo-tipa-i-vynosnoj-s-teploobmennikom-bak-na-trubu-iz-nerzavejki-derevannye-bocki-dla- goracej-vody.html

- https://profpipe.ru/drugoe/kak-samostoyatelno-ustanovit-bak-dlya-vody-na-pechnoj-trube-v-bane.html

- https://bulding.ru/solid/with-external-tank-or-hinged-tub-for-a-pipe-advantages-of-application.html

[collapse]

All the details and nuances

Depending on the purposes for which you will use the room, how many people will relax there, the choice of construction method will vary. If you plan to build an entire complex, then most likely you will have to be patient.

Building a sauna tank with your own hands or calling a construction company for help is a matter of your choice, but its presence will significantly simplify some processes.

Previously, the container was placed directly in the stove or above it. Since the slab itself is made of brick, stone or metal, the structure is truly strong and durable. Today there are many options for replacement. As an alternative to this, you may be offered:

- Remote

- Mounted

- Heated by heat exchanger

Those structures and tanks that have the ability to be transported are much more practical and can be easily moved to other rooms.

Recently, the production of this type of product has become more in demand. The latest generation technologies allow you to choose from a number of tanks with any parameters and efficiency, at a price that suits you.

The main purpose of such tanks is for greater release of light and soft steam, as well as water supply in the shower or other amenities. The volume of the container and its dimensions will depend on how great the need for water is. For 3 people, 50 liters is quite enough, 80 liters or more for noisy companies, or if the bathhouse is heated several times a day.

Good functioning is also influenced by factors such as the density or thickness of the metal. A stainless steel water container is very practical and maintains optimal temperature conditions well. It’s not worth saving on such a device, and you need to understand that high-quality material will cost much more.

The choice of tank plays a big role; during the combustion process, the temperature reaches 400 degrees; if the installation is attached to a chimney, then this level of steam goes beyond such a building and can be called a classic option, since it has become widely used in the last ten years. Choose a manufacturer responsibly and try to purchase only high-quality certified products.