Wooden houses began to be built in ancient times. Previously, there was quite a lot of such building material, so all the walls were built in one piece and only at the end were openings made for windows and doors.

The process of installing a door in a log house depends on what material will be used for construction.

In the modern world, to achieve maximum savings, all openings are marked in advance. This will reduce waste. The installation of a door in a log house is carried out after the construction of the walls and roof has been completed. When building walls, it is very important to leave solid logs or beams in the area of the door opening; this will prevent the crowns from being squeezed out. After the entire structure is strengthened, solid logs are cut from the opening.

The process of installing a door in a log house directly depends on what material is used for construction. Regardless of what is used (log house or timber) for building a house, the installation of the door is carried out in the same way. It is very important to pause when installing the door. Such a temporary break should be counted from the moment of complete completion of the construction of the walls and completion of the assembly of the entire roof structure and be about 6 months.

Doorway arrangement.

During this period, the house will undergo partial shrinkage. Over the next year, the structure will shrink as much as possible. Shrinkage rates will depend not only on the technical characteristics, but also on the moisture level of the wood.

On average, the period of complete shrinkage can reach 6 years. Over the course of a year, a house can change its height by up to 5 cm. Based on these indicators, work on installing a door in a log house must be carried out using a special technology. By following certain rules, you can avoid such a phenomenon as skew. Today there are two options that can be used to install a door:

- installation of a special casing;

- installation of casing when using timber.

How to install?

Before installation begins, as described above, the old door is dismantled. Then you need to take the necessary measurements and remove unnecessary elements from the opening.

In a private house

Wooden house

When installing in a wooden house, it is important to pay attention to some points:

- Strength. Wooden structures visually look very durable. But when a metal structure is installed in the doorway, the area next to the door frame weakens and there is a risk of a gap through which dust and wind will penetrate;

- Shrinkage. After a house is built from wood, its foundation is subjected to severe pressure. For several years, the structure shrinks and therefore window and door openings change in size;

- Correct installation. If the installation of metal doors in apartments and brick houses eliminates the destruction of openings, then the passages in wooden houses weaken and can even crack. Therefore, the process of installing the front door requires care and painstaking work;

- Exploitation. It must be remembered that during use the tree can change under the influence of temperature changes and high humidity.

Doors to wooden structures should be chosen that are more massive than doors to panel and brick houses.

For installation in a log house, one of two installation techniques is used:

- The first technique is installation using bars. The timber is inserted into the grooves at the ends of the passage. They put a lock on it.

- The second technique is to install a door in a log house using a casing. Doors made of wood and metal are installed in the casing. It is recommended to install a passage in a house made of timber no earlier than a year after completion of construction. During this period of time, the main part of the wood will dry and shrinkage will be completed.

Foam block house

Now let's look at the installation of entrance doors in houses made of foam blocks. This material belongs to lightweight concrete, it is quite soft

When installing a structure in a foam block, it is important to remember that it stands on the foundation and not on the block

Doors to houses made of aerated concrete are installed in one of three ways:

- on anchors;

- on a metal frame;

- on a wooden frame.

Entry products can be installed both indoors and outdoors. The external door is matched to the external facade of the room. They must have special reliability and thermal protection. Internal entrance doors are installed inside the house. The quality of an internal door depends on the material and fittings.

The positive side of frame houses compared to timber houses and other wooden structures is that they do not require shrinkage. Therefore, after laying the walls and completing repair work, you can install the entrance door to the frame house.

In "Khrushchev"

Choosing entrance structures for a Khrushchev building is not an easy task. There are two ways to install door products in such apartments:

- Expansion of the opening. In this case, it is necessary to make competent measurements so that the new entrance doors do not disturb the neighbors, since in “Khrushchev” buildings the entrances to the living space are located close to each other;

- Making doors to order. This method is preferable since the passage does not have to be enlarged.

Metal entrance doors installed in apartments differ from doors in a cottage or country house. The differences lie in operating conditions. After all, the doors in apartments are installed on landings indoors and are not in contact with the street, while the doors in cottages are street doors and are exposed to external factors.

Plastic entrance doors deserve close attention. They began to be used in private households relatively recently. Previously, such doors were installed in shops and office buildings. They can also be installed at the entrance to a garage or utility room.

Metal-plastic products have quite a large number of positive qualities. They are environmentally friendly, not exposed to chemicals, easy to maintain, have relatively low flammability and an affordable price.

To produce such input products, metal-plastic profiles are used, consisting of several air chambers and stiffeners. Profiles are found entirely in plastic or using metal reinforcement. Metal mortgages connect parts of the door frame to each other. Frames come in any geometric shape.

There are two types of plastic entrance door covering:

- Blind - made using steel sheets, as well as sandwich panels.

- Transparent. This filling is most often mixed. The upper part is filled with double-glazed glass, and the lower part is blank. Glass comes in a variety of varieties, both transparent and frosted, colored or even stained glass. Doors can also be of different colors.

Features of wooden buildings

Unfortunately, building housing from wood is not an easy task, and its solution can take about two to three years. The main problem with these buildings is that the materials are highly susceptible to deformation, especially at first. So, throughout the entire life cycle, the beams are in slight movement. Changes occur mainly from changes in temperature and humidity. In addition, it is quite difficult to choose the right fastenings for doors and windows that will not damage the walls and keep the timber intact. Also, it is necessary to take into account the strength of the structure around the doorway.

Shrinkage

Each building made of wooden beams undergoes shrinkage. During this period, the walls sag a little, which makes it possible to strengthen the structure. The house can sink by 5-11% of the total height. It is highly not recommended to install windows and doors during shrinkage. If installation is carried out without waiting a certain amount of time, there is a possibility of cracks and chips forming in the wood. As a result, the overall strength of the structure will be compromised, which will contribute to the formation of drafts and cracks. The logs will deteriorate, and over time, individual elements will need to be replaced.

Forgetting about shrinkage means exposing the house to the danger of destruction Source skalice.ru

Fastenings

If we are talking about cinder block or brick houses, then the choice and installation of fasteners does not cause difficulties. Such buildings are difficult to damage, which cannot be said about a wooden structure. When driving an anchor into a beam, there is a risk of splitting. This approach will significantly weaken the structure around the jambs. The installation of a door in a wooden house should be carried out by a professional who knows at what angle to install it. Product quality plays an important role, because fastening is the basis. Poor-quality fasteners will eventually fail, the slopes will settle, and the mechanism will break down. In addition, the strength of the entire wall will be seriously affected.

Strength

The reliability of the wood structure is one of the main qualities. By not following the technological process or making mistakes in it, you can cause great harm to the strength of the building. Violation of integrity is fraught with large heat loss and the risk of destruction. It is also important to remember that it is better to prepare the doorway from the beginning of construction, since after the walls are erected, cutting out a window or passage is difficult and inconvenient. If we talk about an incorrectly executed doorway, then there is a risk of burglary. The log house is very sensitive to any operations, so it is important to use a casing. By neglecting the construction rules, you will compromise the strength around the slopes. As a result, you can simply break down the door without much effort.

Doors for a bath: designs, choice of materials, instructions for self-assembly and installation

Windows to the bathhouse: sizes, types, features, construction installation technologies

The plastic window does not close - causes of problems and their elimination

Types of doorway casings

The window frame allows you to strengthen the walls in the openings and prevent their curvature. If the distortions have already occurred, then the pigtail can correct the situation by fastening them and aligning them. It also protects the house from the penetration of cold air and moisture. At the same time, warm air remains in the room - the window acts as a sealant.

The pigtail allows you to prevent shrinkage of the house, stop the processes of its destruction and deformation.

There are several types of doorway casings

- Chernovaya. High-quality casing at low cost.

- Finishing. This option does not require cleaning the slopes.

- Eurocasing. There is also no need to clean the slopes.

- Power. It is usually installed in arched openings, large windows and large doorways.

- Combined. It is inexpensive and stylish in appearance.

- Arched. Consists of solid pine.

The production time for different sieges depends on the size and quality they will be

It is important to choose high-quality materials, as well as calculate the dimensions of the casing in advance. Today, manufacturers offer a wide range of inexpensive, but quite practical and durable casings

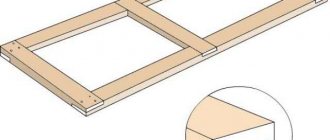

Method N 1. Installing doors using a special casing

The procedure for carrying out work by installing a special casing is as follows:

- The first step is to cut out the opening intended for installing the door frame. It needs to be cut in such a way that half of the log or beam remains on top and bottom.

- Next, using a cutter, you need to cut a groove at the end of the opening measuring at least 50 × 50 millimeters. You can use a chisel to adjust the size of the groove.

- A beam is inserted into the resulting opening. It is necessary to take into account its length. If the log house is new, then the size of the timber should be 5 centimeters smaller. If the structure has already shrunk, then the length of the beam should be less than 2 centimeters.

In some cases, the timber needs to be strengthened. This can be done using a board with a thickness of at least 50 millimeters, and its width must be no less than the size of the wall.

Sometimes, instead of timber, metal channels of appropriate sizes are used. Additional reinforcement of the opening is important when constructing heavy buildings, for example two-story buildings.

Watch this video on YouTube

After the beams are fixed in the side parts of the opening, a threshold should be made. To achieve maximum strength, a timber with a thickness of at least 10 centimeters is used, which must be cut in a T-shape.

Method No. 2. Circular casing made of timber

Installing doors in a log house using the second method can also be done with your own hands. The principle of its implementation is not much different from the first. All you need to do is install the blank under the box, following the rules mentioned above.

In other words, it is necessary to install bars around the entire perimeter of the opening. They can be fastened to each other in several ways:

- tongue and groove method;

- self-tapping screws;

- nails.

In addition, it is possible to install the casing without the use of fasteners. To do this, you need to fit the bars as tightly as possible to each other.

It should be noted that in most cases, the construction of log houses is carried out according to this principle. The pressure created by the weight of building materials is quite sufficient for the stability of the structure. The bars must be installed by surprise.

What tools will be needed for installation?

When deciding how to make a doorway and insert a door, first of all you need to decide on the tools necessary for this work. They must be at hand at all times. This will allow installation to be completed as quickly as possible. To carry out the work you will need:

- chainsaw or electric saw with a bar;

- hammer;

- perforator;

- circular saw or manual milling machine;

- chisel;

- construction measuring instruments: level (preferably laser), tape measure and square.

As a rule, searching for tools will not take much time, because all of them, one way or another, were used during the installation of the log house. Having prepared everything you need and understood how to install the door correctly, you can begin work.

Installation of a street door with casing

When performing installation, a special casing box is often used. As mentioned earlier, the mass of walls is dynamic, which has a bad effect on tightness and strength. The box helps the logs not to fall apart, but at the same time does not interfere with the further shrinkage of the entire building. The door will be completely static and will retain the beneficial properties of the material. But how to install an iron door in a wooden house?

See also: Catalog of companies that specialize in installing windows and doors.

Cutting out the opening and installing the frame Source skandiokna.com

Installation can be completed in five steps:

- Marker designation of the future opening.

- Cutting the desired hole. Spike marking.

- Unraveling the logs into separate boards for future jambs.

- Calculation and sawing of grooves and quarters in jambs.

- Final work on installing jambs.

Window installation has a similar operating principle, the only difference is the size of the required holes.

Marking the doorway

The first step is to decide on the possible size of the hole. It is very important that the cut completely coincides with the size of not only the door jambs, but also the frame itself. If you make incorrect calculations, you will have to grind down or extend the boards of the top, threshold or sides. As a result, the work will drag on and all deadlines will be missed. When measuring, it is necessary to use precise measuring instruments such as a level and a plumb line. It is better to draw with a construction marker. After marking the required lines, you need to move on to cutting the window.

Sawing

Wood cutting should be done by a professional, as you need an even and accurate cut without knots. The ease and quality of further assembly will depend on how professionally the cut is made. Next, you need to cut a spike in the logs, along which the wooden board will slide. Over time, the house will shrink, but thanks to this design solution, the slopes will not be subject to deformation.

Assembly of the structure

It is better to use the base of the box from the same wood as the timber. This way the texture does not stand out, and the properties of the wood will be identical, which will extend its service life for a long time. The easiest way to get such boards is to unravel a few logs that are left after trimming. For professionals, this procedure takes less than an hour. The result should be smooth boards with grooves for tenons. During installation, it is important not to forget about the insulation. Building moss is usually used. It is needed in the gaps between the casing and the wall. Over time, this gap will close completely. After completing this stage, you can begin installing the door. But the question arises: which door is best to choose?

A correctly installed jamb is half the success Source delajdveri.ru

The main advantages of wood as a material for the manufacture of entrance doors

Natural wood has unique properties. Thus, there are types of wood whose strength is simply incredible - the indicators can even be compared with metal. This material also has a fairly long service life - good door models can last from 40 to 50 years, but with proper care this is far from the limit.

Wood is very reliable and has high heat and sound insulation characteristics. Door leaves made of wood perfectly absorb various noise, and also do not let cold and drafts from the entrance or street into the premises.

In addition to all this, wooden doors have a very aesthetic appearance. Even the most expensive finish for metal door systems cannot compete with a solid wood door leaf. It is for this unique appearance that such products are chosen by people who have good taste. And what is the smell of natural wood worth? Wood constantly “breathes” and thereby harmonizes the atmosphere of any room - this material has high bioenergetic capabilities.

Types of structures by opening method

The following interior doors are distinguished by the type of opening:

- Hinged - the canvas opens in one direction; free space is required for their installation.

- Sliding - move along the lower or upper guide rail along the wall, convenient to install if there is no room to swing open.

- Folding like an accordion - they consist of several folded sections, allowing you to save free space.

- Pendulum - made without stops, so the doors open in both directions.

The choice of interior door design determines the availability of free space in the rooms and the type of entrance opening. Products can consist of one or two leaves. The filling of the door leaf depends on the interior and purpose of the room.

Features of installing a door in a wooden frame

Installing doors in a log bathhouse has a number of features, and we will now outline the key ones:

A wooden frame is prone to shrinkage, so the opening must provide compensation gaps, which are filled with easily crumpled heat-insulating material and, upon completion of the work, are covered with decorative elements - platbands. When deciding how to install a door to a log bathhouse, you can go in two ways. The first involves the construction of a solid structure, and then the cutting of openings, according to the markings applied, in accordance with the developed project. In the second, the filling of openings is carried out directly at the construction stage, which implies a set of measures to strengthen the walls in which there is an opening. However, it is necessary to strengthen the wall against longitudinal and transverse displacement of elements in the first case, immediately after the opening is made. The door block of a bathhouse is somewhat smaller in size compared to doors, say, in a house. This is due to the desire to reduce heat loss and minimize the risk of deformation, which manifest themselves more clearly on larger canvases. Thus, generally accepted practice implies that the bath door block has geometric dimensions not exceeding 1820 mm in height and 800 mm in width. During installation, you cannot use polyurethane foam, which is widely used in this type of work. Firstly, in the conditions of a bathhouse this is unsafe for human health, and secondly, the microclimate of the bathhouse contributes to the rapid destruction of the foamed mass. The overall dimensions of the door leaf should be 5 - 7 mm smaller than the dimensions of the opening. This circumstance will prevent the door from jamming as a result of swelling under the influence of moisture in the interior space of the bathhouse. As insulation and gap compensator, you can use tow padding based on flax fibers or jute strips or strands.

Leaving the log house open is important

What does this phrase mean? But here's the thing - after the construction is completed, the most intense moment of shrinkage begins, which will last at least a year. During this time, if the doors and windows are already installed, they will simply be crushed.

Moreover, wood is much stronger than metal and can bend even seemingly reliable structures. To prevent something irreparable from happening, you should carefully consider what is described below.

Before starting work, you should know in advance what size the entrance and swing structures will be. Usually, if the project is standard, then all measurements are put aside on drawings and diagrams and there is no need to bother. But if the log house is installed independently, then there is something to think about and decide quickly, since it is necessary that the cut opening fits together with the entire structure.

So, the installation stages:

Before the log house has to be left to shrink, it is recommended to make the necessary openings. How to saw through a door in a log house? Actually this is not the most difficult question.

The required size is determined, and the diagonals must be taken into account, and the outline is drawn on the log house. You need to make sure that the bottom log is divided in half, and the top one too. Then 7 to 10 cm is added to these sides for shrinkage.

The thickness of the door frame ± 2-3 cm is added to the side ones. It is necessary to fill the edges of the future opening with boards to protect the short crowns from falling out. Thus, when the contours are ready, the desired size is selected with a saw.

If the log house assumes the presence of several entrances, one of which must be the front entrance, then the question of how to cut a door in the log house, when a greater distance is required, must be resolved more scrupulously. Board protection must be present on both sides - external and internal.

Also, after making the cut, it is recommended to place logs in the opening for a couple of weeks - during this time the log house will get used to the emptiness. Well, other aspects will no longer differ from an ordinary opening.

Moment of sawing

To avoid any difficulties with the question of how to cut a door in a log house, you must first determine the middle log of the opening and make slits on it. After that it is easy to knock it inside. Well, then working with a saw will no longer be difficult.

Let's move on. After the time allotted for shrinkage has passed, before installing the door, you need to measure the opening of the shrinking frame and determine the changes.

The difference between a metal and wooden door

Which is better, wood or metal? No material has an absolute advantage. Both metal and wooden front doors have positive and negative sides. Before choosing, you need to have a good understanding of the general characteristics

It is important to compare the advantages and determine where there are more of them. It doesn’t hurt to find an alternative to certain disadvantages

Wooden door

Many people adhere to the version that wood is the best material that can protect not only from bad weather, but also from strangers. Undoubtedly, this type of door has a large number of positive properties, but at the same time it also has negative qualities.

To give a sober assessment and make a choice, it is important to carefully consider the “pros and cons”

A wooden door looks organic and beautifulSource de.decorexpro.com

Pros:

- An ideal combination with the overall interior. The doorway merges with the overall appearance and creates the impression of a monolithic texture.

- Wood is an excellent heat insulator, which will save on heating bills.

- It is not necessary to buy a new part, as you can assemble it from scraps, thereby cutting the construction budget.

- This is an environmentally friendly material that will not cause an allergic reaction or illness (with the exception of pine needles).

Minuses:

- The design is not reliable and can be easily hacked. If this is a country house, then installing a tree as protection is highly not recommended.

- Such a door is highly susceptible to changes in weather conditions. Due to moisture and cold, it can change its size and thereby cause inconvenience.

- The surface is highly susceptible to mechanical damage and requires frequent maintenance.

- Poor sound insulation.

Advantages of a metal door

As is the case with a wooden door, a metal structure also has weaknesses. But still, installing a metal door in a wooden house is the best solution today. The main advantage is that every minus can be removed with a little modification. As a result, you can get an almost ideal input design.

A metal door can also look interestingSource moipros.ru

Pros:

- A strong structure that is difficult to damage without special equipment. Everything is complemented by internal hinges and locks with a built-in complex mechanism.

- With a special coating, a high degree of protection against moisture ingress is provided.

- With seals, there is good sound insulation and protection from drafts and dust.

- The metal is not flammable, which means it does not support combustion.

Minuses:

- The iron sheet freezes strongly and releases all the heat from the house to the street.

- Such a door stands out strongly against the background of a wooden structure and can greatly spoil the appearance.

- Installation and purchase require more time, money and effort.

Door modernization

If you need a metal entrance door to a house made of timber, then it is better to immediately eliminate all the disadvantages and shortcomings. Almost all negative qualities of the door can be corrected, with the exception of the price.

Firstly, it is important to decide on the overall design. Definitely, the door stands out strongly against the general background, and there are two ways to solve the problem. The first is to make windows and doors in the same design style. Then the house will look unusual and interesting. The second way is to purchase special wooden overlays. Such wooden sheets will help to do everything in the same style, and also partially solve the problem with thermal insulation.

Decorating an iron door and windows in the same style will be an advantage for the exterior Source dvervdome.ru

Secondly, you need to deal with the problem of large heat loss. Modern designs have several layers of insulating material. Often, it is a metal base with good thermal insulation that can retain heat better than a wooden one. But it is possible to perform insulation directly at the construction site. This process will take more time, but some money will be saved.

Window as an important power unit at home

Deformation of logs in a log house

A log house, despite its external solidity, is a rather unstable structure. The reason for this is the round shape of the logs and the change in their geometric dimensions during shrinkage and shrinkage.

If you cut openings for windows and doors in such a wall without installing casing frames, it will simply collapse. Therefore, the entire structure of the window openings is not only a place for installing double-glazed windows, but also a power unit that gives the frame additional rigidity.

Note that this feature is inherent in all wooden buildings, including houses made of profiled timber.

How to strengthen a lintel over an opening

Before starting the construction of the opening, it is necessary to install a lintel.

A part of the wall will rest on it, which will remain above the future opening, which will remain from:

- Floor resting on the wall.

- Walls of the upper floor.

- Roof structures.

The safety of the wall structure and the entire house depends on the rigidity of the lintel. When developing lintel drawings, it is necessary, in addition to previously obtained information, to take into account several more factors, which should be:

- The dimensions of the opening relative to the entire wall area.

- The distance between the opening and adjacent walls.

- Dimensions from the ceiling to the upper border of the opening.

- Type and placement of floor slabs.

There are several ways to strengthen the lintel.

Most popular:

From two channels.

When making an opening in the wall, you can build a prefabricated reinforced concrete lintel, which will consist of two profile corner sections. For this:

- a niche is cleared in places where the corners will rest on both sides;

- a thick layer of cement mortar no lower than grade M100 is applied;

- a reinforced concrete beam is laid;

- after the mortar has set, the voids between the wall and the beam are filled with cement mortar, the grade of which is at least M50.

- after the solution has hardened, the opening can be knocked out;

- wrap it with mesh, as in the photo, and plaster it (see).

How to make an opening in a load-bearing wall

It's easier to make a hole in a brick wall.

Wherein:

- It is enough to remove one row of brickwork

- All remaining rows can be removed without much difficulty.

Reinforced concrete is more difficult to dismantle.

You will need:

- Bulgarian.

- Hammer.

Instructions for cutting the opening:

- The grinder disk is immersed into the wall to its full depth.

- Vertical slits are made in increments of approximately 60 centimeters.

- Horizontal lines are then cut with the same step.

- The resulting cubes are knocked out with a puncher.

- The following layers are removed in the same way.

- If the thickness of the load-bearing wall is standard, such notches are made on both sides. In this case, the internal residue is removed in one cut.

This method is used for internal load-bearing walls located in panel houses. In external load-bearing walls, cutting will need to be done several times on each side.

Final design of the opening

The final completion of the reinforcement of the metal structure is as follows:

- They are connected by welding with transverse channel plates on both sides of the wall. Plates are used with a thickness of at least 4 millimeters and a width of more than 5 centimeters, which depends on the instructions in the developed project and technical specifications.

- The elements are distributed in increments of 30-40 centimeters along the entire perimeter of the completed opening.

- At the same time, the channel is welded in previously inaccessible places until the opening has been cut.

- The inside of the opening is plastered and a reinforcing metal mesh is installed, which will be welded onto the channel.

Differences in casing for windows and doors

Differences:

- board thickness;

- view;

- box design.

Window openings, if they have sashes, are small in size in relation to the opening

Opening and closing the doors is done carefully. The load on the casing is not large

It's different with doorways. The opening part is almost 100%. If it is an entrance door, make it massive for strength. This leads to weight gain. When slamming, force is used. The load on the door structure exceeds the window structure.

Doorway without threshold, window completely finished

For the box to work reliably, it must be made of a thick board. The locking connection must have increased strength. To increase the strength in the casing, a quarter is not selected, which automatically transfers it to the category of roughing or power. Often doors are made with a threshold mounted to the frame; the casing is deprived of the lower horizontal part.

The fastening is located in the middle part of the opening

Installing a door frame

To carry out high-quality installation work, you must have the following set of tools:

- long measuring device;

- sharpened axe;

- chisel;

- hacksaw for wood;

- screwdriver

The wooden walls of a log house have a distinctive feature in the form of an uneven structure, since after installation such a structure usually settles. To install the box, 4 beams are used. Along the vertical ends of the doorway, grooves are cut for the ridges on the doorway. At the ends of the beams, fastenings are prepared taking into account the thickness of the door leaf. The door frame is fixed using a tongue-and-groove system and is additionally secured with screws or dowels.

The difference between a metal and wooden door

During finishing work, many homeowners are faced with the question of choosing a metal door. Deciding between a metal and a wooden door is not easy. Before choosing one option or another, you should familiarize yourself with their features:

- The entrance door made of wood will harmoniously fit into the log house due to the combination of the appearance of the materials. However, the modern market offers a huge variety of trims and trims for metal doorways that imitate wood. Of course, such elements cannot be compared with natural solid wood, but if the main task of the door is strength, then you can sacrifice the aesthetics of the facade.

- Thanks to various antiseptic impregnations and fire retardants, wooden doors have high resistance to precipitation and other adverse conditions. In addition, in winter the wooden massif will not freeze.

- Ordinary wood has greater thermal insulation properties than metal. Modern companies offer multilayer metal doors, with various polymer materials that increase thermal insulation properties. One of the warmest options for a street opening is insulated (wooden) entrance doors.

Advice! Metal doors will easily fit into the overall style of the building if there are similar decorative metal elements on the site or facade.

In general, steel products have high strength and safety indicators. In modern construction, 9 out of 10 doors are metal. They are installed both in log houses and in concrete buildings. Three-layer doors made of alloy steel are considered the best option for a log house.

Professionals who choose steel doors are guided by their significant advantages:

- High degree of safety and comfort. Most modern metal doors have unique fittings and locks. Among other things, the products are equipped with durable functional fasteners that do not weaken the door panel itself during operation and installation.

- Possibility of installing automation. Metal doors have special grooves or already built-in automatic control systems. In addition, they are easy to install fasteners for installing cameras and other surveillance and security devices.

- Highest degree of fire resistance. Unlike wood, metal is absolutely not flammable.

- Moisture resistance. Doors with protective coatings can be used without problems in areas with high humidity. Even with active use and lack of maintenance, the products retain their moisture-proof properties.

When choosing a steel door, you should pay attention to the quality of the coating and the multi-layer nature of the material. This ensures housing safety and heat preservation

Leaving the log house open is important

What does this phrase mean? But here's the thing - after the construction is completed, the most intense moment of shrinkage begins, which will last at least a year. During this time, if the doors and windows are already installed, they will simply be crushed.

Moreover, wood is much stronger than metal and can bend even seemingly reliable structures. To prevent something irreparable from happening, you should carefully consider what is described below.

Before starting work, you should know in advance what size the entrance and swing structures will be. Usually, if the project is standard, then all measurements are put aside on drawings and diagrams and there is no need to bother. But if the log house is installed independently, then there is something to think about and decide quickly, since it is necessary that the cut opening fits together with the entire structure.

So, the installation stages:

Before the log house has to be left to shrink, it is recommended to make the necessary openings. How to saw through a door in a log house? Actually this is not the most difficult question.

The required size is determined, and the diagonals must be taken into account, and the outline is drawn on the log house. You need to make sure that the bottom log is divided in half, and the top one too. Then 7 to 10 cm is added to these sides for shrinkage.

The thickness of the door frame ± 2-3 cm is added to the side ones. It is necessary to fill the edges of the future opening with boards to protect the short crowns from falling out. Thus, when the contours are ready, the desired size is selected with a saw.

If the log house assumes the presence of several entrances, one of which must be the front entrance, then the question of how to cut a door in the log house, when a greater distance is required, must be resolved more scrupulously. Board protection must be present on both sides - external and internal.

Also, after making the cut, it is recommended to place logs in the opening for a couple of weeks - during this time the log house will get used to the emptiness. Well, other aspects will no longer differ from an ordinary opening.

Moment of sawing

To avoid any difficulties with the question of how to cut a door in a log house, you must first determine the middle log of the opening and make slits on it. After that it is easy to knock it inside. Well, then working with a saw will no longer be difficult.

Let's move on. After the time allotted for shrinkage has passed, before installing the door, you need to measure the opening of the shrinking frame and determine the changes.

Installation of doors in aerated concrete and in a wooden house

Stages of installing doors in aerated concrete

To carry out such work, it is necessary to prepare welding and buy a metal corner with a shelf width of 3.5 to 5 centimeters (the choice depends on the weight of the door and the expected loads).

Next, it is necessary to trim the metal corner so that when welding the joints of individual parts, it can cover the doorway along the entire perimeter on both sides. To strengthen the two frames together, it is necessary to weld the embedded parts, and the shank must have a thickness of at least 3 millimeters and a width of 5 centimeters. These elements are placed at the places where the door frame is attached. The door frame is fixed using screws on previously installed lintels.

For reliable fastening, you should use 12-centimeter self-tapping screws, which are screwed into each of the tires. It should be noted that the door will also be attached in these places, so the screws should under no circumstances overlap each other. At the next stage of installing doors in aerated concrete, use a building level to align the door frame, and then fix its position using wooden wedges.

The final fixation of the door leaf is carried out using screws up to 15 centimeters long or dowels.

After this, it is necessary to coat all the cracks with sealant or blow out with foam.

Installation of an iron door in a wooden house

You can install a new front door with your own hands in just three steps:

- dismantling the old structure;

- doorway preparation;

- installation of an iron door.

The old entrance doors to the apartment are dismantled like this (mostly wooden):

- Provided that the door leaf worked on collapsible hinges, we pry it open with a crowbar or other lever. This way the panel will rise and jump off the loop. Provided that the hinges are not dismountable: you need to unscrew the screws that hold the door in the frame using a screwdriver or screwdriver.

- It is not difficult to dismantle an empty box with your own hands if it is made of wood. To do this, fasteners (visible) are unscrewed: screws, anchors, nails are pulled out. If the box is firmly held in the opening and cannot be removed, its side posts are sawed off and torn off with a crowbar. After which the lower and upper parts can be removed without any problems.

- If a metal box is being dismantled or a wooden box is attached to the opening with anchors, then it is easier to saw them off with a grinder, just like metal posts.

- Next, the opening is cleaned of old insulation, remnants of plaster, protruding fasteners and other things. Provided that the doorway for the new door has been previously correctly measured, its size should exceed the perimeter of the frame by a couple of centimeters. This is necessary so that there is enough space to align it in the opening. If you made a mistake in measurements earlier, you will have to work hard to widen the passage with a grinder with a circle on the stone. If the opening is too wide, it can be narrowed by additionally applying cement mortar.

A metal frame can be attached to a doorway in two ways:

through technological holes in the box profile;

using special mounting plates.

We put the input structure:

A door frame without a leaf is installed in the opening. Wood wedges are placed under it, which are necessary for fixing, adjusting its position and to ensure technological clearances.

- Having adjusted the position of the box, they begin to drill holes in the wall through the previously made holes in the profile: 15-20 cm deep. Anchors are inserted into the drilled sockets, and the position of the racks is checked again. When positioned correctly, the anchors are twisted and covered with decorative elements matching the color of the box.

- Next, the door leaf is hung on pre-lubricated hinges and all the fittings are attached. The canvas is covered, and the gaps around the perimeter of the rack are checked, which should not exceed 4 mm.

- The functioning of all latches and locks is checked. Inaccuracies are eliminated with wedges. Holes are drilled for the second pillar, which we also secure and check for smooth movement of the door leaf and locks.

- The technological gaps between the box and the wall opening are filled with foam, which must dry for at least 24 hours. After which the remaining foam is cut off, and the surface of the wall is puttied. Installation completed.

Mounting the door block on plates is one of the most common methods and is somewhat simplified for doing the work yourself. Often, metal structures are equipped with mounting plates with prepared holes for fasteners, which are welded directly to the frame.

Installation recommendations

Before you begin the final stage of construction and make doors and windows for your own home, you should give it time to stand. By that time, the owners should have purchased the structures. At the beginning of shrinkage, you should be puzzled about how to cut a door in a log house. There is no point in delaying this - at the end of the term, omissions will become clear and will be corrected in a timely manner. The installation method is selected and installation is carried out. You should not work alone, and especially complex models should be left to professionals for installation. They will make the installation much better. And it’s not a matter of saving - inept actions will lead to even greater expenses.

By following simple rules, the builder will be able to ensure the safety of his own home. And then you see the move!

Boris Shirokov

Author of publications on 1Drevo.ru with topics: Glued logs | Living room interior | Home heating | Calibrated timber | Round house | Water heating | Home heating | House with attic | House made of timber | External insulation | Solid log house | Kitchen interior | Foundation insulation | Timber house | How to cover a log house | Brick cladding | Frame insulation | House made of laminated timber and others.

Was this publication useful to you?

Total score: 8Votes: 16

Overhaul of a log house - how to raise the log house onto the foundation

Internal and external finishing of log house corners - polishing and protection

We recommend! — Encyclopedia Wooden Houses — NEW

You can find out detailed and expanded information on the topic of the article from the book “Wooden Houses,” which reflects all stages of building a house, from laying the foundation to installing the roof. Book price = 77 rubles.

You may also be interested in other BOOKS on building houses from wood with your own hands.

We recommend other posts on this topic:

Window sizes in a wooden house: optimal size Installation of PVC window blocks - GOST for installation

How to insert a plastic window in a wooden house - do-it-yourself installation

What kind of protection is there for windows from sun rays?

Casing in a wooden house: technology for installing a frame in a log house

Technology for installing double-glazed windows in a wooden house

Equipping a doorway using casing

The casing structure is implemented in several stages:

- A tenon is cut out at the end of the opening, the width of which is equal to the height of the ridge. As a rule, this width is 35-38 mm.

- The prepared tenon must be finished manually with tools.

- A wooden beam with a section of 100x100 will replace the casing structure. A groove is cut out in it, the width of which will be equal to the width of the groove. Its depth should be about 40 mm.

- To attach the casing, it is necessary to prepare grooves in the lower part of the opening; their depth should not exceed 5 mm.

To attach the top casing strip, two methods are used:

- In the first option, it is necessary to prepare a board, which is driven between the installed beams and secured.

- In the second case, one wooden beam is installed, a board is placed behind it and the wooden beam is installed again. With this installation, the board does not require additional fastening.

Finishing with platbands

Installation of platbands is the final stage of work. They can be made with beveled corners or rectangular. To make even cuts, it is recommended to use a miter box.

An interior opening decorated with platbands looks more aesthetically pleasing. To fasten them, use finishing nails or nails without heads. If a wooden casing is installed, then securing it with nails will not be difficult, but to attach MDF casings, you first need to prepare the holes. The joints must be filled with mastic.

How to install platbands

Preparatory process

Before you begin installing interior doors, you need to prepare the following tools:

- level;

- scrap;

- nail puller;

- hacksaw and chainsaw;

- chisels;

- fastening parts;

- polyurethane foam.

Every experienced carpenter will tell you that in order for the door not to warp, the doorway must be framed. This can be done in two different ways.

Required set of tools

Pitfall when installing an iron door

The entire installation process described in the previous section may be useless without a bug. We should not forget the fact that a wooden frame, especially a new one, tends to shrink. Of course, it is possible to fasten a metal door directly to the logs of a log house so that it does not deform after a year and a half, but this will require so careful measuring and observing all dimensions that only an experienced specialist can do it. And he, in turn, before starting this difficult work, will offer you to make a frame for the steel door, which will eliminate all these unpleasant moments.

Roughly speaking, the frame is another wooden door frame on which the metal door frame will be attached. It is installed taking into account future shrinkage of the structure. Specially calculated gaps will work and this will not affect the door itself in any way.

The pigtail is usually made from timber measuring 100x150 mm. The side walls are cut to the size of the metal door frame, but so that there is a gap of 9-10 cm to the lintel. This gap will guarantee that during the shrinkage of the house or bathhouse the door will remain in place and can be closed and opened without effort . Technological gaps are not foamed, but filled with heat-insulating material, such as tow or glass wool. The foam can be used after at least three years. During this time, all shrinkage processes should end, the tow can be removed, and the remaining gap can be foamed.

Box assembly

In most cases, the manufacturer completes the door with a frame, which can be either assembled or disassembled. If your box came to you disassembled, then the first thing you need to do is assemble it.

Box assembly:

- if the box contains individual sawn elements, then you will have to knock out the plugs installed at the ends of the racks;

- The edges of the lintel stand must be fastened to the top side of the vertical posts, and the plugs knocked out at the first stage must be installed in the resulting holes;

It is important! The frame is selected so that the distance between the door and the frame is 3 mm. To fasten the box parts, it is recommended to use galvanized self-tapping screws, which must be installed from the back.

- the box can be U-shaped, made of rectangular parts, or beveled, made of racks cut at an angle of 45 degrees;

- When the frame is assembled, it is recommended to insert the door into it and measure the width of the gaps. Immediately measure the interior opening and note at what distance the vertical posts need to be cut so that the box fits into it. Please note that there should be a small distance left under the installed door, about 8-15 mm.

Installing the threshold also has its own nuances. Its size should be selected depending on the distance between the two vertical posts. The door and threshold should be located at a distance of 3 mm. Using a chisel, prepare a place for installing door hinges and install them.

Assembling a frame for an interior door