The continuous permissible current of a cable is an important performance characteristic that must be taken into account when calculating the conductor cross-section. If an incorrect value is obtained, then during the use of the electrical network the wire will constantly overheat.

A short-term increase in temperature as a result of a short circuit is possible, but an incorrect cross-section threatens to increase the long-term permissible temperature. This will subsequently lead to damage to the insulation and fire.

When installing electrical wiring, you need to determine the required cable cross-section

Basic Concepts

Any metal product consists of a crystal lattice. Electrons and mobile particles pass through it, which is why electricity is transformed into thermal energy. This property is successfully used by manufacturers of heaters and lighting devices. However, in conventional electrical systems, overheating of the cable is unacceptable, since over time it will lead to insulation failure and fire. Therefore, it is important to select the correct cross-section of conductors so that they can withstand the permissible (potential) current loads of the network.

For this, two terms are taken into account:

- wire section;

- current density.

Dependence of current density on cross-section

Even if the correct cross-section of the wire is selected, it can still overheat. There are several reasons: weak contact at the joints or oxidation associated with unacceptable twisting of aluminum and copper conductors.

Wire size

To select the cross-section of the current-carrying core (conductor, and not the entire cable with sheath and insulation), they are guided by two parameters:

- heating within acceptable limits;

- loss of voltage.

Overheating of the underground cable placed in plastic hose tubes is dangerous. In overhead power lines, attention is paid to voltage loss. For combined segments with two different sections, select the larger one, rounding it up to the standard value. Before calculating the cross-section or searching for suitable tabular values, you should determine what the operating conditions will be.

An incorrect choice of cable cross-section can lead to overheating and fire.

To calculate the potential heating, the long-term permissible temperature must be taken into account. The value directly depends on the possible current strength Ip. After using the formula, you will receive the calculated current Iр, which should differ from Iп and be less than its value (in no case more!). When choosing a section, use the following formula:

- Iр = Pн/Un,

Where:

- Pn — rated power, W;

- Un — rated voltage, V.

This formula can be used to calculate currents in conductors with an already established temperature, provided that the cable is not affected by other cooling or warming factors. The value of the continuous permissible current Ip depends on various parameters: cross-section, material of manufacture, insulating shell and installation method.

To check the voltage drop on an overhead power line, use the following formula:

- Up = (U - Un) *100/ Un,

Where:

- U—voltage from the source;

- Un is the voltage at the place where the voltage receiver is connected.

The maximum permissible voltage deviation is 10%.

Current Density

This physical quantity is a vector quantity. To designate it, use the Latin letter J. The calculation formula is as follows:

- J = I/S,

Where:

- I—current strength, A;

- S—cross-sectional area, sq. mm.

Limit current density for aluminum and copper wires

Current density is the volume of current that passes through a conductor of a given cross-section in a certain period of time. Measured in A/sq. mm.

Why is the calculation made?

Wires and cables that carry electrical current are the most important part of electrical wiring.

The wire cross-section must be calculated to ensure that the selected wire meets all the requirements for reliability and safe operation of electrical wiring.

Safe operation is that if you choose a cross-section that does not correspond to its current loads, this will lead to excessive overheating of the wire, melting of the insulation, short circuit and fire.

Therefore, the issue of choosing a wire cross-section must be taken very seriously.

What you need to know

The main indicator by which a wire is calculated is its long-term permissible current load. Simply put, this is the amount of current that it is capable of passing for a long time.

To find the rated current value, you need to calculate the power of all connected electrical appliances in the house. Let's consider an example of calculating the wire cross-section for an ordinary two-room apartment.

| electrical appliance | Power consumption, W | Current strength, A |

| Washing machine | 2000 – 2500 | 9,0 – 11,4 |

| Jacuzzi | 2000 – 2500 | 9,0 – 11,4 |

| Electric floor heating | 800 – 1400 | 3,6 – 6,4 |

| Stationary electric stove | 4500 – 8500 | 20,5 – 38,6 |

| microwave | 900 – 1300 | 4,1 – 5,9 |

| Dishwasher | 2000 – 2500 | 9,0 – 11,4 |

| Freezers, refrigerators | 140 – 300 | 0,6 – 1,4 |

| Electric meat grinder | 1100 – 1200 | 5,0 – 5,5 |

| Electric kettle | 1850 – 2000 | 8,4 – 9,0 |

| Electric coffee maker | 630 – 1200 | 3,0 – 5,5 |

| Juicer | 240 – 360 | 1,1 – 1,6 |

| Toaster | 640 – 1100 | 2,9 – 5,0 |

| Mixer | 250 – 400 | 1,1 – 1,8 |

| Hairdryer | 400 – 1600 | 1,8 – 7,3 |

| Iron | 900 –1700 | 4,1 – 7,7 |

| Vacuum cleaner | 680 – 1400 | 3,1 – 6,4 |

| Fan | 250 – 400 | 1,0 – 1,8 |

| TV | 125 – 180 | 0,6 – 0,8 |

| Radio equipment | 70 – 100 | 0,3 – 0,5 |

| Lighting devices | 20 – 100 | 0,1 – 0,4 |

Once the power is known, the calculation of the cross-section of a wire or cable comes down to determining the current strength based on this power. You can find the current strength using the formula:

1) Formula for calculating current for a single-phase 220 V network:

current calculation for a single-phase network

where P is the total power of all electrical appliances, W; U—mains voltage, V; CI = 0.75 - simultaneity coefficient; cos for household electrical appliances - for household electrical appliances. 2) Formula for calculating the current in a three-phase 380 V network:

current calculation for a three-phase network

Knowing the magnitude of the current, the wire cross-section is found from the table. If it turns out that the calculated and tabulated current values do not coincide, then in this case the nearest larger value is selected. For example, the calculated current value is 23 A, we select the nearest larger one from the table, 27 A - with a cross-section of 2.5 mm2.

Which wire is better to use

Today, for installation of both open and hidden electrical wiring, copper wires are, of course, very popular.

Copper, compared to aluminum, is more effective:

- it is stronger, softer and does not break in places of inflection compared to aluminum;

- less susceptible to corrosion and oxidation. When connecting aluminum in a junction box, the twist points oxidize over time, which leads to loss of contact;

- The conductivity of copper is higher than that of aluminum; with the same cross-section, a copper wire can withstand a higher current load than aluminum.

The disadvantage of copper wires is their high cost. Their cost is 3-4 times higher than aluminum ones. Although copper wires are more expensive, they are still more common and popular in use than aluminum wires.

Why do you need to calculate the cable cross-section?

When purchasing a cable, you may see different symbols. For example, a 3x5 wire contains three current-carrying conductors, each of which has a cross-section of 5 square meters. mm. Knowing this, just look at the table of voltage and power.

Only a correctly calculated cross-section guarantees the absence of areas with overheating of the cable. In this case, the wire must withstand temporary loads when the current value is 2-3 times greater than the rated value. You will receive a current reserve, which is important, since at any moment the load on the network may increase due to new household appliances. The absence of heating will prevent spontaneous combustion and fires at objects. This point needs to be thought through in advance, since in most cases a hidden method of installing electrical wiring is used, and the slightest damage can lead to the need to replace the entire line.

Electrical power of household appliances

Advantages

This metal is lightweight. This advantage is particularly noticeable in situations where large amounts of aluminum cable need to be used. Thus, the lightness of this metal makes aluminum cable a favorite when laying power lines. It's worth noting that aluminum is a very common metal and costs less than copper. Actually, these two factors became the reason for the use of aluminum wiring in housing construction in the USSR.

Another feature that can be considered as an advantage is corrosion resistance. Although there are some nuances here. The fact is that the surface of aluminum upon contact with air immediately (almost instantly) oxidizes. A film forms on top, which subsequently protects the rest of the wire from oxidation. The downside is the poor ability of the film to conduct current. As a result, problems arise in the passage of current at the cable junctions.

Choose by power

The wire cross-section can be selected depending on the maximum current load on the line. Moreover, each household appliance has a different power. The list below shows the capacities of the most common equipment:

- electric stove - 5 kW;

- refrigeration unit - 0.8 kW;

- dishwasher - 2 kW;

- microwave - 1.5 kW;

- kitchen hood - 0.5 kW;

- kettle - 2 kW.

Obviously, the listed electrical appliances are installed in the kitchen. If you add up all the specified numerical values, you can get the total load on the kitchen electrical network. It will be about 12 kW, but the cross-section should be selected with a margin of up to 30%. Ideally, an electrical cable with a cross-section corresponding to a power of 15-16 kW is laid in the kitchen. To connect the equipment you will need at least two sockets.

The table below shows the selection of copper cable by power:

Determination of copper cable cross-section

The voltage of the electrical network is 220 V. Knowing this parameter and the total load, it is enough to use a simple formula to calculate the current consumption:

- I = P/U = 16,000/220 = 72.7 A.

This is the maximum permissible current for the cable being laid, but in fact the household appliances listed above will consume about 56-57 A. However, it is not necessary to exclude situations when other devices will be connected to the network - a vacuum cleaner, additional lamps, and so on. Many electricians avoid calculations using the coefficient 1.3 (30% margin), and simply add another 5 A to the actual value of the permissible current. If this option was possible before, today it is unlikely. Every year this parameter only increases: more powerful refrigerators, washing machines and vacuum cleaners appear.

The table below shows the selection of aluminum cable by power:

Determination of aluminum cable cross-section

Having completed the calculations of the permissible current, proceed to the selection of material for the current-carrying conductors. Aluminum cable costs less than copper cable, but the cross-sectional area of such conductors should be much higher. The current density for aluminum is 8, copper - 10 A/sq. mm.

Selecting the diameter of the fuse wire

In this case, you need to solve the inverse problem. Thermal destruction of the wire will stop the power supply, performing protective functions.

Table for selecting a safety element

| Maximum current, A | 0,5 | 1 | 2 | 5 | |

| Conductor diameter in mm for materials | Copper | 0,03 | 0,05 | 0,09 | 0,16 |

| Aluminum | — | 0,07 | 0,1 | 0,19 | |

Current load on the cable: how to calculate the cross-section

The total amount of current moving through a conductor depends on several characteristics: length, width, resistivity and temperature. An increase in temperature is accompanied by a decrease in current. Any reference information that you find in the PUE tables is usually provided for a room temperature of 18 degrees Celsius.

In addition to the electric current, you need to know the conductor material and voltage. The simplest calculation of cable cross-section based on permissible current is to divide its value by 10. If, when studying the table, you do not find the required value, then look for the nearest, slightly larger value. This option is possible for copper wires, and the permissible current is 40 A or less. In the range of 40-80 A, the permissible current should be divided by 8. For aluminum wires, the value is divided by 6. The reason for this was indicated at the end of the previous section.

Permissible current load on the cable

Determination of permissible current

All conductors heat up when current passes.

Excessive temperature increases provoke mechanical destruction of the structure, including protective and decorative shells. To maintain the operability of the route, the concept of “long-term permissible current” is used. Reference values for wires with copper and aluminum conductors are given in the PUE rules and industry GOSTs. Table of permitted current loads

| Conductor material | Shell | Cross-sectional area of the core, mm sq. | Permissible current loads, A | Type of route, number of cables in the channel |

| copper | polyvinyl chloride | 1,5 | 23 | installation in an open tray |

| copper | rubber + lead | 1,5 | 33 | in the ground, two-core cable |

| aluminum | polyvinyl chloride | 2,5 | 24 | open tray |

| aluminum | polymer | 2,5 | 29 | in the ground, three-wire cable |

| copper | plastic, rubber | 2,5 | 40 | relocatable design, single-core cable |

For accurate calculations, experts use the heat balance formula, which contains:

- electrical resistance of a meter of conductor at a certain temperature;

- correction factors to take into account heat transfer to the surrounding space using convection and infrared radiation;

- heating from external sources.

Thermal energy removal is improved when the route is laid in the ground (underwater). The conditions are worse when several cables are in one channel.

For your information. Sometimes an analogue of power calculation is used taking into account the non-destructive heating level.

Calculation of cable cross-section by power and length

The length of the cable determines the voltage loss. One potential unpleasant situation: at the end of the selected wire, the voltage has decreased to a minimum, which is not enough to ensure the functionality of the equipment. In household electrical networks, losses will be small, so they can be neglected. It is enough to use a cable with a margin of 100-150 mm, which is necessary to simplify switching. If the edges of the wire are connected to the electrical panel, then the margin should be higher, since the installation of automatic machines is required.

When placing the cable over longer sections, you need to take into account the voltage drop, which is calculated using the formula given above. Any conductor has a certain electrical resistance, which depends on a number of characteristics:

- Wire length, m. The longer the length, the higher the losses.

- Cross-sectional area, sq. mm. The higher the parameter, the lower the voltage drop.

- Specific resistance of the material (look in reference books).

Maximum cable length for various current loads

To calculate the voltage drop in normal cases, it is enough to multiply the resistance and the permissible current. The actual value may be greater, but not more than 5%. If it does not fit within the specified framework, you will have to use a cable with a larger cross-section.

To calculate the cable cross-section for power and length, proceed as follows:

- Calculate the current using the formula I=P/(U*cosph), where P is power, U is voltage, cosph is coefficient. In household electrical networks, this coefficient is equal to 1, so the formula simplifies to I=P/U. In industry, cosph is the ratio of active and apparent power (active and reactive).

- In the PUE table, find a suitable cable cross-section depending on the current.

- Calculate the conductor resistance using the formula: R=ρ*l/S, where ρ is the resistivity of the material from which the conductors are made, l is the cable length, S is the cross-sectional area. Remember that electric current flows in both directions, so the total resistance is equal to twice the value obtained from the formula above.

- For voltage drop, use the formula ΔU=I*R

- To get the percentage voltage drop, divide ΔU/U.

Thus, if the final value does not exceed 5%, you can leave the cable with the selected cross-section. Otherwise, it will have to be replaced with a conductor with an increased cross-section.

Continuously permissible currents

This value differs depending on the selected cable and the current-carrying cores used. Any wire has a certain long-term temperature Td, which is indicated in its passport. At this temperature, prolonged operation of the conductor cores is permissible, and any damage is excluded.

To calculate the continuous permissible current, use the formula:

- Id = √((Td*S*Kt)/R),

Where:

- Ktp - heat transfer coefficient;

- R - resistance;

- S - core section.

In practice, you can use PUE tables.

Continuously permissible currents for copper wires and cables

Odds

There are certain conditions under which the current inside the wiring can increase or decrease. For example, in open electrical wiring, when the wires are laid along walls or ceilings, the current strength will be higher than in a closed circuit. This is directly related to the ambient temperature. The larger it is, the more current this cable can carry.

Attention! All of the above listed PUE tables are calculated under the condition that the wires are operated at a temperature of +25C with the temperature of the cables themselves not exceeding +65C.

That is, it turns out that if several wires are laid at once in one tray, corrugation or pipe, then the temperature inside the wiring will be increased due to the heating of the cables themselves. This leads to the fact that the permissible current load is reduced by 10-30 percent. The same applies to open wiring inside heated rooms. Therefore, we can conclude: when calculating the cable cross-section depending on the current load at elevated operating temperatures, you can choose wires of a smaller area. This is, of course, a good saving. By the way, there are also tables of reducing coefficients in the PUE.

There is one more point that concerns the length of the electrical cable used. The longer the wiring, the greater the voltage loss in the sections. Any calculations use a loss of 5%. That is, this is the maximum. If the losses are greater than this value, then the cross-section of the cable will have to be increased. By the way, it’s not difficult to independently calculate current losses if you know the wiring resistance and current load. Although the best option is to use the PUE table, which establishes the relationship between load torque and losses. In this case, the load torque is the product of the power consumption in kilowatts and the length of the cable itself in meters.

Let's look at an example in which an installed cable 30 mm long in an alternating current network with a voltage of 220 volts can withstand a load of 3 kW. In this case, the load moment will be equal to 3*30=90. We look at the PUE table, which shows that losses of 3% correspond to this moment. That is, it is less than the nominal value of 5%. What is acceptable. As mentioned above, if the calculated losses exceeded the five percent barrier, then it would be necessary to purchase and install a cable of a larger cross-section.

Attention! These losses greatly affect lighting with low-voltage lamps. Because at 220 volts 1-2 V is not reflected much, but at 12 V it is immediately visible.

Currently, aluminum wires are rarely used in wiring. But you need to know that their resistance is 1.7 times greater than that of copper ones. And that means their losses are just as many times greater.

As for three-phase networks, the load torque here is six times greater. This depends on the fact that the load itself is distributed over three phases, and this is a corresponding exponential increase in torque. Plus a double increase due to the symmetrical distribution of power consumption across phases. In this case, the current in the zero circuit must be zero. If the phase distribution is asymmetrical, and this leads to an increase in losses, then you will have to calculate the cable cross-section for the loads in each wire separately and select it according to the maximum calculated size.

Open and closed wiring

Electrical wiring can be of two types:

- closed;

- open.

In most cases, hidden installation is used for apartments. Using a hammer drill or wall chaser, special recesses are created in the wall or ceiling into which the cable is laid. Additionally, it can be placed in corrugated tubes or sleeves. Having hidden the cable, the recesses should be sealed with plaster. The only acceptable option for modern hidden wiring is copper conductors. In this case, you should consider in advance the potential expansion of the network or the process of partial replacement of its components. Ideally, you should use flat wires.

Laying hidden wiring in grooves

Open electrical wiring involves placing the cable along surfaces. Mainly flexible conductors with a round cross-section are used. They are placed in cable ducts or passed through corrugations. When calculating the load, the cable laying method must be taken into account.

Consequences of overcurrent

An excessive increase in temperature destroys the conductor and the electrical current path. Damage to insulation as a result of thermal effects creates favorable conditions for corrosion and increases the likelihood of a short circuit. In addition to equipment damage, safety is compromised. It is necessary to emphasize the additional costs that are caused by complex operations to restore the functionality of hidden wiring.

The above recommendations must be followed in their entirety. Do not exceed the continuous current allowed by the rules. Favorable operating conditions must be maintained. We must not forget about the appropriate corrections when connecting powerful loads one-time or continuously.

Selection of wire cross-section according to the number of consumers

When calculating cross-sections for an electrical cable in an apartment, it is first recommended to show the wiring schematically. The drawing must indicate all devices that consume electricity. The circuit is divided into different rooms, since each can use a wire of a different cross-section.

Wiring diagram for consumers

The electrical network is divided into several circuits. Each circuit corresponds only to those electrical appliances that are connected to it. To select a cable connecting all circuits, you need to calculate the total total power. This is the main criterion for choosing a section. Each subsequent branching (branch) will lead to a decrease in the total power and, accordingly, a decrease in the required cross-section.

Tips for choosing a cable for household needs

The building materials market provides a huge selection of cables for household needs. As a rule, they differ in the color of the insulation and braiding, but all of them must have special markings that contain all the necessary information.

- When choosing a cable, remember that operating it to the limit will lead to significant overheating of the wires, and in exceptional cases, to ignition of the cable.

- You need to buy a wire with a reserve, but excessive sagging can lead to a break, especially in spring or autumn, when ice forms on it.

- At unacceptably high lengths, significant losses of current power are possible.

- When choosing a wire, be sure to check the markings and all the necessary characteristics, according to the table for selecting the cross-section of cores and wires for power and current.

Current loads in DC networks

When calculating the current load in a direct current network, they are guided by a single-core cable. The voltage of this current is 12 V. Calculation of the load of the wire through which a 0.1 kW light bulb is connected (for example, in the headlight of a car) looks like this:

- I = P/U = 100/12 ~ 8.35 A.

After this, it is easy to calculate the resistance:

- R = U/I = 12/8.35 = 1.44 Ohm.

In the table, find the resistivity of copper, from which the cores of modern conductors are made. Also assume that the cable length is 2 m. Use the formula given in the sections above to obtain the cross-sectional area of the suitable wire:

- S = (ρ*L)/R = (1.68*10-8*2)/1.44 = 1.2 sq. mm.

Selecting a cable cross-section for DC networks

When studying the PUE, you can find countless tables that define the current load for AC networks with single- and three-phase circuits. Therefore, it is not necessary to perform such complex calculations.

Wire marking

The standard designations indicate the important characteristics of products in this category. If the letter “A” is indicated, then the core is made of aluminum. Copper is not marked in any way. The following positions:

- type of wire: “P” – flat, “U” – installation;

- sheath material (conductor, general): “B” – polyvinyl chloride;

- additional protection: “B” – armored with steel tape;

- (number of cores) * (cross-sectional area of the conductor, mm sq.) – (rated voltage, V): 2*1.5-220.

Causes of cable heating

Current-carrying conductors can overheat for several reasons, which are directly related to the nature of the electric current. The electric field sets in motion electrons, which move along the selected conductor. In the crystal lattices of which metals are composed, strong molecular bonds operate. Imagine a table tennis ball and a spider web. The second one is more or less durable, the first one is light in weight, so in order for the ball to break the web, more effort will have to be made. The harder you swing, the more tense your muscles will be. The higher the voltage, the higher the energy expended. Accordingly, the muscles will heat up more.

Likewise, electrons are forced to release more heat, spending a lot of energy to overcome these molecular bonds. This process is called the conversion of electrical energy into thermal energy.

This phenomenon can be compared with the release of heat during friction. We can say that electrons are forced to rub against the crystal lattice of the metal and thereby generate heat. This property of a metal cable has its advantages and disadvantages. Heating can be useful in manufacturing facilities and for household appliances. It is the main property that allows electric stoves, heaters, irons and kettles to operate. However, in conventional electrical networks this can lead to overheating and destruction of the insulation, and subsequently even to a fire. Machinery and equipment may deteriorate. A similar thing happens if the specified norm for long-term current loads is exceeded.

We list three main reasons for conductor overheating:

- The most common is the use of a cable with an incorrect cross-section. Any conductor has a unique maximum current carrying capacity. It is measured in Amperes. Before connecting a household appliance, you need to determine its power and, in accordance with it, select the correct cross-section. It is important to take into account a margin of 30-40%.

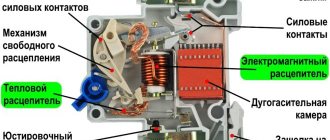

- The second reason is the lack of high-quality contact at the connection points of the line. We are talking about sections of the route where the cable is connected to a panel, circuit breaker or switch. Poor contact leads to heating. In worst case scenarios - complete burnout. In most cases, it will be enough to inspect the contacts and tighten all connections.

- The old electrical wiring was built on aluminum conductors, so when modernizing such cable lines there is often a need to switch to copper conductors. In this case, it is important to follow the technique for connecting copper and aluminum conductors. Without the use of special terminal blocks, the appearance of oxidation is a matter of time.

Old aluminum wiring in the apartment

Which cable is better to buy?

Following the strict recommendations of the PUE, for the arrangement of personal property we will buy cable products with the “letter groups” NYM and VVG in the marking. They are the ones who do not cause any complaints or quibbles from electricians and firefighters. Option NYM is an analogue of domestic VVG products.

It is best if the domestic cable is accompanied by the NG index, this means that the wiring will be fire resistant. If you intend to lay the line behind a partition, between joists or above a suspended ceiling, buy products with low smoke emission. They will have the LS index.

This is a simple way to calculate the cross-section of the cable conductor. Information about the principles of calculations will help you rationally select this important element of the electrical network. The necessary and sufficient size of the current-carrying core will provide power to home appliances and will not cause a fire in the wiring.

Calculation of permissible current for heating cores

If a conductor of a suitable cross-section is selected, this will eliminate voltage drop and overheating of the line. Thus, the cross-section determines how optimal and economical the operating mode of the electrical network will be. It would seem that you can simply take and install a cable with a huge cross-section. But the cost of copper conductors is proportional to their cross-section, and the difference when installing electrical wiring in just one room can amount to several thousand rubles. Therefore, it is important to be able to correctly calculate the cable cross-section: on the one hand, you guarantee the safe operation of the network, on the other hand, you will not spend extra money on purchasing an overly “thick” conductor.

To select the wire cross-section, two important criteria must be taken into account - permissible heating and voltage loss. Having received two values for the cross-sectional area of the conductor using different formulas, choose the larger value, rounding it to the standard. Overhead power lines are especially sensitive to voltage loss. At the same time, for underground lines and cables placed in corrugated pipes, it is important to take into account the permissible heating. Thus, the cross-section should be determined depending on the type of wiring.

Permissible heating temperatures of current-carrying cable cores

Id - permissible load on the cable (heating current). This value corresponds to the current flowing through the conductor over a long period of time. In the process of this, a set, long-term permissible temperature (Td) appears. The calculated current strength (Ip) must correspond to the permissible current (Id), and to determine it you need to use the formula:

- Iр=(1000*Pн*kз)/√(3*Un*hд*cos j),

Where:

- Pn — rated power, kW;

- Kz - load factor (0.85-0.9);

- Un — rated voltage of the equipment;

- hd - equipment efficiency;

- cos j - equipment power factor (0.85-0.92).

It turns out that for any long-term permissible current flowing through the conductor, there corresponds a specific value of the established, long-term permissible heating temperature. It is important to neutralize the influence of other environmental factors. The cable current directly depends on the material from which the insulation is made, the laying method, the cross-section and material of the cores in the conductor.

Even if we take into account the same current values, the thermal output will be different depending on the ambient temperature. The lower the temperature, the more efficient the heat transfer.

Cable correction factors depending on ambient temperature

Temperatures differ depending on the region and time of year, so in the PUE you can find tables for specific values. If the temperature differs significantly from the calculated one, correction factors will have to be used. The base temperature indoors or outdoors is 25 degrees Celsius. If the cable is laid underground, the temperature changes by 15 degrees Celsius. However, it is underground that it remains constant.

What is the difference between a cable and a wire?

Before moving on to the main content, we need to understand what we still want to calculate, the cross-section of a wire or cable, what are the differences between one and the other!? Despite the fact that the average person uses these two words as synonyms, meaning by this something of their own, but if we are meticulous, there is still a difference.

So a wire is one conductive core, be it a single core or a set of conductors, insulated into a dielectric, into a sheath. But a cable is already several such wires combined into a single whole, in its own protective and insulating sheath. In order for you to better understand what's what, take a look at the picture.

So, now we know that we need to calculate exactly the cross-section of the wire, that is, one conductive element, and the second will already move away from the load, back to the power supply.

However, sometimes we ourselves forget ourselves no better than you, so if you catch us by the fact that somewhere you still come across the word cable, then do not consider it ignorance, stereotypes do their job.

Heat transfer conditions

An important condition for heat transfer is the humid environment in which the cable is located. When placing a wire in the ground, heat removal is directly related to the structure and its composition, as well as the level of humidity.

To obtain the most accurate values, you will have to analyze the composition of the soil, depending on which the resistance will vary. Using the table, look for resistivity. Thanks to high-quality compaction, this characteristic can be reduced. Sand and gravel have lower thermal conductivity compared to clay, so ideally the wires are buried last. Instead of clay, you can use loam without admixtures of slag, stones and debris.

The heat dissipation of the air cable is minimal. The parameter decreases for lines in cable ducts that have an air gap. Cables located close to each other heat each other, so current loads should be kept as low as possible. Permissible currents are calculated using two different formulas depending on the operating mode - emergency or long-term. If a short circuit occurs, the permissible temperature for a paper-insulated wire is 200, PVC - 120 degrees Celsius.

It is important to remember the different cooling conditions for cables with and without insulation. In the first case, the heat flows emanating from the heating of the cores are forced to overcome an additional barrier in the form of an insulating layer.

Cable location in trench

When laying cables underground, when two conductors are located in one trench at once, the cooling process will slow down significantly, which will lead to a reduction in permissible current loads.

From the point of view of electrical and fire safety, determining the correct long-term permissible current and cable cross-section is an important condition to prevent overheating, insulation failure and ignition of the cable line. When making calculations, you should be careful and take into account many additional conditions. Certain adjustments are needed even for tabular values.

Permissible current density for copper wire

Connecting the meter via current transformers

When creating networks in modern real estate, they prefer to use just such conductors. With the same cross-section, they overheat less than their aluminum counterparts. Multi-core copper cables are well suited for creating network connecting cords and extension cords. They can be used to create tight radius turns.

Thermal heating

To calculate the amount of heat ( Q ) generated by the conductor, use the formula I *2* R * t , where:

- I – current strength, in amperes;

- R is the resistance of one meter of copper conductor;

- t – test time under certain conditions.

Heat dissipation during cable operation

Thin conductors effectively transfer thermal energy to the environment. The process is significantly influenced by specific conditions. As noted above, contact of the shell with water significantly improves cooling.