Sanding timber inside a house is a mandatory operation that is performed after the construction and complete shrinkage of a wooden structure. The main purpose of this work is to level the surface, remove darkened and blue-damaged areas of wood and prepare the interior walls of a house or bathhouse for further painting or varnishing. Sanding is required not only for newly built wooden houses, but also for old timber buildings. Sanding allows you to remove a layer of old paint and refresh the color of the interior walls of your home. Which tool is suitable for the job and how to properly sand a timber and log house from the inside are questions that will be discussed in detail in this article.

When is wall sanding done?

Sanding is the process of treating a wooden surface before finishing, painting or varnishing. Sanding removes defects and makes the wood smooth, allowing you to achieve an even paint layer; it is used in the following cases:

- When building a new house

. Sanding walls made of timber is done by waiting for the timber to dry, after the building has settled. During the work, irregularities that appear after the wood has dried are eliminated; work can be carried out at any time of the year. - During the restoration of an old house

. This grinding renews the color of the timber walls, after which they are re-coated with paint and varnish.

Walls are polished during the construction of a house and periodically during operation Source drevogid.com

Why do internal timber walls need to be sanded?

Sanding timber walls inside the house solves several problems:

- Prepares the surface for painting

. Before construction begins, any wooden material is treated with an antiseptic and fire retardant. Since most antiseptics are water-based, after getting wet and drying, the wooden wall becomes covered with lint. Sanding removes lint and simultaneously levels the wall, some of the crowns of which may protrude above the surface (sometimes by 1-2 mm). Smooth walls mean easier painting and savings on materials, which can be a noticeable amount if the house is large and the paint is high-quality. - Emphasizes the beauty of wood

. During operation, coatings become obsolete, so wooden walls require periodic treatment. Sanding removes the old paint layer and reveals the texture of natural wood. - Extends the life of the house

. Protective impregnations are absorbed deeper into the newly sanded wooden surface. This is especially true for buildings with irregular winter heating.

Walls made of timber often need tone equalization Source indeco.ru

See also: Catalog of construction companies that have a full production cycle

Professional grinding services

Our specialists are highly qualified, have extensive experience and proven work skills. All this ensures high quality grinding, which we will perform in accordance with the deadlines specified in the contract. In our work, we use modern professional power tools that allow us to achieve a perfectly smooth and even surface. If you need high-quality sanding of a country cottage, country house or bathhouse, we are very willing to carry out work of any level of complexity. Contacting us is very simple - on the “Contacts” page you will find all the coordinates of our company, and you can also leave your request.

Calculate the cost of painting and insulating your home right now

Select types of work:

Select materials:

Grinding: tools and equipment

When choosing how and with what to sand the timber before painting, pay attention to the speed and quality of the process, which depends on the choice of method and tools. If you sand walls made of profiled timber by hand, using sandpaper, you will have to spend several weeks at work, surrounded by a cloud of wood dust. It is much more convenient to process all surfaces with a grinding machine, and use sandpaper only in places that are difficult for the tool to reach. Grinding is carried out in the presence of the following components:

- Sanding machine

with sandpaper of various grits. Some models are connected to a vacuum cleaner, which significantly reduces the amount of dust. The abrasive wheel is selected depending on the type of wood. - Angle grinder

(angle grinder,

grinder

). It comes with a set of abrasive discs with different parameters for rough and fine grinding.

A professional tool will ensure high-quality surface leveling Source ar.aviarydecor.com

- Sandpaper

with different concentrations of abrasive. It is selected depending on the condition of the walls. At the initial stage, unevenness is removed with paper numbered 40-60, the old paintwork is removed with sandpaper 100-140. Lint removal will require the use of numbers 160-220. At the final stage (polishing) a grit size of 90-120 is used. - Protection

. To prevent fine, ubiquitous dust from penetrating the respiratory system and damaging your eyes, you should stock up on a respirator and safety glasses. - Construction vacuum cleaner

. Without thorough dust removal, you can forget about high-quality processing and painting. - Assistive devices

. You will need a stepladder (or its substitute), an extension, a chisel and a sanding sponge with cut corners (for better access to corners).

A respirator and glasses are an indispensable component of equipment Source pinterest.pt

Grinding Tools

If you have already decided to start grinding, then before going to the supermarket, you need to read this section of the article.

List of commonly used grinding devices:

- Belt or angle grinder.

- Sandpaper of different sizes: large, medium, small.

- Ladder.

- Extension.

- Safety glasses.

- Wooden block.

- Stapler for construction.

- Construction vacuum cleaner.

- Respirator.

Before choosing certain tools that are listed, you need to know important criteria. These criteria are power, ease of use and weight.

Next, it’s worth figuring out why there are several types of grinding machines. Here, as an example, you can take a Finnish beam, which has a rounded side. This example will perfectly draw the line between a belt and an angle grinder. It is worth mentioning that the angle grinder is a grinder with the necessary attachments. So, for this beam, a banding machine will not be convenient due to its rounded shape. But there are places that a grinder will not help with; in such cases, I use a time-tested tool - a chisel.

You have heard a little superficially about the “necessary attachments”. This is the sandpaper that was provided in the listing.

When choosing an angle grinder, do not forget about important criteria. It should be light and powerful. Taking it in your hands you will understand how much weight you need the device. For upcoming work, a power of nine hundred or more watts will be enough. The approximate cost of such a tool will be 2600 rubles. It’s worth thinking about devices with built-in vacuum cleaners. Of course, this model will be more expensive, but you will thereby take care of your respiratory organs.

Profiled and laminated timber: differences in the process

Sanding allows you to improve the appearance of walls and prepare them for high-quality painting, waxing or varnishing. For profiled and glued material, the process is different:

- Profiled timber

. Usually processed in two steps. The first time is sanded with a coarse abrasive (a wheel with a grit size of No. 40), even at the construction stage. The second treatment (final polishing) of the walls is carried out after completion of the shrinkage process. - Glued laminated timber

. This building material is carefully processed at the production stage, does not shrink strongly and therefore does not require preliminary deep grinding like its profiled counterpart. To process walls made of laminated veneer lumber, use nozzles with a wheel starting from No. 80. Sanding should be carried out with caution - excessive force can damage the outer lamella.

Preparing for work

While planing, a craftsman can discover a radial structure on the timber. This means that certain sections of the wood may peel off. So first you need to carefully study the structure of the material being processed.

In this case, the wood is treated with a special adhesive solution. You will need to wait a day until the composition dries completely, and then small particles will no longer flake off. Defects will not appear in normal areas of the timber, and grinding wheels will not have to be changed every now and then.

On a note. If such a defect is detected, it is highly advisable to treat the area with an adhesive compound. Moreover, the glue is applied in several layers.

You can process the ends using a blowtorch. All the lint will be burned and removed. In addition, after such treatment, the wood gains increased strength and becomes more durable.

The ends are the weak link of the structure. Firing will provide the opportunity to subsequently polish them more efficiently. Additional polishing can be done with fine-grained sandpaper.

Here are the results of the preparatory work and proper sanding.

Firstly

, the wood will dry out slowly. This means you can count on uniform shrinkage.

Secondly

, it takes significantly less paint and varnish to process timber with dye or coat it with varnish. And this is a completely justified saving.

Process steps

Sanding a house made of timber, when a dry surface is processed, including the ends, takes place in two stages:

- Rough grinding

. The walls are leveled using a belt sander or grinder with an abrasive wheel with numbers 40-60. At this stage, all significant defects are removed, and the surface is prepared for subsequent, finer processing. The attachment on the sander quickly becomes clogged with wood dust and needs to be replaced frequently. - Fine grinding and polishing

. To perfectly level the surfaces, treatment is carried out with a vibrating or orbital sander using a fine-grained abrasive (up to 100). For fine sanding, hand sanding is used using sandpaper (numbers 120-180). Alignment of corner joints is carried out manually, using a narrow chisel. Unprofessional processing can leave scratches and grooves that will have to be corrected with additional polishing. After fine sanding, the surface of the walls becomes smooth, pleasant to the touch and ready for subsequent painting.

Fine sanding of timber inside the house using a vacuum cleaner to collect waste Source nl.decorexpro.com

Timber grinding technology

Sanding the walls of a log house is carried out in stages and includes three types of processing: rough, fine and finishing.

- At the first stage, rough processing of the timber is performed, the task of which is to remove all significant irregularities from the surface and prepare it for finer grinding. For this work, the abrasive with the largest grain size is selected. During initial processing, the nozzles very quickly become clogged with dust, and they have to be changed frequently.

- For basic sanding, fine-grain sandpaper is used. After processing, the result should be a flat and smooth surface, ready for subsequent painting.

- Final sanding is not always performed, but in cases where it is necessary to bring the surface into ideal condition for the subsequent application of a transparent varnish coating. The walls are polished using the finest abrasive to make the surface as smooth as possible.

To grind the grooves, use a grinder with an attachment several sizes smaller than the diameter of the circle. The corners are processed manually with a chisel with a working part width of 20 mm.

After each grinding stage, it is necessary to clean the surface from dust using a vacuum cleaner. After completing all grinding work, the surface must be treated with antiseptics that protect the wood from rot and mold. This must be done no later than seven days after sanding.

Useful tips

Sanding timber walls is a labor-intensive and painstaking process. To ensure high-quality and long-lasting results, the following rules are followed in our work:

- Timing

. Sanding is carried out after completion of the drying process (for profiled timber), before installing windows and doors, and before installing a clean floor and ceiling. The limitation is due to the dustiness of the work. - Preparing the walls

. Before sanding the timber inside the house, remove the resin that has appeared on the surface. The work is completely manual: the resin is removed with a scraper or other suitable tool, and the resin pockets are treated with a solvent. This moment is an important stage in preparing the walls for sanding - the resin can very quickly render the abrasive unusable, clogging its structure, and besides, the remaining resin will not allow the paint to lie flat on the wall. - Technique parameters

. A grinder used for processing timber walls must have a power of at least 1 kW. The operator, working on a weaker machine and trying to involuntarily speed up the process, can increase the pressure. As a result, grooves remain on the surface, which are not easy to remove.

An industrial hair dryer melts the remaining resin from a resin pocket Source starkwood.ru

- Working methods

. In order for sanding to proceed smoothly and give a high-quality result, the stroke of the sanding machine and the direction of the wood fibers must match. - Work planning

. Sanded wood quickly loses its freshness and darkens, which can affect the quality of the future paintwork. To avoid having to repeat sanding (and waste additional time and money), you should stock up on paint in advance.

Preparatory stage

Before starting work, prepare:

- Check the serviceability of the power tool and extension cord. Detected deficiencies are eliminated.

- The timber is cleaned of layers of dirt, and if necessary, burrs are cut off with a chisel. Remove resin drips to extend the life of the sanding paper.

Consumables are prepared in advance, including impregnations, varnishes, paints, and mastics.

Leaving treated wood unprotected for a long time is undesirable; it can lead to rapid darkening of the surface and loss of attractiveness.

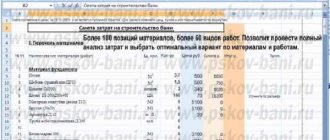

What determines the cost of grinding services?

Sanding timber walls inside the house is an important step, the execution of which is logical to entrust to professionals. The cost of services varies depending on several parameters, including:

- Scope of work

(wall surface area). Some construction organizations offer discounts on sanding if the building is large. Work can last 1-2 weeks. - Type of wood

. The harder the wood, the more difficult it is to process and the work will cost more.

Work algorithm

Turnkey grinding of the ends of timber is a set of activities during which a qualitative transformation of wood occurs in terms of its appearance, mechanical and biological stability.

The work is carried out in the following sequence:

- Inspection of the structure, drawing up an estimate, drawing up a contract (price is calculated per square meter).

- Primary rough grinding of beams.

- Caulk of a log house with natural and synthetic sealants.

- Final sanding.

- Priming and application of paint and varnish coatings.

Finally, the object is handed over to the customer and the acceptance certificate is signed.

Video description

About correcting wall defects before sanding in the following video:

- Condition of the walls

. If walls made of profiled timber are covered with paints and varnishes, you will have to pay additionally for cleaning the old coating. It will also be more expensive to process walls with a large number of defects (jags, irregularities and resin). - Expected Result

. It depends on the customer how many passes will be made before covering the walls with wax, varnish or oil. - House height

. If the work requires the use of scaffolding, the cost of working at height will be higher. - Comprehensive services

. If you order sanding of corrugated timber walls together with painting, the work will cost less than separately.

The cost of sanding internal walls made of planed timber (profiled or glued) is:

- Sanding walls

. Standard processing includes two passes (first with coarse, then with fine sandpaper) and costs from 200 to 350 rubles/m2. - Polishing the walls

. From 170 to 250 rubles/m2. The surface is treated once. - Finishing

. It is carried out after applying wax or varnish. From 320 rub./m2.

The customer determines the degree of treatment of the internal walls Source roomester.ru

Do I need to sand profiled timber?

When transporting a wooden beam and its subsequent unloading, various contaminants may fall on it, which cannot always be wiped off with a regular damp cloth.

It is worth noting that the drying process of the wood mass occurs unevenly. Since summer trunk rings are looser, they lose moisture much faster than winter ones, whose density is much higher and humidity is lower. Even on surfaces treated by planing, this feature will certainly appear after just one year of use of the log. The smoothness of the wood material is significantly reduced.

The destruction of wood by insects, fungi and various microorganisms always manifests itself superficially at first. Therefore, removing the top layer of material can be regarded as an additional protective measure.

During the process of sanding the wood surface, the cellular structure in this place is significantly disrupted. This is both an advantage and a disadvantage. Thanks to the use of this technology, fire retardants and antiseptics used to process wood penetrate as deeply as possible into its structure, which allows for the highest quality protection of the material.

Sanding timber and its main stages of preparation

Sanding timber is a process that is a very important task that must be taken very seriously. It includes quite a lot of work, not only at home, but in other premises. Moreover, the amount of work that is necessary before finishing the interior walls is unlimited.

Tools

First of all, before starting such work, you need to prepare all the tools:

- Sander;

- grinder with special attachments;

- draw machine;

- drill (screwdriver);

- sandpaper.

Technology

It is mandatory to sand the frame before painting the walls or opening them with varnish. Very often, when carrying out such work at home, the frame is polished to level the walls, as well as to eliminate a variety of defects that may or may appear after shrinkage. This process, carried out with a grinder, is rather boring and lengthy, as a result of which the cost of its implementation by craftsmen is not low. The complexity of the work can be assessed in the short video below:

The process itself consists of several steps that you can do yourself. First of all, you need to understand that you can start sanding a log house with a grinder as soon as the wood becomes completely dry. If you do this after assembly, wet elements may scuff and you will not get a smooth surface.

- Using coarse sandpaper (fraction 40), remove the top layer.

- Remove the lint with 120-grit paper.

- When processing ends and puzzles, use a grinder.

- Remove dust from the walls

So, experts recommend using an angle grinder, with which you can get into the most difficult places without any effort. The fact is that grinding machines do not always have enough power. Prepare baits with different grain sizes. To process timber that still has remnants of bark or unevenness, it is worth choosing a nozzle with a very large grain, and when the final stage is reached, use a fine grain. It is worth understanding that you will be changing elements in places very often - they will become clogged with dust and small particles of timber.

The procedure for removing the top layer from a timber or log house is the same

The speed in the process of grinding a log frame depends on how skillfully you do such work. If this is your first time sanding, there is no need to rush. Also, pay attention to the power of the tool and its strength. It is very important. If we take an average speed, then a beam, which has a diameter of about 30 cm, can be sanded in 2 minutes.

When sanding a log frame, a lot of dust will be released, which will get into the eyes and other parts of the body. Thus, experts recommend using masks and goggles when carrying out such work, with the help of which you will eliminate moments of dirt getting on your body or in your eyes.

You will sand the timber of a wooden house, then you must treat it with special materials. Typically, antiseptics are used for different purposes:

- from rottenness;

- for a unique look;

- fire retardant, which increases fire-resistant characteristics.

First, it is important to apply one level of the primer mixture, after which bleach is applied, and lastly the timber is treated with fire retardants.

Each of the above mixtures can be applied with a brush or spray.

Cost of work

It is not always recommended to do this type of work yourself. If you do not have the skills, you should contact craftsmen who have experience in this type of work and can do everything professionally and quickly without any problems. But, due to the fact that such work can confidently be classified as labor-intensive and requiring certain skills, tools, and a lot of free time, the cost of implementation is quite high.

If you do not have the above characteristics, confidently contact the experts. On average, the pricing policy for such work, namely a profiled log house, is about 400 rubles for polishing one square meter of a profiled log house. You can consider offers from specialized companies, because the cost of each may be different, as a result of which you can choose the best option. Usually, you can find the price of profiled timber that is most suitable. There are many offers on the Internet on the topic “price of profiled material”, among which you will find the price of a profiled log house and understand how much it costs.

This is how a house with treated timber can turn out, watch the video.

Taking this into account, you can calculate in advance what the total cost of the entire profiled timber will be and how much all the work will cost you. You can take up work with your own hands only when you have experience, the necessary tools, and also a lot of free time.

Sanding walls inside a glued house has its own characteristics. To process the walls, you should prepare the necessary tools and materials, as well as the mixtures with which you will cover the timber. The main thing in this matter is to do everything to protect the wood from rotting, as well as to make the walls beautiful. When carrying out work inside a wooden house, where there are labor-intensive places, it is recommended to use a chisel. When choosing an angle grinder, it is recommended to hold it in your hands to understand whether you can work with it or not.

Grinding the grooves of timber inside the house

Grinding of log grooves is carried out using special attachments, including:

- plastic;

- metal;

- rubber.

The first option is optimal and practical.

It is worth understanding that when carrying out grinding work inside a wooden room or a glued house, the air temperature should not be lower than +5. The structure of wood very often reacts to changes in temperature and humidity, as a result of which it can begin to collapse. Thus, such rules are very important and need to be followed before starting the process. Otherwise, after some time you risk noticing darkening on the walls of a glued house, and cracks may also appear, which is not at all pleasing.

Features before the house painting process

This process is characterized by special processing of the ends using a rubber hammer and sealant. For painting, different mixtures are used with the requirement of safety for health and the presence of protective functions. These are compositions based on water or natural oil.

The finished result of high-quality painting of a timber house

For outdoor use, it is recommended to use other options, since the above ones are not suitable for external walls.

When carrying out outdoor work in winter, you need to use drying oil diluted with gasoline, which you use as a covering material.

What are the goals of sanding laminated timber?

Residential buildings made of wood are distinguished by a high level of comfort, environmental friendliness and durability. However, despite the fact that wood has many advantages, over time wooden structures lose their attractiveness and manufacturability. The thing is that wood, of all building materials, is very susceptible to external influences. Even though laminated veneer lumber is fundamentally different in its technological characteristics from ordinary “living” wood, it requires constant care.

The material darkens over time, its surface layer loses its strength and integrity. In appearance, the house continues to remain strong and reliable, but from a technological point of view, the process of transformation of the main structural elements has already begun. To slow down the effect of negative processes, grinding of walls assembled from timber is used as a preventive measure.

In other words, holding such events will solve the following problems:

- the sanded timber becomes like new, having a fresh appearance with a clear texture;

- Mold and fungal formations are removed from the surface of walls and other structural elements;

- reveals the surface structure of the timber before treating it with antiseptic solutions;

- improves the quality of the surface of the material for its subsequent painting;

- surface defects that appeared on the walls during the operation of the facility are eliminated.

Purpose of grinding

When building wooden houses, many developers want to emphasize the pristine beauty of the wood texture, rejecting this type of finishing such as painting. To do this, the log house is treated with transparent or tinted products, which, along with decorative functions, also protect the wood from rain and snow. Often the substances included in the coating form a kind of ultraviolet barrier that protects the tree from exposure to the sun.

The problem with wood processing is that the log house cannot be immediately coated with protective agents. Any house cut from a log or timber of natural moisture must first shrink. In this case, the wood will dry out and the humidity will be no more than 20%. Only in this case is it possible to apply various protective coatings. However, under natural conditions, wood drying takes months and even years. During this time, the log house will definitely darken and become gray. In this case, grinding will help, which will precede treatment with protective compounds.

Recommendations and main conclusions

When starting to sand a house made of laminated veneer lumber, you need to have an idea of what you will have to deal with. Superficial and quick grinding will not give the expected effect, so for these purposes you need to choose the time and suitable weather conditions. Do not neglect the following recommendations:

- The weather for sanding should be dry. It is best to carry out such work during the warm period, since low temperatures negatively affect the condition of the sanded surface.

- During work, safety precautions must be observed. Safety glasses and a respirator are mandatory accessories in such cases. To reduce the amount of dust indoors, use air humidifiers. Having a vacuum cleaner, which is best used to regularly remove construction debris that appears, will not interfere with your work.

- It is better to make the first attempts to work with an angle grinder at the ends of the beam. Having practiced processing end surfaces, you can begin cleaning walls and front surfaces.

- Sanding of the timber is carried out before installing the interior structures. Windows, doors, ceiling surfaces and floors are installed after sanding the structural elements of the house.

To summarize, we can say that sanding is an integral part of the proper operation of a house made of laminated veneer lumber. Despite the high technological parameters of this building material, this approach to home care will significantly increase the durability of the residential structure and increase the level of comfort in the house.

Sanding timber walls inside the house

Sanding the timber walls inside the house is a mandatory task before interior finishing. It is always carried out before varnishing or painting, since it allows you to level the walls from the inside and eliminate various defects that may form after shrinkage.

Sanding timber walls inside a house is usually required when restoring an old building - it allows you to update the color of the wood, which can then be coated with clear varnish and preserve its beautiful texture for a long time. Sanding a house made of timber is a painstaking and boring job, which is quite expensive for professionals.

Grinding tools and equipment:

- belt and vibration sanders;

- fine, medium and coarse sandpaper;

- construction trestles or stepladder;

- respirator;

- extension;

- protective glasses;

- wooden block;

- construction vacuum cleaner;

- construction stapler.

Sanding is a dusty job, so you need to immediately take care of respiratory protection. Today you can get a model of sanding equipment that is connected to a construction vacuum cleaner: this allows you to collect small particles of wood in a container and not breathe in wood dust.

Moreover, processing should be performed at medium and low speeds, which allows you to obtain a perfectly flat surface without deep cuts in the wood.

Why is sanding timber walls inside a house required?

Nowadays, in suburban construction, profiled timber with natural humidity is often used. The initially planed surface, being part of the log house, ceases to be so - a decrease in the humidity indicator affects it, and as a result, shrinkage of the house occurs, as well as a reduction in the quality of the surface of the timber. In other words, the walls are no longer as smooth as before. To a lesser extent, these processes are observed for log houses made of laminated laminated material. However, if you have planned a stylish design for a house made of laminated veneer lumber, then you simply cannot do without sanding the walls inside the house.

Sanding required:

- To reveal the wood texture. By “cutting off” the top of the timber, it is possible to focus attention on the natural beauty of this material.

- To make the walls smooth, you will not only make them beautiful, but you will also be able to reduce the cost of paint and varnish materials that are applied when painting.

- For better penetration of coatings into wood, thereby increasing the service life of the coating and providing the necessary level of protection for the walls.

Sanding the walls of a timber house from the inside: main stages

How to properly sand timber walls? This is a rather lengthy process that takes place in several stages:

- Rough surface treatment using sandpaper no. 40 grit. It allows you to remove all irregularities and prepare the surface of the walls for finer processing. During operation, you will often change the attachment on the machine, as it quickly becomes clogged with wood dust.

- Fine grinding allows you to obtain a smooth and pleasant-to-touch surface. As a result, the surface can be ready for further painting. For processing, another sandpaper No. 80-100 is used, the approximate speed of work is approximately 60 centimeters in 10 minutes.

Much directly depends on the level of skill of the builders: an experienced master can cope with such work several times faster than a beginner. If unprofessional self-processing occurs, scratches appear on the surface, and it may turn out to be uneven.

In some cases, additional polishing of timber walls is required. This is labor-intensive and meticulous work, which is used using sandpaper up to 180. This way, you will perfectly level the surface of the walls, making it as smooth as possible.

How to polish the walls of a house made of timber inside so that the wood looks truly beautiful? You need to choose a tool that fits well in your hand and provides high performance. Nozzles need to be changed or cleaned as often as possible, and difficult areas will need to be handled manually.

Knowing how to properly sand timber walls, you will save a significant amount on work. After processing is completed, they must be coated with antiseptics and painted, otherwise they will have to be sanded again. The wood may darken again, so it is important to provide final protection quickly.

Attention! Wood is a living material, and its processing will allow you to get a comfortable and beautiful home where it will be pleasant to stay. Skills in working with wood will allow you to achieve success, and the work will provide the desired result.

How much does it cost to polish timber walls inside a house?

Due to the complexity of the work, polishing by professionals is not cheap. In addition, it will take at least a week to sand the timber walls.

Wall processing should be done in several approaches. Internal grinding for one time costs from 300-350 rubles per m 2. The calculation is not difficult, for example, if the wall of a house is 3x4, then the entire total area is 12 m2. Sanding in one approach will cost 12 m 2 x 300 rubles - 3600 rubles. And this is just one wall. Therefore, if you have the skills, you can save money by doing the work slowly. In addition, you can work inside the house at any time of the day, regardless of the weather.

- From the original state of the timber wall. The most expensive service will be if the walls were previously varnished, since the process is more complicated.

- From the result you expect. The ideal surface here is difficult to achieve, and everything depends on changing the grain size of the abrasive and the number of “passes”. Moreover, the cost of services includes the cost of “consumables”.

- Depending on the height of the house and the need to install scaffolding.

- From the total area of the walls. Builders often offer discounts when sanding large log buildings.

- From the number of services. Complete home finishing services, such as sanding plus painting, will cost you much less than finishing work.

The most common mistakes when sanding timber walls inside a house

The main mistakes that a beginner often makes when doing the work on his own:

- Puts too much pressure on the machine, resulting in grooves left on the beam.

- The work is carried out at high speeds, which is why the grinding is uneven.

- Leave the walls uncovered for a long time after sanding, so they may darken and the work will have to start again.

Without sanding, the timber may look untidy even after painting is completed. Every owner loves his home and cares about it.

conclusions

On average, sanding walls made of timber, the area of which (external and internal) does not exceed 300 m2, takes 1-3 weeks. And the work will not be cheap, which means it makes sense to think about doing it on your own, having carefully studied our material.

How to properly sand timber inside a house, common mistakes, technology and approximate cost of work

Content:

The walls of a timber house need to be sanded before coating. Of course, you can make the interior decoration with gypsum plasterboard or other material, but this will cover up the wood texture, and the point in building with timber will be lost. This article will be of interest to those who do not know how to properly sand timber inside a house, and what tools are needed for this.

Processing of a log house from timber inside

To treat internal walls made of timber, grinding and coating with special compounds are used. The main thing is to achieve two goals: to protect the wood from rotting and to make the walls beautiful. Grinding is painstaking work that requires knowledge and quality tools.

What tool is needed for grinding

For grinding timber, stores offer a variety of tools. But not every tool is suitable for such delicate work. The main criteria when choosing are power and lightness.

Building a house from timber has a flat shape and a belt sander is suitable for sanding. For example, a Makita tool with a dust bag is convenient for interior work. But not all models of grinding machines have dust collection bags.

For processing Finnish timber with a rounded side, a belt sander is not convenient. In such cases, use a grinder with grinding attachments. The grinding attachment for such a tool is a disk with sandpaper attachments.

In the most inaccessible places, grinding is done using a chisel.

When choosing an angle grinder, you should hold it in your hands. The tool must be light, otherwise the labor-intensive DIY work will become even more complicated. The power for grinding timber is 850 W or higher.

Among the most well-proven ones, it is worth noting the grinders from foreign companies Makita, Bosch, DeWalt, as well as the domestic Interskol. These cost from 2,500 rubles.

By purchasing cheap Chinese tools, the buyer receives a kind of lottery ticket. It’s hard to say whether it will be a winner or not.

How much does it cost to sand walls?

Due to the complexity of the work, grinding is not a cheap pleasure for specialists. In addition, sanding timber walls takes time, at least a week.

The walls must be treated in several passes. One-time internal grinding costs from 250-350 rubles/m2.

It is not difficult to make a calculation, for example, if the wall of a house is 3X4, then the area will be 12 square. Sanding in one pass will cost 12x300=3600 rubles. And this is just one wall.

It is better to do this work with your own hands, slowly. Moreover, you can work inside the house in any weather and time of day.

Wall grinding technology

Building a house from laminated veneer lumber involves sanding immediately after assembly. If it is natural humidity, then you need to wait until shrinkage and drying are completed. Otherwise, the wood fibers will lift up and you won’t get a smooth surface.

To work with your own hands you will need the following tools:

- Nozzles with different coarse sandpaper.

- Tape train - machine or grinder.

The first time sanding is done with sandpaper No. 40. It will remove all the unevenness. In the future, No. 80-100 is taken to obtain a smooth surface (for example, domestically produced Fera paper).

Changing attachments occurs frequently, since when working with wood, the abrasive becomes heavily clogged with dust and resin. Experts recommend extending the life of sandpaper using a wire brush and alcohol. But after this the working ability of the nozzle decreases.

Do-it-yourself processing moves on average 60 cm in 5-10 minutes. The speed depends on the skill, the type of timber (building a house from profiled timber from coniferous trees takes longer due to the high resin content), and the power of the tools.

You can sand it the old-fashioned way using a block wrapped in sanding paper. But your hand will get tired quickly, and such grinding of a room of 15-20 m2 will take more than a month. This method is good to use when you need to sand small parts and areas where the tool cannot reach.

All work is carried out in a respirator, since there is a lot of wood dust, and it easily gets into the worker’s nasopharynx. You can use tools with special bag attachments, but these are more expensive.

After sanding, the timber walls must be treated with antiseptics and glazing compounds, or simply painted with varnish or paint. Coating is a simple job and you can do it yourself. You can find out more about how to do this here.

Mistakes you can make

The main mistakes that a beginner makes when doing the work with his own hands:

- It puts too much pressure on the machine, which leaves grooves on the beam.

- The work is carried out at high speeds, the grinding is uneven.

- If you leave the walls uncovered for a long time after sanding, they will darken and you will have to start the work all over again.

Without sanding, the timber looks untidy even after painting. And a real owner loves his home and takes care of it.

What does the tool kit consist of?

In fact, there are not so many of them, since convenient tools have been created and they are constantly used. Let's look at the most popular:

The easiest way to work is with a specialized angle grinder or the capabilities of a modern angle grinder, which has a set of suitable versions of attachments such as grinding rounds of various sizes.

High-quality grinding of timber with your own hands is carried out using grinders of various types, for which coarse abrasive attachments numbered 30-60 are used.

The fine grinding process is carried out with a variety of attachments with a small grain type. The angled version of the sanding machine shows the best performance during the process of processing the interior of walls based on planed logs.

It is convenient to work with profiled timber based on the capabilities of the belt model of the sanding machine. To do this, it has a rotating belt-type version of the abrasive surface. With its help, the process of getting rid of the old varnish coating is simplified.

An increased level of functionality is provided by the length of the blade. It is recommended to use a belt with a length of 610 mm, as it is considered the optimal version of the tool for sanding the largest surface areas of timber.

Almost all models are offered with a container for collecting and disposing of chips, dust and other residues, which helps save valuable minutes during the cleaning process.

The inside of timber premises can be sanded using a vibratory grinding machine model, which has a rectangular version of the working sole.

Such equipment is distinguished by its increased quality of grinding, and therefore is used for the final stage of working with the surface of the timber.

We are talking about fine and polishing processing. Based on a triangular shape, such a product helps to polish hard-to-reach places such as corners or grooves of a log house.

- Soil resistance - a practical guide on how to determine the main parameter (75 photos)

Insulation of facades - selection of materials and instructions for creating ventilated facades (85 photos)

Self-priming pump - 120 photos of the best models and their main characteristics

All about sanding timber

Sanding the walls inside a timber house is work carried out mainly on wooden surfaces. This allows you to give the finish a finished look, making the surface of the walls not just even, but smooth and shiny. Sanding the walls will not require any additional types of work - neither wallpaper nor wall panels will be needed.

What is it and what is it for?

Sanding the walls of a house from the inside allows you to implement several effective solutions.

Preparing walls for painting or varnishing. Before starting work, any material must be treated with an antiseptic and a non-flammable compound. Most antiseptic coatings are water-based, which makes the walls feel fluffy after the composition dries. Sanding erases this hairiness and allows you to smooth out the individual components from which these walls were built. Sometimes the difference between adjacent identical parts reaches 2 mm. A completely smoothed wall allows you to save on varnish or paint - this can significantly save money when covering a large area and using expensive, high-quality paint (or varnish).

- Sanding reveals the pattern of knots and growth rings that make up the wood. Over months and years of use, the wall covering becomes obsolete - sanding and coating are repeated if necessary. Sanding removes the old finish, exposing the wood grain. If the type of wood - initially, before the first treatment - is such that the layers of wood are beautifully and clearly visible, then it makes sense to varnish it rather than paint it.

Despite removing a small layer of wood with each session, sanding the walls extends the life of the building. The fact is that fresh wood, cleared of excess layers, absorbs paint and impregnation as well as possible.

The work is in demand in houses where people did not live all the time in winter - the premises were not always heated.

What is the best way to sand?

First of all, the speed and quality of the work done are important. If using only hand tools, the process can take up to several weeks. In this case, there is a risk of inhaling wood dust, or prematurely clogging your respirator with it, as well as damaging your glasses. Sandpaper alone is not enough here. The efficiency of work increases several times when, to achieve the best result, mechanical tools that operate “from an outlet” are used. Sandpaper is used only in those areas that the grinding wheel or brush cannot reach. There's no point in getting started if you don't have one of the power tools.

Grinding machine. It is suitable for sanding wheels with varying degrees of grit. It is advisable to use a device to which a vacuum cleaner is connected - it will reduce the concentration of wood dust around the master several times. An emery wheel of a certain grain size is selected based on the type of wood.

- Grinder with a set of grinding wheels (discs). Coarse and fine grinding is carried out using coarse and fine-grained discs, respectively.

The higher the level of instrumentation, the higher the quality of the achieved result.

Sandpaper is selected depending on the condition of the surface. The initial rough work is done with 40-60 grit sandpaper. Removing old paint and varnish - with a rating of 100-140. Hairiness is removed with a grain size of 160-220. The final “turning” of the wood is with a circle value of 90-120.

Be sure to stock up on a respirator and safety glasses. The eyes and lungs need to be protected first. You also need work gloves or mittens made of thick and rough material.

If a vacuum cleaner is not connected to the model of the grinder or machine, then make a separate mount that will bring the bell of the suction hose to the work site.

To access the top of the walls you will need a stepladder. To make your work more convenient, use an extension cord with at least two outlets. To access hard-to-reach places, use a chisel and a piece of foam rubber to remove the scraped material at the cut corners.

Technology

Processing the timber smoothly with your own hands is half the battle. Before starting work, decide which beam needs to be sanded - profiled or glued. For both types, the process differs as follows.

The corrugated timber is polished in two stages. The first stage is carried out using a rough wheel with a grit value of 40. The process is carried out during the construction of walls. The second stage is carried out only after the house has settled.

This is a natural process that cannot be ignored when performing finishing work.

Glued laminated timber is already pre-sanded - even before you order it for construction. It will give only slight shrinkage. Sanding with a suitable attachment can begin immediately after the house is built and allowed to settle for the required time. In this case, sanding the outside may not be necessary. The first stage is performed using the 80th circle. Be careful - measure the applied force: if you overdo it, the outer slats will be damaged.

The process of grinding a log frame using an angle grinder or a machine is carried out in two stages. The rough work is that at this stage all significant irregularities that catch the eye of an outside observer are removed. The surface of the walls is prepared for finer processing.

However, abrasive wheels become clogged quite quickly; therefore, a significant number of them will be required. It is difficult to soak them - the adhered wooden dust does not come off immediately, and it is difficult to clean it off. Sandpaper, in general, cannot be cleaned - it would simply soften and become unusable, since the abrasive particles would come off from its base.

Fine work can also be done manually. It is much easier to process a pre-ground surface than to perform the first, much rougher grinding step. Corner edges and edges are leveled by hand using a narrow chisel. The professionalism of the craftsman decides a lot here: not quite high-quality processing of the ends will leave irregularities that are easily visible to an outside observer.

If such an omission does occur, then the corners will need to be sanded to their normal appearance.

Post-processing

If the impregnation against fungus, mold and microbes is made not with water, but with an additive base obtained in production from petroleum products, then the hairiness will not manifest itself in any way when the composition dries. Most often, kerosene with non-flammable additives is used for impregnation (it itself is flammable). After applying and drying the impregnation, the wood must be coated with varnish or paint. Do not use oil paint - it begins to peel off after a few months.

Possible mistakes

If the master is a beginner, allowed to grind walls for the first time, then the work can be performed by him at the extremely fast speed of a power tool. This is not entirely correct, since this approach leads to the fact that the grooves formed during grinding are too deep.

Resin that is not removed from the wood slows down the process of sanding the wall. At this point it sticks to the abrasive wheel or disk, and the process of smoothing out irregularities with a grinder is significantly slowed down.

Defects that occur in the timber must be filled with glue. Most often, this happens when the timber has been overexposed in a warehouse and it has become warped, or the layers (boards) that form it are not glued (not glued together) thoroughly.

These defects can be corrected using a different (or the same) glue, and after drying the wood can be sanded.

You cannot sand the walls before the construction of the main structure is completed. A house that does not shrink will lead to the need for repeated sanding, which results in an absolutely unreasonable thinning of the load-bearing walls, although it is relatively small. Sanding is carried out before doors, windows and suspended ceilings are installed, as well as before the finished floor is erected. Over time, the wood hardens, making subsequent sanding much more difficult.

You should not try to speed up the work by using more powerful machines or an angle grinder. Even a physically developed specialist will get tired faster, which will affect the quality of the work - the surface being treated will be significantly damaged, and the result will be far from what was originally intended.

There is no need to grind the ends to perfection. In timber, they are usually hidden when connecting at the corners, be it a “claw” connection or in any other groove. The same applies to logs - a log house, even built from hand-cut logs, is processed at the ends with a wheel with a grain size of at least 60. Then it is coated with impregnation in this place and painted or varnished. Subsequently, the end of the beam can be brought to an ideal state by finer grinding. The savings in impregnation and varnish here are insignificant, and the ends themselves do not attract the attention of an outside observer as much as the main surfaces of the timber or log.

Wood polishing

Polishing wood products and wooden structures is used to prevent natural hairiness and cracking of wood; polishing enhances the attractiveness of the texture and protects it from external factors. Most often, polishing timber is used for finishing furniture and interior decoration. Technology includes:

- Grinding for polishing. Preparing wood for polishing differs from ordinary sanding; at the final stage of processing, fine-grained abrasive material No. P150-P180 is used.

- Primer. The operation is performed to seal microcracks and pores, strengthen the top layer and prevent the formation of fibers. Transparent impregnating mixtures are used for priming; the layer is applied with a swab or a flute brush. The most common compositions have a casein-rosin and nitrocellulose base. All types of primer are applied in 2-3 layers, the next layer is applied after 1-2 hours.

- Polishing. Apply 2-3 layers of colorless rosin varnish to the primer; after drying, each layer of varnish is treated with sandpaper with a fraction of up to 100 microns (grade P400-P600 according to GOST).

- Polishing. The surface is treated with a felt wheel using polishing or wax paste until a uniform shiny surface is obtained.