And so, important criteria when choosing a stove for a bath:

Furnace power.

The most important thing you need to consider when choosing a stove for a sauna is that the power should be optimal. You can buy a stove made of steel, cast iron, wood, gas, electric, cheap or expensive, any criterion can apply, except for one thing - it must correspond in power to your steam room. The issue of heater power can be neglected only in one case: if you have built a hammam, where there is no sauna stove in the usual sense. Incorrectly chosen power will lead to unpleasant consequences, which we will consider further.

Excess power.

It happens that people want their steam room to warm up faster. In this case, they purchase a stove with a large power reserve; yes, the steam room will warm up faster in this case, but this is only at the beginning. Then the oven will work at the minimum of its capabilities. This is a welcome sign that your steam room will be filled with hot air, but the stones will remain cold, on which it is useless to pour water - there will be no steam from them, and if there is, it will be in clouds and white, like when a kettle is boiling, and not that light and transparent as you expected.

Lack of power.

A completely different extreme is to purchase a stove with minimal power just to save money. Of course, the stove will be able to heat the steam room to the required temperature. But it will have to work to the limit, in this mode the stove will not serve you for long and will entail replacing the stove, spending time and money on dismantling and installation. Ultimately, running your oven to its limits is simply not safe.

Calculation of the optimal power of a sauna stove.

Now the next question: what is the optimal power? All manufacturers indicate for each model not only the power in kilowatts, but also the recommended steam room volume. To make the calculations easier, we will not delve into the details, and we will take the cubic capacity of the steam room as a basis. It's much easier to count this way.

Determining the cubic capacity of the steam room

If you built your bathhouse according to a project, then you will not have problems determining its volume - it is in the project. If there is no project, then you will have to work with a tape measure. We measure the steam room, write down the results, multiply them together and you get the volume of your steam room. It would seem that the volume has been obtained, and you need to select a sauna stove for it, but no, there are a number of nuances that need to be taken into account. If you have uninsulated areas in your steam room, for example, brickwork, stone cladding, windows... then you need to calculate the area of these areas. Then multiply by 1.2 and add to the cubic capacity obtained earlier. If you have a glass door installed in your steam room, then add another 1.5 m3 to the resulting volume. If your steam room is made without interior decoration, then multiply the volume by 1.5.

Example: let's say we have a steam room with dimensions of 2.5x2x1.5 meters. Then, under ideal conditions, its volume will be: 2.5 * 2 * 1.5, which is equal to 7.5 m3. If a glass door is installed in the steam room, then add another 1.5 m3 to the resulting volume and get 16.5 m3. If there is no finishing in the steam room, we multiply the resulting volume by 1.5, resulting in 22.5 m3 - the cubic capacity of the steam room without finishing, therefore, you need to select the stove for this volume. If you do not want to do the calculations yourself, then you can always contact our specialists.

Now you know the volume for which the sauna stove you need should be designed. And don't forget about the stones. To fully utilize the heater’s thermal power, you should load it with as many stones as the manufacturer recommends. This parameter is also indicated for each model.

Furnace material.

It is no secret that the quality of the stove material is an indicator of how long the stove will serve you. Nowadays, the leading positions on the market are occupied by stoves made of steel and cast iron. But which material is better? Steel or cast iron? Let's figure it out.

The main differences between cast iron stoves and steel ones:

Chemical composition of the metal.

The main elements in cast iron and steel are iron and carbon, only their ratio differs. The carbon content in steel up to 2% makes it strong, it can be subjected to any processing, welded, forged, and the presence of more than 2% carbon in cast iron makes it more heat-resistant than steel, but due to porosity, it is more brittle. The main disadvantage of cast iron is its non-repairability, that is, if ice water gets on a heated cast-iron stove, the stove may crack and it will not be possible to weld it, only cast it again.

2. Service life and susceptibility to corrosion.

The second most important indicator when choosing a furnace is its service life. It depends not only on whether you choose a stove made of cast iron or steel, but also on how thick the walls of the stove will be and under what conditions it will be used.

A stove cast from cast iron can withstand high temperatures much better than steel. The walls of a cast iron stove are several times thicker than the walls of a steel stove, so the fireboxes do not deform when heated. Steel stoves cannot boast of this. Another weak point of a steel furnace will be the welds; overheating of the furnace can lead to them, and along with them the entire furnace. Therefore, if you choose a steel stove for a sauna, it is important to ensure that your stove is made of high-quality heat-resistant steel. Heat-resistant steel is of high quality if its chromium content is more than 16%; it is the presence of this metal that gives heat resistance.

Do not forget that cast iron is much less susceptible to corrosion than steel. Of course, both metals rust. But cast iron can withstand both humidity and temperature changes much longer.

Therefore, defects on a steel furnace can appear after two years of operation under extreme loads. Manufacturers of cast iron stoves assure that such stoves will last for 20 years without demolition. With the caveat that, subject to proper operation.

Thus, we can conclude that the choice of stove material is entirely up to you; each material has its own advantages and disadvantages. But with proper use, a stove made of any material will serve you for many years.

As you already understand, choosing a stove for a bath is not at all an easy question; it is worth taking into account all the nuances. Here's another one: should you choose an open or closed stove? What are their differences? Or maybe it would be better to buy a grid oven? Now we will tell you everything.

Let's start with sauna stoves with an open heater.

An open heater is simply a pile of stones stacked above the firebox and not covered with anything on top. The advantage of such a heater is that it quickly warms up the steam room, but also cools down quickly, so you will have to fire the stove constantly while you are in the steam room.

Features of stoves with open heaters.

An open heater can be used if several people will be steaming on the same day. The main feature of such a stove is that it heats up quickly (much faster than a closed one), but also cools down quickly. When creating an open heater, stones are piled on a firebox. Their temperature is 250 degrees. In order for the open heater to be hot all the time, you need to cover the stones with a galvanized tin lid after the steam has been released.

The heating temperature of stones in a stove with an open heater is 250 degrees, but if you decide to purchase such a stove, then you will also need certain stones: smooth, round, ranging in size from 50 to 150 mm.

Stoves with a closed heater.

The main difference between a stove with a closed heater and an open one is the size. A stove with a closed heater is quite large, because it is made of brick, although there are also models with an iron closed heater. Heating of such a stove occurs slowly, but there is a plus - a lot of heat is generated, which remains for a long time after firing.

The design of a stove with a closed heater is a metal form, which is lined with fireclay bricks on the inside. The stove has two compartments: a combustion chamber and a container in which the stones are placed, the grate enclosing the combustion chamber and the container is made of refractory brick, metal is not suitable for these purposes - it simply will not withstand such loads. The flame from the lower floor goes through the sauna stones and heats them, heating the entire steam room - this is the basic principle of operation of a closed heater. While the sauna is heating, the lid of the container with stones should be closed so that all the smoke goes into the chimney. The stones are first covered with soot, which then burns. Therefore, the furnace must be heated until the stones heat up to 400 degrees.

Mesh ovens.

In addition to stoves with an open or closed heater, there are also mesh stoves. Mesh stoves are a special category, although they belong to stoves with an open heater. The difference is that the stones surround the firebox on all sides. What does this give? First of all, this design feature allows you to keep hard infrared radiation from a conventional steel stove. But the heating rate of the steam room with such a stove increases significantly, and the weight of the mesh stove is much greater than other stoves, which requires a solid foundation for it.

How many stones to load and how much to warm them up.

Kamenka is what distinguishes a real Russian bathhouse.

Water, falling on heated stones, turns into steam, which, as you know, does not ache the bones, but on the contrary is beneficial for the body. So how many stones must there be to get enough steam?

There is one bath rule: there must be a lot of stones. Before buying a stove for a bath, you should calculate the volume of the heater, for this there is a simple formula: 3-6 kg of stones per 1 m3 of room volume, but it is worth considering that the stones must be literally red-hot, the more such areas there are, the better.

Pay attention to what stones you are going to use. They must have high heat capacity and be non-toxic. Yes, there are unscrupulous manufacturers who sell ordinary stones under the guise of stones for baths; such stones can not only “explode”, but also release harmful substances. The Dachny Expert recommends you basalt, soapstone, peridoite, porphyrite.

Volume and dimensions of the firebox.

The volume of the firebox, into which the fuel is quite logically placed, determines how much heat will be released during the combustion process. And, the larger the volume of the firebox, the greater the productivity of the furnace itself. As for the firebox parameters, they determine only the functional features of your stove. If the stove has a deep firebox, then you won’t have to waste energy cutting wood into smaller pieces.

It is also worth noting that it is preferable for the cross-section of the firebox to be narrowed downwards - this way the ash and firewood themselves will “fall” onto the grate.

Grate and material for it.

Many people believe that the grate is needed to remove ash, but this is not entirely true. In fact, the grate is needed to supply air to the lower layers of fuel.

It is no secret that the temperature of heated coals can be higher than the temperature of the flame during combustion. Therefore, the best option for the material from which the grate is made would be cast iron, since even heat-resistant steel cannot withstand such temperatures.

Ash pit.

The last part of the furnace, but far from the last in importance. The ash pan is the place under the grate where ash accumulates. Therefore, it is most convenient if the ash pan is made in the form of a retractable drawer - this will facilitate the process of removing ash, will allow you not to get dirty and you will not have to remove the ash with a brush.

External view of the stove.

Modern sauna stoves not only perform their direct duties, but also decorate your sauna. On the market you can find models lined with polymer or organosilicate coatings. But it is generally accepted that the most profitable, aesthetically pleasing and safest decor for a stove will be textured stainless steel. It should be noted that, despite the low cost, stainless steel shows excellent characteristics.

An important element of the stove decor is the presence of glass in the firebox door. Through this glass you can watch the wood burning and enjoy the sight of the flames.

Sauna stoves by type of fuel.

Sauna stoves are divided by type of fuel:

- Wood-burning.

- Gas.

- Electrical.

- Combined.

Let's figure out what the features, pros and cons of each type of stove are.

Wood stoves.

Wood has been used as fuel since time immemorial, and this type of fuel is also considered the most reliable, because you can find wood almost everywhere, this determines the popularity of these stoves.

A wood stove will be the ideal choice for you if you have no gas supply or power outages on your property.

Pros of wood stoves:

- There will be no problems with the choice. Nowadays there is a wide range of wood-burning stoves on the market, from economy to premium class.

- Economical. You will save on electricity and gas consumption.

- No problems with fuel. Now firewood is sold even in ordinary supermarkets, not to mention the fact that delivery is carried out even to the most remote areas.

- Atmosphericity. Of course, only a wood-burning one will give a real woody aroma and fill your bathhouse with it.

It would seem that a wood-burning stove is the ideal option, but there are also disadvantages:

- Chimney cleaning. Even if you install the most modern and technologically advanced chimney, it will still require cleaning.

- >In addition to the chimney, sooner or later you will need to clean the ash drawer.

- The firewood is burning out. Yes, if you don’t add new wood to the firebox, you will freeze.

- Efficiency Unfortunately, firewood has lower efficiency than other types of fuel.

Door type

Pay attention to this factor, because... Ignoring this little thing can ruin a lot. In fact, everything is simple here...

With glass : with fireplace door or with small glass

The fireplace door, as you already understand, is the first sign of fireplace stoves. A small glass is intended only to control the amount of firewood in the firebox without opening the door.

Without glass - just “solid” stoves with a metal or cast iron door.

Gas sauna stoves.

In addition to the fact that the fuel for such a stove is gas, the stove also has a thermostat and a gas fuse. This is how it differs from a wood stove.

Just like with wood stoves, there are pros and cons.

Advantages of gas stoves:

- Compactness. Due to their design, gas stoves do not have a firebox or ash pan, which means that such a stove can easily be installed even in a small steam room.

- Fast warm-up with low gas consumption.

- Maintained temperature. Thanks to the thermostat, you can set a temperature that is comfortable for you and it will be maintained.

But gas stoves also have disadvantages, albeit a few:

- Availability of gasification. Without gas, the oven will not work, so you need either a gas pipeline or a gas cylinder.

- When using a cylinder, you will need to take care of the fire safety of not only the bathhouse and the place where the cylinders are stored.

When buying a gas stove, it is important to follow the rules:

- Be sure to check all documents: technical passport, documents confirming compliance with gas equipment standards. If there are no documents, then only you yourself are responsible for the reliability of the stove.

- Under no circumstances buy gas stoves from private owners; buy them only in large stores that specialize in selling bath equipment.

- Gas stoves have a service life, after which it is dangerous to use the stove.

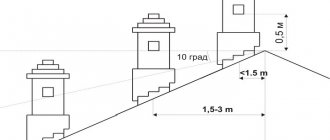

Chimney outlet location

This parameter is determined by the room where the stove will be installed and your wishes.

With top outlet . Stoves in which the pipe is located at the top, respectively, the chimney will go up.

The pipe is a stove element, approximately 5 cm high, on which the chimney is installed.

Please note that with this arrangement, the chimney can be led into the wall, but you will first need to install about 0.5 m of vertical pipe, and then make a 90-degree outlet from it into the wall.

With rear exit . Ovens with a pipe located at the rear. This is a convenient option if you immediately want to move the chimney into the wall.

Electric sauna stoves

If you are ready to sacrifice the traditional components of bath procedures: the smell of burning wood, natural warmth, but at the same time make a choice in the direction of functionality and comfort, then your choice is an electric sauna stove. From this point of view, an electric stove for a bath is an ideal option: it does not require periodic addition of firewood, does not smoke, and due to its lightness and small size, it can fit into the interior of a steam room of even the smallest area.

Let's move straight to the advantages of electric ovens:

- Compactness. Yes, electric sauna stoves are the smallest of all listed. This is due to the lack of a firebox.

- Durability and reliability.

- The steam room heats up quickly and evenly.

- No chimney installation required.

- compactness;

- reliability and durability;

- quick heating of the steam room in a short time;

- uniform heating;

- affordable price;

- no need to build and clean a chimney, install gas pipes, etc.

- high level of fire safety.

Of course, electric sauna stoves also have disadvantages:

The main disadvantage, which outweighs all the advantages, is the type of fuel itself. If there are power outages in your area, then you will not be able to take a steam bath in your bathhouse. Of course, you can buy a generator, but this is not very convenient.

The second disadvantage is that the heating elements, which ensure heating of the stones in the furnace, are not the most reliable part of it. The heating element may overheat or water may get on it, which will cause it, and therefore the entire stove, to fail.

Presence or absence of a long-burning system

So that you don’t get confused, let’s immediately define this: there are long-burning stoves (we wrote about them above), and there are those with a long-burning function.

Almost every modern stove has a long-burning function. Its principle is that we cover the supply of combustion air to the maximum (we remember from school that the combustion catalyst is oxygen - the less of it, the longer and less intense the combustion). Considering that the task of the stove is to generate heat, all modern stoves are equipped with this function (only “stove stoves” lack it).

Steam source

Yes, no matter how strange it may sound, but stoves have different sources of steam, so stoves are divided into two types: conventional and with a separate steam generator. A steam generator is used when the oven does not produce enough dry steam, which is considered traditional bath steam, or you want to obtain finely dispersed steam.

Features of room heating

Your sauna stove can be cold or hot. It is generally accepted that cold ones are those whose walls do not heat up above 45°C, and hot ones are ovens with a wall heating temperature above 100°C. This is an important parameter, because the heat of your bathhouse is transferred through the walls.

Regardless of the type of fuel or material of your stove, all stoves are divided into two main classes - “cold” and “hot”. Let's find out the advantages and disadvantages of "cold" and "hot" ovens.

Let's start with "hot" ovens. Stoves of this type are installed in bath buildings that do not have any other heating option. In a hot stove, the outer surface heats up to 100o C. The main disadvantage is the risk of overheating the room. You can quickly change the temperature in the steam room only with the help of ventilation.

In a “cold” stove, the outer lining does not heat up to significant temperatures, so in winter such a design cannot sufficiently warm up the steam room. This is a model for baths that are heated in some other way.

The outer surfaces of a “cold” furnace are heated to a temperature of 40 - 50 C, which is the lower limit for producing steam. Any “cold” stove warms up the room for a very long time; the air is heated due to the fact that the stove “takes” cold air from the floor of the room, passes it through itself and comes out already warm.

Mistakes you shouldn't make.

- Haste, as you know, is good only for catching fleas. But when choosing a sauna stove, there is no need to rush. Select several models, and from them already one.

- It often happens that consultants do not talk about the stove, but advertise it. It may be that a criterion that the seller did not mention is important to you.

- Do not neglect consulting a specialist.

- If you require specialist advice, please contact us by phone... or in any of our stores. Our specialists will answer all your questions.

- It is necessary to decide on the type of fuel used. This is important because it is the type of fuel that determines the power of the stove, and stoves with different types of fuel require different conditions and additional design elements.

Frequently asked questions

Selecting and operating metal furnaces is a complex undertaking. Inexperienced people have a lot of similar questions. Let's answer the most common ones:

Which type of fuel is more economical?

It is generally accepted that maximum savings can be achieved with gas furnaces. Other designs are more consumable, especially electric ovens.

How to avoid burns from the stove body in a small room?

There are different types of fencing. Some owners line the stove with bricks, increasing the uniformity of heating and the cooling time. The choice of the appropriate option depends on the personal preferences of the owner.

What size heater is needed so that you can safely provide steam in a Russian bath?

The larger the heater, the better. It is believed that in a Russian bath you can use stoves with a heater of 100 kg or more. However, here it is necessary to take into account the design features and shape of the stove itself.

Which stoves are more convenient, with a long or short fuel tunnel?

It is generally accepted that furnaces with a long tunnel are most convenient. However, in practice, everything depends on the type of fuel and the specifics of its use.

Is it necessary to install protective fire barriers for a metal stove?

It all depends on the design features. Some models can be installed without fire protection elements. However, in this matter you should consult with a software inspector, who will inspect the stove and give a competent recommendation.

It all depends on the design features. Some models can be installed without fire protection elements. However, in this matter you should consult with a software inspector, who will inspect the stove and give a competent recommendation.

Rubble concrete foundation

Foundation for the stove.

The formwork must be installed on the base. A layer of large stones is placed in it. The resulting cavities are filled with crushed stone. Then the stone and crushed stone are filled with cement-sand mortar.

Mix the solution as follows: 1 part cement M 400-500 to 3 parts sand. The solution should be thick, like sour cream. They need to pour the first row of stone and take a break for a day, then lay the next row, which is then poured with mortar.

If the volume is small, then you can make a certain amount of concrete and complete the work in one day. After about a week, the foundation is ready for laying.

Ventilation in the steam room of the bath: diagram

Ventilation in the steam room of a bathhouse - system diagram. It consists of two openings: one of which is supply, and the other is exhaust (several exits can be made). When choosing the size of the exhaust opening, you must follow several rules:

- the largest should be at the maximum distance from the stove (so that the heat does not flow outward);

- the rest can be placed around the perimeter of the ceiling;

- The hole size is calculated based on 24 square meters. cm for each cubic meter of room. Most often, the diameter does not exceed 30 cm, but the number is 2 or more.

The traction force is determined by the height difference between the supply and exhaust openings.

IMPORTANT! Do not place the holes exactly opposite each other, this will inevitably cause drafts.

We recommend using dampers or plugs for manual adjustment.

Ventilation in a Russian steam bath: diagram

Ventilation in the Russian steam bath is ensured by a scheme in which there are vents with adjustable plugs, taking into account the above rules. Or by using burst ventilation, which we will discuss later.

Bathhouse: steam room ventilation (if the stove is in the dressing room or rest room)

For a bathhouse or steam room ventilation, where the stove is located in a room other than the steam room, you will most likely have to think about forced ventilation, which will ensure the flow moves in the right direction.

As shown in the diagram:

Bathhouse: ventilation of the steam room (if the stove is in the steam room or the steam room is connected to the washing room)

It is ensured by heating cold air coming from outside from the furnace and repelling it from the heat source, and returning it back after hitting the walls. Air movement can be stimulated by the use of additional fans.

For bathhouses and steam room ventilation, organizing the drying of the bathhouse is especially important, since water in the washing room can have a truly destructive effect on finishing materials and the floor. In addition to the main one, enhanced floor ventilation is required: by installing an exhaust opening between the finished and subfloor, the installation can be accompanied by the installation of a fan.

REFERENCE. Make sure that no water comes into contact with the fan to avoid the risk of a short circuit.

Rating of the TOP 12 best stoves for saunas with a tank in 2022

| Place | Name | Price |

| TOP 4 best sauna stoves with a tank by price/quality for 2022 | ||

| 1 | Harvia M3 SL | Find out the price |

| 2 | TMF Biryusa 2013 Carbon anthracite | Find out the price |

| 3 | Harvia 20SL | Find out the price |

| 4 | Teplodar Sahara 10 LB/LBU | Find out the price |

| TOP 4 best stoves for a wood-burning sauna with a tank | ||

| 1 | Vesuvius Rusich Aqua 22 (DT-4) with 61l tank | Find out the price |

| 2 | Birch Favorite 24 | Find out the price |

| 3 | Vesuvius Rusich Aqua 16 (DT-4) with 49l tank | Find out the price |

| 4 | TMF Skoroparka 2022 Inox Vitra B | Find out the price |

| TOP 4 best inexpensive sauna stoves with a tank | ||

| 1 | Konvetika Konvetika 12B | Find out the price |

| 2 | TMF Tunguska 2022 Inox DN TO anthracite | Find out the price |

| 3 | Varvara Palenica Wall mounted shortened firebox | Find out the price |

| 4 | TMF Biryusa 2013 Inox Vitra ZK | Find out the price |

Finishing the room

Treat surfaces with linseed oil, special antiseptics and wax.

Sanded lumber is used in finishing the floors, walls, and in the construction of benches, so after installation it is enough to go over it with sandpaper. This is how to remove raised fibers that appeared during the process of working with wood. For finishing, compositions are used to add attractiveness and emphasize design elements.

Purchase natural-based products for treating wooden floors, walls, and benches. Painting is carried out with the steam room not working so that the products dry under natural conditions. Synthetic dyes and varnishes are not used for the steam room, as they release harmful substances.

Treat surfaces with linseed oil, special antiseptics and wax. Sometimes oil and wax are combined for better impregnation. Wait at least 12 hours between applying several layers to allow the product to absorb and dry.