The modern variety of metal stoves for baths provides a wide choice. You can purchase and install a ready-made stove, or you can create it yourself. But, in any case, you can’t do without installing a heat shield. Moreover, there are often several screens:

- One covers the body of the metal furnace itself. This shield softens the thermal radiation from the case. Most often it is made of brick.

- There are screens to protect combustible walls. They are made of any fireproof materials and cover adjacent walls.

- And another type is non-flammable material on the floor. This can be either a brick “podium” for a metal stove, or tiles, porcelain tiles, artificial or natural stone, laid on a layer of glue, or a sheet of metal, under which a layer of heat insulation is placed.

There are several reasons for making a protective screen for the furnace. And they all deserve attention:

- During combustion, a metal stove becomes quite hot, and therefore there is a high risk of getting burned. It is clear that the constructed protective wall will be a salvation. In addition, if you do not protect the walls of flammable materials near the stove, you can also expect a fire.

- In some situations, when a metal stove is made by hand, the brick screen around the stove also serves a decorative function.

- A metal stove of any type does not allow you to regulate the heat flow of air in the bathhouse. A well-made brick screen can correct this and create controlled heat transfer.

Everyone knows about the dangers of hard infrared radiation, and such heat comes from a red-hot iron stove that there is no need to lean against it - even from a distance you can get burned. A brick screen for a metal stove will protect the inhabitants of the steam room and allow you to feel the complete comfort of bath procedures.

Any metal stove is a source of danger

Relevance of the design

The screen for the stove in the bathhouse is installed primarily to protect people and adjacent structures from dangerous heating. For vacationers there is a risk of getting a skin burn, for wooden products there is a risk of charring or fire, plastic under the influence of high temperature in most cases is at least deformed. Only materials similar in nature to stone may be damaged to a minor extent.

Enclosing structures can be located not only on walls. Often the screen in a bathhouse is built around the stove. This solution allows you to solve 2 problems at once regarding human protection: from direct contact and IR (infrared radiation). The second problem is especially common in cases with metal units without additional cladding or cladding. Exposure to rays for many people results in a general deterioration in well-being.

An example of a wooden fence around a heating unit Source zoon.ru

In addition to the main functions, shielding structures around the furnace perform 2 particularly important tasks. The first of them is convection. Cold air from below is drawn into the gap between the stove and heats up. That is, the room does not cool down so quickly due to the design features of the bath floor. The second task is heat accumulation. This is especially true for brickwork. When the room is ventilated, the fence gives off heat, which contributes to faster drying of the materials. In conclusion, we cannot fail to mention the decorative side. As a rule, designs are created to be visually attractive.

Acceptable reasons for refusing screens

However, there are exceptions that allow you to abandon enclosing structures. The most common of them are a brick-lined stove, with decorative finishing or simply with a plastered surface. A similar solution is metal equipment with cladding, for example, red brick. An effective option is to decorate the heating system with natural stone, which has low thermal conductivity.

Option for lining a sauna stove with natural stone Source pechi-troyka.ru

Also, the absence of protective screens for sauna stoves can be justified by technically acceptable standards (for example, according to SNiP 41-01 of 2003). They refer to the minimum distance between the heating device and the nearest walls. For example, between the walls of a half-brick firebox and the frame, the lower limit is 320 mm. Before a lined metal stove (for example, fireclay), the space must be at least 700 mm, and without lining the value increases to 1 meter. Compliance with such requirements is relevant for large premises, but not for most private buildings. Therefore, it is easier to reduce these distances by means of protective screens and structures with cladding materials.

When is this required?

There are times when there is no need to protect walls. If the stove is located at a safe distance from the wall from a fire safety point of view, the installation of protective screens and other measures can be neglected. The distance from the walls that is required to reduce the heat from the source varies:

- A stove laid in a quarter of a brick should be located no closer than 35-40 cm from the wall;

- A metal stove without lining should be placed a meter away and no closer;

- A metal one with a lined furnace can be installed 70-75cm from the wall.

However, not every steam room has the opportunity to fulfill these requirements, due to the small area. The layout of steam rooms with an area of 6-8 m² can hardly accommodate the necessary set of items for the steaming procedure. Therefore, the need to insulate walls with special sheathing is relevant.

Technical description

Both the lining of combustible structures and the enclosures of the furnace in the steam room are subject to the same requirements. These include resistance to heat and changes in humidity, safety in relation to human health, and durability. Let’s take a closer look at the optimal solutions that allow for long-term protection of bathhouses and people.

Types of fencing

The most common solution for a protective screen for a bathhouse is to cover the nearest walls, floor and ceiling with non-combustible materials.

An example of protection around a masonry stove Source stroyexpress.ru

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

These include stone and basalt wool, asbestos cardboard. Stainless steel sheets are often complemented. It is worth noting that galvanized analogues are not recommended. When heated strongly, they release substances that can harm human health.

Other solutions are also popular. Let's consider their features depending on the key material:

- Brick.

This can historically be considered the most common and optimal solution for enclosing a furnace in a bathhouse. It would be correct to use a solid fireclay sample due to its ability to withstand high temperatures for a long time (over +1000 degrees Celsius). Red brick is also acceptable, but it will last less due to its “weakness” to relatively sharp temperature changes.

The half-brick screen (120 mm) is assembled at least 200 mm higher than the heating equipment. Holes are formed in the lower part for air convection. A technical gap of 50-150 mm is maintained next to the stove and the wooden wall. That is, from the heating unit to the log house (lining), the standard is reduced to 220-420 mm.

Brick screen around the stove with holes for air convection Source tipdoma.com

- Tree.

Traditional bathhouse material is actively used to create decorative fences around the stove. In this case, a distance from the firebox of at least 500 mm is maintained. Before assembling structures, blanks must be treated with fire-retardant impregnations.

If during use the wood appears black on the surface of the wood, then the fence must be moved to a greater distance.

- Metal.

Heat-reflecting screens for the furnace are made from stainless steel or cast iron. The metal sheet itself quickly heats up and gives off heat, which cannot be considered a protective measure against burns or fires. Therefore, the sheets are sewn onto a frame 100 mm wide. The empty space is filled with expanded clay, broken bricks, and crushed stone.

Additionally, a basalt sheet must be secured behind the metal for fire safety. A distance of at least 120 mm is allowed between such a screen and the stove.

A steel screen for a metal sauna stove can be used as a protective casing if installed at a distance of 10-50 mm).

Metal casing option Source kladempech.ru

Such a “shell” can reduce the temperature of the unit from +400 to +80-+100 degrees Celsius. Then, technically, the standard distance from a stove without lining to wooden structures from 1 meter can be reduced with a shield to 510-550 mm.

Optimal solutions for cladding combustible structures

The choice of means for protecting walls in the field of furnace equipment is limited by the requirements for flammability and thermal insulation properties. In order for a log frame or wood trim to maintain its properties in aggressive conditions, it is important to provide insulation that does not burn and has low thermal conductivity. Let's look at the features of optimal bath solutions.

In the first case, the walls are first covered with heat insulation, then with steel sheets (stainless steel). It is recommended to choose the latter with the most polished surface. In the mirror state, it is believed that it better reflects thermal energy, which means it heats up less. As a result, infrared radiation returns inside the room, warming the room again. In this case, the rays, due to the double covering of the distance between the stove and the shield, lose their power and become safe for humans.

Option of a metal shield made of stainless steel Source dom56.ru

Covering bathhouse walls with non-combustible insulating materials

To prevent the walls from overheating, you can use materials with increased thermal insulation properties and inertness to high temperatures. Two types of materials are used:

- reflective;

- fireproof with lining.

The first type includes materials for wall cladding, consisting of thermal insulation with fire-resistant properties and a metal covering in the form of a sheet.

Insulating walls with reflective sheathing

A protective cake with reflective materials is done this way. First, the thermal insulation is attached using ceramic bushings directly to the wooden walls, then it is sewn up with a stainless steel sheet.

Advice! It is better not to use galvanized metal, since heating may release heavy metals harmful to the human body.

Stainless steel with a polished surface reflects the heat flow inside the steam room, reducing heat loss. In this case, reflected heat is more useful than direct heat. For thermal insulation use:

- basalt cardboard or cotton wool, the only material with increased hygroscopicity, non-flammable, environmentally friendly;

- asbestos cardboard, which reliably protects against flames and has a long service life;

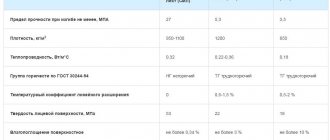

- mineralite, an artificial material made specifically for these purposes.

Protective sheathing requires ventilation gaps of 2 cm from the wall to the insulation, 2 cm from the insulation to the steel sheet. If it is necessary to install the stove as close to the wall as possible, make a double skin of non-combustible insulation, use ceramic bushings to maintain gaps of 2-3 cm and sew them up with a steel sheet.

Insulation with cladding

Measures to protect walls with cladding are necessary in order to preserve the interior decoration of the room. They are more expensive, but no one has canceled the aesthetic advantages of the bathhouse. It is based on tile cladding, which is laid on fire-resistant cladding made of gypsum plasterboard, non-deformable gypsum-based cardboard with fiberglass, mineralite, non-flammable cement-fiber material, moisture-resistant and resistant to biochemical influences, LSU, fiberglass material bound with magnesium additives, resistant to high temperatures, high humidity. Heat-resistant glue is used for installation.

Advice! Use heat-resistant reinforced Terracotta glue, made from fireclay dust bound with kaolin additives, intended for tiling stoves, fireplaces, and all heated surfaces.

The recommended facing materials are quite varied, the best of them are:

- terracotta tiles, they are made from specially fired clay, which gives increased heat resistance and durability;

- clinker, denser clay tiles with a surface of various colors, similar to facing bricks;

- tiles, also made from clay, having an original embossed surface;

- porcelain stoneware made from a mixture of clays, kaolins, quartz sand, feldspars by high-temperature firing under a pressure of 400-500 kg/cm², with imitation of stone, wood, durable artificial material;

- soap chloride, a rock mineral consisting of talc, magnesite and chlorite, an environmentally friendly natural material that does not absorb moisture at all, has an attractive appearance, does not crumble, and is not afraid of high temperatures.

Advice! Use soap chloride to finish the steam room, this mineral has a healing effect on the human body, regulates blood pressure, stimulates cerebral circulation, expels viruses and microbes due to the release of vitamin D when heated.

All of the listed tiles are an element of protection that forms a cake, the basis of which is a fire-resistant material. Just like a screen, sheet material is installed on ceramic bushings with a gap of 2-3 cm from the wall. The minimum distance to the heat source from the tile should be 20cm.

Protection with cladding decorates the room, creates a positive mood, and helps to increase the efficiency of procedures. And most importantly, properly installed insulation prevents wooden walls from overheating and catching fire. Have a nice steam!

Video description

This video discusses one of the simplest options for covering walls next to the stove in a bathhouse using mineralite sheets:

Floor protection

A floor screen for a stove in a bathhouse must, among other things, have high compressive strength. This is justified by the large total weight of the heating system, to which the smoke exhaust network, heater and, most often, a container with hot water are attached. Therefore, stands and platforms are assembled here from materials such as brick, natural or artificial stone, steel or cast iron. The latter are easier to find ready-made on trading platforms.

Option for a floor screen for a sauna stove Source prom.st

Common mistakes and recommendations

Choosing insufficiently high-quality materials and trying to save on resources are the most common causes of breakdowns, malfunctions and fires. In relation to the bathhouse, such negligence is unacceptable. An equally popular mistake is failure to maintain the distance even between the brick screen for the sauna stove and the walls. There are enough ways to competently minimize indents and gaps for this, so you should not allow errors in centimeters. Also, you should not make the decorative side the dominant criterion for choosing protective equipment and structures.

Conclusion

In the proposed video in this article you will receive detailed information on this topic. Moreover, based on it, we can come to the conclusion that the screen is a necessary element of the bathhouse, especially if it uses metal stoves. The choice of a specific type of such design depends only on the personal preferences of the master, although experts say that it is the combined products that give the maximum result (see also the article “Camping sauna - how to steam in the field”).

9ban.ru

Video description

This video examines the causes of a fire in a bathhouse with improperly organized fireclay brick protection:

Among the recommendations on choosing quality materials, craftsmen note several points that will allow you to create durable and visually attractive protection. For example, stainless steel quickly becomes unattractive from frequent heating. This can be avoided by using heat-resistant metal paint or by regularly wiping the surface with household cleaners. It is recommended to cover the log house and ceilings with two layers of heat insulation for the purpose of reinsurance.

Briefly about the main thing

Screens around the sauna stove are installed to protect people from burns and flammable structures from damage and ignition.

Enclosing structures are assembled from wood with fire-retardant impregnation, stone/brick or metal on top of a frame with expanded clay inside.

For wall cladding, a pie is often constructed from a double layer of thermal insulation and polished stainless steel sheets; less often, panels are assembled for the facing material.

Only non-flammable materials with a low thermal conductivity coefficient can act as thermal insulators: stone or basalt wool, asbestos or basalt cardboard, mineralite.

Heat-resistant or clinker tiles are used to cover the walls next to the stove.

It is important at the stage of design, construction and repair to maintain the standard distance between the stove and flammable materials, depending on the type of protective design solution and composition.

The floor is protected from overheating by rigid platforms made of natural or artificial stone, brick or cast iron.

Ratings 0