High temperature, high humidity and other unfavorable factors impose quite stringent requirements on the finishing materials used in the bathhouse, and the culture of installation work must be at its best. Finishing a sauna is a serious stage that requires a sober mind, skillful hands and a clear, pragmatic view of, in general, difficult things. Dedicated to all finishers and sympathizers.

Preparatory work

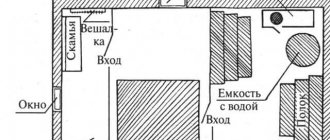

First of all, you need to make a drawing.

The presence of a stable air flow in the building makes it possible to choose sizes based on the number of users and convenience. The possible ceiling height is 1.9–2.1 m. It is not worth increasing this parameter, since this may lead to the appearance of a “tube effect”, due to which the draft increases and a draft occurs.

In addition, the air near the ceiling will be the hottest. Accordingly, the top shelf should be made at the maximum height. It is important to consider that a person should be able to sit on it without resting his head on the ceiling. The recommended distance is 1–1.1 m from it.

An example of the arrangement of shelves and their sizes

The optimal height of the shelf is 45 cm. If necessary, this parameter can be increased to 65 cm, but sitting on it may be uncomfortable. To fix this, you can build a step 25 cm high.

The rest bench is two-tiered. The height of the lower tier is 65 cm, the upper tier is 105 cm. The width is 35 and 70 cm, respectively.

The sauna is smaller in size when compared to a Russian bath. For 3–4 people, a room of 3.3 m2 will be enough. Shelves should be installed in several tiers along the walls. In this case, the optimal ceiling height is 2.1 m.

The length of the wall opposite the entrance is at least 2 m. In order for air to circulate properly, it is important to maintain the ratio of sizes. If you make the correct calculation, then the shelves with places to lie on the upper tier will be exposed to heat from the stove with acceptable air humidity.

What should be the size of the steam room: drawing up a project

The main task of the steam room is to provide high temperature. In the sauna it reaches 120°C. This requires a certain heating of the stove. However, heat in the steam room will be transferred not only from it, but also from the surrounding air. Therefore, metal stoves should not be placed near benches. They can heat up the air very much, which can cause burns.

It is also not recommended to equip a small steam room with a metal stove, as this is dangerous to health. The height of the ceilings in this case will not solve the problem.

The size of the steam room depends on the number of people who will be in it at the same time

Arranging a large steam room with an electric stove is a pointless undertaking, since the cost of electricity will not be offset by any comfort.

To determine the optimal dimensions of a room, the following fact must be taken into account: heat radiation in space diverges in such a way that its intensity after some time weakens in inverse proportion to a value equal to the square of the distance from the radiation device. Accordingly, people located at a distance of 3 m from the stove will be able to receive 4 times less heat than if they were located 1.5 m from the device. Create

This is the disadvantage of large pairs - in order for the heat to reach in the required quantity, you will need to make the stove too hot or overheat the air. Both options are harmful to human health. It is also worth remembering that the main condition for the high effectiveness of sauna procedures is heat dissipation. The larger the steam room, the better this process will occur. Therefore, it is recommended to choose average values for the area of a given room.

To optimize the space inside the steam room, you will need to minimize the base of the floor and increase the area of the shelves. It is recommended to muffle the space under them to reduce the heated volume. This will make it possible to save fuel for the stove and reduce the heating time of the sauna.

It is recommended to indicate all the necessary dimensions in a special technological map.

Video: is it possible to build a sauna/bathhouse in the basement of a private house

Selecting sauna materials

At the next stage, you need to decide on the materials that will be used in the process of building the sauna. You need to prepare:

- brick;

- pipes;

- bars;

- logs;

- sand;

- cement;

- roofing materials;

- glass;

- clay;

- gravel;

- materials for thermal insulation.

You can build a sauna, which consists of one steam room with a locker room, or you can also prepare a washing room or a relaxation room. The set of materials will depend on this.

It is recommended to allocate space for a corridor, which will help prevent the penetration of cooled air into the room.

The main material for a sauna is wood. These can be logs, bars or boards. You can choose exclusively wood to construct the entire structure, including the base and roof. Another option is to use blocks or bricks.

A log house is most often used to build a bathhouse.

Additionally, the log house can be lined with brick to make it more wear-resistant and reduce thermal conductivity.

Log house - logs with specially prepared grooves. They are used for longitudinal fixation. For perpendicular fastening, notches are required. A row of stacked logs is called a crown. To connect the crowns, grooves (have a round shape) and notches are required. If everything is done correctly, then heat loss is excluded.

Pine and larch logs are suitable for making the structure. There should be no resin bags on their inner parts. It is recommended to make the lower crown from dried oak logs, the upper ones from linden or white spruce logs. The fibers should be straight, not slanted.

Straight fiber arrangement is optimal for a bath

If the fibers are inclined, this can lead to significant deformation of the material during the drying process. As a result, the wood will crack.

Nowadays you can find saunas made of glued profiled timber.

The construction made of laminated veneer lumber is quite reliable

Advantages of this design:

- strength of the building;

- flat and smooth surface of the walls, therefore there is no need for finishing;

- there is no shrinkage or deformation;

- resistance to rotting and damage by fungi and pests.

The disadvantage is the high cost.

It is easy to make a sauna from such material with your own hands, and the process takes much less time. There is no heat loss at all, since there are no gaps or cracks.

Which stove to choose for a wooden bath

The heater is most often used because it can provide optimal temperature and humidity.

The optimal stove for a sauna is a heater

You need to select the location of the brick structure at the stage of drawing up the drawing. In the process of laying the base, it is necessary to prepare a place for the stove. A special place for storing firewood is also recommended.

To lay the structure you will need M75 or M150 brick. The amount of material depends on the thermal conductivity of the walls and the layout of the room. On average, 35–40 bricks are needed per 1 m2. For good draft, the chimney device must protrude at least 0.5 m above the roof.

Continuous and temporary stoves are installed in saunas. The latter are able to heat the building more efficiently by heating the stones with hot smoke. The steam from a continuous stove is cleaner.

Heaters can be with a closed or open backfill chamber. This affects the quality of the steam.

An oven with a closed chamber is more environmentally friendly

Next you need to decide on the material for the roof. This is influenced by the climate of the area.

Video: how to equip an infrared sauna in an apartment

Key Features

Plan the interior of the steam room, dressing room and relaxation room together - it’s more convenient, cheaper and easier to immediately calculate the consumption of materials. Refuse parts with sharp edges, avoid unnecessary corners and any other potentially traumatic parts.

Choose light-colored wall paneling because it will make a small, windowless room appear larger and lighter. Instead of decor, use bath accessories and accessories. Completely avoid metal, plastic, artificial materials, slippery surfaces, and bulky furniture.

Calculation of materials for construction

First of all, you need to calculate how many floor boards you will need. For example, we will consider a sauna measuring 3.7x3.7 m. To make a floor in it, you need to prepare 25 edged boards.

Edged floor board

Standard board dimensions: thickness - 0.5 cm, width - 15 cm, length - 4 m.

Accordingly, 4 x 0.15 x 0.5 = 0.03 m3 is the area of one board.

The width and length of the sauna is 3.7 m, so to install the floor base you need to prepare 25 boards 15 cm wide and 4 m long.

To arrange the ceiling in a bathhouse, you need 38 boards of lining. The calculation of the material is carried out according to the same scheme. The thickness of one board is 22 mm, width is 100 mm.

In order to complete the interior decoration of the sauna and install partitions, you need 22 mm thick lining.

Linden lining is suitable for a sauna

If you plan to place the boards vertically, you will need approximately 153 boards.

Standard dimensions: board length - 3 m, width - 10 cm, thickness - 2.2 cm.

3 x 0.01 x 0.22 = 0.01 m3 - the area of one board.

Next, you need to calculate the area of the sauna walls: the height is 2.1 m, and the length, taking into account the partitions, is 24 m.

2.1 x 24 = 51 m2

There are 3 boards in 1 m2, respectively 51 x 3 = 153 lining boards for the entire steam room.

To perform a vapor barrier on the internal walls and ceiling structure, you can use various materials, among which vapor barrier film and breathable membrane are especially popular.

Vapor barrier of sauna walls is required

For a sauna 3.7x3.7 m, 44 m2 of material will be required.

To perform the calculation, you need to find out the total area of the ceiling structure and walls, while partitions do not need to be taken into account.

Length excluding partitions - 14.1 m.

2.1x14.1=29.61 m2.

The width and length of the ceiling structure is 3.7 m. The area is 3.7x3.7 = 13.69 m2.

Next you need to add up the area of the walls and ceiling: 29.61 + 13.69 = 43.3 m2.

At the next stage, the materials for the foundation are calculated. The need for cement, crushed stone, sand and other elements will depend on what type of base is planned to be made.

If it is a columnar foundation, then you will need asbestos-cement pipes with a diameter of 20 cm and a length of 150 cm. In the center of each of them, 2 reinforcement rods with a diameter of 5 mm must be mounted.

Selecting a location

Where to place - the answer to this question depends on several factors in the layout of the sauna in the house:

- If there is a gym or a massage area, it should be located next to these rooms.

- Friendly meetings imply space and a place to relax.

- If the purpose is to relax after a working day or relieve stress, it is usually located near the bedroom.

- If there is free space, a swimming pool is installed, and outside there is a vat or barrel of water for swimming.

Required Tools

To build a sauna base you need:

- carpentry tools;

- shovel;

- trowel;

- building level;

- concrete mixer;

- wheelbarrow;

- container for preparing the solution.

Concrete mixer can be rented

If you plan to mix the solution manually, then you need to prepare a metal container and a shovel. You can also use a construction mixer or a high-power electric drill with a special attachment.

A mixer attachment will help facilitate the process of mixing cement.

During the construction of a sauna, it is impossible to do without an electric jigsaw. With this tool you can make cuts and cuts to achieve unusual shapes in different materials.

An electric jigsaw will allow you to cut a piece of wood into any shape.

Bathhouse and sauna interior – photo

Don't be limited by stereotypes and don't be afraid to experiment. A bathhouse can also be special and individual, fully reflecting your tastes and preferences. Share photos and ideas!

Did you like the post? Subscribe to our channel in Yandex.Zen, it really helps us in our development!

Useful tips for finishing

The final stage of construction is interior and exterior finishing. It is best to cover a sauna with clapboard. Each type of wood has its own advantages:

- Linden has an excellent appearance and smells good.

- Alder is able to retain heat well, while it practically does not heat up. It has a varied palette of colors and beautiful designs.

- Pine is used most often. Releases healthy elements when heated.

The disadvantage of alder is that it is soft. Consequently, impacts may cause dents.

The finishing instructions are as follows:

- The first step is to cut the material to the height of the room.

- Next, do the sheathing. You need to start from the corner, and then move smoothly around the perimeter.

- It is recommended to cover them with wax or natural oils intended for saunas.

Treating the lining with wax will extend the life of the sauna

There is no need to treat the lining inside the sauna.

Types of structures

The types of designs widely available on the market will help you make a choice and answer the question - how to make a sauna in your home. Among the offers:

- infrared steam room;

- transformable model, very convenient, but characterized by high cost;

- frame - ready-made projects of any size. A set of elements allows you to assemble it in a limited space and in mobile conditions. Any corner where there is a tiled floor will do.

Samples can be presented without external cladding, with finishing, or a mixed type.

Using lighting systems in sauna design

The use of lighting systems in the sauna instead of the usual lamps and lamps is becoming more popular. Various forms of lighting fixtures and their shades are selected. The glass door does not allow enough light into the sauna. Because it’s quite dark there and it’s wise to add lighting.

Ready-made sauna cabins come in a variety of sizes, made from different types of wood, but mainly from aspen, linden and some softwoods.

Lighting should be installed in wooden platforms, seating areas and loungers. LEDs make it possible to add light to individual structural elements and surfaces. You can choose lighting of various shades, depending on your imagination and the size of the room.

Doors to mini-saunas are usually completely glass or have a wooden frame with large transparent glass.

See alsoInterior design for a hairdressing salon, photo.

Proper surface preparation

Before starting facing work, it is necessary to prepare the walls, ceiling and floor. They should be isolated from moisture, insulated and ensured strength. Wooden surfaces of the ceiling and walls must be treated with a penetrating primer with an antiseptic additive. If the walls of the sauna are made of bricks or blocks, they are leveled using cement plaster.

Particular attention is paid to the floor surface, since in order to cover it with tiles or to create a plank flooring, it is necessary to have the most even rough base with a small slope angle.

Which trees are better as raw materials?

Pay attention to the following factors:

- Linden - this wood is the most popular. Durable texture with a pleasant creamy shade. A rich aroma is added to the performance properties.

- Karelian birch is rarely used as a raw material in Finnish traditional buildings. It is not practical in terms of interior decoration due to deformation (warping). It is difficult to make adjustments to products.

- Black alder is the main quality: slow heating, due to this the shelves do not warm up for a long time. Used for the manufacture of related bath accessories. Alder has an amazing property - in extreme heat it turns red, when the temperature drops - the color changes to natural. It has a unique and unobtrusive aroma. Resistant to deformation and rotting, has high consumer properties.

- Cedar - opinions on its use vary. Skeptics deny the use of conifers. It contains phytoncides that create a healing aroma in the steam room. The species is praised for its high strength and resistance to fungal diseases of wood. The finished version made of cedar looks decent. The persistence of the aroma decreases after a year of use. Expensive pleasure.

- Spruce is what is most often preferred for manufacturing. Not used for finishing ceilings. Disadvantage: resin is released during sheathing. To decorate the walls, they use “simmered” wood, aged for many years, from which the resin no longer leaks.

- Pine is the least popular. Loses in terms of performance. Used only for the construction of rough structures.

- Abashi is the African equivalent of domestic oak. Lightweight and durable. Contacting open areas of the body does not cause discomfort and minimally overheats. It has no knots and does not emit resins. A significant disadvantage is the high cost.

- Aspen is a soft lining, easy to process. Over time it darkens and is susceptible to fungus.

- Larch is a tree with a reddish texture, its properties are not inferior to oak. It has been in use for decades, which compensates for its high cost.

All wood is protected from moisture. Paintwork is not a substitute for prevention. The difference is in the frequency of treatment - for moisture-resistant ones, this procedure is carried out less frequently.

The choice of method is a responsible decision that will determine the practicality and durability of use in the future.

Bake

But the most important element for creating a sauna remains the stove. She may be:

- Conventional wood-burning, independent of external energy sources. This design ensures fairly cheap operation of the sauna, the creation of soft steam, and a high heating rate. But when installing a wood-burning stove, additional costs will be required to install a chimney, and the risk of fire increases several times.

- New-fashioned electric, capable of heating to a fixed temperature and providing maximum fire safety.

A sauna with an infrared stove still causes quite a lot of controversy. It is believed that such heating does not provide a therapeutic effect other than intense sweating.