Rolled and sheet penofol is attached to the concrete base only with special glue. The adhesive composition allows you to preserve and even strengthen the technical qualities of the heat-insulating material. For high-quality fastening of polyethylene foam, targeted adhesive preparations are used, the technological development of which is aimed at the rapid connection of concrete with penofol.

How to glue isolon to concrete

how to glue isolon to concrete

During the construction of industrial facilities and residential buildings, modern building materials are used to meet the most important construction requirements for heat and sound insulation. Such material, for example, is isolon or polyethylene foam. The use of isolon allows you to reduce construction time and heating costs due to the excellent thermal insulation properties of this material.

Isolon has the following characteristics: 1. Low density (light weight) and at the same time good thermal insulation properties. A 10 mm layer of isolon can replace a 15 mm layer of mineral wool, 45 mm of wood or 150 mm of brickwork.

This reduces the weight of structures and helps save usable space. 2. Freons and other substances hazardous to humans are not used in the production of isolon. Izolon is non-toxic, does not affect the skin, and does not emit harmful substances when used. Has a hygiene certificate, 3.

Isolon is a chemically inert material and is not affected by organic solvents. It is possible to combine isolon with other building materials (concrete, gypsum, cement, lime, wood). It practically does not absorb water and steam, therefore it is resistant to rotting, mold and aging, 4.

Excellent shock-absorbing properties due to flexibility and uniform cellular structure. Isolon is used as a backing for carpet, laminate, linoleum or parquet. Izolon sheets are used to separate adjacent walls if the adjacent walls are subject to movement or vibration, 5. The operating temperature range is from -60`C to +75`C, and if there are no mechanical loads, the operating temperature increases to +100`C. With the exception of special isolons with fire-extinguishing additives, isolon is a flammable material. But at temperatures less than +140`С no harmful substances are released from isolon, 6.

Izolon is produced in different thicknesses and densities (with different foaming coefficients) and is supplied in the form of rolls, sheets, tape or blocks. This significantly increases the possibilities of using isolon in construction. Depending on the production method, isolon is divided into cross-linked (when molecules are cross-linked, a network molecular model is formed) and non-cross-linked (there are no chemical bonds between the polymer molecules).

Cross-linked isolon, compared to non-cross-linked, has improved characteristics: 1. Heat resistance increases (the operating temperature range increases by 20°C), 2. The service life of the material increases due to increased resistance to ultraviolet radiation and organic solvents: oil, gasoline, diesel fuel, Izolon can be used 1.

For sound, steam, heat, waterproofing of walls, foundations, floors and roofs for country houses, cottages, garages, 2. As a sealant under slate, ribbed metal roofs or tiles, 3. Isolon tapes with an adhesive layer seal the joints of windows and doors, connections between the frame and glass, protect from dust, moisture and noise, 4. Izolon strips can be used to insulate cold and hot heating pipes, as well as ventilation pipes, 5. Izolon with a polymer metallized film is used as a heat-reflecting screen to protect against heat loss through the areas behind the radiators of the walls. When using a combined material, a double effect is obtained.

Due to the metallized film, up to 90% of the heat emitted by radiators or other heating devices is reflected back into the room. The big advantage of isolon is its ease of use and installation. It is easy to cut and can be glued to the surface with adhesives (pre-glued surfaces should be cleaned of dust and degreased).

To attach to a smooth surface, use screws, slats, and furniture staplers. To connect the joints, use a hair dryer. Isolon is attached to curved surfaces with double-sided mounting tape.

Thus, when using this modern material, it is possible to significantly reduce construction time and heating costs.

How to glue isolon to concrete

How to glue Izolon to concrete How to glue Izolon to concrete During the construction of industrial facilities and residential buildings to ensure the most important construction requirements for heat and sound insulation

Pros and cons of ceiling insulation

Penofol for the ceiling today is a popular material due to its versatility and easy installation. In addition, construction specialists value insulation for such parameters as:

- Light in weight, due to which the material can be worked at any height.

- To fix the insulation, no additional tools or devices are required.

- The coating is not water- and vapor-proof, incl. not subject to destruction under the influence of precipitation.

- Insulation performs several functions. So, when fixed to the ceiling, it prevents heat loss and absorbs noise. Often used in conjunction with other insulators to improve properties.

- When exposed to high temperatures, it does not release toxins. In the manufacturing process of the material, polyethylene and foil are used, which are used in food production.

- After installing the heat insulator, there is no significant loss of usable area. Because of this, penofol is often used in rooms with low ceilings.

- The material is sold in roll form, which makes the work much easier.

- The products are not subject to combustion and are resistant to rodents.

As for the disadvantages of insulation, there are few of them. Thus, these include a high price tag and the need to use secondary heat insulators to improve the properties of the first one. The second significant disadvantage is the use of glue as fasteners, which also increases the financial burden. Third, the material has a soft structure, so it cannot be used in rooms where you plan to wallpaper the ceiling.

How to install reflective insulation on a concrete wall?

How or with what can you glue or attach reflective insulation to a concrete wall? Thank you.

Reflective insulation is a lightweight, flexible material with a thickness of 4 mm or more, consisting of a layer of foamed polyethylene or other polymer, onto which aluminum foil or metallized film is glued on one or both sides. Foil thermal insulation materials are environmentally friendly, easy to install and significantly reduce heat loss.

Manufacturers of reflective thermal insulation materials do not exclude the use of glue during installation, but draw the attention of consumers that they are most effective if an air gap of 2 to 10 mm is created between the wall and the thermal insulation. After all, air is also an additional thermal insulation layer.

The method of attaching reflective thermal insulation to a concrete wall is chosen depending on the type of material, capabilities, location and purpose of the room. In any case, the concrete wall must first be cleaned of dust and treated with an antiseptic, and if necessary, dried.

When insulating balconies or cold external walls with a heat insulator with a double-sided foil coating, it is necessary to fill the concrete with a lathing of slats 5-7 mm thick and attach the material to it with a construction stapler or glue. A second sheathing is mounted on top of the heat-insulating material for laying the finishing coating with an air gap.

When installing on reflective materials with a one-sided metallized coating, it is allowed to use rubber or acrylic-based adhesives such as 88-NP, Akrol Contact, Neoprene 2136 spray, etc. You can also use polyurethane foam, sealing sealant and double-sided reinforced construction tape . The adhesive composition is applied to the back side of the material pointwise in a checkerboard pattern or randomly, so that after gluing to the concrete the required air gap of about 2 mm remains.

Reflective insulation sheets are glued end to end and the seams must be taped with aluminum tape. As a result, an airtight coating is created on the wall, reminiscent of a thermos, onto which a lath of slats can be mounted to secure the finishing material.

Finally, if increasing the thickness of the walls is undesirable or impossible, self-adhesive foil thermal insulation material can be used for insulation. To install it, you only need to prepare the concrete surface and remove the protective film from the underside of the canvas, and after gluing, seal the joints with foil tape. But when fastened to the sheathing, the efficiency of self-adhesive metallized insulation is higher.

How to install reflective insulation on a concrete wall?

Tips on the method of fastening reflective thermal insulation to a concrete wall, depending on the type of material, purpose and capabilities of the room

How to insulate a ceiling?

Experts recommend penofol as an ideal thermal insulator for the ceiling. This opinion is due to its low weight and small thickness, as well as the minimal amount of effort that will be required to be applied by the person carrying out the installation.

To successfully carry out the work, the contractor, in addition to penofol, will need wooden slats, hardware, tools and facing material.

- Thermal insulation of the ceiling is carried out in two steps. First, using wooden slats, the initial layer is attached to the surface. For this, the thinnest type of penofol is usually chosen. When fixing the first layer, the slats are laid in the longitudinal direction, and when attaching the next layer, in the transverse direction.

- Insulating materials are covered with cladding made of foam plastic or other lightweight materials.

What kind of glue to glue foamed polyethylene with?

When choosing insulation, a special place is occupied by foamed polyethylene - a material with sound, heat and vapor barrier properties. Depending on the manufacturer, it can be penofol, isolon or polyfoam. The construction market offers different types: with one-sided or double-sided foil, as well as with a self-adhesive plane. The material on which the insulation is attached also varies. Based on all the parameters, you need to be able to choose the appropriate adhesive for polyethylene foam.

How to choose glue

There is a fairly wide range of different adhesives for sale for working with polyethylene foam. And it is advisable to make the choice using the following criteria.

- The temperature range must match this characteristic of the insulation.

- Adhesive properties must be extremely high.

- If you plan to use glue for interior decoration, it must be certified and non-toxic.

- If adhesive is selected for exterior finishing, it must be resistant to a variety of weather conditions and temperature changes.

- If you intend to finish the sauna and bathhouse, then the glue will need to be mixed with water-repellent agents.

Water-based adhesive is absolutely not suitable for working with isolon, because it does not allow the adhesive to penetrate into all the pores of the insulation. Consequently, the level of adhesion will be insufficient.

Secret. How to glue foil insulation to a wall.

Kind. Somehow I encountered a problem with gluing foil insulation to the wall. There is a lot of information on this matter on the Internet. But I didn’t try what kind of glue I used, and in the end it didn’t work out. Everything was falling off. And the secret is simple. The insulation is covered with a thin polyethylene film, to which the glue does not stick (to a smooth surface, there is nothing for it to catch on). The manufacturer did not take this into account, or did not want to. It is enough to make the glue application areas rough, that is, sand them with sandpaper. You can use any glue, as well as polyurethane foam. And you won’t need a stapler, nails, dowels, or military-strategic toxic liquids - as mentioned in many construction forums. Good luck everyone, keep at it.

Minor observation. But many do not see the little things. Hence the big problems.

It is enough to make the glue application areas rough, that is, sand them with sandpaper.

And most importantly, why waste money on this and other materials and glue something that will not bring any effect.

jekasus wrote: And most importantly, why waste money on this and other materials and glue something that will not bring any effect.

I’ll support it. Apparently TS just has free material and needs to kill time.

jekasus wrote: And most importantly, why waste money on this and other materials and glue something that will not bring any effect.

Yes, I agree with you. But this effect does not consist in preserving heat; there is enough of it; water heating comes from the house. If you look more closely at the last photo - this is an extension to the future greenhouse on the north side, of course there will not be enough light for the plants. Reflective paint is not available. So the foil serves to reflect it. Even with artificial lighting, when entering a room at night it is impossible to look; the eyes are hurt by the bright, dazzling, iridescent light. (Checked, a few electric lamps are enough) This is a plus for energy saving. In general, the issue was not considered regarding the construction of greenhouses and where and why to glue foil insulation. The meaning is how to glue it!

How to attach isolon to the wall

Kind. Somehow I ran into a problem **gluing** foil insulation to the wall. There is a lot of information on this subject on the **Internet**. But how and with what kind of glue I haven’t tried - in... - photo - Mastergrad Forum

Foil insulation for walls and floors

Foil insulation has relatively recently appeared on the construction market, but is rapidly gaining popularity for various reasons. Next, we will consider the types of this material, the advantages in comparison with traditional insulation and how to use it correctly.

What is rolled foil insulation

This is a combined material for insulating walls, floors and ceilings, consisting of several layers:

- Insulation made from familiar materials.

- A layer of foil.

The material is rolled, therefore it has a relatively small sheet thickness. How does heat retention occur?

- A thin working layer delays the penetration of cold air from outside,

- The foil reflects heated air into the room.

Varieties

Roll insulation materials are classified according to the main material:

- Foamed polyethylene with foil that can be attached on one or both sides.

- Folgoizol is created on the basis of bitumen/rubber, mineral fillers and antiseptic.

- Mineral wool rolls with one-sided foil surface.

- Basalt lamella insulation,

- Expanded polystyrene boards with one aluminum surface.

Each of the presented materials is intended for use in certain conditions.

Application

Penefol (closed cell polyethylene foam) is versatile in use. They insulate walls and floors in residential premises.

Types of material

Let's look at what types of insulation are called:

- With foamed polyethylene, it looks like a roll of self-adhesive material, similar to film with foil. Scope of application in various equipment, lining of pipes, shafts, roofs, since it has a high temperature range from -160 to +160 degrees, it is fire resistant.

- Mineral wool with foil coating can have the form of a plate or cylinder. It also has a high degree of fire resistance.

- Expanded polystyrene, coated with foil on both sides. It also has a wide temperature range, the diameter can be 5mm, 10mm, 15mm.

- Basalt, just like the materials described above, is made on the basis of foil material, however, thanks to its unique technology, it can withstand temperature fluctuations from -200 +600 degrees, and is resistant to aggressive chemical environments.

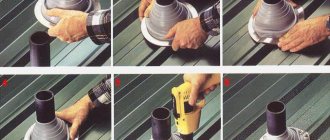

How to put insulation on pipes

As a rule, such material has the form of a pipe “cocoon” made of mineral wool (withstands high temperatures) or polystyrene foam (moisture resistant). And how to insulate them, the question disappears in itself, since they have the appearance of a “cocoon”, which is put on top and fixed. There are main ones for chimneys of various diameters and temperature conditions.

However, if you decide to purchase sheet insulation, you may be faced with the question of how to glue it to metal? Aluminum tape will come to your aid, which is wound onto the insulation over the pipe. And, as in the options described above, you need to wear it with the shiny side facing you.

Is it possible to insulate the walls from the outside?

To insulate the walls from the outside, perforated foil insulation is used. This is a material that, among other things, has soundproofing qualities, can protect your home from moisture and wind, and also does not prevent moisture from leaving the room. This option is ideal for those who do not have the opportunity to perform such work indoors. However, such activities can only be carried out in the warm season and in dry weather.

To do this you will have to do the following:

- If you had any covering on the wall, you need to get rid of it. Then treat the surface with an antiseptic solution. It is better to do this in hot weather so that everything dries well; treat the lower part of the building especially carefully. Within two days the surface will dry completely.

- Next, build a frame from timber, secure it with self-tapping screws. Lay Penafol, then leave an air tunnel, glue the joints, then install the outer frame.

In conclusion, we suggest watching a video about the installation of Penofol thermal insulation:

Advantages and disadvantages of the method

Insulation with foil has a number of features and a minimum of negative aspects. Advantages:

- Foil reflects heat. Thus, the heat remains in the house, on the other hand, it does not allow heat to enter the house in the summer.

- Increased wear resistance.

- Partially applicable as a waterproofing material.

- Easy installation, light weight, simple dismantling.

- The insulation does not allow cold wind to pass through. Maximum insulates from external influences. Resistant to deformation due to sudden temperature changes.

- Keeps out noise from the street.

- Does not rot or mold.

- This material is thinner than others, but is 20-30% more effective.

- The insulation does not emit substances harmful to health and prevents the smallest irritants and allergens from getting inside.

- There is no rigidity, so the top cannot be covered with plaster or wallpaper.

- Special adhesives are required for fixation.

- Sometimes insulation with foil is not enough to insulate a room.

Despite the disadvantages, foil material is widely used for various purposes.

Bonding with epoxy glue

This is the most accessible method, if we talk specifically about gluing and not welding. Before gluing polyethylene, you need to prepare the surfaces.

Epoxy glue packaging

Epoxy glue is not a glue for gluing polyethylene, but, nevertheless, phenol-formaldehyde resin has very decent adhesion to the surface of polyethylene. In this case, you need to act like this:

- Roughen the surfaces with emery cloth, then degrease and dry.

- Treat both surfaces with a 15-25% solution of chromic anhydride or 20-30% potassium dichromate. (Caution, caustic substances and dangerous carcinogens!) You can take another strong oxidizing agent: a strong solution of potassium permanganate. It is not much less effective, but is much safer. After treatment, dry the surfaces again.

- Prepare epoxy glue according to instructions.

- Apply a thin layer of glue to both surfaces and join.

- Maintain at a temperature of +30...+45°C for several hours, but it is better to keep for a day until ready.

Where is the foil insulation method used?

Foil insulation reflects infrared rays, which are essentially thermal rays. But there is no need to use the material everywhere. In some places it will not work properly.

It is mainly installed near thermal energy sources:

- heating devices - batteries, air heaters. The insulation is mounted on the wall with foil in the room;

- boiler, fireplace stove.

It is also used when installing “warm floors”. The reflective layer will direct the heat in the desired direction.

Small spaces where every centimeter plays a role. Here, thin insulation would be appropriate on the walls and ceiling.

In the attic. Here the insulation is installed on the roof. Apply 2 layers to combat heat and cold.

In baths and saunas. The heating of the room is not constant; foil material is suitable for such purposes.

Garages, hangars, outbuildings - an installed radiator or potbelly stove.

They also insulate heating pipes, air ducts, wells and wells.

Foil insulation design

Thermal insulation with foil is produced in:

They differ in size, thickness and the foil-covered base layer used.

Base layer types:

- polyethylene foam;

- basalt wool;

- expanded polystyrene.

The foil is glued to the base layer or applied by spraying.

Some have layers of foil on both sides. Or with a layer of applied glue - self-adhesive, which allows for easy installation. Self-adhesive is used in corners and on uneven surfaces. The joints of the insulation are taped with foil tape.

When purchasing insulation with a reflector, you need to pay attention to:

- base layer;

- foil thickness;

- taped with a reflector on one side or both.

The thickness of the insulation itself depends on the base material used.

How to glue correctly: advice from professionals

Before starting work, you need to prepare tools and materials: the foam boards themselves, a primer for coating the concrete surface, a brush or roller, a degreaser, a spray bottle. It is also advisable to take care of personal protective equipment.

Glue application methods:

- Stripes

– four L-shaped stripes are applied to the sheet in the corners and two long ones in the center, giving an average level of fixation.

- Spot

– dense drops are applied in increments of 30 centimeters, the fixation is of the least quality.

- Solid

– the adhesive composition is evenly applied over the entire area of the sheet, retreating 3-4 centimeters from the edge, this way it is possible to achieve the highest quality connection.

What you need to remember when gluing penofol to concrete:

- It is advisable to do the work together.

- You need to study the instructions in advance, calculate the glue consumption, and purchase the optimal volume.

- For beginners, aerosol glue is best.

- Concrete must first be treated with a primer, which will protect against fungus and increase adhesion.

- If possible and funds allow, it is better to apply the glue in a continuous layer with a maximum thickness of 2-3 millimeters.

- The sheets are leveled immediately after they come into contact with the work surface.

Types of foil penofol

There are 3 types of penofol with foil on sale. Each is marked with Latin letters, which indicate the packaging.

Folgoizolon for external and internal work

TYPE A – heat insulator made of polymer, foil layer on one side. Produced in different thicknesses. Suitable for complex insulation of buildings inside. Glass wool is used together with this insulation. They also produce foil insulation with perforation. It is installed in log houses to allow the wood to “breathe.”

TYPE B – foil is located on both sides. This is maximum protection against heat loss. Penofol type “B” is used for thermal insulation of the attic, supporting structure, basement, and floor. As well as insulation of the pipeline and heating system.

TYPE C - on one side there is foil, on the other there is a thin layer of glue protected by film. Self-adhesive penofol is easy to install without spending a lot of time. For installation, cut into pieces of the required length and glue to the prepared surface.

TYPE R – a complete comparison to type “A”, but with a pattern on the foil. Used as decor for indoor walls. And also with multi-layer insulation, creating an air gap.

TYPE ALP – high degree of reflection. This insulation is used in agriculture, for example, to insulate incubators or buildings for calves.

How to insulate a room from the inside yourself?

Insulating the inside of the house

Before you begin, you need to insulate the electrical wires and stock up on the necessary materials. In addition to penofol, the contractor will need assembly glue or a stapler, as well as wooden sheathing and hardware.

- The first task facing the performer of this work is the construction of a wooden frame to which the penofol will be attached. The air layer separating the insulation from the wall should not be less than 20 millimeters.

- Then, armed with glue or a stapler, you need to fix the insulation on the wooden frame, not forgetting that foil is an excellent conductor of electric current. All electrical wiring must be insulated in advance.

- Now it's time to install the second wooden frame. Finishing materials will be applied to it. The maximum thickness of the structure is 20 millimeters.

What is better - foil penofol or basalt insulation?

The building materials market is full of types of insulation. They have their own characteristics, positive and negative sides.

General thermal insulation parameters:

- Weight. The insulation should not weigh much, because when installing it on the structure there should be no weight.

- Thickness. The thinner the material, the more space remains in the room.

- Low thermal conductivity.

- Moisture permeability. The material should absorb moisture as little as possible.

- Noise insulation. Does not allow sounds from the street to pass through.

- Environmentally friendly material. Should not emit harmful substances.

- Easy to install.

When comparing basalt insulation and foil penofol, you need to compare their characteristics.

Basalt wool

Made from rock of volcanic origin. It does not burn, has good sound insulation properties, and does not lose its qualities over time. It is completely safe for health.

Penofol - application

Made from polyethylene foam with a porous structure. A layer of foil is glued on top as a heat reflector. This thermal insulation material is several times thinner than basalt wool. In addition, it reflects heat and practically does not absorb it.

Which insulation to choose depends on the budget for insulation, as well as personal preferences.

Installation features

Self-adhesive foil penofol is available in rolls, from which you can cut blanks with scissors or a knife.

The process of gluing the insulation is very simple - the protective film is removed, the material is pressed tightly to the surface. There are several subtleties when working with insulation:

- the foil layer is always laid facing the heat source;

- on both sides of the insulation a distance of 10-20 mm is provided for the circulation of air flows;

- sheets of material are glued joint to joint so that the reflection indicators in all areas are the same;

- After gluing the insulation, the joints are glued with aluminum tape;

- if very cold rooms are insulated, the sheets can be overlapped by 10 cm;

- electrical wiring in areas of thermal insulation with penofol must be carefully insulated;

- when laying the material on a wooden surface, the wood must be pre-treated with a sanding machine;

- if the installation of thermal insulation is carried out in the attic, care must be taken to ensure that no water gets onto the penofol either from above in the form of precipitation or from below in the form of steam;

- It is not recommended to use a stapler or nails for installation, as this violates the integrity of the layer and also reduces the thermal insulation properties of the material;

- External insulation of a building is best done using perforated foam foam; it will protect the walls from wind, snow and rain;

- It is better to carry out thermal insulation work in the summer, when there are no large temperature changes, the walls are dry and condensation does not form on them;

- when insulating a base or basement, penofol is mounted to the joists without gaps, the foil layer is located at the top;

- When insulating externally, the walls of the building are pre-treated with an antiseptic, paying special attention to the corners and the bottom of the walls.

Penofol with an adhesive layer cannot be used in flooring under a concrete screed.

By choosing self-adhesive foil penofol as insulation, the owners protect their home from cold and dampness, preserving the usable area of the room to the maximum. The material will not require large expenses, and all insulation work can be carried out independently, without involving craftsmen.

The most popular type of insulation with foil for interior finishing is aluform

Bestizol or alufom is a bubble base consisting of aluminum foil (outer layer) and polyethylene (inner layer) on one side. The foil acts as a reflector of solar and heat rays. The polyethylene layer has a cellular structure and neutralizes sound waves and shocks. The advantage of this material is low thermal conductivity.

Bestizol can be used in both cold and hot weather. Due to its small thickness (1 cm), the material is used for hard-to-reach places:

- for winding ventilation pipes;

- air duct coverings;

- insulation of pipelines and other outlet communications.

Installation of rolled foam foam inside and outside: how to stick it?

Basic installation rules:

- The material is mounted straightened, uncompressed, without folds. Fix to the lathing or directly to a clean surface.

- Penofol is secured with foil towards the heat to reflect it. This is an obstacle to the release of thermal energy to the street.

- The material is glued end to end. The borders are taped to seal.

- To glue the insulation, special types of glue or a self-adhesive type are used.

Installation is quick and easy, both inside and outside. The work is identical in sequence and principle inside and outside. It is easy to cut and quickly installed.

Before gluing penofol, you do not need to pay attention to its weight. The material is lightweight and can be supported by universal glue. But, for strength, they purchase adhesive compositions intended for this purpose.

The adhesive must correspond to the characteristics of the thermal insulation material:

- temperature range +100/-600C;

- indoor use, not outdoor use;

- non-toxic;

- good adhesion.

The adhesive composition should not emit harmful substances. Penofol is able to absorb 3% of heat, which means the glue on the back side can also warm up.

How to glue insulation with foil to the wall near the radiator and door

For gluing the surface and penofol, craftsmen recommend purchasing the following brands:

- Weicon Easy-Mix PE-PP 45. Two-component adhesive designed for gluing concrete (brick) surfaces with polyethylene, polypropylene.

- Moment - has many positive aspects, including good adhesion. The glue will quickly and permanently bond the insulation to the surface behind the radiator or near the door.

- Liquid nails are capable of fixing heat-insulating material for a long time.

Other brands: Titan, Tilit, Atlas Stopter K-20 kley, Ceresit (ST83).

Preparatory work

First, you need to properly prepare the concrete for gluing, which will ensure a monolithic, uniform connection. They eliminate all defects, unevenness, cover up cracks, repair chips, and thoroughly clean the surface from dirt and dust. Cover the base with a primer and wait until it dries completely. All metal elements must be treated with an anti-corrosion compound.

Gluing stage

The glue is applied to the side without foil in a thin, even layer, spreading evenly over the entire surface. The edges are impregnated with glue as thoroughly as possible so that the penofol does not lag behind the concrete surface. The insulation must be held for 10-40 seconds so that the adhesive composition can set and fix the sheet to the surface more efficiently. Next, the sheet is pressed against the concrete, carefully smoothed, distributed evenly, additionally gluing the seams.

Choosing a suitable adhesive for gluing penofol to concrete is a very important task that must be approached seriously. It is advisable not to skimp on the composition, since the strength, reliability, and durability of the fixation will depend on its compliance with the requirements and operating conditions.

Life time

Since foil insulation appeared relatively recently, it is not yet possible to determine the exact expiration date. However, after conducting experiments, we can say that the material does not lose its properties for 200 years.

The service life of the installed insulation depends on the adhesive used. If the adhesive composition has passed its expiration date, then you can re-install it with the same heat insulator.

There are a lot of insulation materials on the construction market. The choice is so wide that the question arises, which is better. To answer, you need to compare the characteristics of the thermal insulation material and the scope of application - street, living room, garage or agricultural building.

Glue characteristics: advantages of the material and selection criteria

The choice of adhesive for polyethylene foam should be based on the type of surface to be treated with the material. To save heat energy in the room, professionals advise installing penofol only from the inside of the structure, which is laid as the top layer on an already adapted insulation. When laying, a mandatory gap between the material and the heat-saving element is observed, an air cushion of 1 cm. External finishing will protect the structure from drafts.

The classic insulation for residential and industrial premises is polystyrene foam, which is attached to concrete with a special adhesive composition. Expanded polystyrene, in turn, is lined with penofol, which adapts to the plane only with glue; the material does not accept mechanical installation.

Advantages of adhesives

High-quality adhesive for attaching penofol to a concrete surface has a wide range of positive characteristics. Advantages of using adhesive:

- minimal time spent on installation;

- relatively low material cost;

- the ability to independently carry out the proposed work;

- lack of special equipment in the work process;

- high-quality fastening to the concrete surface;

- resistance to moisture;

- high-quality sealing of formed seams;

- environmental friendliness and safety of organic compounds.

Mandatory requirements for glue

The adhesive for fastening polyethylene foam must meet the following criteria:

- high threshold of resistance to moisture factors;

- high-quality fastening to the concrete base;

- gentle effect on the structure of the material;

- resistance to destructive environmental factors;

- lack of reaction to changes in temperature;

- long-term operational guarantees;

- antibacterial substances in the composition.