Insulation of building structures of a house under construction or already in operation is the most important task for its owners. Without solving it, it will be extremely difficult, very ruinous, or even impossible to achieve comfortable living conditions. Fortunately, in our time there is no shortage of either available technologies or the necessary thermal insulation materials.

Adhesive for penoplex

The most popular thermal insulation materials include expanded polystyrene boards, in particular those produced using extrusion technology, usually colloquially referred to as penoplex. Indeed, the insulation is very convenient and can be used in almost any construction site. But in some cases, the technology of its installation requires the most tight attachment to the insulated surface. Mechanical fixation is not always convenient and reliable, both structurally and from the standpoint of thermal insulation itself, and in rare cases it is completely impossible. Therefore, we have to look for another way out, and the first thing that suggests itself is to use some effective glue for penoplex.

And we’ll look at which one in this publication.

Types of adhesives

What composition is used to glue penoplex to the surface of a wall or ceiling? There are many options, but you need to choose the product carefully. This glue will hold not only the material itself, but also the entire insulating structure. If the quality of the glue is poor, it will not hold the insulation.

There are several types of adhesives depending on the composition:

- mineral;

- polyurethane;

- polymeric;

- waterproofing.

The first type is used to work with a dry surface, because at high humidity the mineral components immediately harden. It is better to carefully study the advice of the glue manufacturer before purchasing. This will allow you to choose the appropriate composition. It should not contain caustic, aggressive components, because penoplex is a capricious material, its structure is easy to destroy.

Peculiarities

Penoplex is a foam type material that has a homogeneous, uniform structure of small air cells. Only 2 types of this material are available to buyers, differing in density - 35 and 45 kg/m³.

They differ in many characteristics, properties, technological qualities and purpose:

- Penoplex with a density of 35 kg/m³ is used for industrial purposes and can provide thermal insulation in residential premises.

- Penoplex with a density of 45 kg/m³ is used in the construction of highways, the construction of oil and gas pipelines, as well as railway construction.

The material can also be used for less significant purposes, such as insulating the foundation, roof, facades, walls and interiors.

Penoplex has the following technical characteristics:

- Increased strength.

- Moisture resistance.

- Low thermal conductivity.

- Resistance to mechanical stress.

- Easy to install.

- Reduced chemical activity.

- Fire resistance.

- Ecological cleanliness.

- Long service life.

- Reasonable price.

Penoplex is installed using specialized tile adhesive. If you choose the right adhesive mixture, the service life of the material will increase, and it will also ensure safety for the health of people who are often indoors or live in the house.

Polyurethane-based compositions

For the installation of penoplex such products are often used. Most are sold in cylinders, so they are convenient and easy to use even for a beginner. The products are ready for use, they do not need to be mixed, and the consumption is economical. The most popular composition of the series is “Insta-Stik”. It is sold in 750 ml cylinders, the consumption when gluing is 12-15 sq. m, setting time - 20 minutes. Pull-off force – up to 400 kPa. The disadvantage is that it is not frost-resistant - you cannot glue penoplex to walls at temperatures below 0 degrees.

Another well-known glue is Titan Stiro-753. Its consumption is approximately the same (about 14 sq. m). The product has a high peeling force (600 kPa), and the setting time is even shorter (15 minutes). Penosil Fix&Go Montage is frost-resistant; it is used at -65...+130 degrees. Using the described means, it is easy to connect foam sheets together, stick them on wood, attach them to a brick wall, or to concrete.

Adhesive foam Penoplex Fastfix

This foam with adhesive properties is widely used for attaching thermal insulation made of extruded polystyrene foam to all kinds of substrates - ceramic tiles, concrete ceilings, floors and walls, plasterboard, aerated concrete, brick. Adhesive foam Penoplex Fastfix (“Penoplex Fastfix”) is produced in 750 ml cylinders, the product itself is light blue.

If necessary, the adhesive will provide adhesion to most building materials. Among them are plaster, stone, wood, expanded clay concrete blocks, metal, cork, cellulose. If the material had to be foiled, this product is incompatible with it. Foam is also not suitable for polyethylene, silicone, and Teflon. Here are the main characteristics of the material:

- drying – 10-12 minutes;

- complete hardening – 24 hours;

- possibility of cutting – within 30-40 minutes.

The product is used both for external work and for internal thermal insulation indoors; it is suitable for insulating loggias and balconies.

Stamps

Let's consider the most famous brands of adhesives for penoplex.

Tytan

Titanium is a universal adhesive produced in Poland by Selena.

To work with insulation, it is better to use the Professional Styro 753 series. The composition is resistant to the influence of precipitation and is heat-resistant, so thermal insulation can be carried out outside. The product ensures maximum adherence of the insulation to the base.

Ceresit

Using Ceresit products you can attach insulation to walls, ceilings and other surfaces.

- Ceresit ST 84. Foam for insulation. Can be used for outdoor work. Withstands temperature changes from -10 to +40 °C. Hardens quickly. In summer it hardens in 2-4 hours. Can be applied with a mounting gun.

- Ceresit ST 83. Available in bulk form. The complete drying time for the material is 3 days at positive air temperatures. Easy to apply with a notched trowel. Consumption – 6 kg per sq. m. Non-frost resistant.

- Ceresit ST 85. Composition for gluing and reinforcing penoplex. Operating temperature +5…+30 °C. Available in bulk form. After diluting with water, the composition should sit for 2 hours. When gluing in the usual way, the consumption is 6 kg per sq. m., when reinforced - 5 kg per sq. m.

Moment

Fixes penoplex to any base. The moment is also used to create a reinforcing mesh. The composition has good adhesive characteristics, is frost- and moisture-resistant, elastic, does not require shrinkage, and can withstand changes in temperature.

Master termol

- It has a cement-sand composition, which makes it easy to attach penoplex to concrete, cement and lime bases.

- Provides good adhesion to polystyrene foam.

- Very elastic composition.

- Immune to frost.

- Environmentally friendly composition.

Profline 3K-45

The adhesive contains components that increase the level of adhesion of penoplex to any base. Can be used on plastered, cement and concrete substrates.

The adhesive seam is not susceptible to moisture, cold, or mechanical damage.

Penoplex Fastfix

Penoplex Fastfix is an adhesive foam for penoplex, which is used during thermal insulation work. You can use foam to attach insulation boards to concrete ceilings, ceramic tiles, plasterboard, aerated concrete and brick. Penoplex Fastfix 750 ml is available in the form of an aerosol of the appropriate volume. Color – light blue.

The glue has good adhesive characteristics in relation to most building materials, including wood, plaster, expanded clay concrete blocks, cork, cellulose, and metal.

With foil material, the composition does not provide the necessary adhesion; it is also not suitable for gluing polyethylene, Teflon, and silicone surfaces.

The mixture adheres to the plane in 10-12 minutes, within half an hour it is still possible to cut the structure, and complete hardening occurs within a day. Can be used indoors and outdoors. Often used for thermal insulation of loggias and balconies.

Mineral adhesives

Mineral-based adhesives contain cement, gypsum, and alabaster. They harden very quickly and must be applied immediately. The adhesives are mixed in small portions. Only cement compositions are usually used outside the room; products with gypsum components are suitable for interior work. The setting time is long, up to 1.5-4 hours, so it is possible to correct flaws.

The disadvantage of the compositions is that the base must first be well primed and wait until it dries completely, otherwise the connection will not be strong. Another disadvantage is the need for dilution; to obtain a high-quality homogeneous mixture, you need a construction mixer.

The most popular brands of mineral adhesives:

- Ceresit CT 83 - used directly for gluing penoplex, suitable for any substrate, pull-off force - 500 kPa, high frost resistance class.

- “Atlas Stopter K-20” – has an increased tearing force (600 kPa), is viable for 4 hours, consumption – 4.4 kg/sq.m. m, contains special reinforcing fibers.

Products of this type are sold in bags of 5-25 kg and cost about 300-500 rubles. for 25 kg. If the frost resistance class F50 is indicated on the bag, the product is suitable for interior work. Class F100 means that the boards can be glued outside.

Polymer adhesives

Is it possible to fix penoplex with adhesives in small cans? Typically, polymer adhesives are sold in such containers; they are ready for use on any surface. Bonding by this method is practiced if it is necessary to attach penoplex to metal. It is better for beginners not to buy such compositions - they set instantly, and it will be impossible to correct defects.

A good product for slabs is Moment glue. It is resistant to humidity and temperature changes, and is produced in convenient packaging of 0.25-1 liters. Consumption is low, even a small pack is enough for 4-5 square meters. m. Another product is “Emphikol 225”, its technical characteristics are similar. After use, you should ventilate the room well for 2-3 days, but it is ideal to work with it in the air.

Waterproofing compounds

This group of materials that will glue penoplex includes adhesives based on bitumen, acrylic, rubber, they are produced in the form of mastics. You can’t buy simple ones, they corrode the material, just like waterproofing agents with petroleum products. The best way to glue penoplex is Bitumast XPS. The mastic does not include solvents, sets in 2 days, and has a high peeling force of 500 kPa.

Acrylic adhesives can easily attach penoplex to wood, concrete, brick, connect penoplex to penoplex, and glue penofol to penoplex. They are suitable for interior and exterior work and have very low consumption. Bitumen mastics have the most pronounced waterproofing properties and are resistant to low temperatures.

At what temperature can you glue?

By default, interior work is carried out at room temperature, and exterior work is prohibited if the air temperature is less than 10 ° C. Bitumen mastic is suitable for work even in severe frost, and in the heat, and even under the scorching sun, each material will harden longer than usual if will not deteriorate while waiting.

In any case, before construction, you need to familiarize yourself with the operating requirements and storage conditions - indoor solutions are not always universal and reliable.

Instructions for gluing penoplex

When you have chosen what to attach the material to, you can proceed directly to work. It is important to properly prepare the surface of the base; you can do this yourself. It should be cleaned of debris, dirt, and dried. If the manufacturer recommends, you must first prime the surface. Next, you should cut out the necessary pieces of the base material. How to cut penoplex? For this purpose, a stationery knife or jigsaw is used.

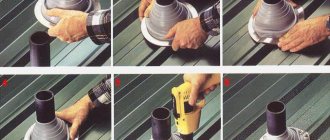

Installation technology

After drawing up an installation plan, you can begin gluing the product to the floor, walls or ceiling. Mineral wool is often used under penoplex.

There are several ways of gluing with glue:

- point;

- solid;

- borderline.

The dot method is more often used, in which liquid glue is applied with a spatula 100-200 mm wide. Then you should wait a certain time and press the material to the surface. After complete drying, the joints are sealed with polyurethane foam or the same glue. The second option is much more expensive.

Glue consumption

All useful information for the user, including material consumption, is always indicated on the packaging. The usual figure is 3.5-5.5 kg/one standard layer of material (for mineral mixtures). Glue in cylinders is more economical and consumes less (from 10 sq. m per cylinder).

Puttying penoplex

After the glue has completely dried, you can additionally fix the penoplex with dowels, this is more reliable. Next, puttying with finishing materials is performed. The putty must be applied smoothly, layer by layer, and the putty must be smoothed evenly. After the first layer, a mesh of metal, plastic, and reinforcing is attached. The thickness of the first layer is up to 1 cm, the second – slightly less. 2-3 layers are performed as desired, with the third layer usually done by spraying and up to 5 mm thick.

External foam protection

For external protection, special glue is used. Which one is used in this case? A product with high adhesion to the surface is suitable; you can choose the brands “Ceresit”, “Master”, “Polymin”. Some professionals prefer to use “Gyprok”, a plasterboard-like insulation material.

Gluing stone and tiles to penoplex

After the final stage of work, you need to think about finishing. Most often it is recommended to glue ceramic tiles, porcelain stoneware or artificial stone. This is done with tile adhesive with frost-resistant qualities; with its help you can easily and quickly finish floors and walls. It is imperative to apply several layers of plaster, preferably Ceresit ST 85 with reinforcing mesh. It is recommended to make a cement screed on the floor indoors, and then create a decorative covering.

Questions and answers

There are a number of questions that concern users regarding the use of penoplex.

How to glue penoplex to penoplex?

There is no difference between how to glue two sections of penoplex and this material to other surfaces. But experienced builders claim that when fastening the slabs together, it is better to use a continuous method of applying glue, and you can do without a primer. In this case, dowel-nails are not required, and any glue listed above will do.

Is it possible to glue the material onto polyurethane foam?

You can glue penoplex to the foam, the adhesion will be strong. On the floor, this type of work is carried out on a self-leveling concrete screed. But gluing onto polyurethane foam is very expensive. It also tends to expand, so you will have to constantly press it until the process is completed.

Is it possible to glue penoplex to liquid nails?

You can use liquid nails, but it’s not very convenient. It should take up to 7 minutes before applying the slab in place, otherwise the glue will not set. In addition, the price of work will increase significantly.

Does air temperature matter?

This depends on the type of adhesive composition. Some lose their properties at low temperatures. Others allow work in the cold. All data must be clarified in the instructions.

The choice of glue and what is better not to use

Before purchasing, you need to consider the following points:

- acceptable price;

- suitability for indoor or outdoor use;

- adhesion strength;

- consumption;

- harmlessness (for interior decoration).

Typically, any polyurethane or polymer adhesives are purchased for interior work. It is prohibited to use waterproofing products indoors; they can be harmful to health. Cement-based mineral mixtures are often used outside the house. For exterior work - balconies and plinths - acrylic mixtures are ideal.

Compositions containing benzene, toluene, acetone, formaldehyde, and xylene should not be used for penoplex. Kerosene and gasoline, coal tar and polyesters, and formaldehyde will also spoil the material. Otherwise, you can easily glue the material with your own hands without extra costs.

How to choose for different surfaces

For each type of surface, you need to choose your own suitable type of substance to glue foam boards:

- For outdoor work, it is better to choose dry mixtures that have good adhesion to stone, brick and plaster. When choosing, you need to pay attention to the packaging, namely, its integrity and the indicated release date. The seal must be maintained.

- To ensure waterproofing of seams and surfaces, you need to choose bitumen or polymer adhesive.

- Polyurethane types are mainly used for reinforced concrete and wood.

- Liquid nails, polyurethane foam or silicone-based sealant provide good adhesion to metal bases.

- To install penoplex on plastic, corrugated board or plywood, it is also better to use liquid nails.

Polyurethane adhesives are excellent for installing materials indoors, as well as for creating floor thermal insulation. To glue penoplex outdoors, mineral adhesives are suitable.

Adhesive foam is considered a universal material used for finishing walls, indoor and outdoor surfaces. Suitable for working with floors and ceilings.