The floor in the bathhouse warms up the slowest, and often remains cold, even when the steam room is heated hotly. It is especially uncomfortable to feel this in the washroom, where you have to leave the hot steam room with your bare feet. And the sharp difference in temperature in the lower and upper parts of the room does not have the best effect on the body. In addition, such conditions negatively affect the indoor microclimate and contribute to wood rotting. It is not difficult to get rid of these problems - it is enough to perform high-quality thermal insulation.

How to insulate the floor in a bathhouse in a washroom

Let's look at how to insulate the floor in a bathhouse in a washroom and what is needed for this.

Guidelines for choosing a future design

The owner of a country bathhouse must initially decide on the type of drainage of water constantly pouring onto the floor and the material for constructing the floor. Basically, in buildings recognized as a mandatory component of suburban areas, the floor is poured with concrete or boards are laid on logs.

- A concrete foundation will require more labor effort, money and time, but it will serve without any complaints for more than half a century.

- It is easiest and cheapest to build a floor in a bathhouse with your own hands using lumber, but after 7-8 years its wooden elements will need to be replaced.

Wood structures, based on the type of drainage and the associated complexity of the structure, are divided into leaking and “non-leaking” subcategories.

Pros and cons of leaking floors

A leaky floor is the simplest and extremely cheap. It is a boardwalk, between the elements of which gaps are left for direct discharge of wastewater into the ground. It does not have any additional sewer “delights” except for the drainage hole located in the underground, and there is no insulation either. Therefore, a leaky floor is suitable for bathhouses in the southern regions and for temporary summer cottage use.

Building such a floor for a bathhouse with your own hands is as easy as shelling pears. It will not be difficult to replace damaged elements and complete repairs. The boards are not nailed to the joists at all; they can and should be removed and taken outside for ventilation and drying. If desired, instead of a drainage pit, you can install a pan, the drainage from which will be discharged into a sewerage facility.

Specifics of leak-proof design

A non-leaking system is much more complex. It is constructed from two rows of boards. The top flooring, going on top of the logs, is made of tongue-and-groove pine or larch boards without the slightest gaps. A subfloor is installed underneath. A non-leaking floor is classified as “dry” and can be equipped with insulation.

The floorboards of the finishing flooring are placed with a slope towards the place where wastewater is collected and subsequently discharged into a sewer ditch or septic tank. A hole is made at the lowest point of the plank surface, to which a siphon is connected to drain the waste. The hole can be replaced with a full-length tray. The tray is installed with a slope towards the collection point of contaminated water.

What should the concrete floor pie be like?

Concrete floors in bathhouses are poured in three technological stages. The exaggerated “sandwich” of the design consists of six components, these are:

- compacted and strengthened soil base prepared for pouring;

- first layer of concrete 5 cm;

- insulation, most often expanded clay or felt;

- reinforcing concrete layer with chain-link mesh;

- leveling layer;

- coating.

Tamping the soil and the reinforcing gravel-crushed stone mixture of 15 cm laid on top of it, as well as pouring each of the “sandwich” layers, is carried out with a slope towards the drainage pit. As a result, the design should have a normal bath drain. The slope is standard, like wooden structures, 10º.

We decided on a scheme according to which the installation of floors in the bathhouse would be carried out. Do not forget that if the floor has to support the weight of a permanent rather than portable sauna stove, you need to take care of creating a foundation for it in advance.

Work technology

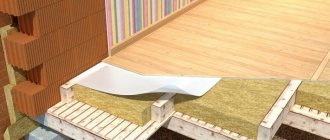

The simplest and most technologically advanced method is when the floor is insulated by laying a heat-insulating layer between the subfloor and the main floor. The thickness of the layer is equal to the thickness of the lag. Depending on the length of the span, it can range from 10 to 20 cm.

If a smaller layer thickness is required, for example, for polystyrene foam, then the subfloor is constructed from short boards nailed to the joists through bars on the sides of the joists. The bars allow you to leave any allowance for the thickness of the lag below the subfloor level.

What can insulation be laid on?

- On a wooden subfloor;

- On a concrete screed;

- On a subfloor made of OSB boards (a common option for pile foundations).

You cannot lay insulation on the ground, soil fill, or sand bed. In this form they are unprotected from rodents and moisture.

In the relaxation room in the bathhouse

In the recreation room you can use almost any thermal insulation materials. Along with polymer insulation, mineral wool, basalt slabs, backfill, sawdust, and cellulose fillers are suitable.

Attention! It is not recommended to use mastics that require heating. All of them have a very high fire hazard

Nowadays, there are enough solvent-based products that can be used straight from the can.

Usually they take the material that is available inexpensively on the local construction market. Also important is its safety for humans and compliance with general requirements for a bathhouse.

Basalt wool is non-flammable and is sold at low prices.

It is used quite often in baths, but it must be taken into account that even after getting wet once, it “shrinks” in volume and its heat-insulating characteristics deteriorate irreversibly.

Also, when using it, you need to take care of insulating the mineral wool from the room.

It is rational to use it only in the relaxation room and avoid using it in the steam room and washing room.

In the steam room of the bath

Information. The insulation of the floor in the steam room of the bath is carried out taking into account the influence of moisture. It must be combined with very good waterproofing. Of all the structural elements of the bathhouse, it is the floor that is subject to the most intense action of water.

One of the options for insulating the floor in a steam room is to use exclusively moisture-resistant insulation materials, for example, mineral ones. A thick layer of expanded clay backfill is created on the prepared base.

Then a drain pipe is installed in the center and a waterproof layer of concrete is poured on top. It is designed to ensure water flow. The field structure is covered with a wooden lattice (finishing floor for the steam room).

Heated floors, which are especially often used in saunas, are insulated using a similar scheme. First, a layer of porous backfill is created. Then - a screed into which the heating cable or pipe coil with coolant is recessed. All this is covered with tiles.

The insulation of the floor in the steam room can be done without expanded clay, for example, using polystyrene foam. In terms of the ratio of thermal insulation characteristics and price, it is much more profitable than expanded clay.

It is used according to the same structural scheme as expanded clay, only the slabs are placed not on a bedding on the ground, but on a subfloor.

The general design of the finished floor is several layers of materials in section:

- Subfloor: board, concrete slab;

- Frame made of boards on edge;

- Expanded polystyrene boards or backfill to the thickness of a lattice of logs;

- Waterproofing layer;

- A layer of screed with an attached slope and a drainage system for draining water;

- Clean wooden grate.

Insulating the floor in a steam room with foam plastic is suitable for server areas, since its thermal insulation properties are much better than expanded clay. Instead of foam plastic, a wide range of materials based on it can be used. Various manufacturers give them their own names, so we do not indicate the exact brands.

Options for finishing flooring in the sink

In the Russian bathhouse, it was customary to make wooden floors: both in the steam room and in the washing room. But times are changing, and tile or stone topcoats for concrete floors are considered the best option. They not only create a refined and unique atmosphere in the bathhouse, but are also a reliable and durable material.

Tree

If we consider wooden floors in the washing department, they can be treated with water-based paints. But it is best to avoid oil and alkyd compounds. But, as practice shows, wooden floors do not need to be painted. A simple treatment with store-bought impregnation is sufficient for them.

Tile

Tiled floors are modern designs that are quite popular not only in the construction of a bathhouse, but also in the organization of floor coverings in other rooms. Such floors are easy to insulate, they have a fairly high water resistance, are strong, reliable and durable. Therefore, ceramic tiles on the floor in the bathhouse sink will be an excellent option for flooring.

Linoleum

Finish coatings made from it have high moisture resistance, are quite durable and reliable. They are used for concrete floors as an excellent and cheaper alternative to tiles. But you need to understand that linoleum is a rather slippery material for a washroom, so its use creates a health hazard.

Rubber

This floor covering is a high-quality material that not only has high moisture resistance, but is also available on the market in a huge variety of colors. This allows you to create your own unique design for the washing room in the bathhouse. Also, compared to simple linoleum, the rubber coating is not as slippery. It prevents the occurrence of fungus, bacteria or mold, and also does not create difficulties in care. This is an excellent choice for those who want to have a reliable and durable floor covering in the wash room of the bathhouse.

Tile

To increase the wear resistance of the material and prevent moisture accumulation in the floor covering, experts recommend pre-insulating the floor. For a "warm floor" system, the best finishing coating is tile. It gives off heat well and is quite easy to care for. But the choice is still yours.

When using this or that floor covering in the washing section of a bathhouse, you must make sure that the material under such conditions will not emit harmful substances that have a detrimental effect on human health.

Proper processing of lining

Having decided how to cover the lining in the steam room of the bathhouse, you can proceed to the processing itself. To perform high-quality impregnation that will last a long time, we recommend that you read the following instructions:

Processing lining in a steam room begins with preparing the wood itself. Clean it from various contaminants with sandpaper or other suitable method. It is also recommended to wash the boards with an aqueous solution of soda (300 g of soda per 10 liters of water); Next, you need to degrease the surfaces. Remember that not only the lining itself is impregnated, but also the frame to which it is attached; Sand surfaces with pumice to obtain a smooth finish; Next, you need to apply an antiseptic that will protect the wood from fungus and mold; Now you can saturate the lining

When choosing impregnation for the dressing room, pay attention to the humidity of the air in it, as well as the temperature of the steam. If the indicators are approximately equal to the indicators inside the steam room, then it is necessary to use the same impregnation.

By doing all the work correctly, you can achieve an excellent result, as in the photo.

Bathhouse roof insulation

An important area of thermal insulation work, because A lot of heat escapes through the roof

If the roof is well insulated, insulation of the ceiling can be eliminated. However, it is possible to insulate the roof only if the bathhouse is a separate building with a pitched roof. For insulation, you can use any heat-insulating material that is laid on the attic floor.

The procedure for using synthetic insulation, wool or polystyrene foam is no different from laying it on the wall.

Insulating the roof of a bathhouse with sawdust

Execution scheme:

arrangement of the frame;

preparation of sawdust. If sawdust is poured in the form of a dry mixture, then it must be dried, deresined, and impregnated with an antiseptic. Dry sawdust can be poured in the form of a mixture between the cells of the frame and covered with a membrane or covered with ash. But more often they are placed in plastic bags and stacked in bags;

Note. In its pure form, sawdust is used only in wooden houses.

Insulation of the roof in a bathhouse with sawdust poured into bags

preparation of the mixture. Sawdust insulation is an effective thermal insulation option if the floor is a concrete slab. Composition of the mixture for insulation (proportions of components): – sawdust – 8 parts; – lime – 1 part; – gypsum – 1 part.

First, mix the dry materials and then add water to the desired consistency.

There is a second recipe:

– sawdust – 5 parts; – clay – 5 parts.

Insulating a bathhouse with a mixture of sawdust, clay and straw

Recommendation. Boric acid can be used as an antiseptic - 10 ml. for 1 l. water.

In this case, the clay is soaked in water, diluted to the consistency of sour cream and mixed with sawdust.

Advice. Instead of sawdust, you can use straw (densely packed).

An effective insulation will be a 100 mm layer of sawdust mixture.

Insulating the roof of a bathhouse with sawdust

Backfilling ash around the exit of the sauna stove pipe from the attic floor

Heating

There are several ways to organize heating in a washing room:

- An example of the location of a stove in a bathhouse

Combined heating of the steam room and washing room. A stove-stove will be used as a heating device. In this case, it must be installed in the wall between the washing room and the steam room. However, this type of heating does not guarantee uniform heating. After bathing procedures in winter, water should be drained from all sources and containers.

- From a practical point of view, it is better to install electric heating in the bathhouse. To do this, it is enough to install only 2-3 radiators in this room. The number of batteries depends on the heated area. The cost and maintenance of this type of heating is expensive. And if the electricity is turned off, the bathhouse will simply freeze, and the heating devices will be damaged.

- It is reasonable to supply gas and install a boiler in a bathhouse only if the building has approximately 150–200 m2. Otherwise, it is better to install several gas convectors in the bathhouse. As for the washing room, one convector is enough to heat it. This unit operates from both natural (mainline) and liquefied gas (in cylinders).

- If the bathhouse is adjacent to the house, then it can be heated from the general heating system of the house. In this case, you need to install an ordinary radiator in the washing room.

Types of floor

A good bathhouse, as a rule, consists of several rooms: a dressing room, a wash room, a steam room and a shower room. The driest of them will remain the dressing room, all the rest are exposed to abundant water. All these points are taken into account at the time of laying the foundation for construction. And at the same stage, the issue of water removal is resolved: drainage and high-quality drainage.

The floor in the bathhouse can be concrete or wood. Both need good drainage and drainage. Many people are afraid of concrete floors, considering them not warm enough. Therefore, wooden grates are placed on top, which can be periodically taken out for drying and treatment with various antiseptics.

Wooden floors in a bathhouse can be of two types:

- leaky

- leak-proof.

The leaking one is made on low piles, under which a concrete base is first poured, and waterproofing is arranged according to all the rules. We will talk about this a little later. A leak-proof wooden floor does not have a concrete base at the bottom and is laid with a slope to one side, where a drain hole is provided in the lowest place, and a pipe is led out of it into the sewer. This design has disadvantages, since the boards do not dry out completely and begin to rot over time.

How to make a frame

Floors in a washing room in a wooden bath can have three types of frames. The first is designed to create a space between the floor and the raised floor, which is filled with insulation. This is a lattice made of standard section logs.

The second version of the frame provides rigidity to the wooden flooring if it has a permanent structure. Finally, the third option is to support a thin reinforced concrete drainage screed.

In a wooden bathhouse on a screw pile foundation, you can get a floor with drainage by pouring concrete onto a wooden frame, but there is another option.

Information. The construction of a foundation for a furnace necessarily requires the use of concrete. At the same time, a screed for the sink is cast in the wooden structure. It should not be made very thick. Mesh is used for reinforcement.

The frame is assembled from beams of the same section. Antiseptic treatment is required even if the frame is located under a drainage screed and under a layer of waterproofing. It will ensure a long service life of the entire structure.

Base insulation on a pile foundation

How to properly insulate floors in a bathhouse built on a columnar foundation? A columnar foundation is usually made on piles of metal supports or brick pillars. This type of foundation is ideal for building a sauna house made of timber. Such structures, in comparison with others, have an important advantage - reliable waterproofing, which is achieved by arranging the foundation above the ground.

In most cases, structures on a columnar foundation have a wooden base, which is formed by laying floor logs. Subsequently, wooden floors are laid on the ceiling, which need to be insulated. For high-quality thermal insulation of the base with your own hands you need:

- Make a wooden pipe that will connect all the support columns into a single structure;

- Then lay the floor beams on the wooden frame, which are secured using metal brackets and special brackets;

- Arrange the subfloor as described in the section “Thermal insulation of wooden bases”.

What materials are best for insulating floors in timber buildings?

- basalt wool;

- granulated expanded clay;

- mineral wool;

- polystyrene foam.

Use of mineral wool

The question of whether it is possible to insulate a bathhouse with mineral wool is usually resolved positively.

After all, mineral wool is an almost universal modern insulation material with many positive technical characteristics. Among them are:

- reliability;

- moisture resistance;

- heat resistance;

- fire safety;

- resistance to rotting;

- easy installation.

Therefore, mineral wool can be used as bath insulation both outside and inside, including a steam room.

Waterproofing in a washing bath

Of all the bath rooms, it is in the washing room that the floor is exposed to the most intense action of water.

The necessary reliability of waterproofing can be achieved using classical technology with roll insulation and mastics.

Liquid and roll waterproofing are ideal here. If it is necessary to waterproof wood, you need to keep in mind that it changes quite significantly in size when it swells and dries.

Here, either rolled waterproofing with reinforcing fiber or liquid special grades with a high stretch coefficient of the finished coating are suitable.

Attention! When working with waterproofing materials, you must use personal protective equipment: gloves, respirators, safety glasses

Where to order or buy

Competent recommendations can also be obtained from specialists from companies specializing in the construction of baths and providing wall insulation services.

Clients with knowledge and skills in the construction industry can complete the work themselves. They will be interested in companies offering wall insulation, collected in a separate section of our website.

Insulation of walls in a bathhouse · 11/16/2016 · 8

Floor requirements

The washing room is adjacent to the steam room

This part of the bathhouse always has special conditions. Firstly, there is constantly high humidity here. Secondly, there are sudden temperature changes in the washing room. The user can enter and exit adjacent rooms and visit the steam room. At this time, cold or hot air penetrates into the washing room.

All these factors can ruin even a solid floor in a short time. To prevent this from happening or to happen as late as possible, the following characteristics should be taken into account during construction:

- the floor covering and its components must dry quickly;

- the floor should easily withstand temperature changes;

- have the ability to pass air;

- the underground space should be ventilated, but not create drafts.

Communications

Ventilation in the bath

To make bathing procedures enjoyable, it is important to ensure sufficient air circulation in the washing room. To do this, install a supply and exhaust ventilation system in it. With its help you can reduce the level of air humidity.

Install an exhaust pipe into the wall and extend it above the roof. This way, the air will be purified more effectively. Install the supply pipe at a height of 2 m from the ground.

The plumbing should also be installed at this stage. It is easier to do this through a centralized water supply system.

Electric boiler in the bathhouse

There is no way to connect to a centralized water supply? Then you need to make an alternative decision. Provide the bathhouse with water from a well. The algorithm of actions is simple:

- Dig a trench below the freezing level of the soil from the source to the washing area.

- Make a sand cushion in the trench 20 cm deep.

- Lay pipes in it to ensure water supply.

- Install two pumps in the bathhouse - one for pumping water from the well and a circulation pump. You will also need to install a water storage tank. Already connect the water heater to this system.

Waterproofing a concrete floor in a bathhouse

Concrete is a strong and reliable material, but without proper thermal insulation it can freeze during the cold season. Therefore, in addition to protection from moisture, it is best to provide maximum protection against cold penetration into the room.

When making a screed, check the evenness of the surface and apply waterproofing mastic in several layers to the cleaned, dried mixture. A thin membrane or dense roofing material in the form of rolls is also laid.

All seams are soldered using a hair dryer. Afterwards, a reinforced mesh is laid on which a new layer of concrete screed will be placed. Next comes the final finishing of the floor.

Application of foam plastic

Many home craftsmen are interested in whether it is possible to insulate a bathhouse with foam plastic. After all, this is a relatively inexpensive and easy-to-use material. However, it should be said that the bathhouse can be insulated with foam plastic from the outside or along the foundation.

When asked whether it is possible to insulate a bathhouse with foam plastic from the inside, most experts will answer negatively. This is due to the fact that foam is easily destroyed when exposed to high temperatures. The low moisture resistance of this material causes it to rot under the influence of high humidity. Therefore, for the interior of a bathhouse, foam plastic can only be used in rooms where there is almost no moisture.

Subfloor

Subfloors in the wash room (washing room), dressing room or other bath rooms can be made from pieces of plywood, unedged boards, OSB, etc. Such floors do not have to be solid. The advantage of this fact is that by leaving 5-centimeter gaps in such a floor, you can get a good effect of saving consumables without losing quality.

A vapor barrier must be installed on the floor.

And all because the underground of any house, including a bathhouse, is a very damp place. By condensing, moisture from there can get onto the wooden structures of the finished floor. And this is strictly unacceptable. Otherwise, the owner of a bathhouse or sauna will be forced, after a short period of operation of the bathhouse, to again wonder how to insulate the floor in the bathhouse.

Non-standard method of floor insulation

A cheap and yet effective alternative to using polystyrene foam is insulating the bathhouse floor with bottles. The principle of any heat insulator is to trap air inside it. Well, as you understand, bottles do an excellent job of this task both in the wash room and in the steam room. They are usually rested on the covered floor surface, installed upside down. Some even call this method of isolation the best.

The insulation is laid between the floor beams. It must be laid evenly, without cracks or gaps. Its thickness must certainly exceed 100 millimeters for the insulating effect to be most noticeable. Which insulation is best to use was mentioned above. This is mineral wool. This is a fairly inexpensive material, while its quality and performance characteristics are almost identical to those of more expensive and “promoted” materials.

Next, the floor in the bathhouse will be waterproofed. When choosing a waterproofing material, the main criterion should be quality, not cost. Because more expensive waterproofing materials are not always of better quality. When thinking about how to waterproof a bathhouse floor, you need to take into account that it is not necessary to spend a lot on waterproofing materials, since ordinary polyethylene film, although inexpensive, has excellent waterproofing characteristics. When using polyethylene film, the insulated floor will be reliably protected from moisture.

When insulating a wooden floor in a bathhouse (it doesn’t matter whether it’s the floor in the wash room, or in the dressing room or anywhere else), it is important to treat this adequately, understanding that not a single insulating or waterproofing material provides 100% protection. However, high-quality insulation of the bath floor will ensure the safety of such precious heat in the bath for a long time

Video on insulating the floor in a bathhouse with your own hands.

More about vapor barriers

The most successful vapor barrier option for all sauna rooms is aluminum foil. It is fire-resistant, durable, non-hygroscopic. The main advantage of aluminum foil is its ability to reflect heat. By using such a vapor barrier in a bathhouse, you can significantly reduce the consumption of fuel material.

Glassine and roofing felt cannot be used in the steam room, since these materials, when heated, emit volatile toxic substances. In some cases, glassine can be used as insulation. It is better not to use roofing material for this purpose at all.

Wooden floors: pros and cons

If you look from the point of view of ease of installation, then a wooden floor will be a priority. The problem is that after 8-10 years some elements will need to be changed. However, this will not be difficult to do. Both deciduous and coniferous species are used as building materials for bathhouse floors. The main thing is that they are resistant to temperature changes and moisture.

PHOTO: bany73.ru Wooden floors in a bathhouse are much nicer than dead stone

The most suitable boards for these purposes are made of oak, larch, beech, and birch. But pine or aspen boards should not be used here.

Spilled wood flooring and its features

A poured floor is a budget option that does not require much time for installation. It is a regular wooden lattice. Its elements are mounted at a short distance from one another, which ensures unhindered flow of water into the ground.

PHOTO: izhevsk.ru Spilled larch flooring - it’s easy to make, and this wood will last a long time

This type of floor does not provide for the arrangement of sewage drainage, as well as insulation. For this reason, a bathhouse with similar floors can be considered a country option, which will be used only in the warm season. In winter, such a bathhouse will be uncomfortable, and heating it in the cold is not so easy.

The peculiarity of the poured floor is that the boards are not fixed to the logs. They can be removed from the base at any time for drying or repair. Installation of such flooring is extremely simple.

PHOTO: avatars.mds.yandex.net The flood floor is installed according to the same principle - individual panels can be pulled out and dried

Leak-proof (classic) floors: installation nuances

Such a floor is much more difficult to install, but its arrangement makes it possible to insulate it. This means that you can use a bathhouse with a classic wooden floor at any time of the year and at any temperature. This floor is assembled on logs that are recessed into the ground or mounted into the base. The coating itself is made with a slight slope towards the drainage hole - the ladder.

PHOTO: avatars.mds.yandex.net Non-spillable classic floor - boards fit tightly to one another

First, a subfloor is laid on the joists, after which a tongue-and-groove board is used for the finishing surface. It must not have defects or be deformed. The subfloor is insulated with moisture-resistant materials.

PHOTO: banyabest.ruSchematic representation of a non-spillable floor layer by layer

Porcelain tiles

The final layer of flooring in my bathhouse is porcelain tiles. I chose porcelain stoneware because of its special strength and frost resistance, as well as resistance to temperature changes. In general, I am sure that my tile will not burst if I decide to heat the bathhouse on a frosty day.

As for the surface of the tile, it must be rough - this is a prerequisite for your safety. Although, soapy water will still do its job and even such a rough surface may turn out to be slippery. In this case, place wooden gratings made from beams on the floor. They can be dried after each visit to the bathhouse, so they will serve for a very long time.

Porcelain tiles are laid with special reinforced adhesive

Choosing a material for a bath floor

The floor in the bathhouse must be installed with high quality

So how to make a floor in a bathhouse? We start with the selection of materials, each of which has its own characteristics, its own advantages or disadvantages.

Previously, the construction of baths was simpler than modern ones. The foundations were not laid, the bathhouse was placed directly on the ground or buried in the ground. The floor, as a rule, was made of trampled earth or simple planed wooden boards.

Now, before building a bathhouse, it is necessary to first equip the foundation; a mandatory drainage hole with a depth of up to fifty centimeters is made in the ground itself, which is filled with gravel or sand. The water is diverted several meters away from the bathhouse. This is done so that the smell of rotting water does not penetrate into the room, where it is very difficult to get rid of it.

When choosing a material for a floor, it is necessary to take into account what the walls are built from, the purpose of the premises (for example, in a steam room or washing room, that is, rooms with excess moisture); the floors are best made of concrete with special wooden gratings on top. After finishing the procedure, they are quite easy to take out into fresh air to dry.

In addition, it is necessary to take into account the type of soil on which the bathhouse will stand. It is advisable to make floors in shower rooms from tiles with mandatory waterproofing; the wooden option is not suitable here due to high humidity. You can also use concrete, on top of which gratings or mats are laid.

In a steam room, floors can be made from different materials:

Installation of a wooden floor in a bathhouse

- Concrete;

- Tile;

- Wood (with proper ventilation of the entire floor).

The wooden floor is laid on special logs with a height of fifty centimeters. In other rooms with relatively low humidity levels, linoleum or laminate can be used for covering. In the dressing room, it is advisable to install the flooring on stands. As a rule, a double floor is used - from rough and finishing flooring, while the rough flooring is treated with special fire protection.

Wall edging

The edging is necessary so that during the washing process water does not flow under the lower crown of the frame and does not lead to rotting of the wooden walls of the bathhouse. However, edging must be done in any case, even if the bathhouse is brick, so that water does not fall directly on the walls.

I made the edging the height of the tile - this is the most optimal. You can make the base higher, but there is no particular point in this.

First, we attach several 2-3 cm thick bars to the wooden walls of the bathhouse to provide a ventilation gap. It is necessary so that the space between the wall of the bathhouse and the inner surface of the flange can dry out during the washing period. We fix the bars vertically according to the height of the future base. We attach pieces of DSP or moisture-resistant plasterboard to the bars, and then glue the tiles onto them. We seal the joint between the flange and the floor with sealant so that water does not flow out beyond the resulting “trough”. We also coat all tile seams with sealant to retain moisture. The top of the plinth is covered with tiles to prevent water from getting behind the wall of the plinth.

Now you can splash around in the sink and pour water onto the floor to the height of an entire tile! And the water will not leak out!

The edging along the walls will allow you to pour water onto the floor to the height of the tiles

The floor design I proposed, firstly, does not absorb moisture and does not cause an unpleasant odor in the sink, secondly, it is as hygienic as possible, thanks to porcelain tiles, and, thirdly, it additionally warms the room with the energy of the electric cable.

I hope my tips will be useful.

Ventilation design

The simplest method of solving the problem of ventilating the space between the rough base and the final finishing of the floor is to create holes to which pipes are connected that lead water out of the washing room.

There is another way to create ventilation - this is the installation of multi-level floors. Therefore, in each room they make a floor structure of different heights. For example, in the washroom the floor surface will be 3 millimeters lower than in the dressing room.

Option one is the most popular among developers, and the order of work is as follows:

- In the corners of the washroom at the base of the floor, holes are left for laying ventilation pipes with a diameter of 5-10 centimeters. The material used to make them may vary.

- Install pipes for ventilation after finishing the walls in the room. Products with a diameter of no more than 5 centimeters can be disguised under the casing. Pipes of a larger cross-section should be installed in bathhouse buildings that are visited more than twice a week. They are mounted in the corners of the room, attached to the surface of the walls using special clamps.

Useful tips

The walls and ceiling of a bathhouse building must be insulated according to the following principles:

- Thermal insulators must be in close contact with the wall surface to reduce the risk of internal moisture and cold air entering.

- A ventilation gap is needed on top of the insulation to dry it.

- All floors and other wooden elements must be treated with an antiseptic composition to prevent premature destruction of the material.

- Materials with a low level of heat and moisture resistance cannot be used in the steam room.

- Insulation materials should be selected from those that do not deform under the influence of moisture and high temperatures and do not emit hazardous chemicals.

Necessary properties of insulation for a bath:

- heat resistance;

- moisture resistance;

- environmental friendliness;

- Fire safety.

Natural insulation materials require special treatment before use. Otherwise, mold, mildew and harmful insects may soon appear. In this case, it is more advisable to use artificial insulation.

Floor installation

The floor in the washing bath must meet several requirements:

- ventilate well and dry quickly;

- freely remove excess moisture from the room;

- be warm, should not create drafts;

The drain must be good

must be durable and not deform during sudden temperature changes.

There are two types of floors in the bathhouse washroom:

- wooden floor;

- concrete floor.

Features of a wooden floor

A wooden floor in a bathhouse is the most convenient covering.

And it is best to use coniferous wood for these purposes:

- pine;

- spruce;

- larch.

Everything is made of wood

This is due to the fact that coniferous wood is the most resistant to moisture.

To install wooden floors in a bathhouse, we will need the following materials:

- sand;

- waterproofing material;

- cement;

- wooden beam (150x150 mm);

- floorboards (35-50 mm);

- impregnation to protect boards.

Wooden floors in the washing area should be multi-layered. This is necessary to ensure its long-term operation and normal functioning.

There are two types of wooden floors:

- A leaky floor is the simplest way to construct a floor. On a concrete base, which is made at a slope, logs are fixed on which the plank floor will be laid. Moreover, the boards of such a floor must be fixed at a certain distance from each other - this is necessary so that water can easily leave the room.

You can do this

Leaking floors, as a rule, are removable - this is necessary for more thorough drying of the floor in the washing compartment of the bathhouse. This method is quite cheap, but has one significant drawback - this type of floor cannot be insulated.

Explanatory diagram

- non-leaking floor. Installation of a non-leaking floor is carried out slightly differently than a leaking floor. Its main feature is that it requires special drainage for water removal and a special ventilation system. After all, a floor that does not leak is made permanent.

Floor diagram

Experts suggest the following method for installing sloping wooden floors:

- Initially, a rough floor covering is prepared, covered with expanded clay chips, and a double waterproofing layer is laid on it (roof felt, roofing felt, polymer insulating sheet);

- then the logs are secured. Moreover, the logs are laid without tilting;

- Thermal insulation material is laid between the joists. This can be polystyrene foam or mineral wool;

We insulate the floor

- bars are placed on top of the joists laid at the base of the floor. The thickness of the bars should decrease towards the drain hole;

- then another layer of waterproofing material is laid on the bars, on top of which tongue and groove floor boards are laid;

- the boards are secured with screws. This will make it easier to dismantle the floor if necessary.

Attention to ventilation

When installing a floor that does not leak, remember the need for ventilation of the underground space. To ensure ventilation, at the time of installing the subfloor, you can make small holes in the floor and insert plastic pipes with a diameter of 5 or 10 cm into them.

Concrete floor

A concrete floor in the bathhouse's washroom is an excellent solution to the problem. It is quite easy to install, it is reliable, durable, and easy to care for. The price of a concrete floor is much lower than the cost of wooden floors.

Concrete poured

However, it has one significant drawback - the concrete floor is cold, and it can be insulated by laying heat-insulating material between two slabs. Installation of a concrete floor requires significant labor costs.

Stages of installing a concrete floor

- preparing the base for laying concrete.

- gravel, crushed stone, broken bricks are laid out on compacted soil. The thickness must be at least 15 cm;

- The gravel area is filled with sand and compacted tightly. Thus, the base is prepared for the first layer of concrete screed;

Don't forget about the drain

Your sauna will be the best

We insulate the steam room

The steam room in the bathhouse requires special attention. After all, it is here that the highest level of moisture and elevated temperature are observed during operation. Therefore, insulation, waterproofing and finishing of this room must be done with special materials.

The ceiling of the steam room is subject to maximum heating during operation (up to 150 °C). Therefore, the question of how to insulate the ceiling of a bathhouse is solved by using materials with high heat resistance.

If there is no attic or attic, insulation is installed in the following order:

- wooden lattice made of timber on the ceiling boards;

- sheathing elements;

- thermal insulation;

- vapor barrier.

If there is an upper room - an attic, an attic - the insulation scheme looks slightly different. A layer of clay at least 2 cm thick is applied to the ceiling boards. This will ensure moisture retention. All small holes, joints between boards, etc. are filled with bulk material. Typically, expanded clay or wood chips are used for this. The thickness of this layer is at least 20 cm.

A box-shaped base of rafter supports is mounted on the ceiling around the chimney. This will provide a gap of 20 cm between the pipe and the heat insulator, required by fire safety. A non-flammable heat insulator such as glass wool or mineral wool is placed inside the box. The main surface of the ceiling is covered with a layer of mineral heat insulator.

general information

A modern Russian bathhouse can consist of several rooms:

- steam rooms;

- shower compartment;

- swimming pool;

- washing department;

- dressing room

In the photo there is a good dressing room

All these rooms are undoubtedly important, but the washing department occupies a special place in a Russian bathhouse.

The washing compartment is the main room of the bathhouse and differs from other rooms in the use of a large amount of water. Here, lovers of Russian baths can take a break from steam treatments. And washing off the sweat from their bodies, those who like to take a steam bath pour water on the floor.

Therefore, special attention should be paid to the installation of the floor in these rooms. The floors in the washing bath should be arranged with special care

Let's take a closer look at methods for installing floors in rooms with high humidity.

Common installation mistakes

Among the adjustment mistakes, let's consider the most common ones:

Lack of thermal insulation. Some owners are trying to reduce costs by installing a thermal insulation layer. As a result, large heat losses occur, the floor takes a long time to warm up and freezes in severe frosts.

The outlet of the taps must be in the place where the water collector is installed, so before pouring the screed you need to make the connection as close as possible to this place.

The lack of heating temperature control leads to the fact that during intensive heating the coolant easily reaches 80–90°C. Naturally, it is simply impossible to walk on such floors. In order to eliminate this problem, you need to install a mixing unit (manifold), which automatically mixes hot and cold water and regulates the temperature. In addition, it allows you to turn off the heating of the bath floor in the summer. Neglecting the mixing unit even for the sake of saving is unjustified - in hot weather, instead of refreshing coolness, you will get warm floors in the bathhouse that are inappropriate for this time of year, and in winter you risk not setting foot in the steam room at all; even your bath slippers will melt.

At least the simplest one, sketched on a checkered piece of paper. Thanks to this, installation work will be completed efficiently, quickly and without much labor.

Many people wonder: is it worth making warm water floors in a bathhouse? Isn’t it easier to build electric heating? Not only is it worth it, but it is also necessary, since they are completely harmless to others, which, alas, cannot be said about infrared heated floors or electric ones.

Yes, electric heating is faster and easier, but installation work must be carried out so carefully, especially in wooden buildings, to avoid a possible fire in the event of a short circuit.

In this regard, water floors are much safer and, despite the complexity of the work, all costs will quickly be recouped by the efficiency of the hydraulic system itself and its high heat transfer.

In any case, the choice of method for arranging a heated floor in a bathhouse always remains with the owner. But, you must admit, it is much more pleasant, especially in the cold season, to visit a bathhouse with warm floors than to step on a cold floor when steamed and hot after a steam room.