Home→Product Catalog→Wind protection and vapor barrier film→Izospan→Reflective insulation Izospan FB, FD, FS, FX (vapor, waterproof)

Sort by: Receipts ↑ | Name | Availability

Izospan FDAvailability: On order Reflective vapor-waterproofing of increased strength |

Izospan FSAvailability: On order Reflective vapor-waterproofing |

Izospan FBAvailability: On order Reflective steam-waterproofing for saunas and baths |

Izospan FX 2 mmAvailability: On order Reflective heat-vapor-waterproofing |

Izospan FX 3 mmAvailability: On order |

Izospan FX 4 mmAvailability: On order |

Izospan FX 5 mmAvailability: On order |

Types of vapor barrier Izospan

Today the following types of Izospan are produced:

- vapor-tight membranes;

- vapor-permeable membranes;

- insulating films with heat-reflecting effect.

The climate in Russia is different in that only a few months of the year the weather is warm, and the rest of the time the temperature inside the house is higher than outside. This leads to the appearance of such a phenomenon as the constant movement of air masses with water molecules in an upward direction.

The main task of vapor barrier is to prevent the penetration of these molecules into the thermal insulation material. There is a huge selection of films on sale for roofing. Each of these products is used in a specific construction field.

One of the main disadvantages of Izospan vapor barrier is that it cannot be used when insulating the roof with inflatable materials - the films stretch greatly and form “pillows”.

Vapor barrier for insulated roofs - characteristics

This product is sold with instructions for use, because each type of this vapor barrier material has its own specific installation work, its own overlap size and its own installation side:

- Izospan B. It is the most economical and at the same time universal material of all those presented on the market. It copes well with its main function, which is to prevent the roofing pie from saturating with water vapor. This material is used for arranging insulated roofs and for creating vapor barriers between floors. It prevents microparticles of the heat insulator from penetrating into the room.

- Izospan C. This type of vapor barrier for double-sided use has a special structure. One side of it is absolutely smooth, and the other, which is an anti-condensation coating, is rough. In essence, this is the same vapor barrier as Izospan B, but this material is denser and can last a long time.

- Izospan D. This is a two-layer membrane with a laminated one-sided polypropylene coating, which can be used both outside and inside the roof. This vapor barrier has high strength. As a rule, Izospan D is used for waterproofing rooms with high air humidity - kitchens, bathrooms, toilets. First, when installing this material, plank flooring is attached to the rafters, the membrane is laid without sagging and securely fixed. Izospan D is mounted on top of the insulation or on the attic side, with the smooth side facing the roof covering.

- Izospan RS and RM . RS film is a three-layer material reinforced with polypropylene mesh or laminate. The basis that holds condensate droplets is a rough surface. Izospan RM is a hydro- and vapor barrier material consisting of three layers, reinforced with polyethylene or laminate.

- Isopans FB, FD, FS, FX . They are part of the newest line of foil-coated four-layer vapor barriers that have the effect of reflecting UV radiation. They not only protect the roofs of buildings from moisture and condensation, but also the attic space from strong heating in hot weather. They are of particular value for homeowners who decide to make the attic a living room, as they allow them to create a comfortable microclimate in it.

At the same time, the characteristics of four-layer foil Izospan differ:

- FB . This material is based on kraft paper, onto which metallized lavsan is applied. Is a sales leader.

- FD . Particularly durable vapor barrier made from woven fabric with a polypropylene base.

- F.S. _ This type of vapor barrier material is made from non-woven polypropylene and covered with metallized tape on top.

- FX . This vapor barrier with a reflective effect is made of polyethylene and metallized film.

Such vapor barrier materials are allowed to be used at temperatures exceeding + 100 degrees. They not only reliably protect the insulation from steam penetration, but also reflect heat into the room. All four types are environmentally friendly and certified.

What is the canvas? ↑

izospana-b-1 izospana-b-2

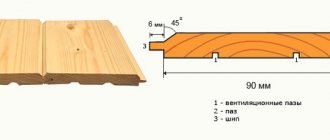

If we compare Izospana with other cheaper analogues of vapor barriers, then it is made not from polyethylene, but from 100% polypropylene. In addition, the material of the panel itself is reinforced and has two layers - smooth (rear) and rough (external).

This structure gives all the advantages: high strength and stability, the ability to remove moisture from the surface, close contact with the insulation.

In the production of Izospan, they adhere to the technology of melting the initial raw materials, followed by rolling and rolling on rollers, forming the residual thickness of the web and its structure.

But, such material has one drawback - its cost is higher in comparison with polyethylene analogues. However, high-quality vapor barrier coatings are well worth their price.

Note It is also worth knowing that although the film contains ultraviolet stabilizers, they do not eliminate the destructive effects of sunlight, but only slow it down. Therefore, the direct influence of UV radiation from the sun on the surface of the material should be excluded!

Vapor barrier materials for non-insulated roofs

A roofing pie made without insulation also requires insulation. Izospan D and DM vapor barriers are suitable for such purposes. Sheets of membranes are fixed across the rafters, starting installation from the ridge assembly. Each sheet must partially cover the other, resulting in the insulation looking like fish scales.

Many consumers are interested in why vapor barrier films are used in some cases and membranes in others. The fact is that all heat-saving materials are produced with closed or open pores. In the first case, the air contained in them does not communicate with the atmosphere, but in the second, this happens.

If heat insulators with open pores are used, then a simple film will be sufficient. In order to prevent the influence of wind on the second side of the insulation, perforated membranes are used, which at the same time allow steam to pass through and can retain water. It is important to ensure natural ventilation through the holes in the ridge.

When the structural structure of the roof is complex, then instead of D and DM products, experts advise purchasing Izospan AQ proff - a professional type of three-layer membrane. It is placed on a heat insulator on the street side as a wind and water barrier that allows steam to pass through.

Foiled penofol for frame housing construction

This article describes the technical characteristics and distinctive features of Penofol insulation. Which can be used for frame house construction, made using wooden house-building technologies or LSTK technologies. Insulation in frame houses is used to insulate the house from external weather conditions. Insulation materials are usually produced in flexible versions, as well as in the form of slabs or rolls. Penofol is available in roll form, which is convenient for insulating corners, roofs and walls of frame structures.

It should be borne in mind that Penofol, due to its small thickness, does not retain heat very well and cannot be used as the only insulation. Penofol is equivalent to stone masonry five centimeters thick.

Penofol - reflective thermal insulation - a new generation of insulation. Unique thermal insulation properties with low thickness.

Penofol is a highly effective vapor and heat insulation based on foamed polyethylene covered with aluminum foil. Penofol - combines the heat-insulating properties of “trapped” air bubbles with the high heat-reflecting ability of pure aluminum (99.4%), thus being a unique product that stops heat in all three ways of its propagation: thermal conductivity, convection and radiation.

Arranging a vapor barrier to cover the attic

To insulate ceilings, many types of Izospan membranes are used, including A, AS, AM. They are characterized by water resistance and the ability to not allow steam to pass through.

In the attic, Izospan B is laid out with the rough surface downwards between the finishing floor covering and the rough ceiling or with the same side on top along the floor beams above the heat-insulating material. In this case, it is imperative to create an air gap measuring 3–5 centimeters. Places where the vapor barrier material adjoins other surfaces must be taped with tape.

When arranging a conventional attic structure, you can use Izospan FD, FS, FX products. It refers, as mentioned earlier, to insulating products in which the functions of vapor barrier are combined with the reflection of heat flow. They should be laid between the ceiling finish and its rough surface, maintaining a 15-20 centimeter overlap or end-to-end if Izospan FX is used.

The main thing in this is to correctly lay these materials, namely with the reflective surface inside the heated room and overlap the canvases using metallized Izospan SL tape. In this case, you should not forget about a gap of 4–5 centimeters between the finishing materials and the reflective surface. The joints between the vapor barrier and concrete or wooden surfaces must be taped with Izospan ML proff tape.

Laying method

- It is necessary to lay any vapor barrier on any type of roof after laying the insulation. It can be placed under corrugated sheets.

- Waterproofing can be laid in any direction.

- If the material is laid along the rafters, the overlap should be directly at the level of the rafters. At these same points of contact, the material must be carefully fixed.

- Where it comes into contact with water pipes that may pass through the roof, the membrane is folded down, wrapped around the pipes and carefully taped.

- Some types of materials require a mandatory air gap. To create this space, thin wooden planks are enough. They are located at a distance of about 50 cm from each other.

Vapor barrier for flat roofs

If a conventional flat roof is being insulated, a vapor barrier is installed under the thermal insulation material on the base. Its main function is to prevent condensation and moisture from passing through.

Izospan RM and D are most suitable for vapor barrier of this type of roof. The difference between these materials is that Izospan D contains two layers, and Izospan RM contains three, and at the same time it has a more dense and durable structure. This type of vapor barrier is indispensable in cases where mistakes were made when arranging the roof or its base is not airtight enough.

Benefits of use

Insulating materials, where water-repellent material is combined with foil, have many advantages, which is why they are in high demand among craftsmen. These include:

- Minimum thickness. Laying does not affect the thickness of the roof pie. If materials with anti-condensation properties are used, then it is not necessary to install a distance gap.

- Lightness. This installation will not affect the weight of the structure. Therefore, there will be no need to carry out additional actions to strengthen the foundation.

- Flexibility. Installation is easy, even if you have to lay the material on complex forms. You can easily go around concave and convex corners, various rounded surfaces.

- Environmental Safety. Vapor barrier films are made from materials that are not harmful to human health or the environment.

- Manufacturability. The sheets are easy to cut with regular scissors, or you can use a construction knife.

- Zero porosity. Vapor barrier does not absorb moisture. Long-term use, even in a damp room, will not cause the foil to rot.

- Multifunctionality. The same film can be used to protect several adjacent structures, creating a continuous sealed barrier.

Assortment of tapes for Izospan installation

To ensure proper installation of vapor barriers, adhesive tapes from the same brand should be used. Most of these products are double-sided tape. Working with them is quite simple.

The following types of products are produced:

- Izospan SL

is a vapor and waterproofing double-sided tape - sealant, which is secured with metal strips. - Izospan KL

is a single-sided tape with a metallized coating. - Izospan ML proff

is a super-adhesive single-sided fiber-reinforced tape. Its difference from similar products is the presence of increased adhesion. The tape is used to seal vapor barrier materials on various surfaces, including brick, metal, etc.

If you want to purchase ordinary products instead of branded products, you need to remember that such adhesive tape can withstand no more than three days in the heat or severe frosts.

Installation technology of isospan vapor barrier

The sequence of actions when laying Izospan using branded tapes:

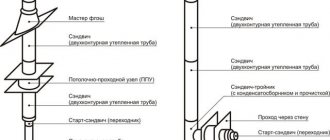

- First of all, a frame is assembled from boards, timber, slats, and plywood.

- The prepared structure is sheathed with wind protection, paying special attention to the nodes located near the pipes.

- Mineral or stone wool is laid between the rafters, the height of which should be 4–5 centimeters less than the height of the rafters.

- After completing the installation of insulation, all gaps, cracks and gaps should be foamed. Next, you need to make sure that there are no conditions for the appearance of cold bridges.

- Now you can start installing a vapor barrier. First, sheets of material are spread on the insulation. The film is attached to the rafters without tension, with a slight sag of up to 2 centimeters, so that it does not tear when the temperature changes.

- A strip of fabric is glued and the protective layer is torn off. When passing through a place where the integrity of the roof is compromised (window opening), you need to cut a hole and attach the material with double-sided isospan tape.

- Press the next sheet of Izospan on top and smooth it out. If there are two strips of vapor barrier, two tapes are glued onto them for reliability. Metallized adhesive tape Izospan FL is used for gluing the joints of several vapor barrier layers on top.

- On the other side of the heat-insulating material, a wind barrier is pulled directly over the roofing pie onto the rafters and secured with counter-lattice bars.

- They begin to install the roofing covering, leaving an air gap between it and the top film. These vents should be opened at windows and ridge vents to ensure free air movement.

- From the inside, the vapor barrier is covered with finishing.

During installation, it is necessary to ensure that dust does not collect on the vapor barrier, otherwise the Izospan tape will not adhere well.

At the end of the work, an inspection is carried out to make sure that the tape adheres to the vapor barrier tightly and with uniform tension.

Application

Vapor barrier membranes are being used more and more often today. They have high-quality indicators of hydro- and wind protection. This material is used today for insulating various surfaces.

Sloping roofs

It is worth paying attention that it is not recommended to cover flat surfaces with them, as this will lead to the accumulation of moisture and minimize the protective properties.

Walls. The membrane can be used both for ordinary standard buildings made of brick or aerated concrete, and for frame structures

It is not advisable to use the material inside baths or saunas. This is due to the fact that the substance is not able to withstand constantly high temperatures.

Attic and interfloor ceilings. With the help of waterproofing films, it is easy to ensure optimal vapor exchange between several buildings.

Installation of such films is not difficult, which allows you to do it yourself. Before laying the membrane, you should first stock up on the following auxiliary tools:

- stapler and staples - their size is selected individually depending on the location of the membrane;

- scissors – you can also use a knife or other cutting tools. The main thing is that they can cut the film well;

- a hammer and nails are used to nail down the wood slats that will act as a frame for the exterior finishing materials. You can also use other types of hardware (for example, self-tapping screws);

- tape measure and construction tape.

When laying vapor barrier membranes, you should follow a few simple recommendations:

- The film should be spread over the covering without stretching it. If this is a roof sheathing, then even a slight sagging is allowed. Experts recommend placing the film with the red side facing the insulation. The outer white layer is more durable and better able to withstand external loads. Sometimes colors may vary, so please check the product instructions directly for the correct side.

- All sheets overlap up to 15 cm. The joints between them must be additionally insulated using special tape. This will prevent water from penetrating into the cracks and will create more reliable moisture protection. If installation is carried out on walls, then the substance should be joined with an overlap of up to 10 cm.

- The membrane is fixed to the frame with staples using a construction stapler. It is advisable to carry out all operations sequentially, controlling the tension and position of the sheet relative to the base. If the design allows, then wooden counter-battens can be used as additional fasteners. They are placed directly along the film joints.

- When the film is fixed, the sheathing slats are nailed to it. Heat-insulating materials are placed in the cells formed between them. You should not use membranes without insulation, as this will give practically no result. It is advisable to leave a small air gap between these substances, which speeds up the removal of steam accumulated inside.

How to identify a fake Izospan

There are cases when, when working with Izospan, consumers remain dissatisfied with the quality of this material because they were dealing with a counterfeit of this product.

To prevent this from happening, you need to pay attention to the following:

- The packaging must be branded. It is a polyethylene sleeve with double-sided printing and a special color.

- Inside each roll there are instructions for use and a leaflet that lists all products.

- Inside the sleeve on which the material is wound, you can see the Hexa logo.

- At one of the ends of the roll, on top of the marking tape, there is a label with the batch number, release date and number of the product packager.

- All ends of the roll are sealed with tape with the letter designation of a specific product.

A truly high-quality vapor barrier will help make the roof reliable and durable.