A bathhouse is a healthy procedure and an opportunity to have a good time with friends and loved ones. Many of us strive to build a bathhouse on a summer cottage or personal plot. Traditionally, timber or logs were used to build a summer house. However, modern materials are confidently replacing wood. Today there are many types of building materials on the market - a variety of concrete blocks, the quality of which is not inferior to natural wood, and the cost is significantly lower. Therefore, the question arises of which blocks to use for the construction of a bathhouse in order to ensure the optimal balance between price and quality of construction.

Aerated concrete

Aerated concrete is cheaper than wood; it is an excellent alternative to wooden buildings. Low specific density reduces the load on the foundation. Aerated concrete can be sawed with a regular hacksaw, drilled, cut, which indicates the convenience of installation on your own. Excellent thermal insulation characteristics eliminate the need for additional insulation. This artificial stone is resistant to mold and mildew and is environmentally friendly. Walls made of aerated concrete blocks will last almost half a century. The material does not shrink, so no time is required to proceed to finishing work.

Bathhouse made of aerated concrete

The only drawback of aerated concrete is its hygroscopicity. Therefore, good waterproofing and careful wall finishing are required.

Bake

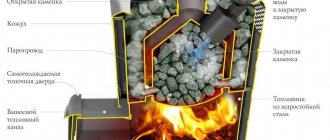

A good stove eliminates the issue of fuel and helps maintain the temperature for almost three days, which completely dries out the bathhouse. And the hot water will boil in a separate remote tank, and not in the steam room.

For example, you can choose a stove with an attached heat exchanger. This design is suitable for covering with bricks, which will serve as a screen. The stove is heated outside in advance to burn through the paint and eliminate the smell in the bathhouse.

For traction they install a meter-long pipe, this is enough, but there may be a little soot. Since the stove foundation is connected to the bathhouse foundation, reinforcement is done when pouring.

The masonry is made with cement to protect the waterproofing, double roofing material is laid, and brick is placed on it. The stove is raised from the foundation 20 cm above the floor. The sand is moistened and compacted to prevent settling.

Take a brick and a stove mixture, dry the mixture and add water. The top rows are sealed with mortar. Immediately install convection doors so that they properly draw air from the dressing room into the steam room.

It is important to carefully bring the stove into the room (a couple of people will be required) and install it in the exact place. A T-shaped branch is placed on top to mount the pipe, which will also stand on the foundation.

Next, hang a heat exchanger from corners, bends, couplings, attach it to the furnace, wrapping the threads with flax soaked in sealant. The masonry is made up to the top of the firebox, a corner is placed with an overlap on the bricks and a gap of 2 cm is left. The front version is almost ready, the contact of the masonry with the stove should be minimal.

Then we cover the entire exchanger with bricks and install pipes to the tank. The holes are covered with steel disks. In the washing room the masonry is done up to the ceiling. They finish the façade work and make a fireplace mantel to redirect hot air.

The last step is to make connections from the pipes to the tank. Prepare the roof for inserting the pipe, drill the ceiling with a margin of 1 cm, lay the pipe and do the masonry at the top. Clean the pipe and coat it with protective varnish three times. Cover the space around the pipe with insulating material.

Now you know how to properly build a bathhouse with your own hands. Calculate all the options, check the availability of materials in the store, make the bathhouse of your dreams for modest money. Also look at DIY bath options and photo projects - they will inspire you to work.

Gas silicate

Gas silicate building blocks are used both for the construction of low buildings and as insulation. In both cases, D500 grade material is suitable. Its main characteristics:

- not flammable;

- resistant to rotting;

- not subject to fungal attack.

The basis for the gas silicate should be a strip foundation. A movable one will not work, since the blocks may become deformed when the ground moves.

Another condition is a waterproofed base, rising 50 cm above the ground, which will not allow porous building blocks to collapse during seasonal temperature changes.

To preserve heat, the masonry is fixed with a special adhesive solution. Strength is enhanced with reinforcing mesh or metal rods. For wind resistance, a monolithic belt with anchors is installed under the roof.

To make the blocks last longer, the bathhouse box is lined with waterproofing on the outside and thermally insulated on the inside. For finishing, mineral plaster for aerated concrete is used.

The better to sheathe

The bathhouse is lined inside and out, but not always. Sheathing or finishing is vital for the frame and concrete; interior is necessary for brick. Log houses may only need caulking and prevention of cracking with oil, for example, but sometimes they are also insulated and lined from the inside with clapboard (usually not because of a good life). See the section on bath finishing materials.

The inside of the bathhouse is finished in the vast majority of cases with clapboard or regular boards (edged or unedged). So there is only one contender for the title of “best material for a bathhouse” - wood. And we are confident that you will agree with us. Although there are options, more about them here.

- Practical interior and exterior decoration of a bathhouse made of foam blocks. How to finish it so that the eye is pleased?

- Finishing with unedged boards in the bathhouse

- Let's figure out how to line a bathhouse with clapboard

- All about covering a steam room: what kind of lining, how to properly cover a steam room in a bathhouse

But with insulation, it’s not so simple.

What insulation to use

Insulation materials come in the form of sheets, rolls or bulk. The first include expanded polystyrene (foam plastic, Penoplex), mineral wool, foamed polyethylene with or without foil, etc. Bulk materials are expanded clay, vermiculite, perlite, ecowool.

Bulk ones are easier to use for floors, but they can also be used for insulating walls. In this case, the bulk material needs voids into which it is poured or blown under pressure. Ecowool has the ability to be applied to the wall while wet.

Sheets and rolls are also used for walls and ceilings.

As for the best, we will say this: it is advisable to use expanded polystyrene in a bathhouse only for insulating the floors of the first floor. They are flammable, harmful and undesirable. However, they are also suitable outside the steam room. But in the steam room this is taboo.

Bulk ones are good for floors, this has already been said.

Basalt wool for baths

In general, we have thought about mineral wool more than once and eventually came to the conclusion that, despite all its shortcomings, it is still the optimal material for insulating a bathhouse. Its disadvantages are known: it becomes saturated with moisture and ceases to insulate, therefore it needs steam and waterproofing (we have written a lot about them, enter these words at the very top of the page in the site search, you will find a lot of materials).

Here we did not take a vote, since different structural parts of the bathhouse (foundation, floor, walls, ceiling, roof) have different requirements for insulation. We recommend that you familiarize yourself with our materials on this topic:

- Basalt insulation for a bath or natural? What insulation for a bath is better? Review of the most popular

- Which insulation to choose for a bathhouse on the inside walls: with or without foil? And is it even needed inside the bathhouse?

- Are we installing a log house or timber? Interventional insulation for a bathhouse: which one to choose, which is better, natural or modern?

- Should I insulate the bathhouse ceiling with clay and sawdust or sawdust and cement? Which is better and is there a difference?

- Let's look at it in detail: how to insulate a steam room in a bathhouse

- Insulating the walls of a frame bath: the right “pie”

- Choosing which insulation to use for a bath in a steam room: so that the steam room is hot and environmentally friendly

- We insulate a bathhouse from inside blocks: foam blocks, expanded clay concrete, cinder blocks, gas silicate. What do they have in common and what are the differences?

- About insulating a bathhouse under the lining

- How to insulate a bathhouse from foam blocks: inside and out. Don't let the walls crumble

Exterior finishing

The outside of the bathhouse can be finished in different ways depending on the original wall material. If it is concrete, then you can plaster it. The same goes for brick, but it is usually left “as is”.

You can make siding - this is a broad concept that also includes wood trim, for example, “American” clapboard, which, in general, gave rise to all sidings. The tree can be either an ordinary board, which is sewn in a herringbone pattern, or a plank, which is sewn onto the frame.

In addition, there are sidings made of vinyl and metal, cement, imitating stone and wood. In general, there are many options for covering a bathhouse.

But we believe that metal siding for a bathhouse is unnecessary.

High-quality plastic will not be cheap, although truly high-quality material has such characteristics that it can last for many years. But the bathhouse is a risky structure, and the plastic burns and releases poisons.

As for cement siding, think for yourself. From the set of options for what material is best to cover a bathhouse, this one does not seem very successful. Maybe the basement one - for covering the foundation.

So we vote for wood paneling. What will you vote for?

Loading …

Foam concrete

To build a bathhouse, foam blocks are used - a material suitable for structures with high humidity levels. Its qualities:

- strength (resistance to compression);

- minimum density;

- wear resistance;

- good heat and sound insulation.

Foam concrete bath

Foam concrete is lightweight, so even one person can install it. When building a bathhouse, you will not need any special equipment. Thanks to the many pores in the structure, extraneous sounds do not penetrate through the foam concrete walls. The thermal conductivity coefficient is almost the same as that of wood, and in comparison with brick it is three times lower.

Gas silicate pros and cons

If you add a special substance to the dough of lime and water, which reacts with the lime to produce gas, then when it hardens you will get a gas silicate, one of the types of cellular stone-like material.

The gas generator is hydrogen peroxide or aluminum powder, the resulting gas is hydrogen. The gas silicate block hardens in an autoclave.

Cellular blocks are recommended only for the walls of the above-ground parts of the building, excluding the basement, for rooms with a relative air humidity of 75%.

Information. Gas-ash silicates are not suitable for baths - their water absorption is too high.

The density of the structural gas silicate block is 0.1–1.2 t/m3, it does not require thermal insulation. The frost resistance of silicate concrete with a cellular structure reaches 100 cycles.

Cinder blocks

One of the most common materials for bath construction. It is inexpensive, lightweight, can be of different sizes, and is therefore easy to install.

Cinder block is resistant to high temperatures, mold, and provides the building with good thermal insulation due to its porous structure.

The disadvantages include toxicity and high moisture absorption. But subject to additional protective measures, a cinder block bathhouse will last for a long time without harm to health.

Building dimensions

What size bathhouse is best to choose for construction? Let's start with the height of the ceilings. To make it comfortable to move around in the room, even if your family members are of average height, you should not make the walls lower than 2.1 m. After all, it is necessary to take into account that the shelves in the steam room are made at a level of 1 m from the floor. A person should sit on it without bending over. Plus, you need to leave free space under the ceiling for the sweep of the broom. You should not make the ceiling higher - it will take longer to heat the room.

Now let's talk about the length and width of the building. As a rule, a bathhouse consists of 3 rooms: a dressing room, where you can undress and relax after the bath, the steam room itself, and a sink. According to the standard, the ratio of such premises is 2:1.5:1. That is, the dressing room is made a little larger.

Steam room dimensions

The size of the sink should be sufficient for at least a couple of people to sit comfortably on benches with basins. There is 1 sq.m. per person. m of free space. It is necessary to leave free space for containers with water. If desired, a shower room or a small pool can be made.

The dimensions of the steam room are minimal. If several people will visit the bathhouse at the same time, then each of them must be allocated 1.5 m2.

The width of the steam room depends on the size of the shelf. Some people like to steam while sitting. In this case, it is enough to build a bench 40-45 cm long. For those who like to lie in the steam room, its length is 95 cm. You can use the space rationally if you build shelves in the letter “L”. In this case, even small benches can accommodate two people. You can make a couple of shelves on opposite walls. For free passage between them, you must leave 80 cm.

The dimensions of the steam room itself depend not only on the size of the shelf, but also on the type of oven. It is also necessary to take into account the recommended distance from it to combustible structures (wall cladding). This is done for fire safety purposes.

You should also focus on the length of the logs. As a rule, it is 6 m.

Landscaping your site with your own hands – (130+ Photos of ideas & Videos) + Reviews

Arbolite

When asked which blocks are best for a bathhouse, many will answer: wood concrete. The material, which contains cement and wood chips, has excellent thermal insulation. Unlike timber and wood, it does not rot or burn.

In terms of thermal conductivity, wood concrete has better performance than gas and foam concrete.

Arbolite bathhouse

The light weight of the material makes it possible not to install the blocks on a massive foundation. When laying walls, wood concrete is moistened with water. It has low hygroscopicity - if you protect the blocks from direct contact with water, moisture from the street will not penetrate into the room. It is enough to make a good exterior finish - plaster or cladding with any material.

Which blocks are best to use for a bath?

Practice shows that virtually all blocks are suitable for the construction of a small building - each homeowner determines which material to use for a bathhouse based on his own priorities. You can use cheap gas silicate and aerated concrete blocks, as well as sawdust concrete and wood concrete blocks. At the same time, it will not be possible to save significantly on building materials, since due to increased hygroscopicity, the construction will require additional costs for high-quality waterproofing.

When considering other materials, you should determine which block is better for building a bathhouse based on its quality characteristics. It is necessary to clearly decide which indicators are the main ones and which are secondary. For example, blocks made of cellular concrete may crack during shrinkage. This disadvantage is eliminated by the inclusion of plasticizers in the composition. Thanks to this, polystyrene concrete blocks practically do not shrink, but the material has low vapor permeability, which is considered a significant disadvantage for a bathhouse.

Many homeowners, when choosing which blocks are best to build a bathhouse from, give preference to expanded clay concrete blocks. Expanded clay grains, produced by firing expanded clay, have a sintered shell and a porous core. This material structure is considered the most suitable for a bathhouse - bathhouse walls built from expanded clay concrete will retain heat well while allowing steam to pass through.

If you find it difficult to determine on your own which blocks are best to build a bathhouse from, please contact our company. Managers of Vertical Group LLC will advise you, telling you in detail about the properties of each material, and recommend the best option.

Expanded clay concrete

One standard block of expanded clay concrete is much larger in size than brick. Such blocks are convenient to cut and drill, easy and quick to lay - a bathhouse can be erected in four days.

Expanded clay does not dampen and does not succumb to fungus. In its production, environmentally friendly compounds are used, so the walls will not emit harmful substances when heated.

One of the disadvantages is hygroscopicity. However, the problem can be easily solved by installing a wind and waterproof membrane along the outer perimeter.

Lightweight concrete with coarse porous aggregate made from recycled materials

Any mineral filler or binder of a building material is subject to an assessment of its radioactivity, but the radiation characteristics of components obtained from industrial waste are especially important.

The effective specific activity of natural radionuclides of slag pumice - molten, expanded and rapidly cooled metallurgical slag - must be checked. The same applies to agloporite - a sintered raw material mixture made from clay rocks and fuel waste.

For the construction of residential buildings, especially bathhouses, you should not choose a material whose composition is not fully known. On the other hand, the use of industrial by-products reduces the cost of building materials and is beneficial for nature.

You can combine concern for the environment with your own safety by purchasing blocks from trusted manufacturers.

Technology for the production of foam compositions

A distinctive feature of production is the ability to carry out activities directly on the construction site, which eliminates the need for transportation. Manufacturing proceeds as follows:

Laying features also affect some parameters that can be compared: gas blocks are placed on glue, and foam blocks are placed on cheaper cement mortar

- sand is poured into the concrete mixer, cement is gradually added;

- the components are mixed evenly until smooth;

- the required amount of water is added;

- the components are remixed;

- in parallel, foam is prepared in the foam generator;

- foam is introduced into the concrete composition;

- the resulting mass is mixed and poured into molds.

The products are sent to a warehouse, where they settle and acquire operational characteristics for 28 days. The process is simple, does not require the use of complex equipment, everything depends solely on maintaining proportions.

High-density blocks are recommended for use in the manufacture of frames and load-bearing walls

Requirements for use

If you decide to use foam concrete or aerated concrete to build a house, then you should take into account a number of specific requirements for the use of these materials.

- The foundation must be as strong as possible, despite the fact that such block materials are light in weight and have a porous structure.

- The horizontal surface of the foundation structure must be covered with waterproofing.

- Drilling holes, cutting, and gating blocks with cells is carried out in the same way. For cutting, a hand saw is used, holes are drilled with a drill and core drills.

- Foam block materials can be laid on cement or special glue. Aerated concrete is installed only with glue.

- Stop work on the house if necessary. Preserve the object for the winter. Nothing will happen to the foam concrete walls during this time, but aerated concrete should be covered with a waterproof film.

- Make sure that the fasteners stay in place on both materials. It is advisable to use special screws, anchors and hardware.

- To cover such block facades, you need to use special plasters, lining, siding, stone and other similar materials. There are no serious restrictions.

- Sometimes it is not necessary to insulate houses made of porous blocks. If this is necessary, then you need to turn to insulation. It is recommended to use basalt wool.

- Not every plaster is suitable for finishing such block bases. For foam blocks and gas blocks, you need to purchase compounds that will maintain their vapor permeability.

Manufacturing of gas blocks

The methods for producing aerated concrete and gas silicate are similar. They consist of mixing ingredients, molding and hardening. The only difference is in the binding components.

| Components | Aerated concrete | Gas silicate |

| Sand, water | + | + |

| Lime | + | — |

| Metallic aluminum | — | + |

| Cement | + | + |

The table shows that lime is a gas-forming agent for aerated concrete, and aluminum powder is a gas-forming agent for silicate block.

All components of aerated blocks must be crushed as much as possible. The smaller the particles, the stronger the concrete.

As mentioned above, blocks are autoclaved and non-autoclaved. The goal of the autoclave method is to quickly gain strength and save time for hardening. If we talk about foam concrete, it also saves cement.

After autoclave treatment, the monolith is cut with a special string into blocks of the required size. Place on pallets and leave for 28 days to dry completely. After this, the blocks are ready for construction.

Building a foundation with your own hands

A bathhouse in a country house is a capital structure, so it is impossible to do without a reliable foundation. Let's look at how to do this with step-by-step instructions.

Which is better

The best option is a shallow strip foundation. You can, of course, use a monolithic slab or a pile foundation, but in this case it will simply be a waste of money.

How to choose the right type of foundation:

How to build

Required tool:

- concrete mixer or container for mixing mortar;

- welding inverter;

- hammer;

- bayonet shovel;

- building level;

- roulette;

- angle grinder (“grinder”);

- Master OK;

- hacksaw;

- rule;

- scrap;

- axe.

Example of a project with an attic and dimensions

You will also need consumables: cutting wheels, electrodes (1.8 mm), nails (60–80 mm).

Click to enlarge

How to build a foundation: step by step

The foundation installation process step by step:

- Clear the area of everything unnecessary, level it, mark the perimeter of the bathhouse using wooden stakes.

- Dig a pit around the entire perimeter of the future bathhouse, 50–60 cm deep and 30–35 cm wide.

- Stick steel pins (rebar) into the corners of the foundation and tie a thick thread to them.

- Using a level, accurately mark the upper horizontal line of the foundation (the thread will serve as a visual boundary).

- Manufacture and weld a steel frame from reinforcement with a diameter of 10–12 mm. It will be enough to place three rows of reinforcement at the top and bottom so that the total height of the foundation is 70 cm. For vertical elements, thinner reinforcement can be used, the step between them should be 1.5 m.

- Put together formwork from boards 25 cm wide around the entire perimeter. In the washing room, provide a hole for the sewer drain in advance by placing a receiving pipe with a diameter of 100 mm.

- Prepare concrete mortar by mixing cement with OPGS in a ratio of 1 to 4.

- Pour the solution into the formwork, align the top edge using the rule according to the level of the tensioned thread.

- Cover the foundation with a tarpaulin or thick burlap, take a break from working until the concrete has completely dried (14–21 days, depending on weather conditions).

A beautiful and elegant building that will decorate your site

At the stage of pouring the base of the bathhouse, a foundation for the bathhouse stove can be constructed in a similar way if it is planned to be built of brick. We also recommend that you familiarize yourself with the projects of brick baths.

The process of constructing walls from blocks is no different from similar actions when using ordinary bricks. However, due to the fact that the dimensions of the foam blocks are larger, the work goes faster. The best option for building walls is M25 blocks.

Features of roof construction

The roof is another important stage in the construction of a new bathhouse

If we consider many projects, it immediately becomes clear that the best option for a bathhouse would be a gable rafter roof.

You can build it according to the following scheme:

- Let's start by laying the mauerlat on the longitudinal walls, and the timber should be at least 18 cm thick. It is attached to special anchor bolts;

- On the ground, we begin assembling the rafter template. To do this, take a couple of boards and connect them with their edges so that you get “scissors” fastened together with nails. The free edges should be placed on the base and a suitable roof slope should be selected - then the edges should be fastened together with a transverse strip. The entire resulting structure is securely scrolled with self-tapping screws in order to avoid breaking the angle;

- Next, you should attach the finished template to the beams measuring 15x50 cm and mark with a pencil where exactly the corner should be cut;

- After all the above procedures, you can safely begin cutting out the rafters, fastening them together with self-tapping screws, and at the crossing points, 3 to 5 screws are screwed in for strength;

- Now, we lift the finished rafter frame onto the roof and install it. Connections to the Mauerlat should be marked by notches, metal brackets or overlays;

- In exactly the same way we make the next rafter frame and install it in place. After this, we stretch the cord between the frames, secure the trusses with special supports and place them at an angle;

- Using the same scheme, we install all the frames and fasten them to the roof in increments of 50 cm, checking the distance with a regular cord;

- Next, we prepare the sheathing - for this we will need 10x40 cm boards, which you can easily fasten to the rafters with nails or self-tapping screws. Moreover, the step must be taken so that the insulation does not fall between the boards;

- Now we start making the rough ceiling of the bathhouse - we take 25 mm boards (thick) and fasten them between the rafters. We lay foam plastic (about 19 cm thick) on top of them and cover the top with the finished floor of the attic. At the same time, do not forget to install ventilation in the ceiling by making two small holes;

- The final stage is to lay roofing material on the roof of the bathhouse and nail the ridge part. Don't forget about the galvanized collar that goes around the chimney.

Objective conclusions

Considering the characteristics of the material, the following can be revealed:

- both the gas block and the foam block require a solid foundation;

- according to most characteristics, autoclaved aerated concrete and factory foam concrete are practically not inferior to each other;

- with equal density, the strength of aerated concrete is slightly higher, which justifies its use in the construction of load-bearing walls, although for experienced builders, monolithic foam concrete can be an alternative;

- the costs of constructing an object using foam concrete are somewhat lower, although this is not a critical indicator;

- foam concrete will have to be insulated, and aerated concrete requires the installation of ventilated facades;

- the craftsman should take into account the construction conditions and, based on this, choose the material.

Description of material

Foam blocks are artificial stones of regular shape made from foam concrete. This material, also called cellular concrete, is created from standard components - sand, cement and water, but with the addition of foaming agents.

The properties and price of foam concrete largely depend on the type of foaming agent, which can be synthetic or organic.

- Synthetic foaming agents are easy to produce and inexpensive, but they negatively affect the quality, strength and fire resistance of foam blocks.

- Organic (protein) foaming agents are created on the basis of natural raw materials and are an environmentally friendly product with no hazard class at all. Foam blocks made with their use are of high quality and strength due to the formation of a thicker interpore wall.

Protein foaming agent

Foam concrete structure

There are two ways to form blocks:

- Pouring the finished mixture into standard size molds;

- Cutting a monolithic cellular slab into bars.

Sources

- https://moydomik.net/materialy/stenovye/377-penobeton-gazobeton-chto-luchshe.html

- https://blog.brigada174.ru/gazobeton-ili-penobeton-chto-vybrat-dlja-stroitelstva-doma-sravnenie-tehnologii-proizvodstva-i-harakteristik-materialov/

- https://hozsektor.ru/dom-iz-penoblokov-svoimi-rukami-podrobnaya-tehnologiya-stroitelstva

- https://m-strana.ru/articles/stroitelstvo-doma-iz-penoblokov/

- https://kblok.ru/dom-iz-penoblokov-svoimi-rukami

- https://moydomik.net/doma/kirpichnyy-dom/360-stroitelstvo-doma-iz-penoblokov.html

- https://postroimdomsami.ru/stroim-dom/doma-iz-penoblokov.html

Insulation

Wall insulation

Upon completion of the construction of the bathhouse, mandatory insulation of its walls from the inside is carried out

In this case, special attention should be paid to the steam room, for the thermal insulation of which a special protective structure is used to prevent heat leakage through the walls

Let us briefly describe how to make such a protective shell. Note that such thermal insulation requires sequential installation of the following elements:

lathing with increments along the width of the insulation boards; the insulation itself, placed in the niches of the sheathing; special heat-reflecting foil, during installation of which special attention is paid to insulating the joints, since they must overlap and be additionally glued. (Thermal insulation of the floor should overlap the walls by about 20 cm; in this case, the elements of the wall “pie” are located on top of it).

You can watch a video on the issue we are considering at the end of the article.

You can watch a video on the issue we are considering at the end of the article.

What's better?

On construction forums, these materials have their fans and opponents.

The negative is often associated with the purchase of cheap, low-quality material produced using artisanal technology (moulded (cassette) foam block and non-autoclaved gas block).

Experienced builders advise purchasing certified material from large manufacturers and following the technology.

Many people are alarmed by the presence of aluminum powder in their composition, which is why they are considered ideal for non-residential outbuildings.

Due to their high hygroscopicity, gas blocks are not suitable for internal partitions in bathrooms, showers and toilets. For the same reason, they are not chosen for the construction of a bathhouse.

For a private home, the most successful option is a combination of gas blocks and foam blocks. The former are used for external walls, and the latter for the construction of interior partitions.

Foam blocks

To understand which material is better, you should compare foam block and gas block according to several parameters:

Structure. Foam blocks have large and closed cells with weak water absorption. Their surface is gray. Gas silicate blocks have smaller pores. They have weaker thermal insulation and require additional finishing.

Strength characteristics. Aerated concrete blocks are less dense (200-600 kg/cube) than foam concrete blocks (300-1600 kg/cube). Despite this, foam concrete is inferior to aerated concrete, since its structure is heterogeneous.

Frost resistance. Autoclaved aerated concrete blocks are more frost-resistant and vapor-permeable than other similar materials.

Features of application. Cellular foam concrete is used in low-rise construction. It is also used in the construction of monolithic buildings (here it is used as an additional insulating layer). Aerated concrete materials are used as the main structural and thermal insulation materials. Houses of varying complexity are built from them.

Production. It is much easier to run into low-quality foam concrete than poor aerated concrete. This is due to the fact that the former is often made at home, while the process of creating aerated concrete materials is more high-tech and is often carried out in factory conditions.

Price. Price is the most obvious difference between foam blocks and gas blocks. The latter will cost more, since foam concrete blocks are made from cheap raw materials.

Soundproofing. Foam concrete blocks have better soundproofing characteristics than aerated concrete options.

Life time. On average, foam concrete lasts no more than 35 years, and aerated concrete – more than 60 years

This is another important difference that needs to be taken into account when choosing the right material.

Shrinkage. The degree of shrinkage of foam blocks is greater than this parameter of gas silicate materials

It is 2.4 (and aerated concrete - 0.6).

Gas blocks

It is not so difficult to distinguish aerated concrete from foam concrete

Just pay attention to their surfaces

Foam blocks are smooth, and gas blocks are slightly rough. It is more difficult to say with confidence which building material is better, since both have their pros and cons.

However, you need to take into account the opinion of experts who claim that gas blocks are stronger and their frost-resistant characteristics are better. As for foam blocks, they are warmer and cheaper.

We must not forget that low-quality foam concrete is more common than second-grade aerated concrete, as evidenced by reviews from many consumers. Be that as it may, the choice remains with the buyer.

Finishing

Finishing is necessary both externally and internally.

Insulation from outside

If you do not do external finishing, the walls will simply be blown through. So you need to at least prime (with Ceresit ST-17 primer), and then plaster (ST-24) with a layer a little more than half a centimeter thick. You can continue finishing after installing doors and windows. Since aerated concrete is a fragile structure, the frames should be wide and attached to the concrete with anchor bolts as large an area as possible, and caulked with jute or tow. More complex external insulation consists of many elements that are attached on top of the sheathing made. The prepared facade can be covered with plastic siding or decorative plaster.

Insulation of aerated concrete from the outside

Insulation inside

Craftsmen advise covering the steam room and the bathhouse as a whole with foam glass tiles - simply placing them on glue. It is heat-resistant and has low thermal conductivity.

Foam glass is laid like tiles

Then the walls can simply be covered with clapboard.

Covering a block bathhouse with clapboard

A “warm floor” is laid on the floors, and tiles are placed on it.

Warm floor under tiles

Important! Before interior finishing work, you need to install all electrical cables and install taps for the water supply system and drains for the sewerage system.

After laying the tiles, ladders are installed.

Tile with ladder

Let's assume that we have overcome all the difficulties and our bathhouse is ready.

How is foam concrete made?

Foam concrete blocks are manufactured using various recipes depending on the required density of the product, which ranges from 400 to 1200 kg/m³. For all recipe options, the main ingredients are:

- fine sand;

- cement M500;

- foaming agent;

- water for foam and solution.

Foam blocks are easier to manufacture

For mixtures with increased density, the proportion of cement and sand is 1:3. In large-scale production, laboratory control methods are used to adjust the ratio of components and clarify proportions.

To produce foam concrete products, prepare the following equipment:

- concrete mixer;

- sifting devices;

- water supply lines;

- steam generators;

- formwork and set of forms;

- buckets and shovels;

- control and measuring instruments.

Manufacturing consists of the following stages:

- Sand is poured into an industrial mixer.

- Cement is gradually introduced.

- The components are thoroughly mixed until a homogeneous substance.

- Water is added in the percentages regulated by the recipe.

- Re-mixing is carried out.

- A foamy substance is prepared in the foam generator.

- Foam is added to the prepared concrete mixture through a hose.

- Mixing is carried out for three minutes.

- The concrete foam composition is poured into molds of the required configuration or formwork.

- The foam mass is left to stand for 4 hours until preliminary setting.

- Foam concrete blocks are transported to a warehouse, where they settle for 28 days and gain strength.

The production process does not require special equipment, and the quality of the product depends on the ratio of the percentage concentration of components and the use of high-quality Portland cement.

Features of manufacturing technology and formulations affect the performance parameters of products. Let's look at it in detail.

Interior work

It is worth noting that the construction of a bathhouse from foam blocks certainly includes interior decoration. Most often, the bathhouse is lined with wood.

Moreover, coniferous species are chosen for the dressing room:

- spruce,

- pine

And for finishing the steam room, linden or aspen are better suited, which are excellent heat insulators and do not heat up at high temperatures.

Wood is a natural product for saunas

Furnace installation

For a bathhouse made of foam blocks, built with your own hands, a very important point is the choice of stove. An internal partition is being built from brick.

The principle of operation of a sauna stoveTo build an additional foundation for the furnace, you should:

- Dig a pit about 70 cm, which should be wider at the base of the foundation by 10 centimeters on both sides;

- A layer of sand 15 cm thick is poured into the bottom of the dug pit and filled with water;

- Then add sand again to the desired level and fill it with water again;

- When the water recedes, broken bricks and stones are laid at the bottom;

- compacted, covered with sand again and filled with water;

- After the sand settles, pour 10 centimeters of crushed stone and compact it;

- Inside the pit, formwork is made, inside which a reinforced frame is installed;

- After installing the reinforced frame, concrete is poured into the formwork, 15 cm high from the ground surface.

Wall insulation

Along the perimeter of the walls, we fix 50x50 beams at a distance slightly less than the width of the insulation, for example, with an insulation width of 60 cm, the distance is 5.9 cm. Then we lay the insulation, on top of which the foil is laid. After watching the video in this article, you will get a complete picture of the proper construction of a bathhouse.

Lining

Before installing the lining on the surface, it should be treated with an antiseptic on both sides. Beams with a cross section of 25x25 cm are stuffed onto the foil. This is done to create a gap between the foil and the lining, the so-called air cushion.

The process of installing lining in a bathhouse