A bathhouse is not just a place to relax, but a way to improve your health and well-being. If you choose the right stones for a bath, the beneficial vapors emanating from the hot stones will help cope with diseases and speed up recovery.

But buying to save money increases the risk that the stones will contain radioactive elements and other harmful particles that are life-threatening.

We will talk about all aspects of choosing the appropriate material for a sauna stove and sauna decoration in this article.

Finishing stones

These include breeds that look beautiful, but have poor resistance to temperature changes.

The main function of finishing stones is decorative. They decorate the walls or the outside of the heater. This design will not be cheap, but will last a long time.

Let's look at the most commonly used minerals for cladding.

Amphibolite

Location in our country is Nigrozero. The extraction method is open. The sawing technology is diamond-wire, performed seasonally on the mountainside: this way the blocks are almost the same size and of high quality.

Garnet amphibolite received several names - “Tundra”, “Nordic Sunset”.

The mineral consists of the following components:

- pomegranate – 15%;

- quartz – up to 20%;

- amphibole – up to 35%;

- aegirine – 2%;

- plagioclase – up to 28%.

It has a polychrome color, where black stripes alternate with white splashes and white stripes alternate with black splashes.

Amphibolite is a beautiful stone, therefore it is widely used for cladding:

- fireplaces;

- ovens;

- stairs;

- house facades;

- parapets;

- steps.

This is an excellent raw material for durable tabletops and sculptures.

Among the advantages:

- salt resistance – up to 0.28%;

- water absorption – 0.09%;

- the level of compressive strength reaches 144.4 MPa;

- resistance to low temperatures and wear.

The downside of amphibolite is that it cannot withstand high temperatures and begins to crack.

Marble

Marble finish adds elegance and is suitable for different types of cladding.

The material is durable. Its strength is due to its high quartz content.

Marble is expensive, so not every owner will be able to afford such luxury in the design of a bathhouse.

Jade

The most popular semi-precious mineral. Suitable for finishing work. Found application as a filler for sauna stoves.

Jadeite has a pronounced healing effect:

- Normalizes blood pressure.

- Helps restore the musculoskeletal system.

- Positively affects the functioning of the nervous system and heart.

- Good for the respiratory system.

Its advantages:

- Low thermal conductivity.

- Uniform compression, expansion with temperature changes. Doesn't crack.

- High density.

- Contacting water, saturates it with metasilicon acid.

- When heated, it saturates the air in the steam room with particles of zinc, argentum, and cuprum.

To fill the furnace, you need to take a large polished stone or one that does not need to be embanked - it will last many times longer.

It is allowed to take small crushed or large jadeite as finishing raw materials. The size is selected individually.

Nephritis

Refers to pyroxenes. Semi-precious mineral.

Depending on the mixtures in its composition, the color of the stone can be:

- Emerald or bright green (rich with chrome).

- Dark brown or black (iron predominates).

- Pink (contains magnesium).

Long ago in the East, jade was called a stone of health because of its healing properties and the ability to speed up the treatment of many diseases.

It is used in baths for decorative purposes, to decorate the walls of rooms. Durable, can retain heat for a long time.

When purchasing it, you should be careful, because often, instead of expensive natural jade, sellers offer inexperienced customers a fake - a cheap coil - for the same money. It is similar in color, but has low strength and cannot withstand temperature changes or constant humidity.

Place of Birth

Amphibolite crumbs

Since there are no large deposits of amphibolites in nature, their extraction (together with the host rocks, which are gneisses and granite-gneisses) is carried out either in separate small quarries, or is carried out simultaneously with the development of other minerals.

It is known that rubies, gold, titanium, rubies, garnets, vanadium and iron often occur next to amphibolites. In this regard, the market value of amphibolite raw materials increases significantly.

The main amphibolite deposits are located:

- In Karelia. The Nigrozero deposit is a supplier of valuable garnet amphibolite, marketed under the commercial names Nordic Sunset or Tundra. A subspecies of this mineral is also mined here, containing up to 70% white mineral inclusions, known as “Ice Tundra”.

- In the Urals. Local orthoamphibolites are associated with rich titanium deposits.

- In the Murmansk region (Musozero deposit).

- In the Yamalo-Nenets Autonomous Okrug (Amphibolite deposit, Kharp village).

- In the Arkhangelsk region (Pokrovskoye quarry).

- In the Eastern Sayan Mountains (Kruchininskoye, Lysanskoye, Malo-Tagulskoye deposits).

- On the territory of right-bank Ukraine.

Selecting breeds from an environmental safety point of view

Minerals of uniform color are considered safe for health:

- dunites;

- jadeites;

- peridotites.

Cast iron and ceramics are not dangerous.

You should not use stones containing:

- sulfides;

- creosote;

- inclusions of rich red and yellow shades;

- with a metallic sheen.

You cannot collect granite, crushed stone, or paving stones for a bathhouse near highways or railroad tracks.

It is better to buy stones for backfilling in a store and demand quality certificates from sellers, which will indicate that the product has passed radio control.

An excellent option for finishing the walls of a steam room is salt stones. Beneficial vapors will protect against possible allergens.

Collect on shore or buy?

It’s up to you to mine stones yourself, looking for the most beautiful specimens on the shore of a reservoir (for free!) or buy them in a store. There is no right answer, but it is worth studying the information to make a decision.

Collect stones yourself if:

- you have experience and skills in determining the type of stone and, accordingly, its qualities;

- you are confident in the environmental safety of the found mineral.

Spend the money on the purchase if:

- you prefer to turn to specialists when it comes to health;

- you prefer to be confident when it comes to safety, including radiation. The packages of tested stones are marked with this safety mark, and they also provide a safety certificate for the stone itself and the place where it was mined.

And if you consider that the price of bath stones is not very high (for example, a heater for 60 kg of stones can be equipped with an excellent stone for 700-1000 rubles!). In general, the choice is yours, but we would still recommend buying them.

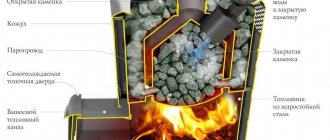

Laying features

The stones are selected in size depending on the type of stove:

- For open-fire wood stoves and Finnish saunas, stones from 8 to 18 cm are used. The larger the size of the mineral, the longer it retains heat.

- In closed heaters, the main requirement is a size of up to 23 cm.

- To fire electric furnaces, you need to take minerals measuring 4–7 cm. The recommended diameter of cast iron balls is 80 mm.

- To properly fill a cast iron pot, it is important to select a filler that is smaller in size than the door.

To ensure good, thick steam in the bathhouse, stones are selected and placed as follows:

- Inspect each element for cracks, sharp corners or chips.

- Suitable stones are washed with water and dried. This is an important point, otherwise, instead of clean steam, the owners will receive steam with dust impurities.

- The bottom is laid out with large cobblestones, which heat up quickly and retain heat for a long time. Soapstone, basalt, cast iron balls, gabbro-diabase are suitable. A budget option is river pebbles.

- Next come medium and small valuable species with medicinal properties. Often they combine crimson with white quartzite and jadeite.

- Oblong specimens should be placed vertically so that they heat up faster.

- All elements are placed tightly to each other, but the gaps for air circulation should remain less than 15% of the volume of the stones.

- When placing filler in an electric heater, you do not need to place the stones close to the pipes or other parts, but always 5–8 cm above the heating elements. Otherwise, the heated minerals will begin to expand and may cause the breakdown of one of the elements.

- 1-2 times a year it is recommended to inspect the filling, remove damaged, broken minerals, fill the oven with new ones, wash and dry the stones.

- Some rocks emit a characteristic cracking sound when first heated. If after several heatings the sound does not disappear, then you should get rid of such cobblestones, since there is a high probability of harmful impurities in the composition.

Only hot water can be poured onto hot stones in small portions. Do not pour oils, honey or other solutions to improve the aroma. The flame will increase, and the stones will begin to smoke and create unpleasant smoke.

It is much safer to dissolve essential oils in water and place the container over the stove.

What to choose?

Yes, we've finally reached this point. Here we can give you two good directions to think about.

Universal option

Jadeite or jade, they are suitable for any stove. Jadeite is a little better, but a little less durable. These minerals can be safely recommended to everyone. If you don’t want to worry about it, but just go and buy, then this is your option.

If you are not satisfied with the price, then pay attention to soapstone. It performs well, is safe, and is durable enough that you won't regret the purchase. Even experienced bath attendants respect this stone.

According to the furnace design

So, for example, if stones come into contact with the metal structure of the stove or open fire (continuously or occasionally), i.e. are exposed to high temperatures, then you should choose the most heat-resistant stones :

Chromite

Vulcanite

Soapstone chlorite

If the stones are not subjected to extreme loads, then the classic options are your choice:

jadeite and jade

gabbro-diabase

It’s probably worth making an important caveat here. After all, to tell the truth, any of the previously listed stones are absolutely suitable for use. If a stone is on this list, then it already deserves to be in your oven. And the disadvantages that we are finding fault with here are not that significant.

What stones are not suitable for steam rooms, decoration

The key factor when choosing is appearance. The surface must be uniform, without colored inclusions, mica, or impurities of other rocks.

It is forbidden to mine rocks for a sauna heater near industrial facilities, railway tracks, or highways. Rocks that remain in such places for a long time become saturated with creosote, a toxic substance whose vapors lead to poisoning.

Acidic, sedimentary rocks with a high silica content are not suitable for steam rooms.

Some minerals are used in the decoration of bathhouses, but are absolutely not suitable for filling the heater due to the fact that they begin to crack under the influence of high temperatures (amphibolite).

And, for example, beautiful rhodonite (shown in the photo) is not at all suitable for use in a bathhouse, since it deteriorates when it comes into contact with water.

Origin

Amphibolites, which are of metamorphic origin and correspond to a medium degree of metamorphism, are most often found in folded belts (for example, in the Alps and the Ural Mountains) and in metamorphic Precambrian complexes (Ukrainian, Aldan, Baltic, etc.).

The formation of amphibolites occurs at temperatures exceeding 400 degrees Celsius and pressure capable of ensuring strong compaction of minerals: such pressure is possible only at depths equal to several kilometers from the Earth's surface.

Source breeds are presented:

- most often - igneous rocks of basic composition (they are called orthoamphibolites), sometimes - ultrabasic composition;

- tuffaceous-sedimentary rocks;

- marly sedimentary rocks (their synonymous name is paraamphibolites).

Comparative characteristics of stones

Based on the performance characteristics, a rating of a number of minerals has been compiled according to several parameters.

By service life

| Place in the ranking | Duration of operation |

| 1 | Nephritis |

| 2 | Dunit, cast iron cores |

| 3 | Chromite, porphyrite, ceramic balls |

| 4 | Raspberry quartzite |

| 5 | Jade |

| 6 | Soapstone chlorite |

| 7 | White quartz |

| 8 | Jasper, gabbro-diabase |

It is important to remember that contact of minerals with open fire, improper placement inside the furnace, or extreme heat leads to a significant reduction in service life and premature damage.

By heat capacity, strength and density

Comparative characteristics of the main indicators of the physical and mechanical properties of minerals used in heater stoves of Finnish saunas and Russian baths.

| Indicators | Jade | Basalt | Gabbro-diabase | Raspberry quartzite | Soap chloride | Porphyrite |

| Compressive strength kg/sq.cm | 20 | over 30 | 15 | 25 | 8 | 15 |

| Mohs hardness | 7 | 8 | 5-6 | 7 | 2-3 | 6 |

| Strength coefficient on a 20-point scale according to Protodyakonov | 20 | 20 | 15 | 20 | 8 | 15 |

| Specific heat capacity kJ/kg*C | 0,88 | 1,1 | 0,7 | 0,95 | 0,98 | 0,85 |

| Thermal conductivity coefficient, kcal m*h*C | 2,3-3,6 | 1,8-3,5 | 1,59-2,98 | 3,7-7,6 | 3,5-4,7 | 1,17-3,37 |

| Coefficient of linear thermal expansion 10³*1/С | 0,35-0,46 | 0,6 | 0,7 | 0,15 | 0,2 | 0,8 |

| Rock density 10³ kg/m3 | 3,2 | 2,9-3,25 | 2,9-3,0 | 2,6-2,8 | 2,8-3,0 | 2,6-2,9 |

| Porosity | 0,01-0,03 | 0,02 | 0,2 | 0,1 | 0,3 | 0,15 |

| Melting temperature | 1040-1060 | 1450 | 1250 | 1700 | 1600 | 1300 |

| Acidity module | 28 | 2,2 | 3,4 | 16 | 1 | 3,5 |

| Class of building materials | 1 | 1 | 1 | 1 | 1 | 1 |

| Heat resistance (heating-cooling cycles) | 400 | more than 1000 | 300 | 100 | 500 | 400 |

| Flaws | SiO2 content more than 50% | No | Sulfur content | Crumbles, SiO2 content is more than 50% | Content of sulfur, talc, flake flaking | Dirty gray color |

It is not recommended to use minerals containing more than 50% SiO2 in baths and saunas.

Before filling the kiln, it is recommended to always check the heat resistance of the stones. To do this, they are heated 2-3 times and lowered into a container with cold water. Elements that have cracked are removed.

Interesting Facts

- In the early Neolithic era, primitive tribes living in Central Europe hewed out their first tools from durable amphibolite - stone axes (choppers), hoes and digging sticks.

- English-speaking authors quite often call amphibolites any rocks of metamorphic origin whose chemical composition contains over 50% amphibole.

Rules for caring for stones

It is important to carry out regular cleaning and inspection.

The need to replace the stove filler may be indicated by the appearance of an unpleasant odor, minimal heat transfer, or poor steam formation.

In regularly used saunas, minerals are inspected every month.

Care instructions:

- Clean off dirt with a metal brush.

- Rinse in a container with clean water without using soap solution or powder.

- A clean stone should be left in water for up to 1.5 hours until it becomes slippery.

- It is recommended to dry the minerals in a well-ventilated area, otherwise fungus will begin to form on the surface.

- Each element should be lightly tapped with a hammer. A loud sound indicates durability and serviceability, a dull sound indicates the need for replacement.

- Cracked specimens must be removed, filling the oven with new ones.

- Oil stains are practically impossible to remove, so the stones are placed with the clean side up.

For a pleasant aroma inside the steam room, you can hang bouquets of lavender and mint on the walls, fill a container with water and essential oil and hang it over the stove.

Benefits of use

Shungite finishing of the steam room allows it to have a comprehensive effect on the human body. A large amount of stone manifests itself under fallow as follows:

| Health sector | Sphere of cosmetology | Emotional sphere |

|

|

|

Energy experts also note that shungite consists of a certain spherical type of fullerene ions. It is these ions, in their opinion, that activate the body’s protective field from negative energies, electromagnetic radiation and vibrations.

With regular visits to shungite baths, the body’s energy comes into harmony, which has a beneficial effect on vitality and prevents the aging of spirit and body.

Top 5 stones for sauna stove

After analyzing the technical characteristics and healing properties of various minerals, we can come to the conclusion that the best choice for a bath would be:

- Jade. Suitable for cladding the walls of a steam room and as a filler for a stove. Durable, with high heat capacity and long service life. It has a good effect on health and helps cope with many diseases.

- Porphyrite and ceramic balls. They have the same thermal conductivity and heat capacity. They have a positive effect on the immune, nervous, and cardiovascular systems. Eco-friendly. Placed on the top layers of the oven.

- Dolerite. Good for backfilling. Keeps warm for a long time. Lasting. Steam has antibacterial properties.

- Soapstone chlorite. A very valuable type of mineral. Able to keep warm for a day. Helps with many diseases. But its service life is limited, so the material is laid on top and requires frequent inspection.

- Basalt. Requires careful inspection before installation for foreign inclusions. Inexpensive, environmentally friendly. Stacked down. It is better to fill the top with more valuable rocks.

Finishing inside the steam room

Since buildings are made of different materials, owners are interested in whether there is any difference in how to decorate a steam room in a bathhouse, say, from brick or foam concrete. In principle, there are no differences even at the level of constructing an insulating pie, and even more so the finishing does not depend on what the walls of your bathhouse are built from.

However, options do exist.

Interior decoration in a bathhouse made of timber or logs

A beam or log is a material that in itself has excellent decorative qualities, so there is no point in hiding it under the skin, unless your area is in the Arctic cold, that is, if the thickness of the log or beam is enough to keep warm.

In this case, the owner’s main concern will be insulating the joints with inter-crown insulation between logs or beams and sealing (which we will discuss separately). In addition, finishing works include protecting log walls from various misfortunes (fire, water, insects, fungi and bacteria) and revealing the decorative properties of wood - both are done with the help of impregnations.

BUT! In the steam room, protective measures are limited to antiseptic on the lower rims and impregnation for the walls as a whole, which will protect them from water.

A well-sanded log has a beautiful “moire” pattern, which can be made more visible with the help of varnish or impregnation. On our website parilochka.com there is an article that talks about paints and varnishes that are acceptable for processing steam rooms.

Finishing with clapboard in a bathhouse made of aerated concrete, foam concrete, brick, frame

The finishing of a steam room in a bathhouse built from the materials listed in the title will in the vast majority of cases be reduced to clapboard cladding. This is the easiest way to make the interior “wooden”. In addition, lining is a convenient and affordable material, and the difference in profiles gives the owner the freedom to choose according to his tastes.

Baths not built from wood are usually insulated. In this article we will not describe the thermal insulation pie - you can read about it in this article on our website. However, we will spoil it: methods of thermal insulation finishing of a steam room in a bathhouse made of aerated concrete, foam concrete, etc. are the same . And the lining is the final stage of this finishing.

The lining is attached to the counter-lattice. There are several ways to attach it inconspicuously. Previously, this was most often done with finishing nails through a groove, but this is hard work, especially when compared with the modern method of fastening to staples or nails using a pneumatic gun through clamps. As an option, you can attach it to self-tapping screws.

IMPORTANT! Clippers do not replace fastening with nails or staples, they only simplify it. A nice and convenient addition.

Watch the video, which clearly demonstrates the method of fastening the lining using clamps:

Regarding the finishing of the steam room with clapboard, it is worth saying one more thing: there are two mounting options - vertical and horizontal. Accordingly, the counter-lattice should go in a perpendicular direction.

Since we are talking about a humid and hot room, it is worth noting that vertical fastening of the lining is not optimal. Each individual lamella with this arrangement is moistened unevenly, which leads to stress inside the wood. In the future it may crack.

At the same time, horizontal fastening makes the lamellas moisturized more uniformly . The main thing is not to forget when fastening that the groove should be on top, and the tenon should enter it from below. Then water will not flow into the lock.

In addition to the above, the described types of lining installation also have this feature: vertical fastening visually makes the room taller, and horizontal fastening makes the room appear lower.

Contraindications

Visiting steam rooms with a stone can cause some harm.

Contraindications sound similar to the usual prohibitions on paired procedures:

- inflammation in the acute stage;

- epilepsy;

- severe cardiovascular problems;

- urolithiasis disease;

- hypertension;

- rehabilitation period after traumatic brain injuries, strokes, heart attacks.

There are also cases of reaction with poor health specifically to shungite finishing. If this is noted, you should stop the procedure and avoid this stone.