For the effective functioning of ventilation and chimney systems, stable natural draft is required. Only under this condition will normal air circulation and effective removal of combustion products occur. To prevent foreign objects and precipitation from entering ventilation and smoke ducts, as well as to protect the internal surface from soot and fat deposits, deflectors are widely used.

A modification of the TsAGI type deflector is one of the most common among such devices. This article will discuss the design features, operating principle, pros and cons of this device.

Types of deflectors and their purpose

There are several types of deflectors, which are based on the same principle of converting wind force into a directed air flow that enhances traction.

In practice, five main types of deflectors are used:

- TsAGI is a development of the Central Aerohydrodynamic Institute. One of the most common types of devices, consisting of a metal pipe, inside of which there is a shielding cylinder and a conical protective umbrella. The design prevents the so-called the draft blocking effect due to strong wind loads, and also protects the chimney from clogging and atmospheric moisture.

- Volpert - practically no different from the TsAGI deflector, but has a slight design difference: the visor to protect against clogging is located above the diffuser, and not inside it.

- The Grigorovich deflector is the most popular type of device, which is a truncated cone that expands at the bottom. At the top of the deflector there is a protective cap mounted on mounting studs.

- An H-shaped deflector is a more complex structure, consisting of a horizontally located metal pipe into which several pipes are vertically embedded. The horizontal and vertical parts of the pipes form a structure in the shape of the letter “H”. Such a deflector is considered very effective in enhancing draft and protecting the chimney from moisture and debris.

- Disc device - is a truncated cylindrical cap, similar in shape to a plate. An upper visor is attached to it on mounting studs, protecting the pipe from precipitation and creating a directed air flow.

We recommend that you read: Is it possible to build ventilation in a private house from plastic sewer pipes?

The types of deflectors described above refer to static structures. In addition to them, there are two types of movable aerodynamic devices for chimneys.

- The rotating deflector is a circular structure with blades located in the same direction. A spherical mini-turbine protects the chimney well and creates strong draft, but when there is no wind its efficiency is almost zero.

- Vane - the design principle is clear from the name. The deflector consists of metal canopies connected in series, fixed on a special weather vane that allows rotation. Canopies protect the chimney or vent from precipitation and pollution, but also require constant movement of air masses.

Regardless of the design, all types of deflectors work to enhance draft in the chimney and protect it from precipitation and foreign particles from the external environment. The difference between them is due to the device, which corresponds to different operating conditions.

These may be weather and climatic conditions in the area, the presence of natural or man-made barriers to the wind (trees, houses), as well as the shape of the roof and the design of the chimney.

Briefly about the main thing

A deflector is an attachment to a chimney or ventilation channel to improve the draft situation and protect the internal space from natural precipitation and clogging.

The operating principle of the devices is based on the fact that a medium with high pressure displaces a medium with lower pressure due to wind speed.

Devices are distinguished according to various criteria, the main ones being material, design features and the operating principle of a particular model.

For ventilation systems, models of different compositions can be used; for chimneys, it is recommended to limit ourselves to samples made of galvanized or stainless steel.

Based on operation and design, there are two groups of nozzles: static and aerodynamic.

Static ones are represented by a single design consisting of a body, a diffuser and a cap (the H-shaped version does not have umbrellas and is made of pipes).

Aerodynamic deflectors, in addition to the static part, have rotating elements: a miniturbine with blades or a weather vane structure.

Installation is best done after connecting the device to the installation pipe.

Ratings 0

Review of popular models

Let's take a closer look at the most common models of deflectors.

Ventilation deflector Tsaga

This model is considered the most popular. This device has a larger diameter than the chimney. Air flows flow around the device from all sides, as a result of which areas of high pressure are formed on the sides, and a vacuum occurs in the rear and front zones, increasing traction.

The design of such a product eliminates the protection of the chimney duct from precipitation. Therefore, after installing this device, additional installation of a protective cap is required.

The Tsaga deflector is suitable for use in both chimney and ventilation systems

Disc-shaped

A simple model that ensures fairly efficient operation of the system and high traction. The two main elements of the device form a protective canopy that prevents snow and rain from entering the chimney channel.

The lower part of the visor is covered with a cap, which is directed towards the chimney. This design allows the device to cope with the tasks assigned to it. The air flow can enter such a deflector from any side and, finding itself between the cones that form a narrowed channel, cause a vacuum.

Ball-shaped "Wolper"

This model has an almost identical device to the TsAGI deflector. However, there is one difference - the canopy, which protects the chimney channel from precipitation and debris, is located above the diffuser.

Grigorovich deflector

A very popular deflector model that increases draft in chimney and ventilation structures. This deflector is easy to assemble with your own hands. The design of this device includes the following components: a lower cylinder with two pipes, an upper cylinder, a cone and two brackets.

The smoke coming from the pipe ends up in the narrowed channel of the diffuser, causing a vacuum to occur. To assemble such a device, as a rule, a tin sheet or galvanized steel plate is used.

The Grigorovich deflector has a very simple design and is often made by hand

H-shaped

This model is used mainly in manufacturing plants or boiler houses that have high power. The installation of an H-shaped deflector occurs as follows: a pipe of a similar size is attached to the mouth of the pipe. In the central part of the pipe there is a special insert, which ensures a tight connection of the device with the chimney pipe. Two more tubes are fixed to the transverse pipe on the right and left, resulting in a device resembling the letter “H” is formed.

This design does not require a protective canopy, since the mouth of the chimney is already protected by horizontal parts. The H-shaped deflector enhances traction in any direction of air flow.

Rotating

Such a device rotates only in one direction. The circular motion provides additional efficiency of the device. In addition, this model provides protection for the pipe from precipitation and debris. Often used for gas-fired boilers.

Deflector "weather vane"

This model includes a rotating body. This device includes the following elements: weather vane, visors, bearing assembly. The rotation of the device is carried out due to the force of the wind acting on the weather vane. The weather vane type chimney deflector works on the principle of a ship's sail.

The weather vane deflector has a part in its design that rotates when the wind blows

The operating features of the device are as follows: air flows pass between the visors, so the air becomes rarefied. This model allows you to increase draft in the chimney, eliminate reverse draft and the formation of sparks.

Causes of smoke

The principle of operation of the deflector as a gas exhaust structure

Smoking in the furnace is most often explained by the so-called “draft failure”, which occurs due to the heating installation being idle for a long time. This leads to cooling of the internal spaces and a decrease in the pressure gradient. As a result, the air flow in the pipe changes its direction and rushes not outward, but towards the heat source.

This phenomenon has nothing to do with the outside temperature and can occur in hot weather and cold weather. To eliminate the effect of backdraft in the chimney, you will need to increase the temperature in the outlet pipe. One of the ways this can be achieved is by installing a high-quality chimney deflector.

TsAGI deflector design

The most common option for installation in a ventilation system is the TsAGI deflector. A simple device consists of the following elements:

- A diffuser, which is a part of a pipe having the configuration of a truncated cone. The narrow side is mounted on the pipe.

- The top is in the form of a cap or umbrella that protects the channel cavity from the penetration of precipitation and debris.

- A ring fastened to the outside of the diffuser using brackets.

- A pipe mounted on the head of the ventilation duct.

- Brackets for fastening the cap.

An exhaust ventilation deflector of this design is common in the construction market; purchasing the device is not difficult. If you wish, it’s easy to make it yourself, the main thing is to correctly determine the size and purchase the necessary materials. The best option is considered to be galvanized and stainless steel; tin and aluminum are less commonly used. There are also plastic products on sale, which have low prices compared to metal products.

In calculations, as can be seen from the deflector diagram, one should start from the value of the diameter of the ventilation shaft. Therefore, you need to measure carefully.

Material for production

Ventilation hoods differ not only in appearance, but also in the material from which they are made:

- Made from plastic, such devices are quite fragile and therefore are rarely found on store shelves;

- Made from metal coated with plastic, such models are more durable and have a rather attractive appearance;

- Made from metal intended for the manufacture of boilers, such devices are expensive, but are highly resistant to burnout from exposure to hot air flows;

- Made from galvanized steel, products made from this metal are considered the most common because they have an affordable price and at the same time have good strength;

- Aluminum, also popular among manufacturers, has good strength and an affordable price.

There are also caps made of copper, but they are too expensive and therefore this metal is practically not used for the manufacture of deflectors.

Protection of deflectors from low winds

Due to the presence of this feature of wind flows, deflectors began to be equipped with special protective devices that help increase the level of draft in the pipe in any weather. To do this, an axis is installed inside the chimney on two bearings located at different levels.

A semi-cylindrical screen, a weathervane and a cover are installed on the axis. It is this design that protects the entire chimney from the effects of the lower wind flow.

After the direction of the wind flow changes, the weather vane rotates, thereby closing the chimney from the wrong wind flow. Thus, any direction and strength of the wind is not able to block the path of the exhaust smoke, and the draft in the chimney remains the same power.

Do not forget that the deflectors are designed for round pipes, which can become a problem if you have an old brick pipe with a square cross-section. In order to solve this problem, special pipes are used that act as adapters.

For chimneys with a large square cross-section, which are built for fireplace heating systems, it is necessary to use adapters in the form of spacer legs that connect the pipe and the deflector itself. These legs are made of metal strips that can be galvanized or high-quality painted.

Brick pipes require an appropriate transition with an inlet in the desired direction, which allows you to connect a round deflector and a square chimney. In other words, it is not difficult to secure this element of the chimney system in the presence of any type and shape of chimney structures.

You don’t have to buy a deflector at a hardware store, because you can make it extremely easily with your own hands. To do this, you need to calculate the size and shape of the element, after which you can begin the manufacturing process.

On galvanized steel sheet it is necessary to draw the upper and lower cylinders of the future deflector, which can be easily done using an ordinary pencil. You can cut out the necessary elements using metal scissors, which can easily cope with this task.

Once these two parts have been cut and filed, which is required to properly join the two edges of one part, you can begin to secure these edges. As a rule, a welding machine, bolts or rivets are used for this.

It’s worth noting right away that connecting a galvanized steel workpiece using a welding machine is extremely difficult, because it burns through thin metal quite quickly. It is for this reason that rivets or small bolts are most often used.

The finished cone cap must be secured to the upper cylinder of the deflector. This is done using small brackets made of the same sheet steel. The brackets are secured to the pipe using rivets. Do not forget that the brackets should be attached only to the outer side of the deflector, so as not to create additional interference in the internal part for proper air flow and smoke extraction.

A reverse type cone must be attached to the element umbrella. In addition, the assembly of all parts of the deflector must be carried out directly on the pipe itself, which will allow for high-quality installation and fastening of each individual part of the structure.

Otherwise, it is possible to connect two elements of the system poorly, which will subsequently cause a malfunction of the structure and the entire chimney as a whole. In some cases, it is simply impossible to make this design on your own.

As a rule, this happens with brick chimneys, which require high-quality adapters or stands. From this we can conclude that it is much easier, more profitable and faster to buy this inexpensive element of the system than to try to make it yourself.

It is worth recalling that only galvanized steel can be used to make the deflector, which successfully resists the formation of rust, which negatively affects the life and quality of service of such a system element.

Work algorithm

- Take measures to carry out work safely: wear gloves and safety glasses.

- Prepare equipment: ruler, drill, scissors or grinder, marker.

- Purchase material: metal sheet 0.3-0.5 mm thick.

- Mark the dimensions on the cardboard. Don’t get confused: the internal cross-section of the cylinder must be the same as the external diameter of the ventilation pipe.

- When drawing the diffuser, an extra 0.2 cm is added from the edge to the joints.

- All elements are compactly placed on a metal strip and cut out with a hacksaw or scissors.

- The cone is formed from a cut out circle. From the border (along the radius - from the edge to the center) an incision is made with scissors. One edge is overlapped with the other until a cone is formed.

- The edges of the rolled diffuser body are connected along the edge with a margin of 10 mm.

- Holes are drilled at the joints. The parts are fastened together using a bolted or riveted connection.

- Self-made brackets are strips of galvanized steel 1.5-2.0 cm wide.

- Install the assembled structure on the upper section of the pipe: the lower cylinder is fixed with bolts, the diffuser is secured with a bracket.

- The cap is mounted on the clamps.

- All structural elements are firmly secured with bolted connections or rivets strictly according to the drawing.

- The draft in the channel during strong winds is adjusted by a special valve installed in it.

Attention! The deflector is placed above the roof in the area of free wind blowing. It is prohibited to place it in the area of an aerodynamic shadow created, for example, by a nearby building.

If you follow the manufacturing and installation rules, as well as master the work skills, installing a TsAGI deflector on the roof will not require much effort and time.

How to make a TsAGI deflector for a chimney pipe with your own hands

The process of developing and assembling a deflector for a chimney consists of four stages: drawing, creation of blanks, assembly, installation of the structure and its fastening directly to the chimney.

Required Tools

You will definitely need:

- a sheet of thick paper for drawing and layout;

- marker for marking;

- riveter for connecting structural elements;

- metal scissors for cutting out parts;

- drill;

- hammer.

Don’t forget about the necessary tools before installing the deflector

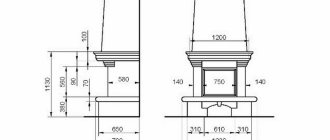

Development of a drawing of a TsAGI deflector model

There is an algorithm for how to make a deflector for a chimney pipe with your own hands. It is recommended to perform the first stage on paper. First you need to calculate the dimensions of the diameter of the nozzle and the upper cap of the structure, and also calculate the height of the reflector.

For this, special formulas are used:

- diameter of the upper part of the deflector - 1.25d;

- outer ring diameter - 2d;

- height of the structure - 2d+d/2;

- ring height – 1.2d;

- diameter of the cap - 1.7d;

- the distance from the base to the edge of the outer casing is d/2.

Where d is the diameter of the chimney.

To make the task easier, a table containing ready-made calculations for standard sizes of metal pipes will help.

| Chimney pipe diameter, cm | Outer casing diameter, cm | Height of outer casing, cm | Diffuser outlet diameter, cm | Cap diameter, cm | Installation height of the outer casing, cm |

| 100 | 20.0 | 12.0 | 12.5 | 17.0…19.0 | 5.0 |

| 125 | 25.0 | 15.0 | 15.7 | 21.2…23.8 | 6.3 |

| 160 | 32.0 | 19.2 | 20.0 | 27.2…30.4 | 8.0 |

| 20.0 | 40.0 | 24.0 | 25.0 | 34.0…38.0 | 10.0 |

| 25.0 | 50.0 | 30.0 | 31.3 | 42.5…47.5 | 12.5 |

| 31.5 | 63.0 | 37.8 | 39.4 | 53.6–59.9 | 15.8 |

If the chimney has a non-standard width, then all calculations will have to be done independently. But, knowing the formulas, it is easy to measure the diameter of the pipe and determine all the necessary indicators to use them when drawing up drawings.

When the patterns are made, it is recommended to first assemble a paper prototype of the future reflector. Even if you are an experienced craftsman and are sure that you can design a deflector for a stove chimney with your own hands without any problems, you should not skip this stage, since it will help you identify possible errors and shortcomings, and correct the calculations or drawing. Only after creating the correct paper layout, which confirms that the deflector diagram is accurate, can you move on to the next stage.

Step-by-step instruction

There is an order of work that must be followed, otherwise you will not be able to connect the individual parts of the chimney deflector yourself with your own hands.

The procedure is as follows:

- Using paper blanks, transfer the template to the surface of the metal from which you plan to make the reflector. Carefully trace the outlines of the paper parts. You can use a permanent marker, special chalk, or even a simple pencil for this purpose.

- Using metal scissors, cut out the blanks of the necessary structural parts.

- Along the entire contour of the cuts, the metal must be bent by 5 mm and carefully passed with a hammer.

- Roll the workpiece into a cylinder shape, drill holes for fasteners so that you can connect the structure with rivets. Welding is permitted, but not arc welding. You need to be careful not to burn the metal. Choose the distance between the main fastening points from 2 to 6 cm, it varies depending on the size of the finished structure. The outer cylinder is rolled up and fastened in the same way.

- By bending and connecting the edges, make the remaining parts: an umbrella and a protective cap in the form of a cone.

- You need to cut fastening elements from a galvanized sheet - 3-4 strips: width 6 cm, length - up to 20 cm. Bend them along the entire perimeter on both sides and go over them with a hammer. From the inside of the umbrella, you need to drill mounting holes, stepping back from the edge by 5 cm. 3 points will be enough. After this, secure the metal strips to the cap with rivets. Then they must be bent at an angle of 90 degrees.

- Connect the diffuser and cone using rivets to the inlet pipe. Having made a deflector for a round pipe with your own hands, you can begin installing it.

A Volper chimney deflector can be created using a similar method. Its design is very similar to the TsAGI model, but there are some differences in the upper part. They are also made of stainless steel, galvanized or copper.

Deflector installation

The structure can be installed in two ways - directly on the chimney and on a piece of pipe, which is then put on the smoke exhaust duct. The second method is much more convenient and safer, since the most labor-intensive process is performed below, and not on the roof. Most factory models have a lower fitting that is simply slipped onto the pipe and secured with a metal clamp.

Fixed deflector - photo

To install a homemade deflector, you will need a piece of pipe with a diameter slightly larger than the diameter of the chimney and threaded rods.

Step 1.

At one end of the pipe, departing 10-15 cm from the cut, mark the drilling locations for fasteners around the circumference. The same marks are placed on the wide part of the diffuser.

Step 2.

Drill holes in the diffuser and pipe, try the elements on each other. The top and bottom holes must match exactly, otherwise the fasteners will not be able to be installed smoothly.

Step 3.

Thread the pins through the holes and secure them with nuts on both sides on the diffuser and on the pipe. The nuts should be tightened evenly so that the deflector body does not deform.

Step 4.

They lift the structure onto the roof, put the pipe on the chimney and secure it with clamps.

It is very important that there are no gaps between the elements in this area, and therefore the clamp must be tightened very tightly. Additionally, you can treat the joint around the perimeter with a heat-resistant sealant

The installation of such a deflector is performed a little differently, since its design has certain differences. First, three holes are drilled in the chimney at the same level for mounting bolts. The ring part of the device is inserted into the cut of the chimney and secured with bolts. Next, the axle is inserted into the ring bearing, the cylinder is put on it, then the weather vane, and the protective cap. All elements are connected using brackets or rivets.

When choosing a deflector with a weather vane, remember that the bearings require regular lubrication, otherwise the device will not rotate. You should also not allow the hull to become icy, and knock off the ice as soon as it appears.

Video - Making a deflector with your own hands

The chimney is one of the most important components of stoves and fireplaces

Also a very important detail is the chimney cap, which ensures correct and stable removal of combustion products

It is quite possible to install a chimney cap yourself, but first you need to know the characteristics of these devices, their main functions and operating principle. We will also find out what reasons contribute to smoke, that is, the occurrence of backdraft in the pipe. A chimney cap (also called a chimney umbrella, visor, chimney, deflector, weather vane) is an ancient architectural element that in our time bears the imprint of antiquity and refined taste. Some modern chimneys are a real work of art that makes the chimney original and the roof complete.

Purpose

An umbrella is installed on the chimney to enhance draft by deflecting air flows. Deflectors of the correct design prevent atmospheric phenomena from entering the chimney - snow, slanting rain (see).

The chimney canopy also prevents debris and birds from getting inside. To do this, a mesh is installed, which freely allows smoke to escape outside.

Main functions

Thus, the chimney canopy performs the following functions:

- increased traction;

- increase in the efficiency of the chimney pipe (up to 20%);

- protection from snow, rain, debris;

- obstacle to the destruction of the brickwork of the chimney.

Chimney cap design

- cover or umbrella;

- drip or outlet for water.

A cover or umbrella is designed to protect against atmospheric agents entering the chimney. A drip line or water outlet is designed to remove draining moisture from the top of the pipe, thereby reducing the formation of ice during the winter.

Materials used to make a weather vane

When planning to make a chimney cap with your own hands, you should use materials that are heat-resistant and corrosion-resistant. The specified characteristics have the following materials:

- galvanized iron;

- stainless steel;

- copper.

It is important to remember that chimney caps are located in hard-to-reach places. Based on this, it is necessary to choose a cap that is made of high-quality material and that, according to its characteristics, is resistant to various atmospheric phenomena

One of the most durable is a chimney cap made of copper.

Selection rules

You can select the optimal deflector based on the goals and tasks assigned to it. It is also worth considering the conditions in which it will operate.

A simple chimney is a cap on a wood-burning chimney, made in the form of a regular umbrella, and has the following advantages:

- maintains the necessary traction both in calm conditions and in the movement of air masses with a power of up to 10 points;

- does not create excessive pressure on the pipe, due to which even in a severe storm the chimney remains in its place; rather, the umbrella itself can break off and fly away;

- has a simple and understandable design;

- practically does not coke or clog, and is quite easy to clean;

- due to the imperfection of the aerodynamic structure, it is insensitive to the shape of the umbrella; if the building is located in the wind, then the chimney can be made in the form of a tent, this greatly simplifies its use and opens up great opportunities for the implementation of design ideas.

At the same time, there are serious disadvantages, such as:

- in weak winds it reduces draft, and the stronger the heating element works, the weaker it is. This is quite dangerous, since in cold winter weather, in the absence of wind, the stove can “choke” and breathe fumes into the living quarters;

- in strong winds, on the contrary, it creates too much draft. This significantly reduces the efficiency of indoor stoves and fireplaces;

- in gusty winds it can cause blowing into the pipe and creating a reverse draft effect.

The aerodynamic open model maintains sufficient draft in any wind for efficient operation of stoves and boilers using liquid fuel and gas. Such deflectors can freeze, they easily become littered and quickly become covered with soot and soot, however, they are easy to clean.

The disadvantages include the following:

- complex body of rotation;

- as a result of the load created by air masses, the umbrella itself can easily fly off the chimney, and at the same time, the direct mechanism of the device can collapse the pipe itself;

- with strong gusts of wind from force 8, the lateral pressure on the structure increases significantly and further increases in accordance with the power law;

- open structures are quite poor at reducing strong dynamic loads resulting from gusts of wind, which is why in no case should such a model be placed on pipes made of brick;

- the modification cannot be used for pyrolysis heat-generating mechanisms, otherwise, when wind occurs, all pyrolysis gases will be sucked out and the stove or boiler will simply go out;

- not suitable for creating design elements, since it is unsuitable for decoration; all kinds of blotches and figures only worsen the overall aerodynamic status of the structure as a whole.

By the way, an interesting study was conducted in the USA. There, at one time, they studied issues related to open deflectors and installed them on locomotives to check the degree of increase in efficiency at low speed. At the same time, the result was the most depressing - at mid-speed, fire began to burst out of the pipe and not a single train was able to reach its maximum speed. In general, the open version of the deflector should be recommended for all types of heating devices, with the exception of pyrolysis ones. At the same time, it must be checked and cleaned at least once a quarter. It is optimal for a chimney with low draft force, it is most effective for wood-burning sauna stoves; not a single case of people burning out due to the ventilation deflector in saunas has been recorded.

The closed or as it is called “perfect” type has such advantages as:

- provides stable draft, which is sufficient for stoves and boilers of any type;

- not prone to freezing and clogging from the inside;

- Dust and ice formed on the outside do not significantly change the operation of the device.

There are also disadvantages, however, users claim that they are not so significant, namely:

- when exposed to strong winds, it gives maximum pressure on the pipe, and then increases linearly, so the chimney under the deflector should be further strengthened with guy wires;

- has rather complex design and technological parameters;

- cannot be used as a design element, since any additional elements significantly reduce the overall level of aerodynamics.

Models may differ in appearance, purpose and material. Most often, plastic, stainless steel or aluminum are used to produce deflectors. In rare cases, copper may become a raw material for production. Many users prefer the sandwich model.

Area of use

Where exactly can turbo deflectors be used? The products have proven themselves excellent in rooms and facilities where air exchange is extremely necessary. Scope of use:

- For private and apartment buildings. In addition, it should be noted that increased demands are placed on the operation of ventilation ducts in a high-rise building. Often in such houses the quality of ventilation is not the best, since they were made in the Soviet Union. But thanks to the use of a deflector, this problem is solved.

- Turbo deflectors are good for livestock farms and agricultural buildings such as stables, poultry houses, granaries and haylofts. They help ventilation more effectively remove odors, fumes and gases generated when keeping livestock. In addition, the humidity in the room is controlled, it is optimal.

- For processing enterprises. Since the turbo deflector does not require electricity to operate, the savings on the device are corresponding. The exception is enterprises that produce or process substances hazardous to humans.

- Public buildings such as sports complexes, swimming pools, shopping centers and cinemas.

Important! The turbo deflector is also used to ventilate the under-roof space. But how to make turbo ventilation deflectors with your own hands? Let's find out

But how to make turbo ventilation deflectors with your own hands? Let's find out.

Product design

If you plan to make a collet deflector with your own hands, then it would be a good idea to consider its design, that is, install all the individual parts of which it consists:

- Bottom cylinder or pipe. It will be attached to the end of the ventilation system duct or the end of the chimney duct pipe;

- Diffuser. This part is represented by an extended cone that goes from the pipe to the top of the product;

- Branch pipe or shell. This is the external part of the device;

- Cap or top cone. That part that is attached to the top of the entire structure and protects the ventilation or chimney system from precipitation;

- Legs for attaching the cap;

- Brackets for mounting the entire device.

Diagram of the collet deflector

It must be said right away that all these elements are made by hand from galvanized sheet or stainless steel. These materials can be found in sheet form in all construction stores.

Purpose

So, the collet deflector is designed to increase the draft of a chimney or ventilation system. Its operating principle is as follows: it is known from the laws of physics that hotter air is lighter than colder air. If the air is heated from below, then unheated air begins to press on it from above, since its mass is greater, and accordingly, the warm flow rises upward. A conventional chimney system is based on this, that is, smoke, like more heated air, rises upward by gravity. However, it is prevented by colder air, since the chimney is a closed system. So, in order to reduce this cold air pressure, that is, reduce the resistance, a deflector is installed that cuts the air flow, thereby establishing a low-pressure area (a vacuum area) above the chimney or ventilation pipe. This naturally increases cravings.

Tsaga deflector

Increased draft ensures that the efficiency of the underlying device, for example, if we are considering a chimney, it could be a stove, increases by 20 percent. This means that the combustion process will be much better without the use of additional combustible substances.

From all this we can conclude that the collet deflector is intended only to increase thrust. However, there is a special group of such devices. We are talking about rotary products. Their essence is that the central part rotates, which creates even greater rarefaction of the air around, and accordingly, the thrust increases.

Such deflectors also serve for forced ventilation, removal of gases and vapors from the room.