The dressing room is the second most important place in the bathhouse after the steam room. Here a person relaxes and his good mood will depend on how comfortable he is. Finishing the dressing room is a crucial moment; here you need to take into account many nuances, from the right choice of materials to interior design.

The main, but not the only function of the dressing room is to prevent cold street air from entering the steam room. In addition, it serves as a storage place for bath utensils, and if space allows, then for a certain supply of firewood.

Spacious dressing room - a great place to relax

To relax after the bath procedures in a good and comfortable way, again, you cannot do without a dressing room with installed benches, a table and clothes hangers.

“The theater begins with a hanger, and a bathhouse with a dressing room”

It is better to enter the bathhouse from the south so that the snow melts faster and the door is less likely to be covered with snow. The dressing room serves as an obstacle to the entry of cold air into the steam room and must retain heat inside the room, which is why the windows and doors are small in size. The door from the dressing room to the steam room is opened inside the dressing room, which protects clothes from excess moisture. The area of the dressing room can be of different sizes, usually no more than 6 m². How to decorate a dressing room and does it need to be insulated? The usual items in this room are hangers, a bench, there can be a table and a shelf in the corner as a means of additional hygiene. A refrigerator and TV are also an excellent choice, but you can only dream about this, and for many these delights are inaccessible. Why focus on the worst, thoughts are material, and we only need the best.

Ventilation

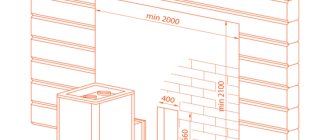

The ventilation system allows you to maintain the quality of the air in the bathhouse, the correct thermal conditions, drying, and ventilation. Ventilation provides air exchange. It is carried out through ventilation ducts. Ventilation can also be provided by opening windows.

The size of the ventilation ducts is about 15x20 cm. The first duct is the supply duct, located next to the firebox, at a height of less than half a meter from the floor. Another channel, an exhaust channel, is made on the opposite wall at a distance of about two meters from the floor. A fan can be installed in this channel to speed up ventilation. The channels are closed most of the time with valves of the appropriate size.

Selection of materials or what they offer

The important point, as presented in the video, is to create a relaxing, comfortable and pleasant atmosphere inside the room for long conversations with friends. Preference is given to the traditional, original Russian style of finishing the bathhouse. Deciduous wood (birch, linden, aspen) and coniferous (spruce, pine, fir), the presence of a samovar, spoon, matryoshka, drying bag, bagel. The waiting room must meet certain requirements:

Attention: The dressing room is arranged with shelves for shoes, with comfortable seats; if the bathhouse is heated with coal, you need a special box with a lid and a space around the box that is convenient for cleaning.

The materials for finishing the dressing room are not as important as when finishing a steam room or sink (see Interior finishing of a bathhouse sink using different materials); panels made of coniferous trees, for example pine panels, can also be used. The temperature in the dressing room is low and there is no need to worry about resin discharge. You can order the finishing of the dressing room to specialists, but there is a second option, doing the work yourself, which is much preferable, and the price is lower, and the savings have never hurt anyone. Pine panels emit a pleasant aroma that has the smell of pine needles and has a beneficial effect on the human body. Instructions for performing panel installation work are provided below:

Requirements

Before building a dressing room, you need to study the requirements that the room must meet:

- There should be enough space in the room. One person needs 1.5 meters of free space.

- If the bathhouse will be used in winter, the rest room should be heated to make it comfortable to be inside.

- A high-quality ventilation system must be installed inside - natural or forced.

- The room should have furniture installed for a comfortable stay.

- The light in the recreation area should not be too dim or bright.

Often the furnace channel with the firebox is discharged into the dressing room. In this case, the area around the firebox door must be fenced off. This space should not be subtracted from the free space.

A little about the floors in the waiting room

Agree that it is unpleasant to step on a cold, not necessarily concrete, floor with warm feet. Selecting the right materials for a dressing room is not as easy as it seems. The dressing room is a place where people run out in negligee, and from which moisture gets onto the floor, spreading through the holes and cracks. It refers to a space where there is high humidity and evaporation. The floor surface should be comfortable, warm, non-slippery when wet, and promote health.

Wooden floor installation

It is made with first or second grade wood, well dried and without traces of fungus and parasites. The humidity of boards made from pine or larch should be no more than 10%; logs are selected according to the same criteria.

Attention: Wood of the second, sometimes third grade is used as beams or logs.

Material calculation

For every 100 square meters of flooring, with a board thickness of 0.3 cm, the following is required:

Attention: The boards are connected to the joists using nails, the length of which is 2-2.5 cm longer than the board, which ensures reliable fastening.

Such a dressing room with walls and floors made of pine material will have a finished look. Knowing the size of the dressing room area, it is easy to independently calculate the materials. Floor insulation is carried out electrically and by water. Floor insulation is taken from Turkish baths and allows you to reduce heat loss in the baths to a minimum. It is economical and affordable to cover heated concrete on top with ceramic tiles and cover the floor of the dressing room with rugs of suitable materials. The material for finishing dressing rooms can be varied; in addition to wood varnish, paint is used. Rubber paint deserves attention, durable and high quality, in a variety of colors and shades, although the base color is white. She feels great in a damp room.

The dressing room, like the bathhouse as a whole, can be finished with clapboard (see Finishing a bathhouse with clapboard: doing it right).

Materials for finishing work must comply with fire safety rules during the operation of the bathhouse. Select individually for each operating room of the bathhouse and be environmentally friendly.

Source

Ceramic tiles comfortable comfort

The washing room is capable of accumulating a large amount of dirt, since it is completely removed by humans here. And the bulk settles on the floor, which requires regular maintenance. And ceramic tiles are perfect for this purpose.

We will start installing the floor in this section of the bathhouse from the center of the room. This is necessary to obtain a beautiful finish in the washroom. Since the base slope will already be ready, we only have to do the finishing coat. For this we need:

The building level will act as a level bar to ensure there are no differences. If there are no deviations, then upon completion of the work we will receive a flat tiled floor with a slight slope. This is exactly what is necessary for a washroom, where in addition to practicality, it is worth paying attention to the attractiveness of the entire room.

We will lay the tiles seam by seam so that they run in even rows. But if you wish, you can make a different design, when the rows go diagonally or staggered. When everything is ready, we will leave the floor in the washing room to dry and only then start grouting the joints. Thus, the installation of a comfortable covering with your own hands will be completely completed.

Which wood is best for a dressing room?

The main advantage of finishing a dressing room with wood over its more modern artificial “brothers” is that, in addition to good performance qualities, this natural material is capable of releasing an aroma with certain healing effects. Therefore, let’s return to the classics and consider which wood to choose so that the finishing of the dressing room inside meets all the parameters of a proper bathhouse:

Finishing the floor in the dressing room

Above, we looked at the most popular options for finishing the dressing room today, or rather, the walls and ceiling. Now let's go down to the floor and figure out which coating is best to use in this part of the bath complex. The same requirements apply here - moisture resistance, wear resistance, comfort. Preference should still be given to natural coatings with the obligatory arrangement of proper water drainage and waterproofing. For greater comfort, it is also advisable to provide insulation or a “warm floor” system.

For example, you can use the same wood (larch or oak), but always impregnated with an antiseptic, or wooden plastic. In general, for the floor in the dressing room you can use any coating that can withstand constant exposure to moisture, including ceramic tiles or porcelain stoneware. Only in this case, installing a “warm floor” or laying insulation is no longer desirable, but simply necessary.

We invite you to watch a video about the interior decoration of a bathhouse with clapboard:

Source

Some tips

When finishing baths, do not use metal parts inside, even in the form of fasteners or holders. It's very easy to get burned by them.

Shelves and benches can be made stationary or removable. It is correct to place them against a blank wall. There should be a free space of 1.2 meters from the top shelf to the ceiling. This will allow you to sit on it comfortably.

Stationary shelves in the bath

Make shelves of different sizes. The lower one can be narrower, within half a meter, but the upper one should be made one and a half meters wide. This will make it more convenient to use them.

Multi-sized shelves are more convenient to use

When finishing the bathhouse inside, chipboard, plastic, and linoleum should not be used. The presence of painted surfaces is not allowed, even in the waiting room.

To ensure an optimal microclimate inside, take care of heat and do not make window openings too large.

Small window openings will help save heat

Set up dim lighting. This will promote relaxation.

Dim light in the steam room promotes relaxation

Install the sheathing lining vertically. In this case, water will not accumulate in the grooves.

With vertical clapboard cladding, water does not accumulate in the grooves

Don't insulate floors. The water flow must be free, then the covering boards will not rot in one season.

How to line the inside of a bathhouse inexpensively?

Construction of a bathhouse is a rather complex undertaking, since the owner has to solve many issues.

Among them is how to line a bathhouse from the inside. This decision must be taken seriously, since there are many different materials for cladding. Moreover, attention should be paid not only to the appearance of the material, but also to its quality characteristics. Don’t forget about cost - the material you choose must have the optimal price-quality ratio. Most owners believe that it is almost impossible to find such material, however, this is not so. There are certain nuances, knowing which you can easily solve this problem.

It should be said that almost any material is suitable for finishing a steam room However, it must meet certain requirements - be moisture resistant, have a low level of thermal conductivity, be resistant to rotting and be easy to restore. Today, wood products have all the necessary characteristics. Among them, the most famous are lining, panels, boards, planks and slats. And the buyer only needs to select the type of material. To make the right decision, you need to take into account, in addition to cost, the water-repellent characteristics and service life of the material.

Which tree to choose for a bathhouse?

The optimal material option for finishing the steam room is oak wood. It has all the characteristics that allow you to create optimal conditions for long-term and high-quality operation of the bath. Oak panels not only look attractive, but also have many other useful qualities:

The last point takes on particular importance in light of the fact that this helps maintain fresh air in the steam room.

A person who is accustomed to taking bath procedures at high temperatures should opt for oak, because under such operating conditions this tree releases useful phytoncides that have antiseptic properties. This will save the owner from the need to buy special fragrances for the room. But we should not forget about the naturalness of the wood, thanks to which it is possible to maintain the national style without additional processing. Although this finishing option is not available to all owners due to its high cost.

You can also choose linden to decorate the steam room. According to experts, this is an excellent option. This is due to the ability of wood to emit a wonderful aroma that no person can remain indifferent to. It is impossible not to mention the appearance of linden boards, the use of which to decorate a steam room will make the room more elegant.

Among other advantages that this type of wood has , we should highlight the low level of thermal conductivity. This means that in a steam room trimmed with linden wood, the surface heats up very little, so even if you have been heating the bathhouse for several hours, you can touch the walls without fear and will not get burned. Linden also attracts attention with its natural texture, and it does not lose its original color even under extreme operating conditions.

Aspen

Our ancestors also used aspen to decorate the bathhouse. There was a belief that this tree has magical properties , giving a person protection from the negative effects of otherworldly forces. At the same time, it has many positive quality characteristics, which makes it an excellent option for a steam room. If you initially decided to build a bathhouse on your own, then you should not give up aspen. After all, this is one of the few materials that does not create processing problems.

If you wish, you can

make from it wide boards of rough work or wooden slats, from which you can create a pattern of any complexity.

Aspen wood has a low level of thermal conductivity. This is also an additional reason to use it to decorate the bath. One cannot help but mention the soft, pleasant aroma emitted by this tree, which allows you to maintain a fragrant atmosphere in the room. Experienced builders value aspen for its ability to resist drying out and cracking. But the material does not have a long service life, and quite soon it loses its original color and begins to turn black. However, according to experts, this problem can be easily solved if you treat the inside of the walls with a special compound.

Alder

To decorate the steam room inside, you can use alder boards . It can be recommended due to the presence of tannins in the composition. The steam room can be sheathed with wide boards, having first removed the top layer from them. This will help them look more aesthetically pleasing. This material is worth paying attention to if your financial capabilities are limited and you cannot purchase oak wood.

In this situation, alder will help you out, because this material is immune to mold and other unpleasant formations . Therefore, even many years after finishing the bath, you can be sure that no foreign stains will appear on the walls of the bath. Increased temperature benefits alder - it begins to secrete special substances that help improve hemostatic processes and fight inflammation.

Other materials for bath lining

Most often, owners use clapboard to cover the walls of a bathhouse, although there are other options besides it. It can be:

Sometimes, when for some reason

the owner does not want or does not want to use the most popular materials, he can sheathe the internal walls of the bathhouse with foil.

But if it is important for you that such an important stage as covering the internal walls is carried out according to all the rules, then you should follow the recommendations of professionals. In fact, foil has been used for lining bathhouses for decades. Owners who are supporters of this material say that they chose foil for a reason, because with its help you can reduce heat loss, and this is a serious cost savings. If you decide to simply cover the room with foil before installing the lining or other material, you will not achieve the desired effect. Therefore, even if there is a layer of foil on the walls, you will not achieve a heat-saving effect.

Also, owners who choose foil for lining a bathhouse explain their choice by the material’s ability to perfectly insulate steam. It’s impossible to argue with this, but there is a serious drawback of foil here - it blocks access to air molecules. This situation becomes dangerous for people in the steam room, who may suffocate. As a result, they deprive themselves of the opportunity to fully enjoy bath procedures.

As an additional reason that explains why you should not use foil to decorate the interior walls of a bathhouse, it is worth mentioning the presence of harmful substances in the composition:

If you wish, you can refuse foil and use synthetic substitutes that have such perfect performance that their properties can compete on equal terms with wood.

But you should take into account that their cost may be higher than foil, and you cannot be 100% sure of their safety.

How to update the lining

Over time, the appearance of untreated lining ceases to please the owners. Wood tends to darken from moisture, but there is also soot that eats into the wood. For those who are no longer satisfied with this state of affairs and have decided to update the lining in the bathhouse, we have found tips that will help cope with any problem.

How and with what to remove soot

When carbon is not completely burned in a furnace (completely is CO2 or CO), it is released as an amorphous substance that we call “soot.” Soot deposited on the walls is soot.

Cleaning the lining in a bathhouse from soot is more difficult than it seems at first glance. It eats firmly into the wood. And when you try to wash it with soap and a brush, cleansing does not happen.

There are two proven methods for removing soot - mechanical and chemical.

Mechanically, everything is clear - the contaminated surface must be scraped off using any available method. Either manually or using a power tool - the same grinder with an abrasive wheel. As a result, the top layer of wood is removed, revealing a clean surface, and the result is what you need.

The chemical method does not require physical effort and takes much less time. On sale you can find products that were developed specifically to eliminate soot or soot from a fire.

As an example, let's name SYNTILOR Fuoco, DOCKER MAZBIT PLUS, “Facade Cleaner No. 2” from and the like.

The video clearly shows how the first of these tools works:

But here’s what’s interesting: all compounds that remove soot and soot contain... alkali as the main active component. No one says the composition, but there are just one or two strong alkalis, and their qualities are approximately the same. We mean sodium and potassium hydroxides - KOH and NaOH.

There is nothing stopping you from buying them at a store cheaply, diluting them with water and washing off the soot from the wood.

After the soot disappears, be sure to wash off any remaining lye from the wall. We recommend doing this first with an acid solution (vinegar, lemon) so that the residues are neutralized, and then with clean water.

There is another way, but we like it even less than dangerous alkali. We are talking about a mixture of gasoline and washing powder with water . You already have a fire-hazardous building with a stove; soaking it in gasoline seems unnecessary.

But if you need to wash, say, a fireplace brick , but there is no alkali on hand, you can mix two tablespoons of washing powder, 100 ml of water, 100 ml of gasoline, then vigorously shake the mixture in a bottle and start scrubbing.

In general, it is clear that soot and soot are removed by degreasers. Yes, by the way, burnt baking sheets are washed in the same way as lining - with alkalis.

How to wash the paneling

We have already recommended a way to get rid of blue stains and lighten darkened wood using bleach (by the way, this is just a solution of sodium hypochlorite, bleach - you can prepare it yourself from powder).

You can do without bleach altogether if you walk over the darkened lining with a sander.

If the task is to get rid of sweat, grease and the like, then it will be enough to wash the lining in a bathhouse with a strong solution of laundry soap . Moreover, what is interesting: laundry soap contains residues of alkali from the saponification of vegetable fat (that’s how it is obtained), so it is not neutral, but slightly alkaline. So it turns out that you are again using alkali, only weak.

Some people may find washing with soap a long time - then just increase the alkaline component. Following the safety precautions described above, of course! Maybe you have a “MOLE” - breed it.

This is such a chemical and not only educational program. Like, share links with friends and subscribe to our channel in Telegram.

Types of finishing material

If the bathhouse is built from logs, then finishing it will only spoil it.

Option for finishing a log bath

You can insulate a brick facade from the outside, but the inside is left unchanged. The only thing that can be applied is to cover it with protective compounds against mold and fire. The use of varnishes and paints is contraindicated. Due to elevated temperatures, they can release harmful substances into the atmosphere of the steam room and dressing room.

The finishing in the bathhouse must meet the following characteristics:

Stylish finishing of the waiting room with clapboard

If we consider popular finishing materials, we can highlight several main ones:

Finishing the bathhouse with the listed materials will create comfort and a healthy microclimate, which is so necessary for proper rest and restoration of health. The ideal option would be to finish the ceiling and walls with wood; floors – ceramic tiles with a warm floor system or wood; the wall adjacent to the steam room is tiled or stone.

Floor finishing

Considering that people most often run out of the steam room barefoot, the floor in the dressing room should be warm. There are two main methods of arranging flooring: tiles and wood.

Ceramic coating in the dressing room

For such finishing, you will need to install a “warm floor” system. Otherwise, your feet will freeze after the steam room, since the tiles do not have a high heat capacity. The tiles can be laid on concrete. This will require a number of preparatory works, depending on the readiness of the rough foundation.

The prepared base can be finished with tiles.

Wooden floor

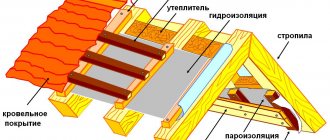

This is the most popular option for dressing room flooring. But you should take into account the increased humidity in the room. Therefore, this decoration of the bathhouse and rest room provides the following layers:

Wood should be chosen from coniferous species. Its resins have natural antiseptic properties, and essential oils have a beneficial effect on human health. It is also recommended to use hard wood types for flooring: oak, larch. But this is a completely different price category. The finished floor is not varnished. When heated, it can release harmful odors into the microclimate of the room.

Finished wooden floor in the dressing room Return to contents

Insulation materials

A comfortable microclimate in the dressing room can only be achieved through high-quality insulation. The thermal insulation material for the floor can be extruded foam, mineral or basalt wool. Typically, insulation is laid out in the space between the finished and white floors. A mandatory factor is the use of vapor and waterproofing materials.

Ceiling insulation is a necessary condition for reducing heat loss in a bathhouse (especially if we are talking about buildings with a cold attic). For thermal insulation, you can use basalt wool, as well as expanded clay of different fractions. Large granules provide thermal insulation, while small ones fill the space between them. Instead of expanded clay chips, clay or sawdust is suitable.

To increase the thermal efficiency of walls, mineral wool or foil foam is usually used. They are laid between the sheathing and finishing material.

A more modern heating option is to install a heated floor system. This can be a water or electric modification.

As a rule, installing a heated floor alone is not enough to heat a room, so you can use it to organize a convection heating system. This method can only be implemented when installing a water system. The heated floor is connected to installed radiators. The heating liquid (usually water, less often antifreeze) circulates through pipes under the floor covering and radiators, this allows you to achieve a comfortable temperature in the dressing room.

The choice of underfloor heating system should be approached responsibly. Each variety has characteristic advantages and disadvantages. If we talk about electric models, then an infrared floor is preferable, as it is as safe as possible in conditions of high humidity. It is capable of warming up a medium-sized dressing room in 15-30 minutes.

Another option to heat the dressing room is to use a special design of a sauna stove. Its heating part is located in the steam room, and the combustion part is moved outside the steam room (for example, into the dressing room). The firebox is designed to resemble a fireplace (a portal and appropriate decorative elements are used).

Closed fireboxes equipped with doors with a glass window allow you to enjoy the warmth and glow of the fire. The glass in such designs is thick (up to 8-10 cm), heat-resistant. This allows us to declare its safety. The presence of a self-cleaning system prevents the appearance of soot on the surface of the glass.

Wall decoration

For installation of any type of coating, it is recommended to provide insulation, waterproofing and, if necessary, a ventilation gap.

Block house and clapboard finishing

Sheathing material of this type requires the construction of a bathhouse frame, which makes it easy to waterproof and insulate the walls. It is worth noting that the lining is often mounted vertically, and the block house horizontally. Therefore, the guides for the first finishing material are mounted horizontally (perpendicular to the installation), and for the second type vertically.

The process itself can be divided into the following stages:

This technology is aimed at maximizing heat retention, and the ventilation gap allows the cladding to be ventilated. There should be no difficulties with clapboard covering. It is mounted using hidden nails or clamps. Fastening materials are selected with an anti-corrosion coating.

Additional components are produced for the lining: corners, plinths, connecting strips. Coniferous wood can also be used, unlike a steam room.

When installing block houses, difficulties may arise with corner joints. They will have to be cut at an angle of 45˚. Interior finishing of this type is similar in method of fastening to clapboard cladding, and its appearance resembles rounded logs. It is not recommended to cover the walls in the dressing room with protective compounds, especially the one that borders the steam room.

Facing with tiles or natural stone

If the bathhouse is made of logs or timber, then you will first have to cover the walls with plasterboard, which will make it possible to insulate and waterproof them.

The installation technology is as follows:

This cladding is more suitable for the wall adjacent to the steam room. Once heated, it will transfer heat to the rest room for a long time and evenly. The decoration of the dressing room with a block house and stone looks interesting. The roughness and simplicity of the lines makes the interior especially cozy. In the case of brick buildings, the outside walls should be insulated using a ventilated façade system.

Insulation scheme for a brick bath

It is good to waterproof the inside before covering it with wood. These measures will significantly reduce heat loss during operation and protect the structure from destruction under the influence of moisture.

Restroom

The dressing room is the first room that a person sees when entering the bathhouse. This is the most spacious room that can surprise a visitor with its originality; there is often a window in the dressing room. Unlike the steam room and shower, the creation of designer lounges can be expanded, allowing guests to enjoy an extraordinary approach.

A room with everything you need

This interior space is necessary for relaxation in order to make a comfortable break between “steam sessions.” A table is often placed in the hall to make it convenient to drink herbal tea; remember that hot drinks are contraindicated in the bathhouse. There are extra sofas, armchairs or benches in the room.

Table for soulful tea parties

If there is high humidity in the waiting room, it is better to install wooden furniture. Woven sofas and armchairs will eventually “catch” mold and mildew.

The design and nuances of the relaxation room in the bathhouse depend on the preferences of the owners. This is a unique room with a multifunctional purpose. Modern baths often have an entrance vestibule, a kitchenette, a toilet, and a swimming pool.

An important element and constant component of the relaxation room in the bathhouse are dishes

It is worth paying attention to the original cups and plates with traditional folk notes in the ornament. To decorate the table in the bathhouse, a popular favorite is the colorful Russian samovar.

Swimming pool for baths

Accents for finishing the dressing room in the bathhouse are placed on soft wood, for example, pine or Nordic spruce. You can diversify wood elements with stone, brick, tile or plastic. Modernist notes in a style that is rarer in our area, such as oriental, English, will be complemented by appropriate furniture, mirrors, paintings, chandeliers, fabrics and other accessory subtleties.

Bath accessories

The living room in the bathhouse can be considered a guest bedroom if it has full beds and is equipped with bedding, slippers and robes.

Bathhouse layout

Bathhouse layout

Bathhouse layout

Bathhouse layout

Bathhouse layout

Headlining

The most suitable option is to trim it with clapboard. The technology for installing a false ceiling is similar to the process of finishing walls with wood. Maintaining a technical clearance for ventilation of the cladding will extend its service life.

The ceiling is the weakest point in the dressing room. Warm humid air from the steam room and temperature changes are the cause of condensation on it.

Therefore, waterproofing is a must. The recommended thermal insulation material is mineral wool. Video instructions for finishing the ceiling in the dressing room.

Furniture

a small chest of drawers or whatnot would be useful

If you want to place a sofa in the dressing room, then choose upholstery made of leather or leatherette; due to high humidity, textiles will quickly become unusable. If you don’t like sitting down on your skin after a steam room, then buy a blanket made of natural fabric. All textiles in the dressing room should be easy to wash and dry quickly. For long service life of furniture and decorative elements in the dressing room, you need to ensure that vapor barrier and insulation are done according to all the rules.

Choose the design you like or come up with your own. Each dressing room looks different and bears the imprint of the owner’s character. You can see interesting ideas in the selection of photos.

https://youtube.com/watch?v=NsGF9KcmAfM

Stylistic design of the dressing room

Having finished the interior with wood, you can choose an interior option that is close in spirit:

Visiting a bathhouse with friends and relatives is a special event. Such a vacation involves a radical change of scenery and relaxation. Therefore, choosing a style for a dressing room is an important point, which is based on individual preferences.

Original interior and dressing room design

Many people can do the interior decoration of a bathhouse. The technology for cladding walls, ceilings and floors must be followed. This will create and maintain a healthy indoor microclimate. For interior decoration, the owner can use his construction experience, and the hostess can use her design skills. Joint creativity will be a special source of pride in front of friends and relatives.

Source

Lighting

When choosing bathroom fixtures, you should take care of their safety. The rest of the choice is determined by the interior style. For dressing rooms in a rustic style, bright lamps are not used. A small light bulb screwed into a socket on the wall will suffice. For spacious rooms and dressing rooms in a modern style, a chandelier under a lampshade (fabric or glass) is appropriate. It gives a cozy soft light. It is better to hang it above the table. A pair of identical wall lamps will add light.

Small iron tablet lamps look harmonious in modern interiors. For eastern recreation areas, it is better to choose exquisite floor lamps. It is logical to place the switches near the door so that it is convenient to use them as soon as you enter the dressing room.