You are on a page that is a guide on the topic “painting a bathhouse”. This means that here we briefly consider all the options for painting a bathhouse - inside, outside, in rooms, on surfaces, and you will find more complete and detailed materials on the links that are given right there. If a question has not been addressed in any of our materials, a detailed answer is given.

Impregnation of wood with imported products

Important! When using old materials and cheap types of wood to make a door, its durability and wear resistance are reduced, so when arranging a bathhouse, it makes sense to use only high-quality lumber.

After installing the door, to prevent it from swelling, it is necessary to cover it with protective substances. This will increase the life of the tree and give it a more presentable appearance. Of the imported door treatment products, the following are of the highest quality:

How to repair?

Over time, the door and its finish will wear out. Various defects appear in the form of cracks, gaps and other things that need to be corrected. Therefore, use our tips to easily repair your door. To eliminate cracks and scratches on the door leaf, you need putty. The putty is matched to the color of the wood species. The place where the defect has formed is filled with putty and, after drying, treated with sandpaper.

The hole can be sealed in the same way. If the hole is large, fill it with polyurethane foam and then apply putty. Re-filling may be necessary to ensure the surface is completely level. Very small holes can be hidden with a dowel: drill a hole and drive in the dowel, placing it on glue. Upon completion, sand the surface. Eliminate the gap with a plank, nailing it in the place where the door does not fit tightly.

To repair fiberboard panels, use pieces of plywood that are nailed to the damaged area with small nails. The hole in such material is sealed with a hook made of wire, which needs to be used to pry up the damaged area. After this, the edges are pressed and glued. After drying, the seam needs to be cleaned and treated with a fixative. A large hole can be repaired using the same method used for wood.

Chipboard repair. To put the material in order, you will need a syringe and glue. We remove the canvas. The delamination of the material is corrected with the help of glue, which we pour and press the sidewalls. Place the door under a press until it dries. After this, the edge is treated with protective tape. The repair work is completed by bringing the door leaf to its original form: painting, varnish, cladding, or you can re-sheath the door.

To learn how to make a door to a bathhouse, see the following video.

Impregnation of wood with domestic products

Although imported products are considered to be of quite high quality, they have a relatively high cost compared to domestic counterparts. We present to your attention the most popular and noteworthy domestic products.

Proper coating of a wooden bathhouse door will increase its wear resistance and help the wood maintain a beautiful and well-groomed appearance for a long time. Choose the optimal impregnation according to your purpose and the described characteristics. You can try to process the door yourself or entrust this task to construction specialists - the skills and professionalism of our craftsmen will not leave the most demanding client indifferent, and the prices for the work will please them with their moderation. You can also order a log bathhouse or caulking services for bathhouses from us.

Source

Thermal curtain

You can additionally block the access of cold air to the dressing room using a thermal curtain.

Additionally, you can block the access of cold air to the dressing room using a thermal curtain. This is done as follows: soft insulation, cut into 10 cm strips, is nailed along the entire perimeter of the door jamb, retreating 2 cm from the edge of the frame. Next, wooden blocks of 2 x 2 cm, neatly wrapped in the same thermal insulation, are nailed onto the strip of insulation. As a result, you get a neat frame on the door frame.

The curtain is made of leatherette or other dense fabric. Along the height of the curtain, a wooden block of 2 x is inserted into the holes sewn at the edges on both sides. 2 cm. It is necessary to provide 7-8 rings along the top of the curtain, with the help of which the curtain-screen will hang on the wire.

The wire is pulled in such a way that when not in use the curtain does not interfere with passage through the doorway, i.e. moved far enough away from the door to the side. It should fit as tightly as possible to the sealing frame when closed: the bars in the cavity of the door leaf should extend beyond the vertical parts of the frame on the door jamb. Additional fastenings for the screen can be provided on both sides of the door.

How to treat a wooden door

After completing the finishing work, a person faces many questions. Do bath shelves and other wooden elements need to be treated? What to use: expensive products or cheap ones with chemical additives? Or maybe it’s better to leave the wood without treatment at all? If you want the shelves to serve you for many years and not lose their beautiful appearance, then you should definitely treat the wood with high-quality safe products that are used in bath rooms.

To make shelves, craftsmen recommend using aspen boards or abasha wood. But pine products are completely unsuitable for a steam room. When heated, pine shelves will begin to release resins, which are not only harmful to health, but also pose a risk of burns during vaping.

What is the benefit of processing

Almost all owners of personal plots who build steam rooms strive to build a room not only for washing, but for comfortable relaxation. That is why they choose natural wood as the building material for the shelves, which is ideal for a steam room. The technical characteristics of lumber make it possible to use wooden boards in rooms with extremely high air humidity, but at the same time, the service life of natural raw materials without pre-impregnation of the shelves is too short.

Since the high hygroscopicity of wood leads to the rapid absorption of moisture, the material of the shelves becomes an ideal place for the appearance of various kinds of microorganisms. The result of all these processes will be rotting of the wood. It turns black, fungus and mold appear on it. Often, the lack of impregnation leads to the accumulation of a large amount of dirt in the pores of the wood, which, in turn, provokes the appearance of parasites in it that destroy the structure of the tree.

Special antiseptics make it possible to reduce the risk of wood contamination, thereby extending the life of wooden shelves and improving the appearance of a product that you may have made yourself.

Today, stores have a huge number of different products that cover the shelves in the bathhouse. They are effective impregnations that not only protect natural wood from rotting, but also give it an aesthetic appearance.

Available methods for processing lining

As a rule, the lining in the steam room is left unchanged, but in the waiting room and washing department it is treated with protective agents. Without additional processing, the material quickly loses its attractiveness and performance characteristics, and therefore requires replacement every 3–5 years.

If you need to protect a decorative board in a steam room, then you should know what special products are intended for use in rooms with high levels of humidity.

Processing of the lining inside the bathhouse is carried out:

For the steam room, it is recommended to use safe natural products that create a protective wear-resistant layer on wooden surfaces. Such preparations include special fungicides and insecticides that can prevent the development of fungi, mold and pathogens.

Criterias of choice

For all its advantages, wood is susceptible to moisture. Over time, it dries out, darkens and begins to rot. Mold and microorganisms may appear on it. All this is true for normal external conditions. And in the steam room the conditions are extreme. Even in the dressing room there are no such impacts on the walls and floor. The influence of sudden changes in temperature and humidity in the steam room accelerates the destruction of wood. When exposed to high temperatures, conventional protective coatings can release harmful substances.

In addition, a steam room is not just a room in which a person is located. He remains there naked, his body in contact with wooden surfaces. And on some it even lies. This means that for shelves and benches you need to choose wood protection that will not be unpleasant upon contact.

Most often in the steam room they try to preserve the natural color of the wood, selecting species that look beautiful. But if you want to paint part of the steam room, then you need to take this into account when choosing an impregnation. Not every impregnation is suitable for subsequent painting.

Wood color after different impregnationsSource elka-palka.ru

It is clear that it will not be possible to find the same impregnation for a bathhouse outside and inside. Even different parts of the steam room may require different protective equipment. Wood treatment in a steam room should be carried out with compounds adapted to its conditions. And the choice must be based on the following criteria:

- Which part of the steam room is the product intended for?

- Will it be primary impregnation of wood, or re-coating of a previously protected surface?

- Method of applying a protective substance to a wooden surface - with a brush, roller or spray

- Are there plans to further paint the impregnated wood?

Features of impregnations for shelves

On the building materials market there is a huge number of different products for treating platforms in a bathhouse. They differ from each other not only in price, but also in quality. Moreover, each impregnation has its own characteristics, which are taken into account when purchasing.

Therefore, when choosing a product for treating shelves in a bathhouse, pay special attention to its properties.

But even if you are absolutely sure of the quality of the chosen product, it is better to consult with a specialist.

What to do if the problem is in the door frame

A rotten door threshold or the formation of gaps between the logs and the door frame also provoke the penetration of cold air into the dressing room. The cracks can certainly be sealed without any reconstruction of the box. But if the reason is more serious, then the door frame will have to be partially or completely replaced.

To do this, the door leaf must be removed and the rotten element of the frame must be sawed in half: the top beam, threshold or side posts are sawed across and the fragments removed from the frame, being careful not to damage the mounting pins. After this, a new part is made and the damaged one is replaced.

The structure of the box and the bathhouse itself are not dangerous and the work cannot affect the integrity of the structure, so you can work slowly and without fear.

Ensuring good thermal insulation of a bathhouse is not only a comfortable stay, but also a guarantee of energy efficiency, since heating a high-quality bathhouse requires much less resources than heating a poorly insulated room where heat loss is inevitable. If necessary, during the warm period you should insulate not only the door, but also the walls, ceiling and floor of the bathhouse.

Work order and nuances

Painting doors yourself is not a difficult task. Every person can cope with such a process. In general, such works can be divided into two groups. The first step is painting new doors. Another issue that will be discussed below is repainting doors.

Painting new doors

Wood that has not been treated absorbs moisture very easily. Therefore, if such doors are placed in a bathhouse, they will very soon lose their original appearance: they will swell and stop closing. This cannot be done without pre-treatment and painting.

Experts recommend that before installing a new door, they must first be properly prepared and treated with special compounds. Doors should be painted in a dry, clean room so that dust and moisture do not get on the wet sticky surface.

A sequential description of the work process is as follows:

After all the wooden elements have dried, you can screw on the fittings.

If you decide to use stain for painting, then you will not need to use a primer. To obtain a uniform color and texture, the product must first be carefully moved, since the coloring elements of the stain tend to settle on them, which will affect the uniformity of the texture.

There are several ways to apply stain, each of them allows you to achieve a different effect.

Painting old doors

Often it is necessary to revive old doors so that they look more attractive and attractive. To make it more convenient to paint the doors, it is better to remove them from the hinges.

The sequence of work is as follows:

As you can see, almost anyone can do painting work. You will have to tinker with old doors, but anyone can do this task.

Materials

There are several types of bath doors, which are classified according to the material they are made of: doors made of wood, glass and doors with double-glazed windows.

Wooden

The most common material is wood, as it is moisture resistant, hygroscopic and can withstand high temperatures. Boards for a bath door can be made of aspen, linden, oak, or larch. After all, it is these types of wood that have the property of having a positive effect on a person during a bath. The price of the door will depend on the type of wood:

- Oak is a very dense wood that does not tend to swell.

- Larch is well suited for damp rooms. Useful properties include: antiseptic effect, as well as resistance to rotting, mold, and various insects do not stick to it.

- Aspen is an inexpensive species that performs well in very dry and wet conditions.

Glass

Glass doors are used in saunas to separate the dressing room from the dry steam room. There are many options for coloring the glass surface: up to full-fledged drawings. There are glass doors: frosted, transparent, opaque and translucent. Doors can be installed in a frame or attached to a door frame.

Glass doors cannot be made independently due to the particular complexity of manufacturing. Having ordered such a door, you can only install it

When choosing a glass structure, special attention is paid to fittings, practicality, reliability and safety of use. The door should look aesthetically pleasing

To ensure tightness, the kit must include silicone seals. Instead of a latch, there is a magnet in the handle and door frame. This type of lock never fails.

There are models in which magnets replace ball-shaped latches, but since they fail over time, magnets are the best option. Models with three hinged hinges are more reliable. Requirements for glass sheet: it must be tempered, high-strength, 8-10 mm thick. The material for making the door frame is aluminum. The glass door and aluminum frame ensure complete waterproofness. The downside is the seals, which can be worn out by high temperatures and high humidity, but replacing them is not difficult.

With double glazed windows

Metal-plastic doors with insulation maintain tightness and retain heat well inside the room. They can be installed not only at the entrance to the bathhouse, but also in the bathroom, and also to separate other rooms. The door to the steam room is made of wood. It is possible to combine wood with double-glazed windows. The design of a wooden door with double-glazed windows includes the frame itself with aluminum inserts, as well as one or more double-glazed windows. This type of door does not require special care. It is enough to wipe the double-glazed windows on both sides with detergent, and a soft cloth will be suitable for the door, which will remove dirt.

Types of products for processing shelves

All wood compositions are divided depending on the formula, the properties they have and the methods of their application. They can be colored or colorless, have different consistencies, have whitening properties, and are also available in the form of aerosols, gels or other solutions. Modern products most often have several properties at once, but the main thing that unites them all is the water-repellent effect. Thanks to this, the shelves are reliably protected not only from high temperatures, but also from high humidity in the room.

Shelf treatment products are divided into two main classes

| Types | Subspecies |

| Impregnations. | The first include waxes, gels, aerosols or antiseptics, which are used as a means to prevent fungus and the occurrence of microorganisms in the tree. |

| Coating compositions. | There are preparations on the building materials market that do not lose their technical characteristics even at high temperatures. |

The versatility of modern means for treating shelves makes it possible to increase the service life of wood and prevent the occurrence of fungus. They also give a change in the color of bath furniture. If we consider drugs depending on their composition, we distinguish the following types:

Water-soluble preparations are produced on an acrylate basis and protect wood well from moisture, contamination, and also from the occurrence of microorganisms in it. These products are colorless. Therefore, if you want to add brightness or a certain color to your shelves, then you should use the color scheme offered by manufacturers.

The main advantages of this type of impregnation for shelves are the absence of a specific odor after treatment, preservation of the external structure of the wood, and the ability to leave the color of the furniture unchanged. The only drawback of water-soluble products for treating shelves is the rapid leaching of the product from the wood structure. Therefore, the need for re-treatment compared to other impregnations increases several times.

Oil impregnations for shelves are deeply absorbed into the wood and retain their properties for a long time, so you won’t have to treat the furniture often. But still, oil products also have disadvantages. They consist of a strong specific odor, which occurs due to the presence of a solvent in the composition of the drug.

Despite the fact that oil-based impregnation saturates and compacts wood well, providing it with high wear resistance, it is not recommended to use it for treating furniture in enclosed spaces. Especially when it comes to preparations for impregnating shelves.

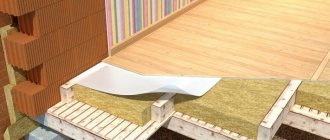

Two-chamber opening filling device: step-by-step instructions

The design makes it possible to almost completely get rid of the problem of condensation forming in the space between the doors, which, when frozen, begins to make it difficult to close them. A two-chamber device for filling an opening made of fiberboard, insulation and boards is effective in smoothing out high temperature contrast.

Sequence of work:

- An inch board sawn in half is brought to a thickness of 15 mm;

- From the resulting lumber, two frames for the door leaf are made according to the size of the opening;

- At your own discretion, mounting spikes are made on the frames;

- 3 blanks are made from fiberboard according to the dimensions of the frames;

- The first frame is placed on one of the blanks, laid face down, and filled with lightweight synthetic insulation;

- The second fiberboard sheet and another part of the frame with insulation are laid;

- The structure is closed with the last blank placed face up;

Advice! When connecting a door, the screws should not pass through both frames, but only up to half the thickness of the second.

- The ends of the resulting canvas are carefully sanded with sandpaper;

- The resulting structure is primed and painted or decorated in another way;

- Installation of handle, awnings and lock.

Measures for thermal insulation of a bath door can significantly reduce heat loss and increase the comfort of procedures. The insulation method can be selected based on the materials and financial resources available.

Peculiarities of processing lining in the washing compartment and dressing room

Decorative finishes in the wash compartment are constantly exposed to the negative effects of steam and water. Therefore, providing protection with antiseptic compounds is a top priority.

You can cover the lining in the bath with the following preparations (our recommendations):

To paint the lining and prevent the negative effects of moisture, steam and temperatures, it is necessary to use safe protective compounds for wood. Even a novice craftsman with minimal experience working with painting tools can master the technology of processing wooden surfaces in a bathhouse.

Types of oil

During wood processing, oil components thicken under the influence of heat, light and oxygen. The result is a semi-solid mass with excellent protective properties. The more linolenic and linoleic acids in the oil, the higher its hardening ability.

We suggest you read: Is it possible to build a bathhouse from sleepers?

After treatment, the wooden product should dry for 2-3 weeks. To speed up this process, you can use:

It should be remembered that turpentine is a toxic substance and can cause thermal burns upon contact with skin. In addition, some people may have an allergic reaction to it. Tar obtained by dry distillation of wood is the same as turpentine, however, it is less toxic.

Useful video

This video shows the process of exterior painting of a bathhouse made of timber, perhaps some of you will find it useful:

*** We again appeal to our readers with an invitation to share their own experience, which will be valuable for other bathhouse owners. Agree that it would be great if useful information was available to everyone.

Painting, Impregnation · 11/14/2019 · 0

What compounds should absolutely not be used?

All wood treatment products have an organic or chemical basis. But here it is worth understanding that the furniture in the steam room is often exposed to high temperatures. Therefore, in order to avoid the release of toxic substances that are found in the compositions of antiseptics and other chemical-based preparations, craftsmen categorically do not recommend using such compositions for furniture in the steam room.

Most often, chemical-based preparations are presented in the form of varnishes or paints. There are also a large number of aerosols, impregnations and other products that contain aggressive chemicals. Therefore, when choosing drugs for shelves, you need to carefully familiarize yourself with its main components.

Paint selection

Based on what exactly will be done with the door, you need to choose the right way to paint the door. In this case, there may be two methods of doing the work:

| Door design method: | Materials used: |

| Highlighting wood texture: | In this case, it is better to paint the surface with clear varnish, oil impregnations or stain, and also use tinting mixtures. |

| Complete removal of the old door surface pattern and application of a new one: | If you need to create a new design that will imitate wood, then the paint should be wood-like, based on an acrylic, polyurethane or oil composition. |

Oil application technology

Stages of work

Work on processing a house made of timber or a log house will be similar. Conventionally, they can be divided into three main stages:

The process of applying oil to wood is described in detail in the article “How to treat a wooden house with oil with your own hands.” Therefore, in this review we will not dwell on the description of all stages, but will provide only the basic rules for oil painting.

Before starting work, it is necessary to determine the moisture content of the wood. The optimal indicator in this case is 15%.

Air humidity during painting is also essential. It should be within 80%.

Conifers with high resin content must first be impregnated with white spirit.

When painting wood with pure linseed oil, at least 4 layers are required to obtain a better result. When using professional products, you must follow the manufacturer's instructions. As a rule, to achieve the desired effect, impregnation manufacturers recommend applying 2 layers to unpainted wood and one to painted wood.

The oil should be applied along the grain of the wood using a stiff brush with artificial bristles or a lint-free cloth.

We invite you to familiarize yourself with the Bathhouse with a relaxation room and a summer kitchen

Be sure to sand between layers after each layer of oil has dried.

After the last layer has completely dried, the wood is polished with suede. Polishing allows you to give the surface an even, beautiful shine.

To check the quality of the resulting coating, you can apply a few drops of water. If the liquid remains in place, then the treatment was done well.

Source

Painting a brick oven

Preparatory stage: If there are minor defects (depressions, bumps, potholes), first plaster and level, and cover the seams with a clay solution.

You can learn how to prepare a good clay mortar from the corresponding article, which is on the blog... Plaster is made from clay and crushed asbestos. The resulting mixture is carefully applied to a well-heated stove.

How to paint: The two most popular proven folk methods are lime or chalk. The third method is again heat-resistant paint, which is also used for iron sauna stoves.

Cooking and painting with chalk

- Pour the pieces of chalk into a container (bucket, basin), fill with slightly warm water so as to cover the surface and leave for at least one hour;

- In another container, mix animal glue with warm water in a ratio of 25:1. Animal glues include gelatin, casein, albumin, and bone.

- Mix both solutions and bring to a homogeneous consistency. “To check the quality of the solution, drop it on a piece of glass or mirror placed vertically. If the density is normal, then the droplet will slide down by 2-3 cm.”

- Apply two or three layers. Each subsequent one, only after the previous one has dried. “For a more “clean” whiteness, you can add a tablespoon of blue to a bucket of the finished solution. It will remove some of the yellowness.”

Cooking and painting with lime

- Solution proportions: 1 kg of lime / 1.5 liters of water at room temperature / 1 tbsp. spoon of drying oil / 25-30 grams of blue / 1 tbsp. spoon of salt. Mix. “The most durable whitewash is made from freshly slaked lime, and salt is added to make the lime coating less dirty.”

- Apply in two or three layers. Unlike whitewashing with chalk, each subsequent layer of lime whitewash is applied to the wet previous one. “If the stove in the bathhouse was previously painted with chalk, and you intend to use lime (and vice versa), the surface must be thoroughly cleaned of old paint.”

The best impregnation for baths inside and outside

In the photo: finishing the steam room of a bathhouse with wood (lining)

Anyone who wants their bathhouse to last as long as possible is considering various options for extending its life. Various impregnations are just among the products that promise just that. But let's find out what they are and where they are most appropriate.

For this purpose, we decided to divide our article into two parts, devoting one of them to impregnations for the bathhouse inside, and the other to the outside.

The difference is obvious - everything that is outdoors is exposed to solar ultraviolet radiation and seasonal precipitation, frost and heat. This suggests some aggressive response. And what is inside the bathhouse should be as harmless as possible to humans, but still quite effective, because the bathhouse has high humidity.

Which are the best for outside treatment?

Let's start with the outside. It can be made of wood in two cases: when the wall is made of wood - timber or round timber, and when it is lined with wood. In this case, either clapboard for external cladding or board can be used.

Bathhouse with a large relaxation room

As for impregnations, they are divided into two categories: for protection against biological damage (antiseptics) and/or fire retardants and for protecting wood from the effects of nature and weather (coatings).

The antiseptic agents that are used to impregnate the outside of the bath will not differ for boards and logs, because in our case they are all intended for manual application . This means that their depth of penetration into wood is limited to a maximum of 5 mm, but in reality it is even less.

Therefore, it is advisable to approach the impregnation of bathhouse timber more responsibly and use stronger antiseptics.

For log and timber

Ideally, for the outside of a log bathhouse, impregnation made in an industrial environment . But it covers the entire surface layer of the log, which is not good for a steam room if it is not insulated and lined with clapboard. If the walls are covered (only in the steam room), then impregnated wood should be considered the most protected from rot and mold.

You can read in detail about what it is and what compounds are used there.

Applying antiseptics manually, as already mentioned, is less effective, but fairly strong formulations can be used.

In general, it is recommended to pay attention to those compounds that are designed for outdoor use.

An example of a good option for impregnating the outside of a log bathhouse is the “Valtti” . They are sold with an antiseptic primer. Ideal compatibility option.

Let me explain. to peel off after three years in the harsh Russian winter Oil impregnations are better in this regard because they form a more elastic coating. The same applies to acrylate compounds.

Actually, here it is. We coated the wood with an antiseptic, after which the impregnated layer must be protected from washing out and destruction by ultraviolet radiation. Therefore, pay attention to the presence of UV filters in the product you will use to coat the antiseptic.

What is good about exterior impregnation of a log house with oil? Thanks to it, the logs will crack much less , because the oil makes the wood less fragile. In our opinion, this is the best impregnation for the outside of a bath. You can use both domestic and imported oils. The main thing is that they are intended for facades, contain UV filters and are resistant to temperature changes and precipitation.

Design

We haven’t touched on this topic before, but why not really think with you about what color to paint the bathhouse and what design options there are in general?

What color to paint

We have paints and varnishes at our disposal. The bathhouse itself is either made of wood, or lined with wood, or brick, or plastered. Perhaps it is finished with stone, for example, on the foundation.

In general, it would be desirable to maintain at least some kind of stylistic unity - at least within the bathhouse itself, and at maximum - in all buildings. That is, if you decorated the house traditionally and in natural wood colors, then painting the outside of the bathhouse pink will look... foreign. But if all the buildings on the site are bright in color, then the bathhouse should be made no less bright.

Now about the styles. We have already said once in other articles that the bathhouse has three conventional styles : tradition, high-tech and “modern” (the latter means the use of modern materials without particularly advanced design ideas).

If you choose “tradition”, then you either have timber, a log house, or lining - paint in shades from yellow through orange and reddish shades to dark brown, better with varnish than paint, so that the texture of the wood is visible.

It’s hard to believe in real “ high-tech And if it is implemented, it will be according to a design project, where all the colors will be painted.

There is only one option left - the same “ conditionally modern ” style, which does not have its own face. Try to “revive” it by using brighter colors. And regarding the combination of colors, we advise you to search the Internet for pictures with the phrase “color schemes” - usually this is a photograph from which several colors have been extracted (stripes under it), forming a harmonious combination. It's easier than learning color theory.

Example of color gamut extraction

Impregnation for baths and saunas inside

If external impregnation has already become more or less clear, you can move on to the extensive issue of internal impregnation.

How does internal impregnation differ from external impregnation? If we are talking about antiseptics, then the degree of aggressiveness. After all, all antiseptics are poisons not only for mushrooms or insects, but also for people. It’s just that now these are low-toxic substances, but before there was a nightmare of arsenic and chromium. However, indoor antiseptics should be even safer.

If we talk about impregnations for wood in a bathhouse for interior work, then these are not paints, which can be more harmful if used outside. Impregnations will differ only in the presence or absence of additives that protect the wood from the sun and other environments. Such additives are not needed indoors.

For lining

Lining is a thin profiled board. What is it impregnated with and why? Of course, any wooden part when moistened is at risk of infection by fungi that cause rotting or mold. the washing room and (attention!) near the floor in the steam room needs antiseptic protection .

Impregnation for lining in a bathhouse

Let us explain: the temperature near the floor, even in the steam room, is not that high, and the lower lining often gets wet. An antiseptic may or may not be used if it is replaced with high-quality ventilation and drying (see the section on ventilation), as well as some life hacks, the point of which is to prevent the lining from coming into contact with the floor.

So, if an antiseptic for lining is needed, it is in limited quantities . In the washing room, a primer for (interior) acrylate varnish will be sufficient.

We also recommend reading the article about all types of lining treatment in a bathhouse, inside and outside, or watching its video version below.

For boards

Lining is also “boards”. But even with ordinary edged (or even unedged) boards, a bathhouse can be sheathed inside and out. low-cost option , so we will not say that such a bathhouse should be covered with compounds purchased for a lot of money from the Finns.

Impregnation for boards in a bath can be quite inexpensive if you use an old and proven recipe for a mixture of linseed oil and wax . Watch the video, which clearly demonstrates the process of preparing such a composition and its application in practice. And note: the owner of the bathhouse was happy to cover it with it inside and out!

For floors

Again the same point: impregnations are antiseptic and water-repellent. Both are in demand for floors, because there is dampness from the underground, and moisture from the steam room and washing room (you shouldn’t think that if water doesn’t pour onto the floor, then everything is dry, there is also moisture in the air, which condenses instantly, if there is a cold surface).

There is a lot of moisture in the bathhouse. Therefore, it must be dried and protected. We recommend covering the floors with some kind of interior antiseptic, but on the condition that the seller or manufacturer was able to assure (or better yet, prove) that this antiseptic protects not only from mold, but also from rot. We have said more than once that these are different types of mushrooms that require different compositions.

can be applied over the antiseptic . Typically, special paints and varnishes with additives are used for flooring, which increase their wear resistance. In particular, these are urethane and polyurethane additives. They are needed because we constantly wear down the flooring with our feet.

yacht varnish as a finishing coating which is not afraid of moisture. However, here we go beyond the scope of our topic. Because varnishes are not impregnations. We have a separate material about impregnations for bath floors.

On the other hand, using oil to impregnate the floor inside a bathhouse is a bad idea. Of course, there are oils that do not cause slipping. But the fact is that oil impregnations do not provide a coating that is resistant to abrasion. And they give varnishes. Therefore, wooden floors are coated with varnish.

Types of compositions for interior work

We have already said a lot above about various impregnations, but it’s time to clarify what exactly you may find on sale.

We will separately consider water-repellent and antiseptic impregnations.

Mixtures for wood: with wax and oil

Pure wax for impregnating wood is used in limited cases. This operation is called waxing, it is applicable to furniture, but our case is different.

The task of water-repellent impregnation is inherent in its name. In addition, it allows the wood not to absorb dirt, sweat and grease. Another couple of important advantages are a reduction in the swelling of wood (you don’t think that after impregnation it will completely stop absorbing moisture? In fact, its amount will become much less), as well as an increase in its elasticity, that is, it will not crack after drying.

Therefore, the basis of impregnation is oil. It comes in flax and paraffin.

Paraffin oil is made from petroleum. It is as safe as flaxseed. In particular, paraffin oil can be bought from Tikkurila, it is called “Supi Laudesuoya”.

Impregnation for shelves in the Tikkurila steam room - Supi Laudisuoja. Banka Photos

By the way, the same company has an impregnation for baths inside with wax, which is called “Supi Saunavaha”. Water-soluble, which means that there is not only wax, but also something that polymerizes when it dries. There are no ingredients on the label.

Flaxseed oil is more traditional, it can be found in many varieties, both domestic and imported. You can buy pure raw (or boiled) flaxseed oil at a pharmacy or in a regular supermarket. Even in this form it can be used as an impregnation, but it will take three days to dry one layer.

Usually the buyer is offered a composition that requires much less time to dry. Boiled butter requires less time to polymerize. Dryers also reduce time, but their use here is inappropriate.

The mixture of oil and wax is called oil wax. Such compositions can be of varying degrees of solid-liquid. Liquid formulations are more convenient to apply, but they have higher consumption.

There are a lot of impregnations. Almost every company that has something for a bath produces such impregnations. Therefore there is no need to list. Decide what is more important to you - price or the authority of a large company. And so, by and large, even what you can do with your own hands will be of very good quality. You use natural ingredients.

Antiseptics

You can also learn about what types of antiseptics can be found on the market from this article of ours. However, here we will briefly go through some of the major market players that everyone knows about.

"Senezh"

produces a whole range of antiseptics that can be used for both internal and external work, that is, you have the opportunity to buy everything you need to protect wood from this company.

Impregnation Senezh and brush

Structural parts such as joists and beams that will not be visible can be treated with a strong, non-washable antiseptic. For example, “Senezh Ultra”, “Senezh”, “Senezh Bio”.

Non-washable is not suitable for facades, because it gives a green color to copper salts. Therefore, weaker compounds are used, but they do not produce coloring (at least in unnatural colors). For example, "Senezh Aquadecor".

Inside, you should use even safer options, which are marked that they are suitable for interior work - “Senezh Ecobio” .

“Senezh Sauna” was developed . To stand out in the market, they added antimicrobial agents. But it is not recommended to use this antiseptic on shelves.

"Neomid"

The products of this company are widely advertised and are known to many. For baths, she has developed such impregnations as “Oil for baths and saunas” - already with an antiseptic, as well as the composition “Neomid 200” , which is suitable for antiseptic steam rooms.

Antiseptic for baths and saunas NEOMID 200, 0.5 l., concentrate. Photo by Maxidom

The rest of the impregnations from this manufacturer are universal for any interior and exterior work. In particular, to protect wood from biological damage, you can use Neomid 400 Neomid 440 outside

There are other options in the catalog on the company’s website that are suitable for building elements under heavy-duty conditions. As well as a series of comprehensive protection against fire and biological damage. Below is a video about using this manufacturer's anti-mold composition.

"Tikkurila"

Well, this name is definitely on everyone’s lips. We have already mentioned their impregnations for baths and saunas inside. Let us repeat - these are “Supi Laudesuoya” and “Supi Saunavaha”.

In addition, the company offers oil for shelves, as well as protective compounds for walls and ceilings, but they are no longer impregnations, but acrylic varnishes. Antiseptic additives are already included in these formulations - “Supi Arctic” and “Supi Saunasuoya”.

For the floor they have Supi Lattiaoljy .