The chimney is an important element of a stove or boiler operating on any type of fuel. It is designed to remove flue gases generated as a result of fuel combustion. Most often, chimneys are laid out of brick, but in some cases it is impossible to do without installing a metal smoke removal device. Many owners of private houses make and install a chimney from a steel pipe with their own hands.

Steel chimney

Scope of application of tubular metal chimneys

The advantages of using such materials include several points:

- Light weight. For chimneys, electric-welded pipes with a wall thickness of 0.5–1.5 mm are used. The total load of this design allows it to be used for all types of stoves, including metal bath stoves, closed and open brick stoves, slow burning stoves in greenhouses and residential premises, as well as for other types of heat sources.

- Tubular devices do not require special support structures in the form of foundations.

- Long service life. For galvanized pipes it is 10–20 years, and manufacturers of stainless steel products declare durability for 100 years. Of course, there is no factual data on this issue.

- The simplicity of installing a chimney from pipes makes it easy for even a person with minimal DIY skills to cope with this task.

The construction of a steel chimney for a sauna stove is quite simple

The limiting factor in the use of steel pipes is their cost, but this only applies to stainless pipes.

Video: what you need to know about metal chimneys

Pipe selection

Currently existing chimneys have complex structures, so their installation must be accompanied by careful selection of materials and subsequent high-quality installation.

The performance of the finished structure will depend on the following factors:

- boiler efficiency;

- volume of fuel consumed;

- level of efficiency;

- safety;

- type of installed stove.

The chimney for a private house or bathhouse must be designed especially precisely. At the same time, it makes no difference whether you have a gas boiler or a potbelly stove, a brick house or a wooden one - you will have to install a chimney in any case.

Types of steel pipes for chimneys

A specialized hardware store offers a wide range of steel pipes, which differ in purpose:

- Single-walled - made of galvanized or stainless steel, cheap, used for repairing existing chimneys.

- Multilayer - consist of an outer shell and an internal conductive pipe, made of stainless steel, galvanized or combined. This allows you to significantly reduce the price. The gap between the two walls is filled with heat-resistant insulation, for which refractory basalt wool is often used.

Sandwich pipe is ideal for chimneys

- Coaxial - the same sandwich pipe, but there are partitions between the walls. Air is supplied inside the furnace through a free channel to improve combustion and increase heat transfer. This is know-how in the field of chimney installation. Coaxial pipes are used for forced draft boilers.

Coaxial pipe went on sale quite recently

The design of a double-layer chimney and its distinctive features

This is a structure of two steel pipes inserted into each other, different in diameter. The outer one is called the casing. A pyre-resistant insulation is placed between the pipes, usually basalt wool (laid so that the fibers are oriented along the pipe) 30–35 millimeters thick, capable of withstanding heat of a thousand degrees. Mineral wool is completely unsuitable.

Sandwich chimney parts

Types of chimneys

Based on the components used, these devices can be divided into the following:

- single;

- multilayer.

The materials used for their manufacture are particularly durable and highly resistant to acid condensate. A clean surface helps to completely remove moisture and soot from the smoke duct.

Single pipe structures are very often used. Such technical solutions are used to adapt old chimneys to new heating equipment. Pipes for them are made square, oval or round. Austenitic stainless steel is used for their production. Enameled pipes are also produced, but they are not widely used because they are sensitive to mechanical stress.

Single chimney needs additional protection

When installing a single chimney, you should be guided by the fire safety rule, which requires a distance to the nearest wall made of flammable materials of at least 1 m.

Double-layer structures have their advantages. The thermal insulation layer between the walls of such a chimney reduces the cooling of the inner pipe, resulting in less condensation. The inner pipe is made of high-quality steel, since condensate has an acidic reaction and other materials, including galvanized steel, will not be able to work for a long time in such conditions.

The double-layer chimney is already insulated

Such chimneys are placed at a distance of at least 20 cm from walls made of flammable materials. If this cannot be avoided, then the wall is sheathed with metal with a backing. It is made from fire-resistant material, for example, asbestos sheet.

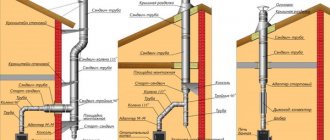

According to the installation method, chimneys are:

- Internal. This design can rise vertically from the furnace through the internal ceilings and roofing pie. Its main disadvantage is that condensate flows directly into the firebox, increasing its concentration in the flue gases. The result may be an unpleasant pungent odor in the room and accelerated wear and tear of the chimney.

- External. With this design, the chimney is diverted from the stove horizontally through the wall. For this, two elbows are used, which can have a rotation angle of 30, 45, 60 or 90 degrees. In this case, the outer one looks like a tee, and at the bottom there is a container for collecting condensate. The vertical part of the chimney is installed parallel to the wall, the pipe is attached to it using brackets and clamps.

Components

It is impossible to assemble a chimney without using fittings. They are intended for:

- performing contours of engineering systems;

- changes in pipeline direction;

- switching to another diameter;

- traction adjustments;

- condensate collection;

- protecting the upper end from precipitation, leaves, debris and nesting birds.

Additional elements for assembling a chimney from pipes must be used

Using these structural elements, you can assemble a chimney of any configuration with your own hands. The permissible length of horizontal sections is no more than 1 m, otherwise the traction will be greatly weakened.

Advantages and disadvantages

In industrial conditions, stainless steel products are used for the inner layer of the sandwich, and zinc-coated steel pipes are used for the outer layer. In this case, the inner contour is covered with thermal insulation and placed inside the outer cylinder. As a result, such a structure functions quite efficiently and efficiently.

Please note that industrial sandwich pipes are sold in lengths up to 1 m.

Installing a chimney made from sandwich products does not take much time and effort - all the work can be completed in a day. Below we present a number of advantages and disadvantages of such pipes.

Among the advantages of such structures are:

- multitasking - such pipes can be used in buildings made of any materials;

- occupy a minimum of space;

- ease of transportation;

- Even a beginner in construction can install sandwich pipes, as it is very simple and quick;

- laconic and pleasant appearance;

- fire safety - this is one of the best options for chimneys in this regard;

- the existing roof truss system does not create any obstacles to the installation of a sandwich pipe;

- due to the presence of several layers, much less soot accumulates in such a pipe and almost no condensation forms, so cleaning it is required much less frequently;

- The sandwich pipe is capable of fully protecting residents from the influence of toxic combustion products.

But such designs have very few disadvantages, although they still exist:

- the price of a sandwich pipe is quite significant;

- The optimal service life of such products is only about 15 years.

If you want to make a sandwich pipe with your own hands, then such a chimney will cost you much less than, say, one made of brick. This will result in a completely reliable chimney, and there should be no difficulties with installation and assembly.

Calculation of chimney parameters

The basis for calculating the height and diameter of the chimney is the power indicator.

The performance of a boiler or furnace is directly affected by the height of the chimney. For household appliances it is 5 m. This characteristic is provided for by the SNiP requirements for stoves in residential buildings. The measurement is taken from the device's grate to the hood. At a lower altitude, the natural draft in the stove will not ensure efficient combustion of fuel; it will smoke and not produce the optimal amount of heat. However, the ability to increase height is limited. Experiencing the natural resistance of the pipe walls, the air will slow down if the channel is too long, which will also lead to a decrease in draft.

Rules for selecting chimney length

For a private house, calculating the height of the chimney is based on certain rules:

- The pipe must be at least 5 m.

- The excess of the chimney end above a conventionally flat roof is at least 50 cm.

- For a pitched roof, a pipe whose axis is located no further than 1.5 m from the ridge, and if there are superstructures, then from their highest point, the excess is 0.5 m.

- When the distance to the ridge is 1.5–3.0 m, the end of the pipe should be no lower than the level of the ridge.

- When installing a chimney at a distance of more than 3 m from the ridge, in particular for outdoor installation, the angle between the horizon level and the conventional straight line between the ridge and the end of the pipe must be at least 10 degrees.

The height of the pipe depends on its location

When choosing a location for the chimney outlet through the roof, it should be taken into account that it should not be located near roof windows and other similar devices in order to avoid creating fire hazards.

Calculation of the chimney cross-section

The procedure given below for determining the size of the channel is valid for a circular cross-section. It is the optimal form, since the flue gases do not move in a monolithic straight stream, but the flow swirls and they move in a spiral. In rectangular channels, vortices are formed at the corners, inhibiting the movement of gases. To calculate the cross-sectional value, the obtained result should be multiplied by 1.5.

You will need the following initial data:

- Furnace power, that is, the amount of heat generated by the device per unit time when fully loaded.

- The temperature of the flue gases at the outlet of the furnace is usually taken to be within 150–200 degrees.

- The speed of gas movement through the channel (is 2 m/sec).

- Chimney height.

- The value of natural draft (4 MPa per 1 m of smoke channel).

The dependence of the cross-sectional area of the chimney on the volume of fuel burned is obvious.

Smoke doesn't move in a straight line

To perform the calculation, you need to use the converted formula for the area of a circle: D2 = 4 x S * Pi, where D is the diameter of the smoke channel, S is the cross-sectional area, Pi is the number pi equal to 3.14.

To calculate the cross-sectional area, you need to determine the gas volume at the point where they exit from the stove into the chimney. This value is calculated depending on the volume of fuel burned and is determined from the ratio Vgas = B x Vtop x (1 + t / 273)/ 3600, where Vgas is the volume of gases, B is the amount of fuel burned, Vtop is a tabular coefficient that can be found in GOST 2127, t - temperature of gases at the outlet of the furnace, usually a value within 150–200 degrees is accepted.

The cross-sectional area is determined by the ratio of the volume of passing gases to the speed of its movement, that is, by the formula S = Vgas/W. In the final version, the desired value is determined by the relation D2 = Vgasx4/PihW.

Having made the necessary calculations, you will get the result - the diameter of the chimney should be 17 cm. This ratio is valid for a stove in which 10 kg of fuel burns per hour with a humidity of 25%.

The calculation is made for cases where non-standard heating units are used. If the power of the device is known, it is enough to use the chimney parameters recommended by experts:

- for devices with power up to 3.5 kW - 140 x 140 mm;

- at 3.5–5.0 kW - 140 x 200 mm;

- with a power of 5.0–70 kV - 200 x 270 mm.

For chimneys with a round cross-section, its area should not be less than the calculated size of a rectangular one.

Video: how to calculate a chimney for a solid fuel boiler

Operation, repair and cleaning

You have received a chimney that will serve you for fifteen years. But you need to follow the simplest rules. It is impossible to replace a boiler or furnace so that the temperature of the flue gases is higher than that calculated specifically for this chimney. It is necessary to monitor the condition of the heat-insulating substance in the wall opening and trouble-free drainage of condensate.

Sandwich chimneys on a brick wall

Such a chimney needs to be cleaned approximately once every three months, but it is better not to use a mechanical method at all. In severe cases, you need to call specialists. And your destiny is chemical cleaning. This is a substance in the form of a briquette or powder, which, when burned in the firebox of a boiler or stove, releases chemicals that dissolve soot and other deposits in the chimney.

Chimney sweep powder for cleaning chimneys

Materials and tools for making a chimney

Before you start purchasing parts, fasteners and tools to perform this work, you need to decide on the design of the device and complete a preliminary design, an integral part of which is a material list, which lists all the necessary parts. By adding the cost of materials to this list, you will receive a cost estimate.

Before construction, it is recommended to sketch the chimney

Installation of the device is carried out from the bottom up, that is, from the stove to the top, for which you will need:

- a transition device made of fittings from the furnace to the pipe; depending on the design, a branch may be required;

- multilayer pipe;

- gate;

The gate allows you to adjust the draft

- fireproof material for the passage through the ceiling;

- plates made of galvanized sheet, approximately 500x500 mm in size - to close the passage;

- materials for insulating the intersection of the roofing pie, for example, a probe for protection from the outside;

- chimney head;

- clamps for fixing connections at the rate of 1 pc. for each;

- brackets for attaching chimneys to walls (depending on its design);

- collection for draining condensate;

- high-temperature sealant for sealing joints;

- steel pipes at the rate of 1 pc. per meter of chimney;

- stainless steel wire for guy wires;

- screws, nails.

The list of tools is small and may look like this:

- drill with drill bits for concrete and wood;

- jigsaw;

- screwdriver or wrench for installing fasteners;

- plastic inserts (dowels) for attaching brackets;

- hammer.

Depending on the design of the chimney, other tools may be needed; this will become clear when drawing up a preliminary design.

Nuances of the device and installation

The design of the pipe, as such, is not particularly important. The number of bends, turns and other obstacles in the path of flue gases only worsens the draft, so you should try to make the pipe as straight as possible.

However, the main qualities of draft are determined by the height of the pipe, which is measured from the outlet of the boiler to the head of the pipe. The pipe head is the end of the pipe that is hidden under the umbrella. By the way, the existence of an umbrella is mandatory; this is protection intended, first of all, for the boiler itself. Moisture entering the combustion chamber can lead to damage to all boiler equipment.

Another point worth noting is the welds and penetrations through the building envelope, i.e. walls, ceiling or roof surface. Welding seams must be made with the utmost care. A minimal rupture can lead to smoke entering the room.

Chimney made of steel pipe

All passages through enclosing structures must be made in the form of a sleeve. A sleeve is a pipe with a cross-section larger than the cross-section of the chimney itself. The space between the sleeve and the chimney is clogged with sealant. This is done in order to protect the space surrounding the pipe from rising temperatures.

Let's summarize the features of chimney installation:

- The height of the pipe must be selected in accordance with the boiler power. Special tables will help you select the height, but it’s easier to just look at the boiler’s passport; as a rule, you can find the required pipe height there.

- All welds must be made neatly and without breaks.

- The passages through the fences are lined and sealed.

- The chimney should not be laid near the passage of wiring and other communications. The outer part of the pipe should be located at a distance from trees.

Wiring a chimney through the ceiling

Chimney insulation

This operation is only performed if single pipes were used. It is necessary to reduce the intensity of condensation and protect combustible structures from exposure to high temperatures.

The best material for this purpose is basalt wool, since it is absolutely non-flammable and does not emit harmful fumes in fire conditions. It is also used in the manufacture of multilayer pipes.

Insulation of a metal chimney may not always be required

An insulating layer of aluminum foil must be installed on top of the insulation, and its installation begins from the bottom up with an overlap of turns of 10–12 cm. This order ensures that the joints are oriented downward, which does not allow water to penetrate into the heat-insulating layer.

Designing a safe sandwich chimney

First, let's figure out what exactly a modern sandwich chimney is:

Now let's talk about the laws of physics. Modern sandwich-type steel pipes are designed to allow stainless steel to withstand 600 degrees Celsius without changing the structure of the metal. But such a pipe, within only four to five hours of good combustion, is capable of transferring heat to the enclosing structures.

In addition, quite a lot of sandwich chimneys today are sold with the parameter “up to 400 degrees Celsius”, and above this threshold, stainless steel quickly loses its properties: it burns, burns out and ignites the insulation. Moreover, the thicker the thermal insulation layer itself, the faster this happens.

But all this does not mean that you should give up the sandwich chimney! In comparison, a single-circuit steel pipe emits the harshest heat and is capable of heating combustible structures until they ignite even at a distance of 40 centimeters.

Then what is the solution? Do everything with high quality from the beginning! And such a seemingly homemade chimney in practice often turns out to be more reliable and safe than its store-bought counterparts.

Here is a wonderful video master class that clearly shows that it is absolutely possible to make a serviceable and reliable chimney from a sandwich pipe yourself, from ordinary materials that are sold in any construction supermarket:

Sometimes the design of a chimney involves the presence of complex transitions and parts, for example, if the room has an unusual geometry or the installation of a straight vertical pipe is fire unsafe:

The design of such a chimney is relatively simple:

- The inner pipe is designed to pass smoke through itself, forming an aggressive environment. That is why for the installation of such a chimney it is allowed to use only certain grades of steel: AISI 304, 321, 316 or 409.

- But a larger pipe (otherwise called an outer casing) must withstand precipitation and other atmospheric conditions. It protects the insulation and provides it with a sealed, dry condition. It is made of galvanized, stainless steel or copper. By the way, stainless steel pipes are often tinted with quartz powder in a color according to the RAL catalog.

If this is your first time making such a complex structure as a chimney, try to avoid bends and corners altogether - even professionals do not welcome them.

How to purchase high-quality sandwich modules?

You can really get a reliable and high-quality sandwich pipe for a chimney (made and installed with your own hands). After all, ordinary living people work in production. The only question is how carefully and correctly you will do it all.

As for the choice of material for the manufacture of such a chimney, everything is simple: galvanizing does not like constant changes in temperature and is not airtight in such extreme conditions for long. Therefore, make the outer contour of the sandwich pipe only from stainless steel, for which even a small condensation on the inner wall will not be particularly dangerous.

And now - the most important moment. It is extremely important to initially purchase modules for self-assembly of a sandwich chimney of high quality:

- The metal used is 430/430, 430/ots or 430/ra for baths and 316/304, 316/ots or 316/ral for boilers. Additionally, the inner tube is made of 310 steel, heat-resistant.

- According to all the rules, such modules must be manufactured using laser cutting, either cold or plasma. The chimney modules were welded using 400 series overlap or 300 series butt welding. Definitely no traces of any manual work should be noticeable! There are a lot of fakes in the construction market, and even in such a sensitive area.

- The end connection must be butt or overlap; the seam can only be on the outer contour, and with a colored coating. Such end connections must be made by continuous welding on a roller machine. The pipes are connected through expanders.

- Modular elements purchased from a reliable manufacturer always come with all the necessary fastening elements.

- The insulating layer must be designed to fit together as tightly as possible - this is one of the most important fire safety rules.

- High-quality packaging should completely protect the product from damage and dents.

In total you will need all these parts for assembly:

Finally, pay attention to the label: this should contain complete information about the product. We are talking about the steel grade, metal thickness, certificate and calculated temperature loads. After all, even the most modern chimneys made from the best materials are also not protected from becoming clogged with soot and having potential weak points.

The fact is that soot itself is a very corrosive substance, and it can cling to any joint or even a scratch inside the chimney. After this, it spreads over the rest of the pipe surface. And the most common reason for a sandwich pipe to break and catch fire is precisely that the purchased sandwich modules were not designed for certain loads.

Ask yourself these important questions right now:

- Is your stove or fireplace designed for complete combustion of fuel in the firebox? The accumulation of soot in the chimney depends on this.

- What temperature will the exhaust gases be? What grade of chimney steel do you need to purchase, what is it made of and what is the warranty period? What exactly does the chimney warranty cover?

- What temperature is the sandwich insulation designed to withstand?

- What kind of wood is allowed and recommended to burn such a stove, is it ready for high loads and different fuel qualities?

And when buying, it’s better to play it safe, overpay, but take care of your life.

How to make additional parts?

However, you can also make not only additional pipes, but also the pipes themselves at home. It is only important to follow a few rules.

All seams on a homemade sandwich chimney must be welded. Weld butt to butt, and in no case overlap, to ensure maximum tightness of the products and correct geometric shapes.

Pay special attention to the joint of the thermal insulation along the long side: it is necessary to overlap, cutting about 10 cm by half the thickness for precise geometry. You can, of course, manually stuff it all with a stick, but then your final quality may be unpredictable. Look how these seams should look:

The second point: the outer contour of such a pipe must have its own constant diameter and in no case should it narrow or widen at the ends even by 1 cm. This is also important so that the upper pipe does not eventually drive into the lower one. For additional reasons, secure them both with self-tapping screws during assembly.

And finally, when thinking about the design of a sandwich chimney, keep in mind that it must be vertical, and ledges are extremely undesirable. Only as a last resort is it permissible to deviate the smoke channels at an angle of 45 degrees from the vertical. And at the same time, it is necessary to construct a heat-insulating shaft around such pipes - from foam concrete blocks of brick and mineral wool.

What should be used as thermal insulation?

In total, you can use the following thermal insulation materials to assemble sandwich pipes yourself:

Insulates a modern sandwich pipe with vermiculite, basalt or ceramic wool:

- Vermiculite is a crushed material of natural origin, which is additionally slightly fired in ovens. As a result, it is light in weight and voluminous. The operating temperature of vermiculite is from minus 250 degrees to 1150 degrees. Sandwich chimneys insulated with vermiculite are the lightest and have good thermal insulation properties.

- Basalt wool is made from basalt (which is easy to understand from the name) or at least other rock materials similar in properties (but always from the basalt group). This type of cotton wool does not add any synthetic or mineral substances. As a result, such insulation for a sandwich pipe is allowed to be used at temperatures only up to 600 degrees Celsius. And such a sandwich pipe turns out to be a little heavier than the one in which vermiculite is used, but at the same time it is more affordable.

- And finally, a modern sandwich chimney is insulated with ceramic wool. It is made from aluminum, silicon and zirconium oxides. The fibers have special temperature, chemical and deformation resistance. That is why such a pipe will be a little more expensive than one insulated with basalt wool or vermiculite, because... it can withstand temperatures up to 1260 degrees.

Experienced stove makers advise using basalt wool from the well-known company Rockwool, with a nominal value of 4000 by 1000 by 50, for thermal insulation for sandwich pipes.

The thermal insulation material, no matter what you choose, must be in a pipe at least 5 centimeters thick. It is this thickness that will provide sufficient fire safety, and will also protect the chimney from freezing and condensation during frosts in early spring.

At this stage, we will dispel one very dangerous myth regarding modern sandwich-type chimneys. The problem is that despite the fact that, although the sandwich chimney consists of two stainless steel pipes, and a heat insulator is laid between them, it is this heat insulator that still conducts heat (albeit not as intensely as air or other material does ).

Interestingly, in Russia, most people believe that such a layer of insulation was invented by some genius for the sake of fire safety, but in fact (and Europeans know this), this layer of insulation is intended precisely for heat, so that the metal pipe gives it away longer and warmed the room on the second floor. And fire safety is just a nice bonus, and you shouldn’t rely on it too much.

How to properly connect chimney elements?

It is not difficult to join such chimney elements - just insert one pipe into another. The depth of the joint will be 5-6 centimeters, and in no case more or less, because metal tends to expand greatly when heated.

If you make such a mistake with installation, soon enough the chimney pipes will begin to “play”, and the main elements risk being disconnected. And it is extremely important to start the assembly correctly:

If you assemble the sandwich yourself, always leave the top tube in the bottom tube - never the other way around. After all, it is important here to protect the heat-insulating material from moisture from precipitation and condensation, i.e. assembling such a chimney “by condensate” is much more important than “by smoke.” And the condensate itself will hardly penetrate due to the tightness of the entire assembly.

Let us explain this point in more detail - is it smoke or condensation? After all, there are countless disputes on this matter on the World Wide Web. If this is your first time encountering these concepts, then imagine what exactly happens when the pipe from the lower elbow enters the pipe of the upper one - it turns out that smoke rises unimpeded and does not penetrate into the room:

The chimney is assembled using condensate when the upper sandwich pipe is inserted into the lower one. Then a certain barrier is created for the smoke, but such a device prevents the formation of condensation. But in sandwich pipes, thanks to their insulation, the problem with condensate almost never arises, and therefore there is no need to be afraid of a small amount of it.

We talked about the classic, standard design of a modern sandwich chimney. But another wonderful new product on the construction market is the so-called three-layer sandwich. It includes a ceramic pipe, a 60 mm thick heat insulator and an outer shell - a steel pipe.

And this entire structure fits directly under the stone shell of the casing! Such chimneys are suitable for absolutely all types of stoves and heating boilers. Therefore, our advice: since you have decided to build a fashionable sandwich chimney with your own hands, make it great!

How to assemble a modern ceramic sandwich chimney?

In addition to the steel and metal sandwich chimneys that we just talked about, ceramic ones are gaining popularity. Inside such a chimney there is heat-resistant ceramic, which is factory-coated with a high-strength glaze on the inside. And such a pipe is inserted into a shaft made of expanded clay or foam concrete blocks:

Features of operation

Metal chimneys, having a lot of undoubted advantages, require increased attention both during assembly and during operation:

- They should not be located near other utilities, such as electrical wiring or plumbing.

- Before starting installation work, the internal longitudinal seams of the pipes must be coated with a special sealant, since they are subject to temperature changes, which gradually weakens the joining edges.

- When cleaning stainless steel pipes, it is better not to use traditional metal balls with a wire “hedgehog”. Their influence deteriorates the mirror inner surface, making it difficult to drain condensate into the storage tanks. It is better to choose a brush made of synthetic materials.

Mechanical cleaning method is the most effective

Features of using sandwich pipes for baths

Since a bathhouse, as a rule, is built of wood (and if it is made of foam blocks, then it is lined with flammable material), issues of thermal insulation become of particular importance. It is prohibited to use single-layer chimneys for bathhouses - only brick and sandwich chimneys are allowed. All distances from the chimney to flammable objects must be carefully verified and observed in accordance with SNiP. All pyrohazardous surfaces must be insulated with vermiculite or asbestos. It is forbidden to install a deflector on a sauna chimney due to its strong windage. The distance from the chimney to the wall is at least 25 centimeters!

Caution: under no circumstances should a sauna ventilation system be combined with a chimney.

Chimney maintenance

With a properly manufactured chimney, especially if it is made of stainless steel, the main maintenance operation is to clean the internal surface of soot.

Causes of soot formation

Combustion is the reaction of fuel oxidation with atmospheric oxygen. If it is insufficient, soot is released and adheres to the walls of the chimney. In reality, conditions arise under which the smoke duct becomes clogged in just a few months:

- A lack of oxidizer in the firebox can be caused by deliberately reducing draft by manipulating the damper in order to achieve slow burning or even smoldering of the fuel, which can quickly lead to negative consequences.

- Another firebox mistake is the use of damp firewood. Moisture prevents intense combustion of fuel, resulting in the formation of a large amount of soot.

- The use of resinous firewood, the combustion of which is accompanied by the release of soot, should be considered an unfavorable factor. Of course, heating stoves with oak or ash is too expensive, but you should strive to use firewood from non-resinous tree species.

- It is strictly not recommended to burn garbage in the oven, especially plastic bags or bottles for the same reasons.

- It is especially unfavorable to use plywood, particle boards and other materials for the manufacture of which synthetic adhesives are used for burning waste. With such fuel, the chimney becomes clogged with soot most quickly.

Assembly Rules

To properly assemble a chimney made of galvanized steel, you must first mark out the layout and laying of the pipe. Using this drawing, you should determine how many pipes are required and cut them into sections of the required length. Assembly is performed as follows:

Options for placing chimneys or galvanized steel

- First of all, the chimney pipe is connected to the inlet pipe of the heating device using a special adapter. It is important to ensure complete tightness of the connecting seam.

- After the first segment, a tee with a condensate collector and inspection is connected. Each piece of pipe is inserted into the previous one, and the joint is coated with heat-resistant sealant and secured with a steel clamp.

- Where the pipe passes through obstacles in the form of walls or ceilings, holes are cut out and a fire-resistant box made of galvanized steel or asbestos slabs is installed.

The space between the walls of the pipe and the box is wrapped with basalt fiber or filled with expanded clay. Equipment for the passage of the pipe through the ceiling - A protective umbrella is put on the head, and the junction with the roof is isolated with sealant or elastic rubber penetration. If the roofing material is not fire resistant, a spark arrester is installed.

Note! The smoke exhaust duct is installed on the roof at a distance of 30-50 cm from the ridge. To ensure the level of draft, the height of the chimney should be 50 cm above the ridge. Incorrect placement on the roof can cause backdraft or wind backlash.

How and with what to insulate

Non-flammable thermal insulation material in cylinders for chimney insulation

Insulation of the chimney is carried out both at the stage of its installation, if a single-wall steel pipe was chosen as the material, and after the construction of the structure. To insulate steel chimneys, non-flammable types of insulation are used: expanded clay, mineral and basalt wool.

When installing yourself, it is better to use basalt heat-insulating cylinders of the required cross-section and thickness. This is insulation in the form of a pipe with a longitudinal cut for easy installation. The insulation goes around the pipe along the contour and is fixed with metal ties.

The thickness of the insulation depends on the air temperature in winter and is selected individually for the specific type of chimney. For example, a heat-insulating cylinder from Rockwool with a thickness of 300 mm and a cross-section of 133 mm will cost 275 rubles per linear meter.

An alternative to cylinders is pierced mats - this is a similar in composition insulation in a roll, which during installation will have to be adjusted to the outer diameter of the chimney. Depending on the manufacturer, the mats have different sizes. For example, a stitching mat from TechnoNIKOL with dimensions of 2400x1200x40 will cost 970–1000 rubles per package.

Installation recommendations

To carry out the work, you will have to purchase pipes whose length is 1 meter. The chimney in a house is made up of main parts. You will also need a tee for pipe inspection. It is important to buy a tee for collecting condensate, which is used to clean joints. If the pipe has turns equal to 45 degrees, then you will need corners that are made of the same material. Make sure you have a compensator; it takes on the load from the expansion of the chimney elements during cooling and heating. The system must be installed on the roof; for this, an adjoining unit is useful. In order to prevent the entry of rain, leaves, snow and dust, the system should be equipped with a cap.

Suitable materials

At first glance, it may seem that all sandwich chimneys are exactly the same. However, this opinion is wrong. It should be noted that such products are produced with different levels of quality. It is not recommended to purchase products based only on their appearance.

It is important to pay attention to the grade of steel and its quality, and also consider how suitable it is for the construction of a vertical channel.

If you look at websites dedicated to the construction of a pipe device for removing combustion products, you can come across many photographic examples showing a completely burnt-out steel structure. Deformation of such a pipe can lead to a fire or severe carbon monoxide poisoning.

Looking at the pictures, one can come to the conclusion that the wrong metal was used for the cylindrical product.

To prevent this from happening to you, let's look at the types of stainless steel from which you can mount a sandwich chimney yourself:

- AISI 430 . It is considered the cheapest grade of metal. It is good for making the outer casing of the system. This steel is resistant to any weather conditions. However, this material is not suitable for the manufacture of internal channels. The metal does not weld well, so it will be quite difficult to obtain reliable welds.

- AISI 439 . This brand differs from the previous one in its composition: it contains titanium additives. The material is characterized by increased mechanical strength and corrosion resistance. Chimney pipes made of such steel can be installed in gas appliances, solid fuel stoves, as well as low-power boilers.

- AISI 316 . The steel contains special alloying additives, as a result of which the metal acquires anti-corrosion protection. Nickel and molybdenum protect it from highly aggressive acids. This grade of steel has increased heat resistance. Pipes made from this material are suitable for installation in any gas boilers, regardless of their power.

- AISI 304 . The steel is similar to the previous grade, but it contains fewer alloying components. The cost of such metal on the market is much lower than its analogues. The quality of the material is not very high.

- AISI 316i, 321 . These brands are considered the most universal. They are not afraid of corrosion and are characterized by high ductility. In addition, these types of steel can withstand temperatures up to 850 degrees.

- AISI 310S . This alloy is considered the most expensive and high quality. Steel has high heat resistance and the ability to withstand temperatures of 1000 degrees. Such properties make it possible to use the material in chimneys installed on pyrolysis boilers that develop high power.

Any high-quality sandwich chimney always has technical documentation, which necessarily lists all types of steel grades used to manufacture the system.

When such documentation is missing, there is reason to think that the proposed device is a high-quality fake.

There is also another way to recognize stainless steel. If the steel contains a lot of alloying additives, it stops attracting the magnet: it simply slides over the surface of the product.

If the pipe is magnetic, it means that this is ordinary metal that has nothing to do with stainless steel.

Selecting the internal diameter of the pipe

The correct selection of this value depends on the parameters of the heating installation. To determine the cross-section of a cylindrical structure, a special calculation method has been developed, in which the thermal power of the equipment is taken as a basis. The calculation formulas are quite complex, so you can simply use the average values:

When determining the diameter of the pipe, it is important to take into account the size of the layer and the type of thermal insulation. The most suitable heat-insulating materials are from some of the most famous manufacturers in the world:

- PAROC ROB 80t;

- MAT 30;

- ROCKWOOL WIRED MAT 80.

All these brands are basalt wool, characterized by fire safety.

The thickness of the insulation is selected depending on the type of heating equipment. In this case, the average heating temperature of the exhaust gases is taken into account.

The table shows several averaged data:

Types of steel structures

Such structures are divided into the following:

- Chimney with one wall.

- With two walls. In these types, fire-resistant insulation is located between two blanks of different volumes.

- Coaxial. With two walls, but without an insulating layer between them.

The first type of chimney is used in areas with warm climatic conditions. The third type is suitable for gas boilers.

But the second type is considered a popular option, because the insulation reduces condensation, as a result the structure can last a very long time.

Rules you need to know when installing a chimney

Making a chimney is not difficult, the main thing is to adhere to some nuances that are important when arranging it:

- the location of the pipe above the roof surface - the higher it is, the better the traction, but there is no point in making it more than 2 meters above the house;

- fastening - if the model is external, then the brackets are located at a distance of 1.5 meters, and everything is fastened in three places;

- connection - the end of the higher pipe should look down, that is, the upper one fits onto the lower one, otherwise smoke will leak out and rainwater will get into the cracks;

- a deflector or umbrella is a mandatory part that protects from precipitation.

When heating the furnace for several weeks, there may be a smell and slight smoke from heating the sealant and oils, this should not be alarmed.

It is important to know! It is forbidden to connect pipes of different diameters into one system, as this can cause a fire and cause fumes, since smoke will enter the room through the cracks. You cannot continue the brick model with metal pipes. The only way to combine them is by lining a brick pipe with a steel pipe.