A Finnish bathhouse is called a sauna, which, in fact, is very similar to a Russian one, and it also contains a wood-burning stove.

Wood burning stove for a large sauna

Having achieved good heat in the firebox and good heating of the stones, cold water is splashed on them and dry steam is obtained, which gives a pleasant aroma to the steam room. Sometimes decoctions of fragrant herbs or essential oils are used to create steam; in this case, the bathhouse is filled with healing air and helps to cope with many diseases.

How they work and how they are installed is a must-know to ensure their safe and easy operation.

It is believed that Russian and Finnish baths promote relaxation and increase vitality, heal mental wounds, and are also a place where you can hide from what spoils your mood. But if you decide to visit the sauna for the first time, it would be a good idea to consult a doctor so that the bath will only bring benefits and not harm your health. The heat coming from the heater, which maintains the room temperature at 75-120 degrees, can negatively affect the condition of hypertensive patients and people with heart disease.

Traditional Finnish saunas include six rooms: a waiting room, a locker room, a shower, a steam room, a swimming pool and a relaxation room, where green tea must be present.

Today, they usually make do with two, or at most three, rooms - a locker room, also known as a furnace room, a steam room and a shower room. A sauna stove is usually installed in the wall between the dressing room and the steam room, so that it is possible to add firewood from another room, this is very convenient and functional, we advise you to do just that!

Principle of operation

And the operation of these devices is no different from their analogues. The oven consists of several main parts:

- furnace body;

- separate compartment for burning wood;

- an ash pan, which is located in the lower part of the stove and serves to collect ash and as a blower to increase draft during the initial ignition of wood;

- grate. It is installed above the ash pan and serves to protect the furnace body from exposure to high temperatures and unhindered pouring of ash into a container for collecting it;

- a screen that is installed in some models and is designed to prevent the direct passage of heat into the chimney. Heat is reflected from the screen, passes through the inside of the stove and only then enters the upper compartment and passes to the chimney, heating the stones;

- exhaust gases exit into the chimney pipe and are released into the atmosphere;

- On top of the furnace body there is a grid for laying stones. When wood burns, the stones heat up. Anyone can raise the temperature in the steam room by splashing several ladlefuls of aromatic infusion or water on the heater.

Heating system

In most cases, continuous burning stoves are installed in bathhouses. which do an excellent job as the main source of heat in the room. At the same time, it is worth immediately making a reservation that for arranging the stove it is advisable to use only cleaned stones, the diameter of which reaches 10 centimeters. To achieve the optimal temperature in the room, it takes at least two hours to heat such a stove, during which you will have to periodically add firewood.

The bathhouse is a wooden building with a high level of humidity in the premises. As you know, wood that is regularly exposed to water can become unusable in a very short time. Because of this, unpleasant odors may appear in the bathhouse, and the building itself will require repairs in the future.

To avoid this, issues related to its quality heating should be resolved in advance. At the same time, it is advisable not to limit yourself to just one stove, but to supplement it with various heating systems, which, moreover, will significantly reduce the time it takes to warm up the premises before taking water procedures.

For safety reasons, in a wet room such as a bathhouse, it is allowed to use one or two heating radiators, which must be connected to the heating system of a residential building. In addition, there are several other options for heating a bath, the choice of which depends only on your requirements and wishes.

Heating radiators in the bathhouse

Possible difficulties

Matching seams is a difficult task for a beginner. Solution: make guides from metal rods. Diameter - 3 or 5 mm. Before laying the stove row, place them on the edges of the brick and press the next block down. Get the rods. The remaining notches will disappear on their own after completing the row.

If the laying mortar does not “grab” the bricks, wet them with water. This way the coupling will become reliable.

During construction, the errors are invisible, but in the end you can see them all. Solution: check each row of the stove horizontally and vertically with a building level.

If you do not follow safety precautions when laying a stove, you can injure your hands. Wear rubber-lined gloves and wrap duct tape around your knuckles.

Where and how to put it correctly?

Depending on the material of the walls, ceiling, and floor in the bathhouse, it is recommended to maintain certain minimum distances from them to the stove. These numbers are the same for all types and sizes of sauna stoves:

- if the floor in the bathhouse is made of wood, you need to make a simple foundation of bricks, laying them out in 1 row, with dimensions larger than the dimensions of the heater by at least 500 mm;

- distance from the floor to the bottom of the stove – 140 mm;

- the distance to the wooden ceiling from the top of the heater is at least 1 m;

- to an unprotected wooden wall, the gap should be 1 m;

- walls protected by panels made of non-combustible thermal insulation materials - a gap of at least 380 mm;

- the walls in the bathhouse are lined with bricks around the stove or if the stove is lined with bricks and the walls are covered with protective screens - a distance of 130 mm.

Before installing the stove, be sure to do a test run of the heater outdoors. In this case, the first stack of firewood in the bathhouse will not cause a lot of smoke from burnt-out residues of oil and other materials.

After this, you can install a mini-oven and connect a ventilation system to it. If you want to maintain the performance of the stove while reducing the amount of firewood, you can select a segment in the damper and almost completely block the access of air to the firebox. Now the firewood will gradually smolder, and the savings in firewood will become evident after the first use.

The chimney is discharged through the roof or wall and covered with a protective screen. The pipes must be secured with clamps, and the passages through the ceilings and roof must be reliably insulated from heat loss and water penetration.

Criterias of choice

The main indicators that must be taken into account when choosing a stove are the following:

- mechanism of action;

- manufacturing materials;

- fuel.

Baths can be heated using permanent or temporary (periodic) stoves. The first ones need to be kept burning the entire time the steam room is in use. For the second, preliminary high-quality heating is enough.

The range of materials from which a heater can be made now includes a large number of traditional and new technological elements.

The best stoves are made of steel and brick.

Brick structures

The leaders in demand are heaters made of periodic bricks. Continuous combustion heaters are also used to provide heating for saunas. but much less often.

Brick kilns of intermittent operation have both an advantage - they maintain a high temperature in the room for a long time, and a disadvantage - they need to be warmed up for at least 5 hours. In winter this takes even longer. Therefore, if bathing procedures are planned for the evening, then you need to start heating in the afternoon. After this, you can steam and not be distracted by other things, the heating will work without outside interference.

There is another disadvantage of such models - high cost. It is quite difficult to make such a heater yourself. To get a truly functional stove, you need an experienced stove maker. And his work is highly paid. The high cost of the heating structure can also be explained by the fact that it is necessary to lay a powerful foundation that will support a heavy brick heater.

Metal heat sources

Metal furnaces are characterized by the principle of constant operation. A stove with thin steel walls does not retain heat for long, which can be attributed to its disadvantages. And the advantage of a metal sauna stove is that it will take much less time to warm up the room.

In winter, this will take no more than 2 hours. It is better to organize heating using a steel heater in a small bathhouse. You can install the stove yourself.

Advantages and disadvantages

Let us note right away that such stoves have no disadvantages. It can be emphasized that they are made of metal, but by covering such a stove with bricks or covering it with screens, you can not only protect people from burns, but also increase the productivity of the stove

The main thing when buying is to pay attention to the thickness of the metal and the quality of its processing and welding.

Among the advantages, a number of points can be highlighted:

- The furnace body is made taking into account the calculation of the geometry of the firebox surfaces. It is customary to make it round, in this case the level of heat transfer when burning wood increases and the efficiency increases;

- Manufacturers use heat-resistant steels in the manufacture of heaters;

- due to its small dimensions, the mini heater can be installed in any sauna, even a miniature one;

- industrial designs are made taking into account fire safety requirements;

- Carbon monoxide poisoning is excluded if used correctly.

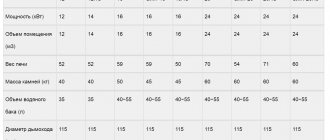

Before purchasing, it is first important to choose a model that is suitable for your premises in terms of power. An approximate calculation of this value will not be difficult to perform if you have all the sizes of the bath and a calculator

How dangerous are wood stoves?

The danger of wood-burning stoves lies in the presence of carbon monoxide and the possibility of fire in the bathhouse. Carbon monoxide can fill a room and pose a threat to people's lives. At the same time, it is not detected by the senses in any way - it has no color or smell, which makes it very dangerous.

The most effective way of protection is to install a high-quality chimney with a stable draft, and choose the right time to close the views. The dangers of carbon monoxide have been described many times and are well known, but the number of cases of poisoning remains too high.

The possibility of fire is a typical drawback of all heating devices, especially if they use combustion. It is necessary to comply with fire safety measures, having first carefully studied the requirements and followed all instructions.

However, the dangers of wood stoves should not be exaggerated. Statistically, they are less likely to cause trouble than gas or electric structures. If you take operation seriously and carefully, no problems will arise.

How to choose?

First you need to figure out the power of the steam room stove.

As an example, we take the dimensions of the bath:

- width – 2 m;

- height – 2.2 m;

- length 3 m.

In this case, the total area is calculated by multiplying the length and width of the room. In our case, it is equal to 6m2. But volume is important to us to calculate power. Therefore, you will need to multiply the area by the height of the walls - 6 * 2.2 = 13.2 m3.

Now it is important to calculate possible heat losses. To do this, having determined the total area of windows and doors, multiply this value by 1.2

Our steam room has one stove and a window in the dressing room. Therefore, we take heat loss equal to 2.3 m3. We add up the total volume and the volume of losses - 15.3 m3.

Next, you need to determine the power taking into account the level of heat absorption. For calculation purposes, we assume that our bathhouse is made of wooden logs. In this case, we multiply the resulting volume and the coefficient; for log walls it is equal to 1.6. 15.3*1.6=24.48. We round up and get that for our steam room made of logs with one door and window, you will need to purchase a stove with a capacity of 25 kW.

This is an approximate and rough calculation. When choosing a stove for a sauna, you need to pay attention to several more factors.

In addition to power, when choosing a mini-oven, it is important to pay attention to several more factors;

Type of fuel burned. Domestic and foreign manufacturers produce stoves for small baths that run on different types of fuel. The most expensive ones to operate are electric heaters. Even stoves have been developed that run on diesel fuel or coal.

But for Russian lovers of steam and brooms, wood-burning stoves remain the most popular. You should pay attention to the design of the combustion chamber. You can purchase a design with the ability to move the firebox to a separate room

For mini baths, this is the best option, but it will require large expenses when purchasing. But this option has one undeniable advantage - you don’t need to litter and stack firewood in the steam room. Find out the type of backfill and the device of the heater. They can be closed or open. Of course, open heaters are most in demand among conservatives, but it is closed compartments with stones that are gaining popularity.

When choosing small stoves for a bath, pay attention to several models presented in our TOP on pechnoy.guru

Review of the best models

| Model name | Description | Advantages | Price |

| Russian mini-stove “Anyutka” | Installed for servicing premises with a volume of up to 10 m3. Made from mild structural steel. Equipped with a convection casing, which ensures uniform and fast heating of the steam room. With minimal dimensions, it can accommodate 25 kg of stones in the compartment | The minimum dimensions allow installation anywhere in a small steam room. Provides comfortable conditions. The design is reliable and easy to maintain. The chimney is located in the center of the stove. | Average price 8000 rub. |

| Mini-heater “Sudarushka MK” | Made in Russia. Provides comfort in a steam room up to 18 m3. One year warranty. Dimensions: · height -95.7 cm; · width – 59.5 cm; · depth – 96.5 cm. Made of cast iron. Weight 140 kg. | Up to 100 kg of stones can be placed in the net. This allows you to additionally accumulate heat and heat the steam room for a long time with minimal use of firewood. | Over 3700 rub. |

| Model "Kutkin Premium 1.0 | Steam room up to 12 m3, country of origin: Russia. The height of the oven is 90 cm, with a width and depth of 45 cm and 46 cm, respectively. The material of the combustion chamber is stainless steel. Closed heater with up to 50 kg of stones. Time to reach a comfortable temperature is up to 2 hours. | This is one of the inexpensive brands with a combination of price and quality. Available with 3 types of cladding for the outer surfaces of the body. If desired, the stoves can be converted to use gas heaters. | Minimum price – 39,000 rub. |

| "Heat - Extra 400" | Steam room up to 12 m3. The firebox is made of structural metal, 6 mm thick. 12 month warranty. Weight 40 kg. with dimensions: · height – 640 mm; · depth – 530 mm; width -400 mm. The minimum weight of the stone is 60 kg. Possibility of removing the firebox to the dressing room. | This is an inexpensive, but convenient and productive stove, which allows you to further save space in a small steam room when moving the combustion chamber to the dressing room. | Average price 8000 rub. |

| The next three stoves differ only in characteristics and price; each of them has the same advantages. "Vulcan - Mini 15" | The weight of the stove is 90 kg. the weight of the stone in the net is 120 kg. Serves rooms up to 15 m3. Warranty service life – 5 years. The length of the firewood used is 550 mm, with the volume of the combustion chamber being 85 hundredths of m3. End of form | High level of efficiency. The body is made of alloy steel, so the stove will last for several decades. Can be installed outdoors, in a dressing room. The stainless steel water tank can be installed in various places of the oven; special fastenings are equipped for this. The grate is made of cast iron. The time required to warm up the steam room is within an hour. | Average price 16,000 rub. |

| "Granite - Mini" | Weight – 87 kg. Body metal – steel 09G2S. The firebox with a volume of 72 hundredths of a cube can accommodate firewood with a length of 490 mm. The mesh of the heater can hold 70 kg of stone. The cubic capacity of the steam room is up to 15 cubic meters. Warranty period – 5 years End of form | Average price from 16,200 rub. | |

| Oven “Magic – Mini” | Weight 80 kg. Alloy steel. The volume of the firebox is 86 hundredths of a cube and can accommodate firewood 550 mm long. The weight of the stones is 70 kg. 5 year warranty. | From 14800 RUR |

Exploitation

Operating rules:

- The first heating must be done in a gentle manner. To do this you need to use wood chips and straw.

- Do not load too much wood into the firebox.

- Before leaving the bathhouse, you must make sure that the fire goes out.

It is recommended to use a special firewood rack for storing firewood.

If a small bathhouse is built on a private property, a large stove will not be suitable for heating it. The best option is a mini oven. You can buy such equipment in a specialized store or try to assemble it yourself if you have practical skills in using various tools.

Installation

Regardless of which stove was chosen - a purchased model or home-made equipment, you need to install it correctly inside the bathhouse. A few recommendations will help with this:

- Surrounding surfaces should be covered with asbestos sheets, on top of which metal reflective sheets should be secured.

- It is better to make the base for the furnace equipment from fireclay bricks. Check its levelness with a building level.

- Assemble the chimney from separate pipes. Treat the joints with heat-resistant sealant. Where pipes pass through the roof, special sleeves should be installed.

Once the stove is installed, you can begin to operate it.

Features of operation

The operation of such ovens is simple. Having laid the firewood, place some thin wood chips near the door for kindling. Now open the slide valve completely and open the ash pan slightly and light the wood. The firebox door must always be kept closed. After the firewood has ignited, the ash pan drawer is completely closed and the air damper is closed.

All that remains is to wait for the steam room to warm up and enjoy the fragrant steam. Do not use damp firewood; the humidity level is at least 20-30%.

You should not burn resinous fuel; in this case, the chimney will have to be cleaned more often than once a month. At the first symptoms of deterioration in draft, immediately repair the breakdown or clean the ventilation pipes.

Varieties

Furnace equipment is classified depending on various factors. According to the material:

- Brick structures. Durable, reliable, durable. Slowly heat up and cool down. Difficulties may arise during laying if you do not have practical skills in working with bricks.

- Metal constructions. They are light in weight, durable and strong. The main disadvantage is that metal surfaces can rust when exposed to moisture. You can buy ready-made designs in specialized stores.

Depending on the type of fuel, the following types of equipment are distinguished:

- electrical;

- gas;

- solid fuel.

You can also select stoves that have a built-in water tank.

Even though the stove is small, it heats wonderfully!

Building a brick stove for a bathhouse is labor-intensive work, but it is worth it. The main thing is choosing quality material and following the instructions.

Tips for using the oven:

- Chopped and dry firewood is suitable for the stove. Wet logs take up energy to evaporate moisture, which means more fuel is wasted.

- Light wood in the stove only when the chimney is fully open and the ash pan is 5 cm wide.

- Clean the inside of the oven and water tank once a month.

- If the stove becomes red hot when adding wood, stop adding logs and pull out the extra ones. Open the stove chimney halfway.

- To heat water instantly, throw hot stones into it. Use metal tongs.

Using these recommendations, you can safely light a sauna.

Brick or metal

The choice of furnace material matters only from the point of view of individual preferences and conditions:

- Price. Based on the cost of the final product, purchasing a metal furnace will be cheaper than purchasing material and paying workers to build a brick furnace. If you do the masonry yourself, the final cost will decrease due to the deduction of payments to hired workers, which will significantly affect the price.

- Bath area. Metal stoves take up less space, so if the area is small, the choice is definitely in favor of a metal product.

- Difficult to install. A brick stove requires a separate foundation, which lengthens the installation period; a metal stove is installed on a lighter base. The wood-burning sauna stove is quite popular and is practical.

- Sometimes the decisive factor is a photo of a factory-made metal stove - the range of modern manufacturers is distinguished by functionality and attractive design.