When choosing a door for a bath or sauna, you should take into account that during the construction and finishing of these objects, compliance with certain norms and rules is required. Accordingly, doors are given great importance. Moreover, she will not be alone. The more rooms there are in the bathhouse: vestibule, sink, rest room, steam room, the more doors will be needed. Each room should have its own microclimate.

It is important to install high-quality doors both at the entrance and inside the premises.

What should a bath door be like?

- Must be made of high quality and environmentally friendly materials.

- Designed specifically for use in conditions of high temperature and humidity.

- Doors from the manufacturer must have the necessary certificates and hygienic conclusions.

- Each door in the bath complex must meet certain requirements and standards, based on its purpose.

- It should be comfortable, safe, reliable and have an attractive appearance.

Doors must comply with all standards and requirements so that in an emergency they do not become an obstacle to vacationers.

Characteristics of the design installed in the washing room

This is another door that is equipped with a bathhouse and sauna. The room's characteristics resemble a bathroom: the same temperature changes and high humidity. According to buyers, it is worth choosing a plastic sheet or frosted glass. Such materials are classified as hygienic. They are easy to clean: wash with detergents or disinfectants. They comply with all sanitary standards and regulations.

Where to buy the product you like? You can purchase popular models at specialized retail outlets, or you can order online in an online store, having first read user reviews and carefully studied the photos. Which company is better depends on the person’s preferences and taste. Famous manufacturing companies annually present their fans with new products at an affordable price.

Installation can be ordered from a specialized company, or you can carry out the work yourself. If you don’t know how to install, you can turn to the Internet for help. Expert recommendations and installation videos are posted there.

Pros and cons of bath doors

The main advantages of doors for bath rooms:

- Energy saving - they prevent the removal of heat from the steam room or washing room, thereby significantly saving fuel and electricity costs.

- They have excellent hydro- and vapor barrier. Door structures for the washroom and steam room are designed in such a way that dampness and steam do not penetrate into the dressing room.

- They are distinguished by a variety of shapes, structures and textures.

- They can be very ordinary, or they can become a bright decoration of the interior.

Each room needs its own door with certain standards made from specific materials.

The only disadvantages of bath doors include low-quality raw materials and improper use.

Types of doors for baths

Door designs can be completely different: distinguished by classical severity and simplicity, or, on the contrary, surprise with their originality and pretentious, sophisticated beauty.

Types of doors:

- entrance;

- doors to the steam room;

- door to the washing room.

Entrance door

Much attention should be paid to entrance doors. They should look presentable on the one hand, and emphasize the style of the interior on the other hand. Don't forget about strength and reliability. It should open easily and provide quick, unobstructed access to the room.

The door leaf should open outwards.

Doors to the steam room

Special attention is paid to the doors leading to the steam room, since it is necessary to create a special microclimate here. Wood is used that is distinguished by its ability to retain heat, resistance to thermal influences and durability.

The following types of wood are used to make doors to the steam room: cedar, aspen, larch, linden. Of all the listed wood species, the greatest preference is given to linden. It has a unique texture and is easy to process. When exposed to steam, it releases pleasant substances that not only smell pleasant, but also have healing properties.

Linden doors have a presentable appearance and reliably protect the steam room from heat leakage.

Door to the washing room

Doors to the washing room must meet all the requirements already mentioned above.

Peculiarities

Door structures designed to be located at the entrance to the steam room must have special features and be able to withstand heavy loads. They must meet all quality and safety standards, because in a stuffy and hot room it is easy to bump into some hot surface. Installation of conventional door panels is impossible in such premises, since special structures must be purchased for the bathhouse, made from appropriate raw materials and using individual technology. The main properties that a door to a steam room should have are as follows:

- Maintaining optimal indoor temperature. The canvas must not have cracks or gaps through which cold air can penetrate.

- Resistance to constant humidity and high temperatures.

- Non-standard doorway. The door frame in a steam room always has smaller dimensions, unlike a standard door. This is necessary to retain more heat inside.

- Ventilation ability, which is achieved by installing the structure 5 cm above the floor. If the building has a ventilation system, then it is not necessary to leave a gap.

Door structures must also meet a number of requirements that will ensure the safety of the structure. The door must be installed so that it opens outward. This will help you leave the room with ease and avoid touching the iron hinges.

It is very important that there are no elements on the canvas that can become hot and burn a person. Both the internal lock and the handle must be made of wood

To further secure the room, you need to purchase a canvas with a window. It is possible to do it yourself if you follow special instructions.

Selection of materials for bath doors

The front door can be made of any material, but for the steam room it is better to choose a solid fabric. The construction markets offer door structures for bathhouses and saunas made from the following materials:

- Wooden.

- From glass.

- Made of metal.

- Made from thermoplastic.

- Made from chipboard, MDF and plywood.

The main advantages of wood are naturalness, environmental friendliness, ease of processing, aesthetics and beauty. Not every breed is suitable for a bathhouse.

They should retain heat inside the room as much as possible and not let it into other rooms.

Wooden

Solid wooden doors are made from high-quality wood, most often from linden, ash, cedar, oak, and abash. These breeds have good resistance to “bath procedures”. For example, abash does not deform or rot when exposed to high humidity and temperature changes. The popularity of aspen lies in its healing properties; it is believed that it can draw out diseases and relieve pain.

Innovations in bath fashion include original doors made of solid wood with carved decorations in the form of fancy patterns, birds, and flowers.

It is not recommended to install doors made of pine wood in a steam room. It heats up at high temperatures, absorbs moisture well and becomes deformed, which can be dangerous, and also releases various resins into the room, which can negatively affect the human condition.

Quite often, not just a solid wooden sheet is used for a bath, but in combination with glass. Such models are distinguished by their original design, as well as high strength and reliability, which attracts buyers.

For production, the same listed wood species and tempered glass of various textures are used.

From glass

Glass doors are extremely popular. The range of similar models presented is quite large:

- translucent;

- matte;

- mirrored;

- with patterns;

- various color variations.

The product must be made of a material that is not subject to deformation from constant high humidity and temperature changes.

Glass doors for baths and saunas must have a thickness of at least 8 mm; in addition, they must meet a number of requirements:

- heat resistant;

- impact resistant;

- glass – high quality tempered;

- safety;

- tightness;

- A seal is required.

Glass doors are made of tempered glass, which is highly durable.

The cost of such door structures depends on the complexity of production, materials and quality. Their versatility lies in the competent combination of practicality, reliability and uniqueness of design ideas.

Main advantages:

- no deformation;

- have high resistance to humidity;

- not sensitive to temperature changes.

Therefore, glass doors are often installed in washrooms.

These models will bring a feeling of freedom and spaciousness to the interior, and can also become the highlight of the interior of the entire room. With proper use and compliance with all operating requirements, they can delight their owners for many years. They are unpretentious in maintenance and can be easily cleaned of any dirt using special means.

Glass is a material that does not require constant maintenance. It is enough to occasionally wipe them with glass cleaner.

Made of metal

Although metal is considered a very reliable material, this option is not suitable for steam rooms and showers. In extreme cases, a metal door frame lined with more suitable materials is used. Metal structures are most often used in bathhouses for entrance doors. They are better and more reliable than all others in protecting against burglary and entry into the premises by unauthorized persons, and will also allow you to avoid drafts.

By finishing the metal with clapboard or solid wood and adding thermal insulation material, you can get a beautiful and functional product.

Thermoplastic

Modern thermoplastic has many advantages:

- high resistance to moisture;

- good tolerance to high temperatures;

- strength, reliability and durability;

- the ability to order models with different tinting and various decorative elements.

You cannot use plastic as the main material for this canvas. When heated, it can not only melt, but also release toxins that are harmful to the body.

However, despite all the listed advantages, they are not recommended for installation in a steam room.

Made from chipboard, MDF and plywood

Such doors are unlikely to be suitable for a steam room or a washing room. The slabs easily absorb moisture and become deformed, which can lead to poor opening and closing of the door structure, and this is unacceptable for bath rooms. They can be used as entrance doors, or to other rooms that are less susceptible to moisture and temperature changes.

Characteristics of the design installed in the washing room

This is another door that is equipped with a bathhouse and sauna. The room's characteristics resemble a bathroom: the same temperature changes and high humidity. According to buyers, it is worth choosing a plastic sheet or frosted glass. Such materials are classified as hygienic. They are easy to clean: wash with detergents or disinfectants. They comply with all sanitary standards and regulations.

Where to buy the product you like? You can purchase popular models at specialized retail outlets, or you can order online in an online store, having first read user reviews and carefully studied the photos. Which company is better depends on the person’s preferences and taste. Famous manufacturing companies annually present their fans with new products at an affordable price.

Installation can be ordered from a specialized company, or you can carry out the work yourself. If you don’t know how to install, you can turn to the Internet for help. Expert recommendations and installation videos are posted there.

Types of door fittings

The final stage in the work is the direct fastening of the door leaf in the frame and installation of fittings (canopies, hinges, door handles). Awnings or decorative hinges must be attached from the outside, on the side of the dressing room.

To protect hands from contact with heated material, it is preferable to make door handles from the same wood as the entire structure. Most often, acacia, walnut or elm are used to make wooden handles. You cannot use beech, larch, aspen, spruce - these types of wood under the influence of temperature and humidity can split and injure visitors with splinters.

The ideal option is a linden handle; it remains comfortable even when exposed to high temperatures. Even after 10 years, she will continue to delight her owners.

The most popular models:

- Handles in the shape of an arc (branch or root, can be decorated with carvings).

- Direct - models that do not contain decorative elements, most often industrially manufactured, are used more for glass doors.

- Compact wooden furniture models in the shape of an umbrella, mushroom or ball.

- Dual Designs: The handle, locking mechanism, or deadbolt are combined in one design.

- Carved handles are a special category. Products are made by professional carvers to order.

There are a huge variety of shapes and options for door handles for bathhouses: from standard ones, in the shape of a small ball, to intricate designs.

Quite often, factory-made plastic handles are used for bath doors, which are coated with silicone for greater strength and safety. Metal fittings can be used on the front door and in the dressing room - in these cases, the door leaf does not heat up, therefore, there is no chance of getting burned.

Manufacturing of bath doors

The production of bath doors consists of several stages:

- The first thing you need to decide on is the size.

- Selection of necessary materials and tools.

- Manufacturing of door panels.

- Installation of doors and fittings.

- The final stage of processing the bath door.

Deciding on the sizes

Bath door dimensions:

- optimal height – 150-170 cm;

- width – 70 cm;

- threshold from 15 cm.

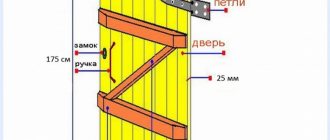

Detailed diagram for making a door for a bathhouse.

Note! In the doorway between the washing compartment and the steam room, a threshold is not installed. Doors should open outwards - this rule should definitely be taken into account. It applies to all existing structures for baths and saunas. This will reduce heat loss at entry and exit, and also save space in the dressing room.

Fabrication

The door leaf can be made of wood, linden or birch. An important condition is to use well-dried wood. Also, after delivery of the tree, it is necessary for it to lie for several days in the room where it will be installed.

For manufacturing you will need the following materials:

- Wooden beam for the frame.

- PVA glue.

- Board with tongue and groove joint, thickness – 27mm, width – 15cm, length – 163cm.

- Loops – 2-3 pieces.

- Door handles.

- Insulation and outer covering (lining, leatherette).

- Self-tapping screws.

- Carpentry tools:

- screwdriver or screwdriver;

- hammer;

- clamps;

- plane;

- jigsaw;

- bar;

- roulette;

- bubble level.

Tools for making a door.

The length and width of a sheet of boards with a tongue and groove connection should be 7 cm smaller than the planned size. This distance will be needed to attach the timber harness.

All boards are cut to the same length - 163 cm. The side tongue of the first board of the door is cut off to obtain a smooth and even door end. Pre-assembly is then carried out to understand the finished version, and to check the canvas materials for defects. After this, you can begin the main assembly.

PVA glue is poured into each groove of the board to enhance the strength of the canvas. The base may be several centimeters wider than the planned size. In such cases, the outermost board of the base is cut along the length of the canvas to the required size. For better shrinkage in the grooves, each board must be tapped with a hammer. The finished canvas must be laid on a perfectly flat surface and under a press; it must also be fixed on the sides. The door leaf should remain in this position for several days until it dries completely. This will strengthen the connection between the boards.

All cracks and gaps that appear during this procedure must be filled.

After drying, the surface is processed with a plane, and it is recommended to remove a layer no more than 2 mm thick.

The resulting base (frame) of the future door must be tied with timber. It should be noted that butt joints are not made at the corners. The “spike” connection is considered ideal. The timber is attached to the boards using self-tapping screws. Across the frame made of boards, on the outside, additional stiffening ribs are made using timber.

The door leaf is almost ready for installation.

Installation of doors and fittings

The door leaf must be secured in the door frame. Before installing the box, grooves must be cut in the top and side openings. Their dimensions should be 0.5 cm larger than the width of the door frame beam. This reserve is made based on shrinkage and correction of the door leaf after installation.

It should be taken into account that the thickness of the door leaf should be 5-7 cm less than the width of the frame. It is better to make the door frame from timber with a section of 6x15 cm. There should be a groove on the outside into which the door leaf will rest.

If the door opens outward, the recess will be on the outside.

After cutting out the groove, it is necessary to remove all chips and clean the surface with sandpaper. Then the top jumper and the side posts at the corners of the box are connected into a “tenon”. After installation is completed, be sure to check again how level the structure is installed. Only after this is the threshold installed.

After completing the preparation of the door leaf and frame, you can begin installing the fittings.

Note! For a heavy insulated structure, it is better to use three canopies or 3 loops. The top one should be placed at a distance of 140 cm from the floor surface. The middle one is 50 cm from the floor and the bottom one is at a height of 20 cm. The hinges are specially installed unevenly - this will help protect the structure from distortion.

The next step is installing locks and door handles. Wooden carved handles will fit very stylishly and attractively into the overall picture and can become a worthy decoration for a wooden door structure.

Custom-made carved models in the form of exotic birds or flowers look beautiful.

After installing the fittings, the door leaf can be attached to the frame using a building level.

Important! If the ends of the doors cling to the edges of the door frame, then the fastening is installed incorrectly. This can be corrected by widening the groove in the door frame or trying to re-hang the hinges. If you do not pay attention to the difficulty of opening and closing doors, then over time the door will swell a little, and the situation will only get worse.

The gaps formed between the doorway and the frame are filled with polyurethane foam or felt. After drying, excess foam is cut off with a sharp knife. If all installation work is carried out correctly, the door opens and closes easily, the door leaf is made of high-quality materials - this means that the structure will serve for a long time and delight the owners.

In order to hide all unaesthetic moments, the box is lined with special platbands.

Finishing the bath door

The final stage consists of treating the canvas with a special composition to protect the wood from harmful insects, as well as mold and fungi.

After drying, the door is insulated if necessary. For this, isolon or mineral wool is used. In order for the door to look aesthetically pleasing and not seem bulky, the thickness of the insulation should not exceed 1-2 cm.

The inside of the door can be covered with clapboard made of wood no more than 7-8 mm thick.

Dermatine fabric is stuffed on top of the isolon, which is an excellent protection against drafts and moisture.

Room layout

Having outlined the goals of building a bathhouse, the number of guests who will be inside the building at the same time, we begin to calculate the internal space. Initially, you need to determine the area of the necessary premises, without which it is impossible to imagine a bathhouse. These include:

- steam room;

- sink or shower;

- dressing room;

- bathroom (at recreation centers).

Steam room

People usually gather at the bathhouse to visit the steam room. For some, it is enough to warm up for a few minutes to steam the skin before soap procedures. The more experienced ones will prefer to linger inside: make a few passes, whip themselves and their comrades with a broom. It is necessary to provide both sitting and lying areas; usually they are combined to save space.

The steam room is made in the room farthest from the entrance, this is due to the fact that the main (more often the only) heat source is installed in it. The entire building is heated by hot air when entering/exiting the steam room. During pre-firing of the furnace, the doors in adjacent rooms (washroom, dressing room) are left open so that warm air warms them up to a comfortable temperature.

When drawing up a steam room design, the following parameters are taken into account:

- The minimum area per person in the steam room is 1 square. m, preferably more, but you shouldn’t go below this level;

- Everyone’s perception of temperature is different, so you need to provide shelves at different levels;

- the upper shelf (lying down) is made wide (60-120 cm): further from the floor - the temperature is higher, in the lying position the heat seems less;

- the width of other shelves is usually no more than 40 cm: enough to accommodate while sitting, and the steamer can freely reach the person on the top shelf with a broom;

- the distance from the top shelf to the ceiling is at least 100-120 cm, in order to sit without resting your head, and for a normal swing of the broom in a lying position;

- height between shelves of adjacent levels: 40-50 cm, this allows you to rest your legs on your feet in a sitting position to relieve stress from the joints;

- shelves are placed along one or several walls (L-shaped, U-shaped) depending on the shape of the steam room, its size, location of the front door, stove.

Sink or shower

The washroom occupies a place between the steam room and the dressing room. It is equipped with tanks with hot and cold water, benches, basins, or it may have a shower, which is more practical, but not everything is so simple. Both options have the right not only to life, but also to peaceful coexistence.

Many people are looking for an opportunity to escape from the bustle of the city for a while and get a little closer to nature; for some, this opportunity is a bathhouse. Scoop up water from the tanks with a ladle, mix it in a basin to the desired temperature, slowly sit on a bench with soap and a washcloth... There is a special charm in this, understandable to anyone who has been to a village bathhouse. In addition, not everywhere there is running water. Many people carry water in buckets from the river or use imported water. In this case, building a shower does not make sense.

However, the shower came to the bathhouse from city apartments for a reason. It allows you to speed up the washing process and free the room from water tanks, basins, and benches. Using shower cabins simplifies the organization of drainage, but shower heads installed on the wall or ceiling allow you to use space more efficiently.

If you have a connection to the water supply, there is no reason to refuse a shower, but you should not forget the old “old-fashioned” method. Soaking hands, feet and other parts of the body in a basin filled with healing infusions cannot be done in a shower stall. And it’s easier to wash a child while sitting on a bench. If there is enough space, it would be a good idea to install benches with water tanks and shower heads on the opposite wall in one room.

Waiting room

The room in front of the entrance to the sink is used for changing clothes and storing things, as well as for relaxing between trips to the steam room. For some, it’s a respite of a few minutes before a new wave of impressions in the steam room; for others, the steam room is just an addition to meeting friends. The layout of the dressing room and its equipment with furniture and other interior elements depends on this. In one case, benches with a table will be enough; in another, a refrigerator, a bar counter and a sound system will not be superfluous.

Pool

A separate room for a swimming pool with a total area of 24 sq. m. m (excluding walls and partitions) there is no need to allocate. This will negatively affect the rest of the premises. If there are no natural bodies of water nearby, but you want to take a dip in the water, you can borrow part of the washing basin to install. It must be remembered that each cube. m of water in it will weigh 1 ton, and this is a significant load. If the foundation is slab, the font can be placed anywhere, otherwise a separate foundation may be required for it.

Useful tips

When installing a door structure in a bathhouse, you should remember some nuances:

- It should be taken into account that the door will shrink after some time: a frame made of raw wood shrinks by approximately 8%, and a frame made of dry wood - by 2%.

- It is not recommended to install locks or latches on door structures leading to the steam room. This is done for safety purposes, so that it is convenient to get into the premises in case of accidents or emergency situations. In addition, at high temperatures, metal fittings heat up, and when exposed to steam, they quickly become unusable and can jam at any moment, which is very dangerous.

- It is strictly forbidden to treat the door leaf leading to the steam room with paints and varnishes.

- A threshold of 15-20 cm is always installed under the entrance door. Under the door structure leading to the steam room, a threshold is not installed, but a gap of 3 cm is made.

- The doors always open only outwards, and the hinges are mounted on the opposite side from the wet room.

Whatever doors to the bathhouse are chosen, it is important that they consist of moisture-resistant and sealed materials that can withstand constant pressure.

It doesn’t matter at all whether the door structure is made independently, in production, or purchased from an expensive, prestigious showroom. The main thing is how comfortable, reliable, aesthetically pleasing and easy to use it is.

Door leaf for steam room

But installing a door to a steam room requires compliance with a number of rules, since during bath procedures an appropriate microclimate must be maintained inside - high humidity and temperature, so that, if possible, steam should escape as little as possible. Consequently, the door height will be much less than standard values.

Since steam accumulates mainly near the ceiling, occupying a layer of approximately 60-80 cm in height, it is at this level that the upper edge of the door - the lintel - should be located.

If we consider, as an example, a steam room with a ceiling height of 230 cm, then from this value you need to subtract the thickness of the steam layer, about 60 cm, although more is possible. The resulting figure will be an acceptable door height for a steam room, and the standard height is 160 cm.

In addition, a high threshold should be provided at the entrance to the steam room - approximately 20 cm.

The threshold performs the following functions:

- eliminates the possibility of drafts;

- prevents cold air from entering the steam room;

- forces the person entering to bend down slightly, thus preventing him from hitting his head on the doorframe.

Along with height restrictions, the width of the door to the steam room can be even greater than usual. This will make it easier to enter. For example, for a door height of 160 cm, its width of 130 cm would be quite acceptable and comfortable.

It is worth remembering that for safety reasons the door should open from the steam room towards the dressing room. In this case, it is easier to knock it out in case of emergency.

Traditionally, only wooden doors for the steam room are installed in the bathhouse. True, sometimes there is an argument about the type of wood that should be used. According to some opinions, coniferous trees, which tend to release resins, should not be used for a steam room.

However, in the conditions of a Russian steam room, temperatures, as a rule, do not rise to the values at which resin smelting begins. Consequently, a steam room in a Russian bath, with its temperatures not exceeding 85 ° C, may well be equipped with spruce or pine wooden doors.

Judging by some reviews, pine boards are often used in steam rooms of Russian baths, not only for installing the door to the steam room with your own hands, but also as a material for covering walls, as well as making furniture - shelves, sun loungers and benches. At the same time, no resin stains or drips were noticed on the wood, no burns occurred, and the smell was pleasant.

As for the Finnish bathhouse - sauna, it uses exclusively hardwood.