Characteristics of the Kalita stove

According to user reviews, “Kalita” is one of the best stoves for a truly Russian bath. It quickly (in 1.5-2 hours) warms up the steam room to 70 degrees thanks to the constant heating mode, accumulating “light” heat. The firebox design helps maintain convection of hot air in the steam room, which eliminates the appearance of “cold zones.” The combustion inside the firebox is natural - without gas generation. Its strength can be adjusted by opening and closing the flap on the door.

The furnace body is made of cast iron alloy, which heats up quickly and releases heat for a long time. The soapstone finish makes the steam particularly pleasant. The internal space of the firebox is designed so that the stones are easily heated from all sides, which is why the steam is so rich. Manufacturers are constantly improving the design of the furnace. Over the past few years, engineers have made the following changes:

- the unit now has a steam gun;

- all fittings are made of high-quality cast iron alloy;

- Covers made of finishing stone were placed on the convection openings, which do not interfere with good air exchange;

- The firebox was equipped with panoramic glass, adding aesthetics to the steaming process.

The body of the Kalita stove is made of cast iron with a thickness of at least 10 mm. It does not burn out, does not become covered with scale, and is not subject to corrosion. The firebox door is made of different materials: steel (stainless, black), cast iron. Each model has its own color, some are decorated with cast iron.

Cast iron stoves "Kalita"

Range of stoves

The sauna stove is the heart of the sauna.

It is this that primarily determines the entire microclimate in the bathhouse. Without the right stove, it is impossible to create a regime that is balanced in temperature, humidity and overall air quality, not only in a steam room, but in a bathhouse in general. It is precisely these conditions that the furnaces of the Kalita model range meet in the best possible way. The volume of the steam room is 18-34 m3. + - more details...

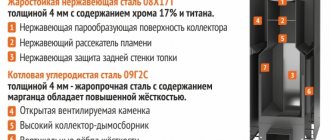

The parts of the combustion unit of Kalita furnaces are cast from high-quality cast iron, the structure of which contains lamellar graphite, which makes the cast iron more resistant to corrosion when operating at high temperatures. The wall thickness of the parts of the combustion unit is 10-12 mm. The side walls of the combustion unit are decorated with special register ribs, which not only increase the heat transfer surface area of the entire unit, but also give it additional rigidity. The use of cast iron as a material and the perfect design of the combustion unit itself ensures excellent thermal characteristics, high reliability and durability of the stove. Since the combustion unit is the most critical part of the stove, including in terms of its fire safety, special attention is paid to the quality of the cast iron from which it is made.

Castings from each melt are necessarily checked for compliance of the chemical composition of the metal with regulatory documents. Tensile testing of castings is also carried out using special tensile testing machines. The tensile strength of cast iron used in the manufacture of parts for the combustion unit of Kalita stoves is at least 200 MPa.

Unfortunately, metal wood stoves have a low coefficient of performance (COP). And the low efficiency of the stove means excessive fuel consumption and a long time to warm up the steam room. A significant part of the heat generated during fuel combustion simply “flies down the drain” and does not go to heating the room. In this case, the first elements of the chimney find themselves in a zone of high thermal loads, the temperature of the outgoing combustion products reaches 800°C. The main reason for this shortcoming is the suboptimal organization of the movement of fuel combustion products inside the furnace and the lack of special design solutions to increase the amount of heat released by the combustion unit into the room. A significant part of the furnaces on the market today are so-called “direct-flow furnaces”, which to one degree or another have the disadvantages noted above. When designing the combustion unit of Kalita stoves, special attention was paid to minimizing these disadvantages.

The container for stones is a non-removable structure of complex configuration, causing not only turbulence (turbulization) of gas flows inside the furnace, but also their organized gas circulation, and as a result, a decrease in the speed of their movement and an increase in the time spent inside the combustion unit. The amount of heat transferred to the elements of the combustion unit increases, optimal heating of the stones for steam generation is achieved, and the temperature of the outgoing combustion products is significantly reduced. Unfortunately, it has not yet been possible to replicate this complex and original design in any similar cast iron product from other manufacturers, despite their “external” similarity to Kalita.

But it’s not enough to heat the combustion unit; you need to transfer this heat as efficiently as possible to heat the room and the stones for steam generation. For this purpose, the walls of the combustion unit are equipped with a developed system of ribs, increasing the area of the heat transfer surface of the combustion unit by 80%.

These and a number of other technical and design solutions made it possible to increase the efficiency of Kalita stoves by 15-25% higher than that of its analogues.

Only natural, environmentally friendly materials are used as materials for the external design of the stove: natural soapstone stones or coils. Natural stone cladding converts hard thermal radiation from a hot combustion unit into softer, more comfortable and pleasant radiation from the stone massif of the external cladding. Due to its large mass, stone cladding is capable of accumulating a significant amount of heat and then slowly releasing it, maintaining a consistently high temperature in the steam room with virtually no additional heating of the stove, at least in the domestic use of the steam room. The use of natural stone to decorate the outer body of the stove not only corresponds to all the thermophysical processes when using a bathhouse and specifically a steam room, but is also an excellent solution for their style and design.

Depending on the client’s wishes, several options for the design of the combustion tunnel are possible, without changing the technical characteristics of the furnace. The combustion tunnel can be made of stainless steel or cast iron and be equipped with various types of doors: with forged finish, made of mirror stainless steel, with a vertical lift mechanism, cast iron, etc.

The high thermal power of the combustion unit, natural stone cladding, reliability and ease of use allow Kalita stoves to be the undisputed leaders in the sauna stove market. And a number of technical innovations: a container for stones built into the firebox, a steam gun, and a convection regulator make these ovens unique in their own way.

The Kalita stove is the perfect combination of tradition and modernity.

To meet the numerous wishes of our Clients, a new combustion unit “Kalita+” with a thermal power increased by 15% was developed and put into production in 2014. The Kalita+ combustion unit is equipped with a cast iron door with a large panoramic glass. This unit can be equipped with any of the furnaces of the Kalita model range.

Traditionally, the Kalita series of wood-burning stoves is a massive cast-iron firebox, which, together with natural stone cladding, provides a unique form of heat transfer into the steam room.

With the advent of the “Kalita+” option, all stoves in the “Kalita” line are equipped with a cast-iron combustion unit increased in height by 50 mm and a cast-iron door with a large panoramic glass.

By choosing “Kalita+” you get: - an increase in the thermal power of the furnace; — possibility of increasing the volume of a steam room; — reduction of heating time for a steam room; — increasing the size of the furnace loading window; — possibility of more convenient fuel loading; — increasing the heat storage capacity of the furnace.

Using any of the Kalita stoves in a steam room creates a special atmosphere, which is characterized by a mild microclimate, stable temperature, and comfortable thermal energy transmitted by the stove.

Since January 2016, the new Kalita+ has replaced the old Kalita model. Now Kalita=Kalita+

+ — Certificate of conformity for the stove-heater for baths “Kalita”

+ — EAC Declaration of Conformity for Kalita stoves

Advantages of the Kalita cast iron stove

The main advantages of Kalita brand stoves include:

- Durability, long service life. It’s not without reason that they say about “Kalita”: I bought it, installed it and for a long time forgot about the problem of servicing the sauna stove.

- Careful approach to the selection of materials. The stove body with lining not only makes the stove reliable and durable, but also helps create a healing atmosphere inside the steam room.

- Environmental friendliness. Among the materials from which all elements of the Kalita stove are made, there are no environmentally harmful materials. When heated, not a single part releases substances hazardous to health into the air. The main fuel is firewood.

- Multi-stage quality control system - from the purchase of materials for production to the release of finished products. The risk of marriage is minimized.

- A closed heater helps to quickly saturate the air with pleasant, finely dispersed, non-burning steam. It is beneficial for the respiratory system. People with high blood pressure and cardiovascular diseases can take bath procedures with the Kalita stove.

- Thoughtful ventilation helps saturate every corner of the steam room with hot air. The floor will also be warm.

- Another big plus is the ease of design and operation of the Kalita sauna stove. It can be disassembled, moved, and assembled in a new place with your own hands, without involving stove makers. The main thing is to take into account the weight of the equipment and make the right foundation at the installation site.

To heat a steam room, you need to put firewood in the firebox and set it on fire. Next, it is enough to select the intensive combustion mode for quick warming up or the heat preservation mode to maintain a steady temperature. Caring for any model is simple - after each use, you need to clean it from ash and keep the chimney clean.

in Moscow, it sells Kalita cast iron stoves for baths and saunas. We deliver throughout Russia and the CIS countries. Along with the order, the buyer receives a full set of documents - warranties, furnace technical passport, operating instructions for Kalita equipment, payment documents.

Wood stoves Kalita Russian steam5.000

The warranty period is the period during which the customer, having discovered a defect in the product, has the right to demand that the seller or manufacturer take measures to eliminate the defect. The seller must eliminate the defects unless it is proven that they arose as a result of violations by the buyer of the operating rules.

When does the warranty begin?

- from the moment the goods are transferred to the consumer, if there is no specification in the contract;

- if it is not possible to determine the date of purchase, then the warranty starts from the date of manufacture;

- For seasonal goods, the guarantee starts from the start of the season;

- When ordering goods from an online store, the guarantee begins on the day of delivery.

Warranty service includes:

- elimination of product defects in certified service centers;

- exchange for a similar product without additional payment;

- exchange for a similar product with additional payment;

- return of goods and transfer of funds to the buyer’s account.

Rules for exchange and return of goods:

Exchange and return of products of good quality

The seller guarantees that the buyer, within 7 days from the date of purchase of the goods, can refuse the goods of proper quality if:

- the product has not been put into use and is in marketable condition, is in packaging with all labels, and there are also documents for purchasing the product;

- The product is not included in the list of products of good quality that cannot be returned or exchanged.

The buyer has the right to exchange goods of good quality for another trade offer of this product or another product identical in value or for another product with an additional payment or refund of the difference in price.

Exchange and return of products of inadequate quality

If the buyer discovers defects in the product after purchasing it, he may request a replacement from the seller. Replacement must be made within 7 days from the date of the request. If an examination is ordered to determine whether the goods comply with the specified standards, the exchange must be made within 20 days.

Technically complex goods of inadequate quality are replaced with goods of the same brand or with a similar product of a different brand with recalculation of the cost. The return is made by canceling the sales contract and returning the amount in the amount of the cost of the goods.

A refund

The refund period depends on the type of payment that the buyer initially chose.

For cash payments, refunds are made at the checkout no later than 10 days after the buyer submits a return request.

The cost of the goods is credited to the customer’s card, if non-cash payment was used, occurs immediately after receiving the request from the buyer.

When using electronic payment systems, the refund is made to an electronic account within 10 calendar days.