One of the main disadvantages of wooden building materials is their high susceptibility to rot and vulnerability to wood-boring beetles. Since these processes are a direct consequence of increased wood moisture, most often such damage occurs in the lower part of the walls, for which the lower crowns have not been properly waterproofed.

It should be noted that moisture insulation of the lower crowns means not only the physical and chemical treatment of building materials, but also a number of design solutions, during which a slight modernization of the foundation may be necessary.

This review examines what affects the durability of the base of a log house, and what technologies exist to prevent its destruction.

What destroys the lower crowns of log houses

Modern technology for building wooden houses involves installing a log house on a stone foundation.

In this case, the foundation of the house is exposed to several dangerous factors:

- capillary moisture coming from the foundation;

- humid atmosphere from the basement;

- lack of sunlight, since the lower part of the wall is often in the shadow area;

- drip moisture and temperature changes from the outside of the walls.

Damaged logs

In the latter case, the situation is aggravated by the fact that if the base configuration is incorrect, moisture flowing from the walls during rain accumulates in the lower logs and in the inter-crown seals.

A direct consequence of the factors listed above is the development of microbiological formations in the wood, affecting its structure and ultimately leading to a complete loss of strength in the lower crowns of the frame.

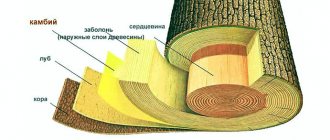

The greatest biological danger to logs is represented by fungal structures, the first signs of which are the so-called blue discoloration, sometimes penetrating into the very core of the log.

The nutrient medium for such fungi is lignin, cellulose and oxygen. But the main catalyst for their development is always high humidity.

The second factor in the biological damage to wood is wood-boring beetles, the appearance of which is almost always associated with fungal infection of wood.

Taking into account the above, the main methods for solving the problem of lower crowns are:

- saturation of wood with antiseptic compounds that impede the development of microbiological formations;

- reduction in the capacity of the external capillaries of the logs, necessary to stabilize the internal moisture content of the wood at an acceptable level.

As mentioned earlier, the solution to the listed problems is carried out not only through additional processing of wood, but also through the use of special design solutions, the most significant of which will be discussed below.

Purpose and technology of protection against rotting of the lower crowns of a wooden house

One of the main disadvantages of wooden building materials is their high susceptibility to rot and vulnerability to wood-boring beetles. Since these processes are a direct consequence of increased wood moisture, most often such damage occurs in the lower part of the walls, for which the lower crowns have not been properly waterproofed.

It should be noted that moisture insulation of the lower crowns means not only the physical and chemical treatment of building materials, but also a number of design solutions, during which a slight modernization of the foundation may be necessary.

This review examines what affects the durability of the base of a log house, and what technologies exist to prevent its destruction.

Special design of the lower crown

Cause of the problem

If you imagine the volumetric structure of a log house, you can see that the classic lower crown, assembled “in a bowl,” cannot be placed on a single-level foundation without a gap. It should be remembered that the larger such cracks and gaps are, the higher the likelihood that they will become moisture accumulators and cause the logs to rot.

In this connection, sealing the lower crown begins not with treating the logs with mastic or impregnation, but with pairing its geometry with the geometry of the foundation.

There are two options for solving this problem:

- production of a two-level foundation;

- sawing logs to create a dense contact zone along the entire perimeter of the crown.

Example of a multi-level foundation

Second method, schematically

The first option is used for the construction of small buildings (baths, barns, etc.).

The second method is more commonly used, as it avoids the need for “shaped casting” in the corners of the foundation and allows the use of a solid interlining board made of durable wood.

Laying board

We will separately consider such a solution as the above-mentioned spacer board, which is the simplest way to extend the service life of a log house by a good ten years, and also greatly facilitates the repair of the lower crown, if the need arises.

The essence of this solution is that a wide board made of the most stable type of wood (oak or larch) is laid between the foundation and the lower crown of the log house.

Please note that a wide board is always made from the central sectors of a log, the maximum stability of which is observed only in larch.

At the same time, it is important to take into account one feature of this technology: additional processing of the padding boards with any chemical compounds is not carried out. The sealant is laid using the same method as for inter-crown gaps.

Pest Control Materials

When trying to prevent a log house from rotting from moisture, one should not forget about protecting it from various pests that threaten the integrity of the crowns. If the logs of the log house were prepared or stored incorrectly, various insects can settle in them: bark beetles, weevils and other small creatures that can turn the logs into dust.

It is considered correct to use material for the log house prepared in winter. Then you can count on the absence of bugs and their larvae in the wood. Before processing, the prepared material must be well dried. There are special antiseptics on sale that are designed to protect against mold and fungi, containing chemicals - fungicides and more modern biocides, which are poisonous to beetles and other wood pests. Known effective products containing fungicides are:

- products: Neomid 400, 450, 500;

- impregnations Prosept Exterior, Prosept Interior, ;

- drugs produced by;

- drug "Bioshield - 2";

- drug "Sagus".

Harvested wood must be treated after drying with one of the products containing fungicides, or directly with a fungicide.

Waterproofing between the foundation and the log house

The most important point affecting the durability of the lower crowns in houses made of timber or logs is the correct organization of waterproofing between the foundation and the log house.

The fact is that most of the now popular “stone” building materials have good capillary conductivity, and if additional waterproofing measures are not taken, the lower crown will always be wet.

In this case, moisture is cut off by laying sheets of roofing material or by covering the contact zone with liquid rubber.

Roofing felt waterproofing

Roofing felt is laid according to the standard method (on liquid bitumen), and an inter-crown sealant must be laid between the waterproofing and the crown.

Correct first crown

Double harness

This type of strapping involves the use of two rows of wooden beams of different sections. The structure can be fixed to a screw foundation in two ways:

Threaded connection

They place roofing felt under the supports, place a beam with a cross-section of 20 × 20 centimeters on the screws and tap it with a hammer. In the corner parts, wooden products are fastened using a metal corner and self-tapping screws. The second row of strapping is secured using through metal pins.

Clamps

When fixed to clamps, the first row of timber with a cross-section of 10 × 15 centimeters is laid edge down. The joints of the elements are made in a checkerboard pattern; they should not coincide. The harness is attached to the piles using U-shaped bar clamps. They are mounted on the previous element.

At the final stage of work, the structure is tested for durability, and corrections are made if necessary.

Protective ebb

Low tide

In some cases, it makes sense to mount additional flashings above the lower crown, minimizing the flow of moisture into the first inter-crown seams.

On the front facades of houses, such a solution is not always acceptable for aesthetic reasons, but on the rear walls, which are often shaded or stand adjacent to outbuildings, such protection will not be superfluous.

Please note that it is advisable to make such ebbs from the most protected material, since it will have to work in conditions of constant humidity.

Chemical treatment

A huge number of different impregnations and mastics make novice builders tempted to cover the first crowns of a log or timber house with a thick sealing layer that completely eliminates the circulation of moisture.

The expediency of such an action is very questionable, since complete sealing will lead to the opposite effect - the log will remain stably moist and, as a result, will turn into an excellent incubator for microbiological substances.

But what is really worth doing from the operations of chemical preparation of wood for long-term use is antiseptic treatment, which minimizes the risk of biological contamination of wood.

We recommend not experimenting with the so-called “folk methods of antiseptic treatment (vitriol, old machine oil, etc.)”, since in this case there is always a risk of getting a stable source of carcinogens, emitting them, by the way, not only into the external environment, but and in the underground

Fumigation of logs

In any hardware store today you can purchase inexpensive antiseptics that are certified in government laboratories and have a number of additional useful qualities (for example, almost all antiseptics can be used as a primer before painting).

Among the “ancient” methods of extending the life of the lower crowns of a log house, it is worth mentioning fumigation, which consists of burning logs in an open fire.

The essence of the technique is that when the outer layer of the log is fired, the capillary network of the wood becomes clogged, through which dangerous saturation with moisture occurs. But - what is important - in this case the effect of vapor permeability is preserved, which, by the way, is absent in many polymer sealants.

works on construction sites in Moscow and the Moscow region and provides services for the assembly, repair and restoration of log houses in wooden houses of any design, including restoration of the lower crowns. You can clarify the details of cooperation and order a work estimate via e-mail or by phone numbers published on the “Contacts” page.

Calculate the cost of painting and insulating your home right now