Special putty is what you need to coat the oven with to prevent it from cracking

You can buy this mixture for eliminating cracks or make it yourself.

Fireproof putty for stoves and fireplaces purchased at a building materials store is ideal for repairs. It perfectly withstands temperatures of 1000 degrees. Before applying it, the stove and cracks should be treated with water. You can do the grouting yourself, following the instructions:

- Pour clay into a container and break up the lumps.

- Fill it with water and leave for 12 hours.

- Pour sand into the clay and knead the mixture.

- Finely chopped straw is added in small portions.

- Add one pack of salt.

Sand and clay are mixed in a ratio of 1:4. For 4 buckets of clay you will need about 50 kilograms of straw.

Clay-fireclay mortar

Designed for laying fireboxes. It differs from the usual one in its increased degree of heat resistance. Able to withstand temperatures within 1200-1300 degrees Celsius. For the mortar used for the main masonry of the structure, this figure is two times lower, so it is not suitable for the combustion chamber, where the seams formed are exposed to extremely high temperatures. Fireclay sand gives the composition heat resistance. But, given that the base remains clay, this makes it possible to prepare the solution in large volumes. It is enough to add a little water to the prepared mixture, and you can use the pre-prepared mixture again if it has already become more viscous than necessary.

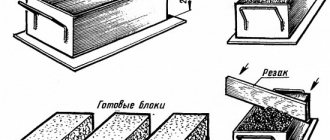

Production of material

It is important to store the dry fireclay clay mixture in a dry place

To make a solution of fireclay clay for laying out a stove with your own hands, you need to follow certain instructions and use the main components in certain proportions.

Fireclay powder has the properties that it acquired depending on the production method. The fraction of the material also matters. Fireclay clay has its own special marking. If the letter “U” is indicated on the packaging, this indicates the use of defective kaolin in production. It is cheaper, but you should not use it in important work. Options for diluting fireclay clay:

- 2 parts of fireclay sand with a fraction of no more than 0.5 mm to 1 part of kaolin;

- 4 parts fireclay sand to 1 part kaolin and the same amount of blue clay.

For the durability of the treated surface, the solution with clay must be mixed correctly

Ordinary sand should not be used when preparing such a solution. When heated, it will expand greatly. River water should also not be used, as it will not provide the necessary adhesion. If the solution needs to be more durable, Portland cement is added to it. But this ingredient will reduce the fire resistance characteristics. If you take into account all these features, working with this material will be easy and simple.

It is important to keep the solution and not rush to add water to it. Patience is key here, otherwise the clay will crack.

There are special compositions for quick mixing. They are convenient because you don’t have to wait for several days. True, they cost more. PVA glue is added to this mixture. Fiberglass is used for reinforcement.

Clay selection

When choosing refractory clay, you should pay attention to the packaging labeling. It has a special digital combination showing the fire resistance of the material. You should know that large values indicate high fire resistance of the clay. In addition, by the markings you can find out about the area of use of the material and for laying which bricks clay of this type is used.

The shelf life of chamotte clay is of great importance, since after a certain time kaolin loses its technical properties. Therefore, you should not purchase material after the end of the sales period.

Advantages and disadvantages

This material does not cause controversy both among professional builders and among those who like to do household work with their own hands, since it is practically indispensable in the manufacture of stoves and various fireboxes. Fireclay clay does not have any obvious disadvantages, but this does not exclude its negative properties. The advantages of the material include:

- Excellent heat resistance;

- Reliability and long-term durability during professional masonry;

- Environmental friendliness of the material;

- The presence of micropores for the passage of steam, which also prevents the expansion of the masonry and its destruction;

- High level of adhesion.

There are fewer disadvantages, and besides, they are typical for many high-quality materials:

- High cost, since the production of such clay is technologically more complex and dangerous than the production of ordinary building clay;

- Fireclay dust enters the respiratory tract, so it is necessary to use a respirator when working.

How to use it correctly

The basis of the composition is clay powder and water in the required proportion. During the production of fireclay, kaolin loses its plasticity. To restore the pliability and elasticity of the mixture, special additives are added to the composition. For each task, there are rules that allow you to obtain a strong fire-resistant material.

For laying the furnace

Plasticity indicators are often improved with kaolin sand. The white substance is sold in construction stores in bags. In one container, clay is mixed with the additive in proportions of 4 to 1, then water is slowly poured in small portions. To obtain a uniform consistency, professionals recommend using a special mixer.

In order for the ingredients to reveal their characteristics, the preparation is left for 3 days. The finished mixture resembles plasticine in thickness. The solution should not stick or flow easily, and there should be no lumps under your fingers. If you scoop it up with a trowel, the mass slowly slides off, without leaving a residual mark.

Features of technology for the stove Source stroyfora.ru

The presence of clay components is called fat content. The parameter is responsible for the plasticity of the finished material. You can increase or decrease the characteristic using sand or fireclay. Oversaturated solutions do not affect the quality of the stove, but due to “lean” options, the structure will crumble.

To find out the fat content of clay at home, you need to roll a ball from the finished raw materials. The samples are pressed down on top with a long board. If cracks appeared under low pressure, then the solution is “lean”. If ruptures occur at half the radius of the ball, it indicates high plasticity indicators, and at a third – average (normal). The last two types are suitable for construction work.

The surface to be treated must be prepared. The old finish is removed from the wall and the reinforcing mesh is fixed. In order for the product to hold tightly, a layer of solution must be applied on top. Knowing how long fireclay clay takes to dry, you can begin laying out the stove in 3-4 days.

The classic stove mixture consists of base material and sand. An experienced master uses at least 3 types of solution with different additives when working. Cement-lime varieties are recommended for the base and chimney. When assembling the frame, cement is added to the composition; for the combustion chamber, red clay is added.

Rules for using chamotte Source vbud.in.ua

Checking the properties of the main ingredient of the refractory mixture

There are several proven methods for checking the quality of clay:

Determining the readiness of the solution.

- Take about 1 kg of dry clay (0.5 l) and pour water into it portionwise, mixing it with your hands. The clay should completely absorb water and be a solution with a thick consistency. The next step is to roll balls with a diameter of 4-5 cm. A flat cake with a diameter of 9-10 cm is made from the resulting ball. All this is dried naturally for 3-4 days. Next, inspect for surface cracks. Identification of cracks on the ball and cake indicates increased fat content of the material. If no cracks are found on the ball and cake, then it is necessary to drop the ball from a height of no more than 1 m. The preservation of the integrity of the ball after the fall indicates the quality of the clay, and destruction shows that the clay is thin.

- Take approximately 3.6-5.4 kg of clay (2-3 l) and pour it into a container, thoroughly mixing with a wooden spatula and kneading the lumps. If the clay sticks to the shovel quite well, it means it has a high fat content. You need to add a little sand to this solution. If the clay remains partially on the blade, then such material is considered high quality and suitable for use. Poor adhesion of the mixture indicates that the mixture is lean and requires the addition of fatty clay.

- Take up to 1 kg of dry clay (about 0.5 l) and prepare a thick solution, mixing thoroughly with your hands. Balls with a diameter of 4-5 cm are prepared from the resulting composition. Next, take two smooth plates of chipboard or wood, place the ball on one of them, cover with the other and squeeze until cracks appear on the ball. Test control:

- if the ball collapses at the slightest pressure, it means the clay is thin;

- if cracks appear when squeezing up to 1/4-1/5 of the diameter of the ball, then the clay has a low fat content;

- if cracks appear when compressed to 0.3 of the ball diameter, then the mixture is normal and suitable for further use;

- Oily clay cracks when compressed to 0.5 times the diameter of the ball.

- A ball is made from the resulting steep solution and rolled out until sausages with a diameter of 1-1.5 cm and a length of 160-200 mm are formed. Next, they are stretched until they break. A sample made of lean clay practically does not stretch and gives a rather uneven break. Normal clay is characterized by smooth stretching and breaks when thinned to 20% of the original sample. Oily clay, on the contrary, stretches out gradually and gives a smooth break with the formation of sharp ends at the point of break.

Checking the consistency of the solution

To check the correctness of the kneading, you need to dip a clean trowel soaked in water into it:

- If the solution sticks to the surface of the tool, it means that the clay is too oily, and a small amount of sand must be added to the mixture.

- When the mixture does not stick to the tool, the fat content is normal, but the plasticity is not enough. This indicator can be increased by adding clay with high fat content.

- The presence of protruding water in the solution after settling is evidence of the mixture being too lean. The composition can be corrected by reducing the sand component by introducing fatty or ordinary clay.

Each time you change the mixture, you need to lower the tool again until the ideal consistency is achieved.

Making your own mixture - all options

Having understood the principle of determining the plasticity of a masonry mortar, you can begin mixing it. This operation can be done with your own hands using different methods. A very simple technique that we, in fact, have already considered. You need to soak the clay in a small volume of water 24 hours before the planned procedure for laying the stove. Then (a day later) add liquid to the soaked material and mix the composition with a shovel until it becomes creamy. After this, you need to strain the resulting mixture and add sand to it (remember the proportions indicated above).

Mortar on brick

In cases where impeccably clean clay is used (without foreign inclusions and small stones), the mixture for stoves can be prepared with your own hands using the second method. Its essence is this. Add fine sifted sand to clean clay and fill the resulting composition with water (a quarter of the total volume of the mixture). Mix the mixture thoroughly until it reaches a creamy consistency. At the exit, it should slide off the shovel without difficulty, but under no circumstances should it spread. The next step is to add cement and salt to the resulting composition. These components will increase the strength characteristics of the clay mortar for the oven. For 10 liters of mixture take 750 mg of cement, about 200 g of salt.

The third method involves the use of fireclay and chamotte sand. These components should be mixed with each other in the same ratio. Then add water to the mixture. Its amount is 25% of the volume of clay. Mix the composition. That's all. This is perhaps the most basic way to prepare mortar for laying stoves. There is another method for preparing the mixture we are interested in with your own hands. It is made from loam. You will have to mix 10 small portions of different solutions. The first mixture has proportions - part cement + part sand + 10 parts loam, the second - 2 hours sand + 1 hour cement + 9 hours clay and so on. The latter composition will thus contain 1 hour of cement, 10 hours of sand and 1 hour of loam.

All mixed solutions should be placed in small boxes and left until completely dry in the fresh air (6-7 days). After a week, you begin to inspect the resulting mixtures. For masonry, choose the composition that contains the maximum amount of clay and completely eliminates the phenomenon of cracking. Believe me, it will be ideal - it will be able to withstand oven heating temperatures of up to 500–600 °C without deformation or crumbling. Choose your own option for preparing clay mortar!

Specifications

When considering the technical characteristics of fireclay clay for oven plaster, it is necessary to note the following:

- The grain size corresponds to two millimeters.

- Highly fired fireclay absorbs no more than 10% moisture, and low fired fireclay absorbs no more than 25% moisture.

- The maximum temperature that the material can withstand is 18500C.

- The humidity of quality material does not exceed 5%.

When determining the required amount of material, you should know:

- A standard 20 kg package of clay is enough to lay 30 bricks.

- For 1 m3 of masonry, you should purchase 100 clay.

- A solution prepared with precise adherence to technology becomes absolutely solid after 24 hours, provided that the air temperature does not fall below +100C.

Clay in industrial packaging can be stored for 3 years from the date of manufacture.

How to dilute and what to mix fireclay clay with - step-by-step diagram

Step 1: Infuse the powder in water

To prepare a mortar from fireclay clay for plaster, we need a pack of fireclay powder. Pour the powder into the container, gradually adding water until the powder is completely covered with water. Before diluting the final solution, the fireclay clay must sit for at least three days.

Step 2: Making the final batch

After we have waited the required time, we will stir the resulting mixture again, adding a little quartz sand and water if necessary. If the solution turns out to be liquid, you can sprinkle in more powder; if it is too thick, dilute with additional water. The consistency of the ready-to-use solution should resemble sour cream - with such a thickness it will not drain from the surface and will stick well to the wall.

Of course, you can also purchase a composition for instant mixing - it does not require steeping for three days, but it also costs more. In any case, PVA construction adhesive should be added to the resulting composition; it would not hurt to reinforce such a solution with crushed fiberglass. Plastering with this solution does not require any special skills - just prepare large and small spatulas in advance and apply the solution evenly to the surface.

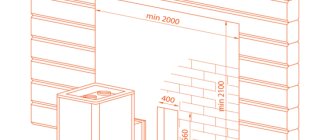

Step 3: Prepare the surface

Based on the reduced plastic properties of fireclay, it is imperative that the surface you want to plaster be provided with a mesh, and to improve adhesion, it must be treated with a good primer. Since we are most often talking about plastering stoves and fireplaces, the primer should be heat-resistant and the mesh should be metal. In this case, you will compensate for the plasticity of fireclay and achieve the highest fire resistance of the plaster.

Pros and cons of fireclay mixtures

When constructing a furnace, it is imperative to use refractory material for both internal and facing work. Among the advantages of chamotte mortar are:

- High level of environmental friendliness.

- Excellent steam permeability.

- Resistant to high temperatures and temperature changes.

- Long service life.

However, the masonry mixture is not famous for its advantages alone. It also has certain disadvantages. First of all, it is necessary to address the issue of price. Even if you prepare the solution yourself, its cost will be very high, when drawing an analogy with other materials in this group.

The mixture contains phenolic resin. This element has a high level of toxicity, and accordingly, environmental pollution occurs during production. And the work itself at the enterprise does not benefit anyone, since a lot of harmful dust is generated during the entire work process.

Factory produced mixture

As for efficiency, it is not as high as we would like. For example, if you need to lay only 25 bricks, then you will need to purchase about 20 kg of clay mass, but to lay one cubic meter of structure you will need as much as 100 kg of material.

What is included in the process of preparing the solution?

The process of preparing the solution occurs according to the following algorithm:

- Dry clay is poured into a pre-prepared trough.

- If the clay can be classified as a fatty type, add river sand at the rate of 1 part clay to 2 parts sand.

- Then add water at the rate of 1 part water to 4 parts clay solution.

Determination of the plasticity of clay mortar.

The masonry mortar is ready. You can check it in a simple way: by making a round ball of small volume from the solution and throwing it with force on a hard surface. The ball will collapse if there is excess sand, if not, the solution is normal. You can also determine the quality of the clay before preparing the mixture. Taking half a liter of clay, mix it, gradually adding water, mix by hand until the clay solution sticks to your hands. At the end of the manipulations, roll a ball with a diameter of 40-50 mm, place it and let it dry for three days.

If there are cracks, it is necessary to add river sand to the mixture, after sifting it on a special sieve. If the ball is not damaged and does not collapse when dropped from a height of 1 meter, then the clay composition is suitable for construction.

The following method of testing clay is one of the most optimal. You need to beat 0.5 liters of clay by hand, like dough. From the specified mixture, prepare a spherical object with a diameter of 50 mm and, placing it between two parallel wooden planks and applying mechanical force, deform the ball until it cracks. Let's look at the result:

- the presence of skinny clay - the ball disintegrated;

- average presence of fatty parts in clay - deformation of 1/5 of the ball;

- normal clay - cracks when compressing 13 balls;

- greasy - the appearance of small cracks when deformed by half.

Putty and additional additives

The material can be used for putty. True, there should be a slightly different composition here. Stock up on the necessary materials - take 1 part of Portland cement, 2 parts of fireclay clay and 7 parts of quarry sand. The mixture is mixed in the same way as for laying bricks. Metal mesh is used to fix fireclay plaster.

Materials can be added to the clay solution to enhance the necessary properties.

Additives are used to enhance individual properties of the solution. This is PVA glue, liquid glass or table salt. The latter is used 100 g per bucket of solution. The mass fraction of glass should be no more than 3% of the total quantity. Additives are a good option for improving product performance.

Fireclay clay is absolutely safe, but getting it on your face is still undesirable. In addition, optimal air circulation in the room where work is being carried out should be ensured.

How to dilute clay to putty a stove

Despite the sea of modern technologies for laying stoves, fireplaces, fireplace complexes and all kinds of heating and decorative innovations, stoves are still laid using clay mortar. They also use it to repair, plaster, and correct defects in masonry. Ready-made clay stove mixtures have appeared in building materials stores. Unfortunately, it is only suitable for working with fireclay bricks, where ordinary clay will not work. In other cases, to prepare a masonry or coating mixture, you will have to look for clay yourself.

How to make a clay mixture

It is necessary to distinguish between the process of plastering a stove for whitewashing and the process of sealing cracks in masonry joints. Accordingly, the solution will require different thicknesses and compositions. The ideal clay for coating and repair is the same clay from which bricks are made. Unfortunately, they stopped making bricks on their own long ago, preferring to buy them, and therefore it’s impossible to find a “deposit” for them.

You should choose low-fat red clay, and if necessary, additionally deplete it with sand. The mixture for sealing cracks in seams is prepared as follows:

- We take a clay-sand mixture and experimentally determine the required proportions of the components. To do this, prepare a plasticine-like solution and roll small balls from it (no more than 2 mm in diameter).

- We stretch our hand with the clay ball forward and drop it on the floor. If the ball does not crack or smear with a blot, then this is an ideal mixture for repairing stove seams.

- Add finely chopped straw for reinforcement and 1 kg of salt per bucket of the mixture. You can start working.

The solution for plastering the stove is prepared in a similar way, only its consistency is creamy.

How to coat a stove

When starting repairs, you should warm up the stove a little before work. The procedure for sealing cracks in the furnace is as follows:

- remove all the crumbling layer and all the lime whitewash (clay will not fall on it);

- spray or wet the repair areas with a brush so that the dry areas bond better with the repair solution and do not draw moisture from it;

- seal the seams tightly with a plasticine-like mixture, and plaster the surface with a liquid solution.

You can coat the oven by hand or use a spatula and trowel.

After the solution has dried, additionally coat small cracks. Date: September 25, 2022

Use Cases

Kaolin can be used for furnace masonry. It is also used as plaster and for making decorative items.

In addition to being used for decorative purposes, chamotte clay is actively used when laying stoves and fireplaces

When building stoves, they look at the markings applied to the surface of the products. Usually the letter "Ш" is indicated. The material most often used is for masonry of the firebox, since its cost is high, so it is impractical to use it for the rest of the work. They lay it on special clay. Its characteristics are the same as those of brick.

Fireclay fireclay has a unique texture and composition. That is why designers paid attention to it and began to use it to produce unique blanks. These can be ceramic dishes, original figurines. To ensure greater plasticity, various impurities are added.

Fireclay sand

Fireclay is called sintered clay completely devoid of moisture. Refractory sand is usually obtained by grinding fireclay bricks, that is, from scrap. Bulk material is considered more resistant to fire than ordinary sand. It is recommended to add it to the solution for laying the combustion chamber. In addition, it interacts well with the heat-resistant brick from which it was obtained, which allows you to create a particularly strong bond. You should not skimp on this component. It is required in small quantities, but provides the longest service life, which is especially important for the combustion chamber.

Features of storing self-hardening polymer clay

In a closed package, any self-hardening clay can be stored for quite a long time. However, due to the peculiarity of this type of clay, it is necessary to remember 3 important rules:

- For work, only the amount of clay that is required at the moment is taken. You should not take extra clay out of the bag. We put the material that is not needed now into a hermetically sealed bag.

- An open pack of self-hardening polymer clay must be stored in an airtight container. In addition to the film and the clay bag, it is worth placing it in some container with a tight-fitting lid.

- While working, always keep a damp cloth nearby (covering the clay with it) and a bowl of water to wet your fingers.

- It is worth remembering that the shelf life of self-hardening clay is limited - carefully read the instructions on the package.

How to protect products made from self-hardening clay?

Unfortunately, self-hardening clay is afraid of water. And even a finished product that seems to have dried out long ago and nothing can happen to it, sometimes loses its beauty only if it gets slightly wet.

To protect your creations made from self-hardening clay, it is recommended to coat the finished product with acrylic varnish:

- sculpted

- dried

- painted

- dried again

- varnished

- let the varnish dry

- applied another coat of varnish

What varnish should I use? After drying, matte will be absorbed into the clay and paint, strengthening it and becoming almost invisible. Gloss varnish will make the surface shine, giving brightness and visibility to the product. The choice is yours what result you want.

However, even applied varnish, even in several layers, does not guarantee the safety of the product when it gets into water. Take care of your masterpieces.

We hope that this review will help you choose the most suitable material for your creativity and that we could be of some help to you.

Methods for checking the quality of the resulting substance

After the droplets of condensation have disappeared, you need to carry out quality control of the dried oven. For this purpose, firewood is laid that will be used every day. The total mass of burnt firewood will be 20 kg. It is advisable to adjust the draft so that combustion efficiency is maximum.

Over the course of several hours, the masonry in the firebox area is inspected very carefully. Ideally, no cracks should occur. But in some situations, the appearance of small cracks is considered normal. Small formations that look like cobwebs do not need to be sealed. The oven is ready for use.

The preparation went well

Fireclay clay is used to make dry mixtures for preparing plaster and masonry mortars and creating fireproof bricks.

Furnace laying

When building a stove or fireplace, many stove makers try to use heat-resistant bricks made from a clay-fireclay mixture. When choosing it, you should pay attention to the labeling; the letter “Ш” should be indicated on the packaging. Since such a brick is much more expensive, only the firebox is built from it, and the rest of the stove is laid out from ordinary red brick.

Fireclay bricks must also be laid on refractory clay, which has the same expansion coefficients as bricks. For 100 bricks you will need approximately three buckets of mortar.

The consistency of well-prepared clay paste resembles sour cream. The plasticity of the finished mixture is checked in one or more ways.

- The solution is taken with a trowel or spatula and tilted at an angle of 45 degrees. A normal solution does not flow from the trowel, does not fall from it in lumps, but remains on the working surface of the tool.

- The solution is applied to the brick in an even layer (5 mm) and dried. If the composition is “lean” (contains excess sand), then after drying the paste crumbles off the brick with light mechanical stress. After drying, the greasy solution will become covered with cracks; it contains a lot of clay and little sand. Normal paste hardens in an even layer without cracks. It does not crumble, does not crumble, does not crack.

Photo 1. Method for checking the quality of the mortar: on the first brick the dried mixture crumbles, on the third it cracks, the best consistency is on the second.

- The plasticity of the finished mixture is checked with a flagellum. A “sausage” with a diameter of 1.5-2 cm and a length of up to 20-22 cm is rolled out of the solution. The flagellum is slowly stretched and wrapped around a cylindrical object. A less flexible strand of thin clay will immediately break. A flagellum made from a fatty mixture will stretch strongly and stick to the surface. A bundle of a solution of normal composition will break when stretched when its diameter decreases by approximately 20%.

If the solution is too thick (the consistency is thicker than sour cream), add water to it and stir thoroughly.

If the solution is liquid (drains from the spatula), all the ingredients (clay, sand) are added to it in the previously selected proportions and also mixed.

The mixture, without adhesive additives and cement, retains its qualities after drying. It needs to be filled with water and soaked. If the paste is completely dry, soaking will last several days.

If the solution contains chemical additives, cement and adhesives, then the dried solution cannot be soaked (like, for example, mortar). The manufacturer indicates this information on the packaging.

Different clays differ in their plasticity. There are:

- “fat” clays with high plasticity;

- material of medium ductility;

- “lean” clays with a low level of plasticity.

I determine the level of plasticity using a simple method. The clay is poured with water to turn it into a dough-like mass suitable for molding. The material is used to make cylinders seven centimeters long and 30 mm in diameter, the ends are pinched with fingers and slowly torn apart. Plasticity is judged by the shapes that the cylinder takes at the point of rupture, by its elongation. A plastic material is characterized by the formation of a long and thin neck, and if the clay is thin, the neck will be thick and short.

The level of plasticity is determined in another way. Flagella about twenty centimeters long and 1.5–2 mm in diameter are rolled out of the working material and bent into semicircles or pretzels. If cracks appear on the materials at this time, the clay is thin. Cracks that form during bending indicate that the clay is of medium plasticity, and fatty clay can be identified by the complete absence of cracks in the samples.

We make a solution for plastering stoves and fireplaces ourselves

There is nothing better than a fireplace or stove in the house, near which you can spend quiet, comfortable evenings with your family. But to create a comfortable atmosphere near the fireplace, only a well-made stove is suitable. So during the fire its surface heats up, it must be treated with special plaster.

What options there are for plaster for stoves and fireplaces and how they are used will be discussed in this article.

Many people think that plastering work is not necessary, but there are many aspects that suggest otherwise. Here are the cases in which it will be necessary to finish the stove or fireplace with a plaster composition:

If the stove is quite old, and its surface has peeled off, revealing not very neat masonry.

If there is even the slightest possibility of cracking the mortar in the masonry and the penetration of carbon monoxide into the room. As a rule, this occurs during long-term operation of the furnace without restoration.

If the house is undergoing renovation and you need to transform the existing hearth and fit it into the new interior.

If insects appear in masonry joints. This often happens when natural materials are used to create a stove. Timely plastering will help remove this problem.

If the stove, even a brand new one, does not look very aesthetically pleasing.

Plastering a brick stove will be an ideal option for bringing its surface to its normal appearance. This finishing method will be the most profitable compared to decorating with tiles and tiles.

Fundamentally! You can plaster both a folded stove and one that was built earlier.

Plaster always increases the thickness of the furnace wall, so the fireplace takes longer to cool down. As a result, fuel consumption is reduced.

Thanks to the plastered surface, the fire safety of the fireplace or stove is increased and the release of carbon monoxide to the outside is prevented.

Another advantage of plaster is that the finished surface can be additionally decorated with all known decorative materials.

For this purpose, a special fire-resistant plaster for the stove was created, which is made from a reinforcing material that can give the finished surface elasticity and strength, and also protect it from cracking and deformation during exposure to heat.

When purchasing, you should pay attention to the heat-resistant consistencies “Terracotta”, “Pechnik” and others. These consistencies include special components, usually glass, quartz sand, fireclay clays or iron aluminate, which provide resistance to high temperatures.

All mixtures that are produced independently can be divided into ordinary and complex. The first ones consist only of sand and clay, and the second ones also contain additional components.

When mixing the consistency with your own hands, the components must be prepared in advance. Sand, for example, is sifted through a fine sieve, and clay is freed from plant roots and small pebbles.

Fundamentally! clay is selected for the solution in order to improve adhesion to the surface of the oven.

The clay must be soaked in water in advance and left for several hours. If after this time it has absorbed all the liquid, then you need to add more. This is done until 10–15 cm of water remains on top of the clay. After which it is mixed. Its correct mixture looks like thick sour cream.

To give a reinforcing effect, asbestos is added to the mixture. It can be replaced with finely chopped grass or fiberglass.

It is very important that the plaster contains only natural ingredients that will not emit vapors and substances harmful to the body when the oven is heated.

When salt is added to the composition, the hygroscopicity of the clay increases, which prevents cracking of the plaster. Insects will not appear inside such a layer.

If you decide to make a mortar for plastering the stove without the help of others, then you need to strictly adhere to the proportions and tips for implementation. There are several recipes for making plaster composition:

1st recipe. For it, clay, lime, asbestos and sand are taken in a ratio of 1: 1: 1/10: 2, respectively. All components are painstakingly mixed together until a homogeneous mixture is obtained and diluted with water.

The 2nd recipe involves the use of sand, clay and cement of the M400 or M500 grade. To begin, the clay is mixed with water to form a thick dough. Afterwards, asbestos, cement and water are added to the finished mixture. The mixture of the correct solution resembles very thick sour cream.

Fundamentally! This plaster must be completely used up within 1 hour.

Gypsum is added in a certain proportion to certain mixtures for plastering ovens. It acts as a bonding agent. But it’s worth keeping in mind that plaster hardens very quickly. It sets immediately after application to the surface of the oven.

After 15 minutes, the solution containing it can no longer be used for its intended purpose. In this case, diluting with water will no longer help. That is why you need to prepare only small portions of the solution. This building material is usually used together with lime.

It helps it become stronger and dry out faster.

Plastering can be done with your own hands, but you must definitely follow the method of work.

No matter what surface it is, it must be properly prepared for applying plaster. Here are a couple of steps:

When plastering an old stove with your own hands, the old decorative layer is removed and the surface is cleaned of dust.

Conducting deepening of masonry joints. To do this, dry solution is removed from them to a depth of about 10 mm. After removal, the seams must be cleaned of dust.

The walls are primed and the seams are painstakingly processed.

If the walls of the oven are very uneven, then a reinforcing mesh is placed on them using nails that need to be driven between the bricks. This mesh will strengthen the surface of the fireplace.

To maintain the evenness of the corners, perforated or iron corners are installed on them.

The solution for plastering the stove is mixed using a drill with a mixer attachment. If a solution is prepared from a purchased consistency, then the required proportions of the powder are diluted with water in a suitable container. The purchased mixture is left for 10 minutes, after which it is mixed again and becomes ready for use.

READ DIY bath chairs

If you are preparing your own solution, then it must be done in accordance with the recipes that were given earlier. It is also painstakingly kneaded until smooth and ready.

It’s worth mentioning right away that the full layer of plaster can be less than 1 cm. Heat-resistant plaster for stoves is applied in an even layer from top to bottom for the best drying. After the plaster has set, the surface is treated with a wood float using radial movements. In case of strong hardening of the composition, it is moistened with water.

Fundamentally! After plastering is completed, do not rush to light the stove.

If cracks appear on the finished surface during the drying process, they are pulled apart with a knife and rubbed with the same substance. If, after drying, cracks begin to appear, then the cause of this must be removed.

Typically, heat-resistant plaster for stoves and fireplaces can peel off due to shrinkage, the large thickness of the plaster layer and incorrect technology for bandaging the seams during laying.

But small cracks may also appear due to overheating.

Plastering a stove or fireplace is almost always a must. This process must be approached very carefully. The main step is to create a solution for plastering. At the moment , you can purchase ready-made mixtures or make them yourself. In any case, there are certain aspects that are listed in this article.

A properly prepared solution will be applied sparingly to the surface, and after hardening it will not cause cracks or deformations. A well-designed home stove will become a real decoration that will work for a long time without repair.

Popular recipes for clay plaster mixtures

Clay is distinguished by the highest thermal conductivity and has a similar nature to brick, which is why it is used as the basis for impeccable plaster for brick ovens. Before mixing the solution, the clay is soaked for two days in settled water and then passed through a sieve.

The amount of sand in the solution is on average twice the volume of clay, but it is always determined experimentally - the higher the fat content of the clay, the more sand is required. The solution should be thick but plastic. For binding, sawdust, crushed fiberglass or asbestos are added to it.

In addition to clay-sand mortar, for plastering the stove with your own hands, they use compositions with additives that increase the strength and durability of the structure. Here are tried and tested recipes from stove makers:

- Combine one part of clay with 2 parts of small sand mixed with a tenth of fluffed asbestos.

- Take clay and lime in equal portions, combine them with 2 portions of sifted sand and a tenth of asbestos.

- Mix sand and gypsum in similar volumes, add two proportions of lime, a fifth of asbestos and one part of clay.

- To the mixture prepared from one portion of cement, add two parts of sand and a tenth of asbestos. You will need as much clay as cement.

Before making a mortar for plastering stoves, all components are sifted through a fine sieve in an indispensable order. Professional stove makers first combine the dry ingredients and then add them to the moistened clay. Gypsum is diluted with water in advance and added to the mass as work progresses, because it hardens very quickly.

Preparatory work

- Before applying the mortar to the brickwork, its surface must be well prepared. Specifically: they create cleaning from dirt, dust, and solution residues - they are often found;

- The solution can be easily removed with a metal brush or spatula, and a soft brush is perfect for dust;

- Experienced craftsmen also recommend clearing the seams between the bricks - to a depth of 0.5-1 cm. Then the adhesion of the plaster and the base will be good;

- Nails are driven into the joints (4-5 cm products are suitable), the step between them must be maintained at 15 cm. These nails should protrude approximately 1 cm outwards;

- The surface of the masonry must be treated with a primer - many do not do this, which they later regret;

- Another trick: you can using a fiberglass mesh. Its watery consistency strengthens it to the masonry;

- It is most convenient to do plastering when the walls of the oven are heated.

Surface preparation

Before starting plastering work, it is imperative to prepare the surface of the oven. In this case, it will be easier to apply the solution, and the finish will ultimately look better and last longer.

If we are talking about an old stove, then it will be necessary to prepare the surface according to the following scheme:

- Cleaning the stove surface from old plaster. This can be done using a spatula or chisel.

- The surface is rubbed with sandpaper - this will help remove small bulges.

- Use a vacuum cleaner or dry cloth to remove any debris and dust that has formed.

In this case, when it is necessary to plaster a freshly laid stove, such work should begin approximately a month after the completion of the brickwork.

This period is enough for the mortar used for masonry to dry out, harden and gain strength.

Before starting work, it is necessary to clear the seams between the bricks that make up the stove to a depth of about 0.5 cm - this will help the plaster mortar to adhere better to the masonry.

Step-by-step instructions for plastering a stove

Once all the necessary materials and a set of tools have been prepared, you can begin the process of plastering the stove with your own hands. Plastering a brick stove can be done using an easy scheme consisting of 5 main steps:

- Heat the stove. The walls of the furnace must be thoroughly warmed up before work. This step is required even during the hot summer season.

- Surface preparation.

- Applying the first layer. It is necessary to moisten the surface to be plastered with water (with a brush or spray), and then apply a thin layer of watery clay (for this, use a wash brush). Before the next step, this plastered layer should dry out a little.

Reinforcement. Features of this step depend on the selected material:

- Reinforcing mesh. To secure it in the center of the bricks, it is necessary to drill holes, the depth of which should be approximately 5 cm. The distances between them should be less than 0.5 m, and the holes should be placed in a checkerboard pattern. A wire with a diameter of 3 mm must be inserted into each of the holes (its length should be 100 mm). Any piece of wire is bent in the center at an angle of 900, and inside the bricks they are fixed with cement mortar. After the cement has hardened, you can lay the reinforcing mesh on top of the furnace - it must be secured to the free ends of the wire. In order to do everything correctly, we recommend watching a video on attaching reinforcing mesh to the stove:

- Sackcloth. The material must be cut and soaked in a solution of watery clay. After which it must be distributed throughout the oven: the laying process is done from top to bottom, the overlap should be about 50 mm. If such material is used for reinforcement, the furnace must be protected from overheating during operation;

- Plastering. The solution is applied from top to bottom, each layer should be even - its thickness should not be more than 5 mm. After the solution has set, it should be rubbed using radial movements with a float. If the plaster has become very hard, it can be moistened with water. Some home craftsmen advise, after applying the plaster solution, to smooth it with a rag (it must be moistened in the same solution beforehand).

READ How to insulate an attic in a private house

Plastering a brick oven with your own hands. Video instructions test 4 types of stove plaster.

After finishing applying the plaster, it must be allowed to dry. If cracks occur, they can be widened using an ordinary knife, then wetted with water and covered with a substance (if a clay-based solution was used, for these purposes you can use the remains of plaster, which can be stored in an airtight container).

Manufacturers and brands

| Brand of solution | Description | average cost |

| Heat-resistant plaster for “Terracotta” stoves. Package weight 5 kg. | Made from fireclay and kaolin clay, with the addition of binders and heat-resistant additives. The material is environmentally friendly and does not contain harmful substances. It is easy to apply and hardens quickly and has the highest level of adhesion to surfaces. The solution retains its characteristics for 1 hour after mixing with water. Work is carried out from 50 to 350. The thickness of the 1st layer is up to 10 mm. | From 140 |

| Fireproof plaster from. Packaging 10 kg. | Can be used for laying stoves. Made on the basis of refractory clays. Mineral and heat-resistant additives are added to the solution. The mixture hardens quickly and does not shrink the layer much. It is simply applied and removed from surfaces during potential repairs. Withstands the highest heating temperatures. Can be applied to old and new stoves. The plasticity of the consistency allows it to be smoothed and not destroyed during shrinkage of the seams and the foundation of the furnace. Fire resistance level – 6000. | 225 |

| Snow-white thermal plaster “Plitonit SuperKamin Thermo”. Packaging 25 kg. | Can be applied to fireclay or ceramics. blocks. Thanks to its properties and easy application of an even layer, it can add attractiveness to the stove. Possible next painting, finishing with various finishing elements, right down to tiles and ceramics. tiles Reinforcing elements have been added to the composition; they can be used for preparatory sealing of wide cracks and leveling of surfaces. The thickness of 1 layer is up to 30 mm with all parameters preserved. When sealing cracks, the layer can be made up to 50 mm. | 475 |

| Clay mortar for plastering the Kalina Master stove. Package weight 25 kg. | Portland cement has been added to the composition. This mixture has the highest strength, ductility and is able to withstand the highest temperatures when leveling surfaces in fireplaces. A layer of plaster increases heat loss by 15%. Good adhesion makes the plaster resistant to mechanical stress. | 265 |

| Mixture for plastering fireplaces and stoves from. Bag weight – 20 kg. | Made on the basis of reddish refractory clay with the addition of fire-resistant fillers and reinforcing heat-resistant glass fibers. This composition guarantees the highest level of resistance to high temperatures while maintaining physical parameters and adds strength to the composition layer. Made in St. Petersburg. Can be used in the construction of fireplaces and exhaust pipes. It will last a long time if you follow the operating rules of the stoves and their protective layer. | 500 |

| Dry plaster for stoves “Parad” | Made in Belarus. The base is cement with the addition of thermal insulation materials and fiberglass reinforcement. Such additives increase the heating temperature while maintaining the properties and characteristics of strength, ductility and protects against cracking. May be used for laying stoves and fireplaces. | 1300 |

| Dry mixture for stoves and fireplaces "Real". 5 kg bag. | Can be used for laying ceramic facing bricks and constructing chimneys. The highest level of heating of the plaster layer is up to 12000. Operating temperature is 5000 with a layer thickness of up to 5 mm. | 89 |

| Ready-made mixtures for plastering the RusGips 5 stove. | This mixture can be applied in slightly frosty conditions. It consists of a mineral consistency that comes out when sifted sand of a certain fraction is mixed thoroughly with Portland cement and a complex of performance-enhancing mineral additives. | 256 |

| Fire-resistant plaster "ByProc TFS-170". Packaging 3 kg. | Used for application to the internal and external surfaces of stoves and chimneys. Serves to level out unevenness and then apply an even layer of solution protection. Operating temperature 5000, maintaining the characteristics of strength and elasticity. | 40 |

| Consistencies "ByProc" MMW-070. Package weight 3 kg. | All data are similar to those of the previous consistency. The only difference is the highest temperature while maintaining great performance properties. For this solution, it is 11000. | 40 |

What is the best way to plaster a stove? No specialist can answer this question for you. Each stove maker has his own secrets and mortar compositions for plastering the surfaces of brick heaters at home.

You can make it from a consistency of clay and sand or knead a ready-made dry mortar. This is a purely personal question. The main thing is to properly mix and apply a layer of plaster on the surface of the stoves.

Sources:

https://teploizolyaciya-info.ru/teploiz_sidebar/obekt-teploizolyacii/dom/shtukaturka-pechi-svoimi-rukami-prigotovlenie-rastvora-i-porjadok-raboty.html