Advantageous properties of clay

Fireclay has some advantages over other materials due to the following characteristics:

- Long service life. Fireclay clay mortar does not crack, does not crumble, and retains its original shape for a long time.

- High adhesive properties, thanks to which the material adheres perfectly to any surface.

- Vapor permeability.

- Ability to withstand fairly high heat.

- Safety and environmental compliance.

Clay selection

When choosing refractory clay, you should pay attention to the packaging labeling. It has a special digital combination showing the fire resistance of the material. You should know that large values indicate high fire resistance of the clay. In addition, by the markings you can find out about the area of use of the material and for laying which bricks clay of this type is used.

The shelf life of chamotte clay is of great importance, since after a certain time kaolin loses its technical properties. Therefore, you should not purchase material after the end of the sales period.

Specifications

When considering the technical characteristics of fireclay clay for oven plaster, it is necessary to note the following:

- The grain size corresponds to two millimeters.

- Highly fired fireclay absorbs no more than 10% moisture, and low fired fireclay absorbs no more than 25% moisture.

- The maximum temperature that the material can withstand is 18500C.

- The humidity of quality material does not exceed 5%.

When determining the required amount of material, you should know:

- A standard 20 kg package of clay is enough to lay 30 bricks.

- For 1 m3 of masonry, you should purchase 100 clay.

- A solution prepared with precise adherence to technology becomes absolutely solid after 24 hours, provided that the air temperature does not fall below +100C.

Clay in industrial packaging can be stored for 3 years from the date of manufacture.

Features of refractory clay

The preparation of mortar from fireclay clay for laying stoves is carried out by analogy with plaster mixtures, the application methods are also similar, which gives a big advantage to the material.

Fireclay mixture is suitable for sculptural work and decoration, for the construction of stoves and fireplaces. Products become durable due to the evaporation of moisture during the drying process of the clay composition. The result is a high-strength material that is resistant to high temperatures.

The following features of fireclay include:

- It does not crumble under high temperature.

- The material is resistant to the external environment.

- The original form remains unchanged for a long time.

To work with clay, you do not need to purchase special tools; the work process is carried out using a long and short spatula. Use one tool to lay the solution, and use another spatula to remove smudges.

Applying glaze

Your tiles need to be shined. To do this, you can prepare your own special glaze. It may consist of glass, kaolin and tripolyphosphate. These components produce a dust-like powder. It must be mixed with clean water. Other minerals can be added to this mixture. The general list includes about 30 species.

The prepared glaze is applied to the tile using one of three methods (or combinations thereof): spray, brush, or pour-over method.

The coating must harden thoroughly and bond to the terracotta. To do this, it undergoes secondary firing. It is important here that the ceramic mass does not reach a critical value according to temperature data. Otherwise the tile will melt. Glaze will allow you to create unique and elegant artistic solutions.

Clay preparation steps

It is very important for home craftsmen to know how to prepare fireclay clay for laying stoves. To do this, you can use the following scheme:

- Take a package of powder and pour it into a previously prepared container.

- Pour the powder with water and leave to swell for three days.

- After this time, water is added again and the clay is mixed at the same time. The process is continued until a homogeneous mass is obtained.

- In some cases, sand may be added.

When working with clay, it is necessary to constantly stir the solution; the quality of the work depends on this. In addition, it is important to pay attention to the consistency of the solution; it is recommended to add water to a too thick composition, and powder to a liquid one. It is especially important to fulfill this condition when laying a furnace using refractory clay.

The amount of water in the solution plays an important role: the dry composition crumbles and crumbles, the liquid composition flows down the working surface. Therefore, it is very important to know how to dilute fireclay clay for laying stoves. When calculating the water used, it should be taken into account that a solution of normal consistency resembles thick sour cream.

If clay is used in the process for instant work, then you need to pay attention to its features. When preparing the solution, you do not need to leave the powder to swell for three days, so the whole process will take much less time.

How long does clay mixture take to harden?

The time for complete drying of fireclay paste in air is 72 hours , inside the brickwork this time increases, it depends on the thickness of the masonry, temperature and humidity of the surrounding air. Petrification of fireclay mortar occurs at 800 degrees Celsius .

Important! Fireclay masonry does not like sudden changes in temperature.

for the first time three days after construction is completed. Use thin, quickly burning logs. The dampers and vents are fully opened during the first fire. Then the stove is dried for a week , burning small portions of wood daily.

Fireclay masonry dries faster than masonry made from ordinary clay-sand mortar and ceramic bricks, but only the firebox is usually made of fireclay. Therefore, the timing of the start of operation of a furnace with fireclay masonry will be the same as the timing of use of a furnace built on clay and lime mortar. In summer, a new stove is heated to maximum after 10-14 days, in winter - after a month .

Laying stoves and fireplaces

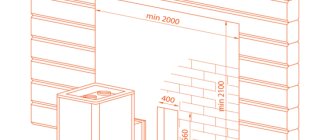

Stoves and fireplaces are structures that are constantly exposed to intense heat, so it is very important to choose the appropriate material. Firebricks made from fireclay clay are ideal for this purpose. When buying bricks of this type, you should pay attention to the marking, which should contain the letter “W”. However, fireclay brick is expensive, so it is purchased for laying out the firebox, and ordinary brick is used for the construction of the main structure.

It is very important to remember that fire bricks are only laid on a fire clay mortar. In this case, the expansion coefficient of the mortar and brick should be the same.

Plastering process

A solution of refractory clay is used in cases where it is necessary to obtain a perfectly flat surface. In the process of work, corners and a special profile are necessarily used. Several profiles installed on one wall help to achieve absolutely even plaster. During the installation process, it is recommended to use a plumb line or building level. Corners are used to obtain smooth edges; they are glued directly to the plane.

To obtain a perfectly flat surface, you should use the rule. It is fixed across the vertical profiles so as to achieve simultaneous contact of all beacons horizontally.

When installing beacons, you should also pay attention to the level of extension of the furnace door and the blower. The level of the profiles and doors must match so that the surface is smooth, without protrusions and depressions.

To make working with refractory clay mortar easier, you can use a special leveling tool. In this case, you can easily get a flat plane, but with small cracks. This problem can be solved using an ordinary wide spatula, which can be used to smooth the entire surface.

How to make tiles yourself? Technology overview

| Different types of dry mix and wet clay | Before starting work, wet clay is kept in a bag | After the clay dries, its color and mass will change |

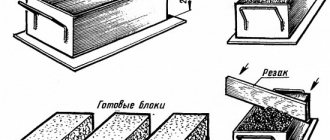

In modern factories and factories, tiles are often produced by pressing and firing dry mass. Huge, expensive pressing machines and special ovens are responsible for this. At home, this is not the best option, so you will need to use wet clay, which you will shape into any shape.

Briefly, the process goes like this: take wet clay, shape it, dry it, fire it, glaze it, and fire it again (to set the glaze).

Now a little more detail

Before starting work, the wet clay rests in a bag and waits for you to make something out of it. When you start making tiles, they turn into raw ceramic products. While you are molding the tiles, they will gradually dry out, and by the end of molding they will harden a little. This stage, when the clay is still wet, is called the hard skin stage.

Once your tiles are completely dry, you will find that the color of the clay has become lighter. Now we can say that it is at the raw stage. At this point, the tile is already quite hard, but if you hit it lightly, it may crack or crumble. If you leave such tiles to dry outdoors and they get exposed to rain, the tiles may become limp and turn into a lump of clay. There is no need to be upset about this, because this property of clay is very beneficial. If you make a bad sample, just toss it in the clay scrap bucket and forget about your troubles. Later, when the clay has lain, it can be reprocessed and made into something new and beautiful.

After all the moisture has evaporated from the clay and the tiles have reached a raw state, they are ready to be placed in the kiln and fired. What you do next depends on what glazing technique you use; but in accordance with general practice, during the first firing, which is called biscuit, the clay is not specially fired. Depending on the temperature of clay maturation, the biscuit firing temperature can range from 850°C to 1000°C. Under these conditions, ceramic products remain porous and are able to easily absorb glaze.

The second (glaze) firing occurs at the temperature required to mature the glaze. This temperature may be lower - but never higher - than the temperature required for the clay to mature; otherwise, the glaze will melt and turn into glassy balls.

Additional uses of fireclay clay

Very often, refractory clay is used to make decorative elements. These can be tiles, figurines and even household dishes. The plasticity of such clay is given by special components added to the composition.

Fireclay clay can be used to prepare high-quality mortar for laying stoves and plastering various surfaces. When deciding how to plaster a stove with fireclay clay, strict adherence to all technologies allows you to independently complete the entire process from preparing the solution to applying it to the surface.

Master class on making designer ceramic tiles

Ceramic tiles, created according to an individual design by hand shaping, always reflect the individuality of the author. Bright or delicate colors of painting, the embodiment of your own decorative ideas will allow you to create a unique piece of decorative and applied art. At a master class in our workshop you will create ceramic tiles of your own design, embody your personal creative ideas and realize artistic plans. Since the dimensions of the tile are 10*10 cm, it can be used in the design of your own space or as a hot stand. Elegant stylistic solutions will allow such an object to fit into any interior.