SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

A water seal for sewerage is a mandatory element of plumbing equipment. It serves to prevent the entry of strong unpleasant odors into the room from the waste system. What is the operating principle of the device, what types of hydraulic valves are there, how to choose the right product and install it? All answers are contained in this article.

The sewer water seal is used to prevent the penetration of unpleasant odors into the room from the sewage system

Water seal: this is a mandatory element of plumbing equipment

The first step is to understand what a shutter is. The element is represented by a pipe with bends, which has a certain shape. It can be additionally equipped with dynamic or dead-end devices. There is a permanent water plug in the lower elbow of the siphon, which, if the system is not used for a long time, can evaporate, which will lead to the penetration of unpleasant odors from the sewer network into the room.

For the water seal to work correctly, there must always be water in its cavity.

With active use of plumbing equipment, the supply of liquid is constantly renewed, successfully containing foul-smelling substances. When drained, wastewater flows freely through the siphon, which eliminates the possibility of clogging the system.

Important! For the water seal to function correctly, a certain volume of water must be located in its cavity, which is necessary to prevent gas backflow and unpleasant odors.

Why do you need a water seal? The siphon blocks hydraulic shocks, which significantly reduces the load on sewer pipes and devices. It also protects living spaces from the penetration of unpleasant odors from the waste system.

A hydraulic valve is rarely found inside a specific plumbing fixture such as a toilet or urinal. Mostly it is mounted to a fixture. A washbasin, bathtub, shower or toilet without a water seal is not installed in a residential building.

The hydraulic valve can be inside the plumbing fixture, but it is preferably mounted separately

How does a siphon work and on what principle does it work?

Wherever this device is located, its purpose is always the same:

- compensation of hydraulic shocks to limit loads on the gravity sewage system;

- preventing foul-smelling air from entering the living space from the drain system.

If the hydraulic valve is selected correctly and installed in accordance with the requirements for it, clean air is maintained in the room, and the sewage system works for a long time without failures. This can be achieved by knowing what a water seal in a sewer is and using it correctly.

The designs of closing devices are different, but, in general, it is a product made of pipes, in the bend of which water is stored, blocking the lumen along the inner diameter.

The water plug is constantly inside the pipe, periodically renewed. During a long break, the liquid in the hydraulic seals gradually dries out, allowing the smell to enter the room. This phenomenon is typical for buildings that are periodically visited, for example, country houses.

All elements of the sewer system are interconnected. For example, a drain pipe prevents “siphon failure”—the drawing of water into the riser during descent by equalizing the pressure in the sewer pipe. Air valves of various designs are also used for the same purpose - see installation features, types and manufacturers. They are used when there are no vent pipes in the building structure.

Types of hydraulic valves depending on design

Depending on the design features, there are 6 types of water seals: cranked, bottle, double-turn, corrugated, dry and with an overflow system.

An elbowed siphon with a water seal is easy to recognize by its appearance. Its design resembles the Latin letter U. The siphon is made of plastic or metal. The first option is represented by products made of polypropylene, which are characterized by reliability, simplicity and ease of installation. For the manufacture of metal siphons, cast iron or bronze is used. Today, such models are less common, which is due to their high cost.

Plastic devices can be produced in a disposable design; they do not have the ability to adjust the position of the element. In case of failure, the product is completely dismantled. Other models consist of components that can move and rotate to adjust the position of the nozzle. The parts are fixed using overhead plastic nuts and clamps.

The elbow has two bends: inlet and outlet. The lower position of the second element is 5-6 cm below the first. More reliable and durable options are represented by the S-shaped design. Cleaning the product is carried out using a special flexible cable with a brush at the end or manually after disassembling the product.

The elbow water seal for sewerage has a U- or S-shaped design

This sewer water seal is characterized by durability, which ensures free and easy installation of the system without fear of damage. Elbowed siphons are mainly installed on sinks, bathtubs and toilets. There are models equipped with an additional outlet, which makes it possible to simultaneously use the water seal for the washing machine.

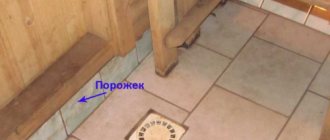

Sewerage and floor installation

It is worth saying that laying a sewer line will be much more difficult than arranging a drain from a bathhouse, but this should be done as carefully as possible.

Even if the bath floor is covered with wooden gratings, it is still better to make a screed along the beacons with a uniform slight slope towards the ladder; you will need to lay tiles along it. The last trimming of the drain extension is done when you know for sure the height of the tiles in relation to the drain point. If everything is done as carefully as possible, then even with a small slope there will be no puddles.

For an ordinary bathhouse, providing access and the ability to replace all elements without exception is an almost unrealistic phenomenon. Do not avoid those works that, at first glance, may seem insignificant, for example, the depth of laying a sewer system should at least correspond to the freezing depth.

If the ladder is dry, then if dirt gets into the seal, it will prevent the water seal from closing tightly. At the end of the season, it is recommended to wash the removable elements.

You need to choose a water seal depending on your needs . Whether you buy it ready-made or do it yourself is your own business. If the design is made well, it will not be worse than the factory model.

Source

Distinctive features of bottle hydraulic valves

Bottle devices are most often installed in kitchens under sinks. To understand how a water seal works, you should study its design. The product is designed in such a way that food waste particles are retained, preventing clogging of the system in order to maintain its good performance. At the same time, such a shutter performs the main function, which is to retain unpleasant odors and eliminate the possibility of them entering the room.

A bottle water seal consists of pipes and an additional element in the shape of a bottle, which is a kind of container for collecting food waste. This container is located below the level of the drain pipe, this provides free access to the element. The container includes a vertical drain pipe connected to the sink, and a pipe for connection to the sewer network comes out of its side.

Bottle siphons are made of polypropylene, but in terms of strength they are inferior to their knee counterparts. This is due to the fact that the connection of all elements may not withstand strong water pressure. However, the bottle siphon is most suitable for use in the kitchen. A positive point also lies in the lower price of a water seal for 110 mm sewerage, which averages 250 rubles.

Due to its structure, the bottle water seal is most suitable for use in the kitchen

For normal operation of the device, it must be periodically cleaned, since food waste residues accumulate in the cavity of the container, preventing the free flow of drain water. To clean the container, it must be removed. To do this, unscrew the cover nut and shake out all the debris from the container. Then you should thoroughly wash the inside of the container using detergents and hot water. After this, the device is installed in its original place. The nut is tightened tightly to prevent water leakage.

Important! Bottle water seals are capable of trapping an object that accidentally falls into the drain.

What is the purpose of a sewer well?

It is almost impossible to imagine the life of a modern person without sewerage. And it doesn’t matter at all whether the conversation is about life in a large-populated city or a small country cottage outside a populated area. The role of sewerage is to remove waste, which is not possible to dispose of without such a system.

Each sewage system, along with other utilities, needs periodic maintenance and performance testing. When the system becomes clogged, it is impossible to avoid emergency intervention. It is to gain easy and quick access to pipes and other parts laid in the ground that a sewer well is intended.

Many citizens are confident that manholes on city streets are located in a chaotic manner. This opinion is erroneous, since their placement is regulated by SNiP, which contains special standards, types of structures, as well as requirements for arrangement and subsequent maintenance.

What is a double-turn water seal for a bathroom?

A double-turn siphon is an analogue of a knee outlet, but differs in a more complex water seal design. The drain pipe of the device is connected to the outlet pipe of the plumbing equipment. A filter grid is additionally installed in this place to trap hair and animal fur. It smoothly passes into an elbow that connects to another pipe, which is directed to the drain. The last element is located at a slight slope.

How to use the water seal when cleaning it? To do this, some models of double-turn siphons can additionally be equipped with inspection holes, which are tightly closed with plugs, which makes it possible to inspect and clean the water seal cavity from contaminants. They are located at the bottom of the device. The function of the hole can be performed by a removable fragment of the knee located in the upper part of the device.

A double-turn water seal for a bathroom is similar to a cranked one, but is a more complex device

Important! Double-turn valves are mainly installed in bathrooms.

Double-turn siphons are made of polypropylene. More expensive luxury models can be made of brass with a chrome-plated surface. When installing such products, you will need a special tool equipped with soft jaws, which will eliminate the possibility of damage to the mirror surface of the device.

Bottle-type hydraulic valves are characterized by strength, reliability and long-term operation. The design is easily adjustable thanks to movable components. It is easy to install and can be installed even in narrow spaces.

What type of device is it?

The well has acquired multiple uses over the long period of its existence. At its core, it is a depression in the earth's surface - a mining opening in which anything can be placed, and the dimensions are adjusted to its purpose.

In this particular case, a water seal for the sewage system is placed in the well, which, through a water plug, prevents the spread of odors, flammable gases, fires when draining oil products into the system and the spread of water hammer.

As can be seen from the description, this device is of great importance in ensuring the safety of pipelines and protecting the environment, therefore there are standards that prescribe in what quantities and places they should be installed. The document is called SNiP - Construction Norms and Rules. According to this regulation, the purpose of wells can be as follows:

- Observations. They are installed to carry out certain specific actions on the water pipeline: observations, prevention and repairs, clearing blockages.

- Straight-through. They can be linear, control and flushing.

- Rotary and nodal. They are installed in places where pipelines change direction and at their convergence points.

- Drops.

The latter will be considered in more detail, because this type of well includes the use of structures with a water seal. The material used for their manufacture is brick, reinforced concrete or plastic corrugated rings.

Advantages and disadvantages of corrugated hydraulic valves

The corrugated type of siphon is represented by a polypropylene modification, which is durable, flexible and can be installed when installing sewerage systems in small spaces. Due to its plasticity, such a pipe can be located in places where other types of siphon cannot be placed. This is the simplest option, which contains a minimum number of elements that do not require assembly.

The corrugated hydraulic valve is the simplest option with the fewest elements

The corrugated siphon can be rotated at any angle and directed in the desired direction. This do-it-yourself version of a water seal for sewerage is often installed under the bathtub, since the model easily fits in a cramped space between the floor and the bottom of the container. One end of the water seal is connected to the drain hole, and the other to the sewer pipe. Using corrugation, you can also organize a drain with a water seal in the bathhouse of a private house.

Despite many advantages, the corrugated siphon has a single, but significant drawback. The surface of the pipe has ribbed walls on which debris in the form of hair, soap, sand and other dirt accumulates. When installing such a siphon, you should install a filter with a fine-mesh grid.

Important! If a bellows gate is not cleaned for a long period of time, it may lose its strength and elasticity due to excess weight in the form of dirt.

When operating a corrugated water seal, its condition should be monitored. The formation of sag causes debris to accumulate. The folds will quickly begin to wear out, crack and let water through.

If the corrugated water seal is not cleaned, it may lose its elasticity and strength.

Floor and drainage

Laying a sewer line is much more hassle than directly draining a bathhouse, but it is better to do it, the more carefully, the better.

Even if the floor in the bathhouse is covered with wooden gratings, it is still better to make a screed along the beacons with a slight uniform slope towards the ladder , and lay tiles on it. The final cutting of the drain extension can be done when it is known exactly at what height the tiles will approach the drain point. If the work is done very carefully, then even with a minimal slope there will be no puddles.

Providing access, with the ability to replace all elements, is too much of a luxury for an ordinary bathhouse. Therefore, you should not avoid work that may seem unnecessary, for example, the depth of laying the sewer system should not be less than the freezing depth . Insulating the floor under the screed with a 20 cm layer of expanded clay with a rich cement mortar is by no means an excess. A dry ladder is also not a panacea - dirt that gets into the shutter can prevent it from closing tightly. At the end of the season, it doesn’t hurt to wash the removable elements. Buying a dry water seal in a store or making it yourself - this question is not necessarily related to financial difficulties.

Source

Characteristic features of the overflow system

Another type of product is a hydraulic siphon with a water seal for a sink or sink, equipped with an overflow system. The device is equipped with an additional pipe, which eliminates the possibility of flooding of the apartment if it is impossible for water to drain into the sewer. This pipe is inserted into a hole specially created for it, which is located in the upper part of the sink or sink.

This siphon prevents flooding, but increases water consumption. If the tap is turned on and the drain is closed, water will flow through the overflow pipe into the sewer when it reaches a certain level. A water seal with an overflow system can be installed in the kitchen or bathroom.

Hydraulic valves with an overflow system are made of plastic or metal. Plastic products have a lower cost and are very flexible. Brass-bronze siphons are characterized by strength, durability, complexity of installation and high cost.

Important! When choosing a siphon with an overflow, you should pay attention to the throughput of the pipe so that the device will work efficiently in the future.

The water seal for a sink or sink is equipped with an overflow system - an additional pipe, thanks to which the possibility of flooding of the apartment is eliminated

Why is it needed and where is it used?

A water seal is needed to prevent the penetration of gas from sewer pipes into the rooms where devices connected to the sewer are located. The same problem can be solved by a household pneumatic valve installed in the drain network.

Its operating principle is based on mechanically blocking the sewerage section with plugs.

If solids become trapped between the wall and the plug, the valve's performance will be reduced. In contrast, a water plug in the siphon will, under any circumstances, completely block the drain hole into the sewer.

Installing a siphon with a water seal not only performs a protective function, but also solves additional problems:

- reduces the sound volume during drainage;

- serves as a sump - large particles of debris settle at the bottom of the siphon;

- prevents bacteria and insects from entering living spaces through the sewer system.

Water protection is used in all plumbing fixtures. Water seals for sewerage are installed in the bathhouse, as well as in the bathtub and shower. The toilet is the only device that does not require connecting a water seal. Its design involves the use of a built-in siphon to remove waste.

What is a dry siphon for sewerage

The operating principle and design of a dry water seal for sewage differ from previous analogues. A non-return valve is installed in the threaded drain pipe, which prevents the return flow of water and the entry of unpleasant odors from the sewer system into the room.

Important! It is advisable to install such water seals exclusively in shower stalls, and in kitchen sinks they can cause permanent blockages.

The dry water seal for the shower stall is available in several varieties. In the membrane version, the hole is closed at the moment of liquid outflow using an elastic silicone membrane in the form of a short sleeve. Pendulum siphons, thanks to curtains, provide quick blocking of access to the hole.

Float models operate on the principle of a flush tank. The design is an inverted light glass, the edges of which are immersed in water. A light float is located on the surface of the water. After draining it, lowering itself, it blocks the drain. In some models, instead of a float, a light ball is installed, which, after the liquid has flowed out, is lowered into the outer seat, ensuring a hermetically sealed closure of the drain hole. This option can be made independently when arranging the sewer distribution in the bathhouse.

It is advisable to install a dry siphon for sewerage only in shower stalls

Important! If the sewer lines dry out during a period when they are not in use, the dry seal will prevent the unpleasant odor from entering the room.

Dry shutter

A modern dry hydraulic seal for sewage is noticeably different in design from its hydraulic counterparts. It is recommended to install such devices on the lower floors of multi-story buildings, as well as when plumbing fixtures are rarely used.

“Dry” membrane-type valves are closed by an elastic membrane after the water has drained, and pendulum models close instantly in the absence of liquid. Float valves function similarly to cistern flush fittings.

Types

Dry seals are available in several versions, each of them has its own characteristics. Here are the most common options:

- Membrane. This is the simplest and most common option. The valve operates due to a spring membrane, which opens when water flows from the drain hole, but remains closed until the water is used.

- Float This option can be called transitional between dry and water seals. The device is equipped with a float valve. When liquid enters, the float floats up so as not to interfere with the liquid leaving. And after the water leaves, the float falls into place, sealing the lumen of the sewer pipe.

- Pendulum. The valve in such a valve has a single attachment point. When water enters the drain, the pendulum deviates, opening the passage. Then, under the influence of gravity, the valve returns to its place.

- With molecular memory. This is a high-tech option; such shutters are quite expensive. Thanks to new technologies, membrane elements reliably seal the pipe lumen after water stops flowing into the drain.

So, there are different options for water seals for sewerage. The choice of option is made depending on the type of plumbing element, as well as operating conditions. Installation of water seals is a prerequisite for assembling an internal sewerage system. If they are missing or installed incorrectly, an unpleasant sewer smell will certainly appear in the apartment.

Pros of the option

Advantage of the option:

- the device does not require water supply for normal operation;

- the model can be installed even in unheated rooms, since there is no threat of destruction due to freezing water. This option is suitable, for example, for a summer cottage that is not used during the cold season;

- dry siphons are compact and convenient;

- it is much more difficult to break a dry seal than a water seal;

- eliminate the backflow of dirty water, which can occur when a blockage forms;

- the shutter can be installed both vertically and horizontally;

- water does not stagnate in the shutter, in which harmful bacterial flora can develop;

- has excellent sound insulation;

- has a long service life.

Characteristic features of a sewer drain with a water seal

When drainage is carried out from the entire surface of the floor, a sewer drain with a water seal is installed. It is mounted in the central part of the floor with a slight slope at the time of construction of the shower stall.

A drain for a shower with a water seal consists of a receiving funnel, a siphon with a removable grate and an outlet with a coupling. The first element is designed to receive water and discharge it into the sewer. It is securely attached to the floor surface.

Related article:

Sink siphon with overflow. Subtleties of selection and installation

Types of siphons. Nuances when choosing siphons for a sink with overflow. Complete set of products, features of correct installation.

The tightness of the connection is ensured using a waterproofing membrane. Next, the water enters the siphon, which is represented by a small-volume chamber, passing through the upper filter grid and pipe. Then the drain, overflowing through the outlet openings or edges of the container, moves along the outlet pipe connected to the sewer pipe.

A sewer drain with a water seal consists of a siphon with a removable grate, a receiving funnel and an outlet

In terms of design, such a mechanism resembles a bottle-type device. However, the shower tray siphon with a water seal does not have a removable bottom cover, which is used to remove debris. This is due to the fact that the siphon body is hidden in the floor screed. All debris is collected in the inner cup, which can be easily removed from the body and cleaned with detergent.

Design and material for the manufacture of a shower drain with a water seal

Sewer drains can be made of plastic or metal. Polymer water seals for showers in the floor do not corrode, are easy to install, are characterized by durability and low cost. Metal products can be made of cast iron or steel. The first option is characterized by high throughput and durability. However, due to its significant weight, it is labor-intensive to install. Cast iron drains are suitable for swimming pools, toilets and laboratory areas.

Stainless steel drains are lightweight, reliable, durable and easy to install. They are usually installed in medical and research organizations because the devices meet the requirements of sanitary standards. The receiving grid can be in the shape of a circle, square or rectangle.

The sewer drain with a dry water seal has a horizontal or vertical design. The first option, whose height is 6-10 cm, is often used for an apartment or private house. It is also installed in confined spaces.

Float models of sewer drains with a dry water seal operate on the principle of a cistern

The vertical sewer drain has a height of 15-18 cm, is characterized by high throughput and is used mainly for shower stalls. In apartments and houses, a drain with a drainage system with a diameter of 50 mm is installed, and in public premises a water seal for sewerage of 110 mm is installed.

Making your own siphon

Simple plastic siphons are inexpensive. The average price of a sewer hydraulic bottle seal with a corrugated outlet and stainless mesh is 90–100 rubles. Complex structures or devices made of metal are more expensive. Their price starts from 2000 rubles.

If you can’t buy a suitable siphon or want to save money, you can create a water seal for the sewer system with your own hands. To do this, you will need a plastic pipe and coupling, a knife, a screwdriver and an adjustable wrench. The steps for making a water seal are simple:

- The pipe is bent into a horseshoe shape.

- Connected to a coupling 60 mm high.

- They are attached to a drain funnel or welded to the opening of a sewer pipe.

You can also make a dry shutter with your own hands. Use a regular tennis ball. It must be placed so that it covers the entrance to the sewer pipe. When the water flows, it will float up and ensure its passage.

How to choose the right water seal for sewerage

When choosing a water seal for sewerage, the price of which is in the range of 300-600 rubles, the following factors should be taken into account:

- dimensions of the siphon assembly;

- features of this type of device;

- material for the manufacture of pipes and fasteners;

- number of drains and possible additional connections;

- level of protection against blockages;

- presence or absence of overflow.

The type of shutter is selected based on the installation location. For a kitchen sink, the best solution would be a bottle design equipped with a container for collecting food waste. For a bathtub, it is most convenient to install a corrugated siphon, which can be located even in the most cramped conditions.

If the shower siphon will be used rarely, it is recommended to install a dry water seal

The shower siphon option is selected taking into account the frequency of its use. If it will be used rarely, you should install a dry water seal for the bath or shower, which, even when the water dries, will not let foreign odors into the room.

The number of inlet holes in the siphon must correspond to the number of drains for which this water seal is intended. An important criterion is the diameter of the neck of the device. For the sink and washbasin it can be minimal, and for the toilet it can be the largest. The diameter of the outlet pipe is also taken into account when connecting to a sewer pipe. For sinks and washbasins, a 50 mm drain seal is sufficient. For a toilet, this parameter must be at least 100 mm.

Material for the manufacture of hydraulic valves

The reliability and durability of the device depend on the material of manufacture. Traditionally, water seals for baths, bathrooms and kitchens were made of cast iron, due to which they were characterized by strength, resistance to aggressive environments and a long service life. The disadvantages of the products include the presence of an internal rough surface, which tends to retain various contaminants. This is an ideal option for industrial construction.

Most modern models of water seals are made of polypropylene, as a result of which they have a low cost. The devices are characterized by strength, reliability, chemical inertness, and lack of tendency to accumulate contaminants in the cavity (due to the smooth inner surface).

Premium siphons are made of brass or bronze and have a nickel plated finish

Siphons with a premium dry seal are made of brass or bronze with a nickel plated finish, which gives the products an aesthetic appearance. Such valves are characterized by a long period of reliable operation. Siphons made of stainless steel are in demand in medical and children's institutions. Such devices are well cleaned and disinfected, which does not affect their durability.

Guidelines for choosing a water seal

If you are installing or replacing plumbing fixtures (bathtub, sink or toilet), you will definitely need a siphon.

To select a device that fully complies with plumbing, it is necessary to take into account a number of factors, including:

- dimensions of the assembled device;

- siphon type;

- the material from which the pipes and fasteners are made;

- number of drains or additional connections;

- protection against blockages;

- diameter of inlet and outlet;

- presence or absence of overflow.

Let’s assume that for a kitchen sink, the most suitable option is a bottle model that traps food particles. You can also use a knee device, but then all the waste will flow into the sewer pipe, and over time there is a risk of blockage.

For both sinks and bathtubs, models with an overflow are considered more effective, preventing room flooding. The recommended material is polypropylene, but for finishing the external parts it is better to buy models with chrome parts

If the project involves installing a sink or washbasin with two sinks, a device with two drain points will be useful. Its operating principle is the same, the only difference is in the design.

Before purchasing, be sure to measure the size of the space where the installation will take place. It happens that the siphon simply does not fit in the allotted space (this is especially true for the close gap between the bathroom and the floor). If you choose the right water seal, there will be much fewer problems with its installation and repair.

If the water seal from the siphon is pulled into the sewer, the system is modernized by installing a vacuum valve:

Image gallery

Photo from

Types of Vacuum Valves

Protecting the water seal from flushing into the sewer

Connecting the bath to the sewer outlet

Vacuum device at the system inlet to the toilet

Do-it-yourself installation sequence for a water seal for sewerage

Installing a water seal for a sewer in a bathhouse, bathroom or kitchen is a simple task that can be done with your own hands without having any specific skills. The installation process under a washbasin or sink is quite simple, but under a bathtub it is more labor-intensive, due to the inconvenient location of the drainage system.

Important! Any type of siphon can be purchased complete with all its components at a plumbing store.

Let's consider installing a 110 mm bottle-type water seal for sewerage with your own hands. The kit includes a siphon, a corrugated pipe, overflow design elements and fasteners. The first step is to install an overflow hole. To do this, an elastic gasket is inserted into it, which is fixed using silicone sealant. Then a chrome-plated decorative element is screwed onto a rod onto which the wing is attached.

After installing the water seal, you must remember to connect it to the sewer pipe

At the next stage, fittings are installed to design the drain hole in the bathtub, sink or washbasin. A long mounting screw is screwed into it, which secures the siphon. First, it is twisted by hand, then clamped with a key. A rubber gasket is placed on the plastic outlet pipe. Next, you should insert the knee lock. Finally, tighten the plastic outer nut. The water seal is connected to the sewer pipe via a polypropylene pipe.

After installation is complete, the system is tested. To do this, the device is filled with water. All elements of the system are inspected for leaks.

Installation Rules

Sink drain diagram

Installing valves is not the most difficult process. The easiest way to connect a bottle siphon is under the kitchen sink. In the bathroom or bathroom it’s a little more difficult. But it will also not be difficult for a person who has basic skills in working with the tool.

Instructions for installing a new siphon to replace the old one:

- Turn off the water and place a basin or cloth under the device.

- Unscrew the fasteners securing the shutter. If they are stuck, simply crack the device and carefully remove it from the system.

- Remove the device and plug the pipe hole with a roll of rags to prevent the smell from escaping.

- Clean the joining areas.

- Install a protective grille on the drain. To do this, use the seal that comes with the shutter or silicone.

- Secure the connecting pipe to the grille with a long screw.

- Place a union nut, a cone gasket, and then a water seal onto the pipe, and adjust the height.

- Connect the outlet pipe to the sewer hole.

Test the quality of the joints: run water and check if drops or streams have formed on the surface.

The valve must be connected to the outlet pipe carefully to ensure tightness. Otherwise, leaks cannot be avoided.

The cross-section of the water seal is smaller than the sewer outlet openings, so a rubber or plastic ring approximately 15 mm thick is placed on it. Its outer diameter must exactly coincide with the cross-section of the socket, and its inner diameter must coincide exactly with the dimensions of the outlet pipe of the valve.

How to install a sewer drain with a water seal

Installing a sewer drain with a dry water seal is a very responsible and labor-intensive process. The correctness of the work directly determines the level of high-quality and durable operation.

At the first stage, the floor in the shower or bath room is raised, which should have some slope towards the drain, which will facilitate the spontaneous drainage of water from the horizontal surface.

The sewer drain is installed according to the instructions - thermal insulation, waterproofing, cement screed and floor tiles are laid on the floor

The sewer drain is installed according to the instructions that come with the device. A heat-insulating material is laid on the floor surface, which simultaneously acts as sound insulation, which facilitates the quiet drainage of water from the plumbing fixture into the sewer system. Expanded polystyrene is suitable for this. Then a layer of waterproofing is laid. To do this, you can use rolled material with a membrane structure or a coating mixture.

Next, a cement screed is made, the thickness of which is selected taking into account the height of the ladder and the thickness of the tiles. Floor tiles are laid on top using an adhesive solution.

Important! The water seal grate should be flush with the tiles.

Features of the device and principle of operation

A hydraulic valve is a structural element of a pipeline that constantly contains water. A water plug separates the drain openings of sewer appliances from the pipes - as a result, foreign odors from the sewer do not penetrate into the room.

To install a water seal, two main methods are used.

In the first case, the pipeline is bent or a separate element is installed, giving it a U-shape - here the water seal is the water collecting in the lower part of the bend. In another method, the drain pipe of plumbing fixtures is lowered into a deep glass that has a side branch - in this case, the water seal is a water column collected in the lower part of the glass body.

When draining water from plumbing fixtures, the water plug is always renewed - thus, there is no long-term stagnation of water in the water seal, which leads to the appearance of moldy odors.

Possible reasons for the failure of the water seal to work correctly

The hydraulic valve is a simple product in design, which consists of a minimum number of simple elements. Therefore, siphon failure is extremely rare. In this case, situations may arise that negatively affect its normal functioning.

Failure to comply with slopes and violation of the hydraulic seal assembly sequence can negatively affect its operation

A malfunction of the device can occur as a result of a sharp decrease in pressure in the pipes, a malfunction of the sewer network, or depressurization of drain pipes, which is possible as a result of mechanical damage or improper connection.

If in a multi-storey building on the upper floors the riser is clogged, when large volumes of water are drained, a vacuum is formed in the pipe, as a result of which water is drawn from the water seal. This causes unpleasant odors to appear. In this case, the question arises of how to eliminate the air lock in the sewer. The problem can be eliminated by cleaning the riser or installing a vacuum valve at its end. Dry valves often begin to malfunction as a result of clogging of the descending float or closing membrane.

Incorrect installation will also negatively affect the operation of the device. The reason may lie in non-observance of slopes, violation of the sequence of assembly of system elements, spontaneous straightening of the corrugation.

Important! If the siphon is quite old, it may no longer cope with its main function of protecting the room from the penetration of unpleasant odors. In this case, you will need to disinfect the well with a water seal or replace the device with a new element.

If the siphon is old, it may not cope with its task; it is necessary to replace the water seal with a new one

If there is a sewer smell in the room, it is necessary to check the functionality of the water seal. You should pay attention to the water level in the toilet, which should be the same every time you flush. In the bathroom and kitchen, the test can be done using a flame. To do this, bring a match as close to the drain as possible. The absence of flame will indicate normal operation of the device.

If the flame fluctuates, turn on the water for a minute, and then check the operation of the device again using the flame. If it still wobbles, the siphon is faulty.

Tips and tricks for use

For sinks, do not use a corrugated siphon, despite the fact that these pipes are flexible and compactly laid. The downside is that debris is deposited in the bends of the corrugation, and the diameter of the pipe decreases. It is advisable to use it for a bath.

It is undesirable to expose the water seal to boiling water or hot oil - this will lead to cracks in the pipe and, as a result, leakage.

For rarely used plumbing fixtures, only dry water seals are required. If there is a cold effect on the sewer, you should not use a combined float design. Modern siphons are made of polymer materials, they do not rot, are easy to install, and serve for a long time. Metal products are chrome plated to resist corrosion.

The reason for the appearance of an odor in a room with properly installed hydraulic equipment can be depressurization of drain pipes, a long-term operated sewer system in which bacteria multiply on the vessel wall, or a broken water plug. To check the tightness of the equipment, you need to bring a lit candle to the opening of the sink or toilet. If the flame does not fluctuate, there is no depressurization and it is enough to pour a disinfectant into the sewer.

Plug failure occurs if the diameter of the sewer pipes is small and the volume of drained water is significant. A pressure difference is created in the pipes and the liquid moves in the opposite direction. In this case, it is enough to open the tap for 2-3 minutes so that the water restores the seal in the siphon. This will solve the odor problem.

Blockage

If using a plunger or unscrewing the siphon does not help get rid of the blockage, then it is advisable to use a plumbing cable.

Unscrewing the upper nut and lower fasteners at the junction of the siphon with the sewer system, after which the entire siphon part is removed.

Immersion of the plumbing cable into the drain pipe until the resistance level. Clear the blockage using a rotating motion.

At the final stage, the siphon with a hydraulic seal is screwed on.

Prevention

To avoid significant accumulations of scale or any other deposits in the drain system, it is necessary to flush the inside of the siphon monthly with hot water with the addition of citric acid.

Also, special chemicals such as “Phlox” and “Ruff” can be used for this purpose.

Every six months it is strongly recommended to replace rubber gaskets that have lost elasticity and become thin. The use of protective grilles and meshes prevents large particles of debris from entering the pipe.

To prevent clogging of the bathroom drain, periodically clean the water seal of hair and other debris.

After the water supply is shut off, the siphon “up to the knee” is disassembled and cleaned. After assembling the structure, the joints must be treated with a special waterproof sealant. It should be remembered that siphons with any chips or visible cracks cannot be repaired and must be completely replaced.

The sewerage system in urban and suburban conditions provides comfortable living for people, and for the full functioning of sewage networks, it is necessary to correctly select and install a water seal. Despite the apparent simplicity of such a device, improper installation and use of the wrong type of hydraulic valve can be one of the reasons for the failure of the sewer system or plumbing fixture.

Varieties

There are only three main types of water seals:

- Knees.

- Bottled.

- Dry.

Knee water seals

The knee water seal is the simplest device in design, consisting of two U-shaped elbows connected in the shape of the letter S.

The role of the container for the locking liquid is played by the half to which the drain pipe of the plumbing fixture is connected.

At the end of the water flow, liquid remains in it.

The inflection point of the first knee should be 5–6 centimeters lower than the bend of the second. Then the locking will be reliable.

If the drain hole is located too low and a water seal made of two elbows does not fit under the plumbing fixture, then one elbow can be used. Its bend should be such that the remaining water fills the knee completely.

The device is simple and reliable. It can be made of cast iron, polypropylene, and in rare cases, bronze.

Its main advantage is that it can withstand quite high pressure in the system, and its throughput is determined only by the internal diameter of the pipe.

Therefore, knee valves are used when connecting bathtubs and toilets, in which they are part of the structure; in toilets produced recently, there may be two such valves.

Their disadvantage is that they cannot be disassembled. To eliminate very stubborn blockages, it is necessary to use a special tool - a plumbing cable or disassemble the line.

A type of knee water seals are devices with an additional outlet in the housing, to which, for example, a bathroom overflow pipe or a washing machine drain hose is connected. They are usually made from polypropylene.

Bottle water seals

This type of water seal plays two roles - a locking device and a sump. The outlet pipe from the drain hole is located inside the container, which has its own outlet connected to the sewer system.

The bottom edge of the drain pipe should be below the level of the outlet, which ensures reliable locking.

Most often, such water seals are made of polypropylene, and their design is collapsible. It consists of a drain pipe with a protective grill and a settling tank.

The drain pipe is connected to the sump tank by simply passing it into the sump hole and deforming the sealing gasket when tightening the nut on the body.

This connection is not strong enough, it cannot withstand high water pressure, so bottle water seals are not used to connect bathtubs and toilets.

The settling tank, in addition to the outlet, has a threaded bottom lid, which allows for cleaning of accumulated sediment.

Bottle valves are easy to install, but can only be connected to drains on sinks and other small-capacity sanitary fixtures. They must be periodically cleared of sediment; eliminating blockages in them does not require skilled labor.

Gangways

A type of bottle water seals are the so-called drains - drain holes in the floor.

They are installed if the outlet to the prefabricated main can only be made horizontally, along the ceiling.

The drains are most often made of metal and non-removable, and the settling tank is cleaned after removing the drain grate.

Dry water seals

Dry water seals are fundamentally different devices; the prefix “hydro” in their name is used simply by analogy, in accordance with the location under the sanitary fixture. The principle of their operation is based on the so-called nipple system.

This is a polypropylene pipe with threads on both ends. Inside it there is a flexible membrane that really looks like a nipple. It allows water to flow in only one direction, closing immediately as soon as the flow of liquid stops.

The device is quite interesting, but, like any “European thing,” it is very difficult to use. If you use the sink to wash dishes, it will not last long.

Preventing blockages

Of course, it is easier to prevent pipes from clogging too often than to constantly clean them. To do this, you need to constantly follow simple rules:

- always place a grate on the drain to prevent large particles from falling into the pipe;

- after washing a large amount of dishes, pour hot water into the pipe for a minute;

- do not pour waste fat into the sink - it is better to do this into the toilet;

- It is also better to drain water after washing the floors into the toilet;

- Once every six months, try to clean the pipes with a plunger or disassemble the siphon and remove excess debris from it.

These methods will at least increase the service life of the siphon and relieve you of the need to constantly clean it.

Materials for arranging a sewer shaft

Plastic materials are very popular. Such shafts have important advantages, including the reliability of the structure, its durability, as well as easy installation work.

According to its technical characteristics, plastic has the following advantages:

- High margin of safety and resistance to critical loads;

- Increased wear resistance;

- Smooth surface of the pipes, preventing the formation of build-up;

- Possibility of obtaining perfect tightness at the joints of parts.

An important disadvantage of plastic systems is considered to be used only in cases where the load on the sewer system is minimal. In addition, plastic is not suitable for installing a well in soft or constantly moving soil.

Concrete is not giving up its position either. This material, despite the difficulties during installation, is used everywhere.

Among the advantages of concrete structures it is worth noting:

- Possibility of use in any type of soil;

- Quick installation of rings;

- High margin of safety and reliability;

- Unaffected by chemicals.

The disadvantages are the large weight of the structures, which requires the use of special equipment, as well as the need to equip a tray in the sewer well for each structure.