began the history of Russian extruded polystyrene foam by launching in 1998 a production line for PENOPLEX boards at a plant in Kirishi, Leningrad Region.

Penoplex production method: Polystyrene granules enter an extruder, where they are heated and mixed under high pressure. At the same time, a gaseous blowing agent is supplied to the extruder. Thanks to high pressure and heat, the blowing agent enters the granules and increases their volume. The resulting mass is pressed through a die, the material is cooled and cut into slabs. As a result, small closed cells are formed in XPS, which give penoplex excellent thermal insulation properties and negligible water absorption.

Penoplex brands

- Penoplex COMFORT

- Penoplex BASE

- Penoplex FOUNDATION

- Penoplex GEO

- Penoplex ROOFING

- Penoplex FACADE

- Penoplex 45

Penoplex COMFORT

Overall dimensions: Length-1185 mm, width-585 mm, thickness 20; thirty; 40; 50; 100 mm.

TU 5767-006-54349294-2014

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex COMFORT

It is used for thermal insulation of canopies, plinths, and pitched roofs. Strictly not applicable:

- in loaded structures.

Areas of application of Penoplex COMFORT:

- Roofs, walls, balconies, loggias.

- Thermal insulation of utilities.

- Insulation of livestock farms, cowsheds.

- For insulation of greenhouses.

Advantages of Penoplex COMFORT:

- Thermal conductivity coefficient is 0.032, hence high thermal insulation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

- Resistant to temperature changes.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Easy installation, convenient dimensions.

- Poor steam conductivity.

- Selected quarter (L-shaped edge). Allows you to join slabs like a construction set.

Penoplex COMFORT technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.15 (1.5; 15) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G4 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | from 20 kg/m3 | |

| Elastic modulus | 15 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.25 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 20, 30, 40, 50, 100 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Advantages and disadvantages

Like any building material, this insulation has its strengths and weaknesses. The fine balance of price and quality makes it competitive and distinguishes it from numerous analogues. Let us immediately note that it is not worth singing odes of praise to Penoplex: despite many undeniable advantages, there are also disadvantages. If you conduct an impartial analysis of the characteristics, you will get the following picture.

Pros:

- High thermal insulation performance.

- Absolutely neutral to humid environments.

- Convenient installation.

- Easy to process.

- Multifunctionality.

- Durability (subject to certain conditions).

- Soundproof.

Minuses:

- Low fire safety of unmodified material.

- Low vapor permeability.

- Sensitive to aggressive substances: gasoline, acetone, oil paint.

- Unstable to ultraviolet light. Destroys in direct sunlight.

Penoplex BASE

Overall dimensions: Length-1185 mm, width-585 mm, thickness 20; thirty; 40; 50; 100 mm.

TU 5767-006-54349294-2014 amended. 1-6

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex BASIS

This brand of penoplex is intended for insulation in civil and industrial construction, in walls, roofs, anywhere where there are no special loads on the structure being insulated.

Advantages of Penoplex BASIS:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex OSNOVA technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.17 (1.7; 17) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G4 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | from 20 kg/m3 | |

| Elastic modulus | 15 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.20 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 20; 30, 40, 50, 100, 120, 150 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Recommendations

When purchasing penoplex, you should pay attention to the labeling of the product, the safety of the packaging, and the technical characteristics of the material. It is worth buying 10% more material from the measured initial quantity, in case it is rejected during use. It is necessary to work with the material carefully, since if its integrity is damaged, water may get inside, which will shorten the service life of the material. It is better to use the services of professionals or read the instructions yourself and work with penoplex correctly.

Due to the possibility of toxic vapors being released under the influence of UV rays on penoplex, its use outside is considered optimal. The insulation must be treated with mesh plaster or other façade material on top of the insulation.

It is not worth covering the insulation with a water-repellent agent, because the penoplex itself is waterproof. You should be careful when you are near penoplex with other substances. Some of them can destroy the cellular structure of the slab

As a result, its technical performance will deteriorate.

Penoplex slabs should be used in the range of -50… +75 degrees. At this temperature, all the characteristics of the material are perfectly preserved. They can be stored for a long time in the manufacturer's packaging, but they should be protected from direct exposure to sunlight.

When choosing penoplex, the question is how to make the correct calculations of raw materials. For this purpose, many manufacturers’ websites have a special calculator. In it you can indicate the area of the surface to be insulated, and he himself will calculate the amount of material required.

Before you begin installing penoplex, you need to complete several points:

Preparation of the working surface, this is especially important for walls. It is necessary to remove all dirt and smooth the surface of the wall. If necessary, it is worth treating the facade walls with a primer. To fix the slabs, a special mixture with an adhesive base is prepared. To prevent the slabs from moving due to wind, they are additionally secured with fasteners.

See below for a master class on floor insulation with penoplex.

Penoplex FOUNDATION

Overall dimensions: Length-1185 mm, width-585 mm, thickness 50; 100 mm.

TU 5767-006-54349294-2014

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex FOUNDATION

Thermal insulation of deeply low (buried) places. Namely deep and shallow foundations, garden paths, septic tanks.

Swedish stove technology.

Engineering Communication.

Advantages of Penoplex FOUNDATION:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex FOUNDATION technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.3 (3.0; 30) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G4 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | 27-35 kg/m3 | |

| Elastic modulus | 17 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.4 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 50, 80 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

What is it made of? Compound

We have before us a completely artificial material, which is made from chemical components mixed in certain proportions. The technology involves using a temperature of 140 degrees, which causes the ingredients to melt and foam, forming porophores. If we talk about specifics, the following materials are used in production:

- Polystyrene.

- Ground perlite.

- Lemon acid.

- Tetrabromoparaxylene.

- Barium or zinc stearate.

- Bicarbonate of soda.

The use of such components in certain proportions forms a strong cellular-porous structure filled with gas.

Penoplex GEO

Overall dimensions: Length - 1185 mm, width - 585 mm, thickness 40, 50, 60, 80, 100 mm.

TU 5767-006-54349294-2014 amended. 1-6

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex GEO

This brand of penoplex is used for thermal insulation of loaded floors, foundations, roofs, stylobates, as well as in places where high fire resistance is not required. All these are areas of civil and industrial construction.

Advantages of Penoplex GEO:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex GEO technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.3 (3.0; 30) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G4 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | 28-36 kg/m3 | |

| Elastic modulus | 17 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.4-0.7 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 20, 30, 40, 50, 60, 80, 100, 120, 150 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

What is this. History of the creation of the material

The material first appeared back in 1941, when the DOW CHEMICAL company (USA) patented a fundamentally new product with high thermal insulation properties and moisture resistance. The production of the material was put on stream, but initially it was manufactured only for the needs of the Navy.

Due to its resistance to wet environments, Penoplex has been used for the production of life rafts. After some time, the material began to be used in refrigeration units. Penoplex occupied its rightful niche only in 1950, when it began to be used in construction. It is curious that in the US construction market the material is known under the brand name STROYFOAM.

Penoplex is a Russian brand that appeared only in 1988.

What is Penoplex? Essentially, it is foamed polystyrene, which is produced on extrusion machines. In its structure, the material resembles polystyrene foam, which is familiar to many, but has a denser structure and, accordingly, better characteristics.

Penoplex ROOFING

Overall dimensions: Length - 1185 mm, width - 585 mm, thickness 30, 40, 50, 60, 80, 100 mm.

TU 5767-006-54349294-2014 amended. 1-6

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex ROOFING

Penoplex ROOF is used for insulation of load-bearing roof structures of any type. Including for thermal insulation of stylobates and parking lots.

Advantages of Penoplex ROOFING:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex ROOF technical specifications

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.25 (2.5; 25) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.4% by volume | |

| Fire resistance category, flammability group | F3-123 | group G4 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | 26-34 kg/m3 | |

| Elastic modulus | 17 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.4 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 20, 30, 40, 50, 60, 80, 100, 120, 150 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Useful tips

Most homeowners turn to external rather than internal wall insulation with penoplex. This is explained by the fact that the second option hides the usable area of the room.

When decorating floors after insulation, they often turn to grouting. For this it is better to use sandpaper. You can proceed to this stage after the reinforcing layer has completely dried. Despite the strength of penoplex, you should be careful when working with it, since this material can still be damaged or broken.

Select high-quality and most effective glue for penoplex. A special adhesive foam is ideal for laying this insulation: it firmly and tightly attaches the material to the base and holds it quite reliably. Make sure that the thickness of the penoplex for wall insulation is at least 5 cm. Ensure that the insulation is securely and tightly attached to the base. Use both nails and glue.

When installing insulation, you cannot do without a profile, especially when it comes to installing a frame structure. It is advisable to purchase a bubble or laser tool, which is both easier and more convenient to use.

To make the external insulation of a house more effective and complete, it is recommended to insulate the foundation in advance (the basement can also be insulated along with it). In this case, all the work is done quite simply: first you need to dig out the foundation, clean it of any dirt, and then glue the foam sheets. After this, the base can be buried.

When installing penoplex on the facade of a building, you must ensure that the panels overlap each other by about 10 cm. This way you can avoid the formation of cracks.

Extruded polystyrene foam is a strong and durable material, but it does not tolerate contact with the following substances:

- gasoline, diesel fuel, kerosene;

- acetone and other ketone solvents;

- formaldehyde and formaldehyde;

- benzene, xylene, toluene;

- various esters;

- polyesters;

- coal tar;

- oil paints.

It is most convenient to apply glue to materials using a notched trowel. In this case, it is advisable to make the adhesive layer no more than 10 mm.

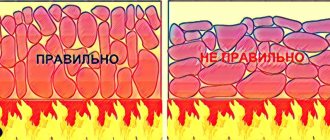

Facade penoplex glued to the ceilings needs to be bandaged vertical seams. This technology is very similar to laying bricks.

If you are going to plaster a wall insulated with penoplex, then you should first apply a base composition with a reinforcing mesh. The density of the latter must be at least 145 g/m2. Make sure that the size of the overlap is about 10 cm. Next, you need to lay a leveling plaster layer (its thickness should be at least 5 mm). Only then should the thermal insulation material be covered with decorative finishing.

If you are sheathing a house with penoplex in 2 layers, then first glue the starting layer, and on top of it place the next layer with a slight offset. Before this, it is worth treating the slabs with a roller.

Before installing insulation, old coverings should be removed only if they have noticeable damage or crumbling areas. If the previous finish does not have any defects or complaints, then penoplex can be placed on it.

Penoplex can be installed on a variety of substrates. It can be safely used for a private/country house or city apartment. In addition, you can easily install this insulation not only on walls, but also on the roof/ceilings.

Experts advise not to rush to insulate the house until it shrinks completely. Otherwise, the layer of plaster will become cracked and may begin to crumble. To carry out thermal insulation work, it is necessary to select only high-quality materials and tools.

Leveling the bases for laying penoplex can be done with plasterboard. However, the presence of this material will reduce the additional space in the room. Owners of city apartments with uneven floors often turn to such solutions.

If you decide to lay penoplex on a wall made of foam concrete, then it will come in handy to install a vapor barrier material. These components are not needed only if we are talking about bases whose structure is not porous.

Penoplex FACADE

Overall dimensions: Length - 1185 mm, width - 585 mm, thickness 20, 30, 40, 50, 60, 80, 100, 120, 150 mm.

TU 5767-006-54349294-2014 amended. 1-6

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex FACADE

It is used as thermal insulation for insulation of internal and external surfaces, that is, facade systems, walls, wall partitions). Penoplex FACADE is designed with a milled surface, which facilitates the adhesion of plaster and glue to the surface and reduces the time required for plastering the building facade.

Advantages of Penoplex FACADE:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex FACADE technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.2 (2.0; 20) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G3 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | 25-33 kg/m3 | |

| Elastic modulus | 15 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.25 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 20, 30, 40, 50, 60, 80, 100, 120, 150 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Installation technology of polystyrene insulation boards

Insulation of external, internal walls and other structures using extruded polystyrene is carried out in several stages. Let's look at each of them:

- The preparatory stage consists of preparing the walls for insulation, cleaning them from dirt, dust, old finishing materials, and paint coatings. In case of large unevenness, it is recommended to level the surface using a plaster mixture (and other methods depending on the design) and treat it with an antifungal compound.

- Fixation using special adhesive facade compounds . The adhesive is applied directly to the insulating board using a comb.

- Mechanical fastening is done using dowels.

- Installation of facade mesh . For better adhesion of the glue to the insulation, you can create roughness on the surface of the slabs. The first plaster layer of façade adhesive is used to fix the reinforcing polymer mesh. Next, a second layer of plaster is applied, after which has dried, the walls are covered with decorative plaster (optional) and painted.

- Instead of plaster, it is possible to decorate the walls with siding, wood, as well as the use of ventilated facades.

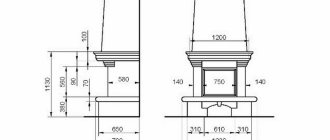

EPS installation technology

Thermal insulation of roofs is carried out either at the construction stage or during the reconstruction process, for example, when converting a cold attic into a living space. In this case, the insulation is laid on the base in several layers (the joints of the top layer should not coincide with the joints of the bottom). Next, a vapor-permeable membrane is spread over the penoplex. The resulting cake is secured with longitudinal slats with a thickness of at least 40 mm to ensure ventilation between the insulation and the roofing material.

Penoplex 45

Overall dimensions: Length - 1185 mm, width - 585 mm, thickness 40, 50, 60, 80, 100 mm.

TU 5767-006-56925804-2007 amended. No. 1-6

Orange color.

Surface: smooth.

Plates 45 are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex 45

Wherever there are special requirements for the heaviest loads. This, for example, is the construction of airfield runways and roads.

Advantages of Penoplex 45:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex 45 technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.5 (5.0; 50) MPa |

| Compressive strength at 2% linear deformation, not less | GOST R EN 1606 | 0.19 (1.9; 19) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.2% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G3 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | 38-47 kg/m3 | |

| Elastic modulus | 20 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.35-0.7 MPa | |

| Standard sizes | Width | 600 mm |

| Length | 1200/2400 mm | |

| Thickness | 40, 50, 60, 80, 100, 120, 150 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Category “Penoplex”

Most Russian regions are characterized by low temperatures in winter, and other seasons do not guarantee comfortable weather for people.

Therefore, the problem of insulating building structures in our country is especially relevant .

Manufacturers are constantly developing new insulation materials that can protect a home from heat loss.

During the time during which this insulation has been produced, several of its varieties have been developed. Each of them is designed for insulation of various types of structures and operation in various conditions. The main differences between the types of penoplex are the characteristics of density and water resistance.

Although penoplex is a universal insulation material, manufacturers recommend using each of its types in accordance with its intended purpose. The name received from penoplex manufacturers for each type of this insulation accurately indicates where it can show its best qualities.