- At the location of the water tank

- Sauna stove with boiler

- What you need to know about operation

- Coil for furnaces

Having made the right choice of heating equipment, you can steam and wash without purchasing and installing a boiler. A reliable, modern, spacious heat exchanger for a bath will perfectly cope with the role of a heater: it will be able to supply the required volume of hot water to the storage tank. In this article you will learn about the options and operating features of the technical tool that exist today, practical advantages and the most popular models.

Manufacturing and connecting a sauna stove with a water heat exchanger

By making a sauna stove with a water heat exchanger with your own hands, you can save on buying ready-made factory heaters, without losing any of the pleasure of visiting the steam room.

This work is not particularly difficult, so you can easily do it yourself. You just need to select a high-quality stove design and manufacture it in full accordance with the documentation on hand. If in the past the most popular were classic heaters, which only allowed heating the steam room, today universal stoves with heat exchangers are in demand on the market. Such installations allow you to simultaneously heat the steam room and solve the problem of heating water. Thanks to their use, the comfort of bathing procedures increases and the costs of purchasing appropriate thermal equipment are reduced. Stoves with a water heat exchanger will be a convenient solution when the steam room and washing room are located separately in the bathhouse. Universal heaters are easy to use, they are extremely convenient, quickly heat the room, completely solving the problem with warm water. The choice of stoves with heat exchangers available today allows you to purchase or make them yourself for both a small steam room and a spacious public bathhouse. Advantages of stoves with a thermal circuit:

- long service life;

- compactness of heaters;

- efficiency and high speed of heating the room;

- possibility of making it yourself.

Certain types of heaters can be used as an autonomous boiler to heat nearby rooms in the house. It is only necessary to connect a closed circuit with radiators to the existing heat exchanger, inside which the coolant will circulate.

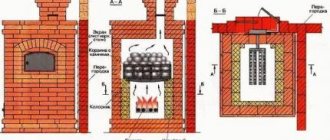

Depending on its design, the heat exchanger in a sauna stove can be made in the form of an iron water tank with two pipes or a metal coil. In each specific case, the size of the tank is chosen depending on the power of the stove and the desired volume of heated water. Heat exchangers can be of two types:

- 1. External ones are fixed on the chimney or on the wall near the stove.

- 2. The internal ones are made in the form of a water jacket, which is located at the bottom of the stove or attached to one of the side walls.

Internal type heat exchangers are most widespread, which is explained by their improved heat saving performance.

Water is heated in such a metal circuit until the stove cools completely. If you choose a stove with a heat exchanger that will be responsible for heating the water in the bath, then you can choose a compact option with an external tank of 5-6 liters. If you plan to use heated water to heat adjacent rooms, then the total volume of the system can be 15-20 liters. In the latter case, it is additionally recommended to install circulation pumps and expansion tanks, which will protect the pipe circuit from damage when pressure increases from the heated coolant.

A prerequisite for the proper functioning of sauna stoves with a heat exchanger is filling the pipeline with liquid, which will prevent failure of the entire heating system. If the heat from the stove in the bathhouse is planned to be used for heating adjacent rooms, then water and antifreeze can be used as coolants.

The liquid heated in the water jacket will be supplied independently or using circulation pumps to the external tank. A small tap can be embedded into it to draw heated water, or a circulation pump can be installed to supply coolant to the circuit with heating radiators. Hot water, having given up its heat to the radiators, returns to the boiler heat exchanger, where it is heated again, after which it is fed back into the pipes for heating the room.

There are various designs for a bathhouse stove with a heat exchanger, which will differ in their design depending on the purpose of the heater. The easiest way is to make your own heater with an additional water tank and a coil , which will significantly simplify hygiene procedures after visiting the steam room. If you plan to make a stove for heating adjacent rooms, then you need to correctly calculate the total length of the pipeline and the number of radiators used.

To ensure the highest possible efficiency of self-made equipment, it is recommended to install a stove with a heat exchanger in the bathhouse, which has an open water heating system. The coolant in the pipes will move by gravity without pressure, which eliminates the need to purchase expensive circulation pumps.

The most efficient heating system will be one in which the length of the pipes does not exceed 3 meters. With this length of pipeline, the hot water tank can be installed directly behind the wall of the steam room. Depending on the location of the container, water can be supplied into it by gravity or under pressure using special pumps.

In open systems where circulation pumps are not used, the internal diameter of the heat exchanger pipes should be greater than 1 inch. This will allow the heated liquid to easily cope with resistance, move by gravity, quickly passing through the system, and there will always be the required volume of hot water in the tank.

It is necessary not only to choose the right stove model for the bathhouse with a heat exchanger, but also to correctly install the heating installation. The efficiency and complete safety of its use will subsequently depend on how correctly the installation of the heater is carried out.

It is necessary to install a sauna stove with a heat exchanger for heating on a properly prepared foundation. The minimum depth of the base should be 400 millimeters. The height of the pedestal is chosen depending on the type of firebox and the overall dimensions of the stove. The foundation is poured from cement with a strength of at least M300, additionally waterproofed and covered with fireproof materials. It is prohibited to install the stove in a bathhouse directly on a plank or log floor.

The heater in the bathhouse must be fenced off from the wooden walls using brickwork. Ceramic or fireclay material can be used for it. Laying is done with a high-temperature clay solution. This allows you to increase thermal efficiency, making the heaters completely safe to use.

Pipes coming directly from the heat exchanger should be insulated. For their insulation, mineral wool or other material characterized by improved fire resistance can be used.

The chimney from the stove is led into the roof, having previously treated all the wooden elements. The pipe passes through the roof using a special metal box, which is additionally lined with asbestos.

All joints between pipes and heat exchanger should be additionally sealed, which will prevent coolant leakage. If there are leaks, the stove may run idle, the temperature inside the water jacket will increase, which will lead to complete failure of the heater.

The cost of ready-made sauna stoves with a heat exchanger is extremely high, so many homeowners decide to make such heaters with their own hands. The easiest way is to make an internal metal heat exchanger, which is mounted in an existing furnace. To make it yourself, you will need the following tools and materials:

- metal pipes with a diameter of 20-30 mm;

- metal plates 3 mm thick;

- welding machine;

- grinder with a circle for stripping metal.

The easiest way is to make a coil from a copper pipe, which is twisted into a spring, after which fittings are welded at both ends to connect a plastic or metal pipeline. All that remains to be done is to place a self-made heat exchanger coil at one of the walls of the stove, inside which antifreeze, water or other coolant will circulate.

Types of tanks

Water tanks of different configurations are installed. The method of heating water may also differ. When choosing a container, you should take into account all the nuances.

The purpose of the hot water tank in the bathhouse

Capacity

The volume of the installed tank depends on the number of people who can simultaneously be in the bathhouse and use hot water. On average, 10...20 liters of boiling water should be provided for each person (with a small reserve). Today, tanks with a volume of 50...100 liters are produced. As a rule, it is not advisable to install a tank with a capacity exceeding 100 liters.

The shape of the container can be any

Material

When choosing a container, you need to consider that it must be able to withstand high temperatures (up to 250 degrees) for a long time.

Metal tank for water in the bath

You should not try to save money and install tanks made of ferrous metals. This approach cannot be justified not from an aesthetic point of view, but mainly from practical reasons. Due to constant exposure to high temperatures, the metal will deform over time and traces of corrosion will appear on it. This significantly reduces the service life of the tanks and the quality of the water in them.

The most common tank option is stainless steel construction. The demand for such tanks is explained by their attractive appearance, durability, resistance to various types of external influences, high heating rate, ability to retain heat for a long time, relatively low weight, hygiene, high durability and ease of maintenance. The tank configuration may vary. But high-quality stainless steel costs a lot. And you need to take into account that today there are many counterfeit products on offer, which will soon rust.

Not so often, but there are tanks made of cast iron. They are not afraid of rust. However, it must be borne in mind that, despite the fact that the water in such structures will not cool quickly, it takes more time to heat it up. Due to the bulkiness of the tanks, you need to carefully consider their location. Today, not many companies produce cast iron tanks, and they are not very cheap.

Enameled containers can be used, but they are not the best option. Of course, such material does not corrode and is very hygienic.

But low resistance to mechanical damage over time will inevitably lead to the fact that the metal with a fairly thin coating will become chipped (as a result of not very careful handling) and these areas will rust. It will no longer be possible to fix the problem.

Location and design

Three methods are used to place the tank: traditional (directly near the firebox), on the chimney, and remotely. What is the difference?

Bath stove with tank

Tank built into the oven

The reservoir can be located on the side or above the firebox. The water in it heats up quite quickly (exposed to open fire). To drain it, a ball valve is installed. Of course, this design does not involve pipeline laying work, which saves labor and material resources. However, using such a container is not very convenient; usually a tank of not very large capacity is installed, and its installation takes up useful space in the steam room, which usually is not very much. The best solution in small-sized baths is the top location of the tank. Since the metal will be in direct contact with the fire, the thickness of the tank walls must be at least 8 mm.

Water tank next to metal firebox

Reservoir on a pipe

If the ceiling height allows, you can install the tank on the chimney. Water is heated by hot gases passing through it. To simplify the installation process, it is possible to purchase a container with built-in chimney elbows. This tank can be fixed without much effort. By laying a pipeline from the tank, you can carry water to any point in the bathhouse, for which a pipe is connected to the bottom of the tank, ensuring the flow of liquid, for example, into the shower. Filling a tank installed in this way is not very easy due to the high location of the filler hole. It is best to use a hose lowered into a container for these purposes.

Reservoir on a pipe

Remote design

Thanks to the installation of a heat exchanger on the heater (on the chimney or directly on the stove) and natural convection, it is possible to place the tank in the washing compartment.

Water tank over brick firebox

The heat exchanger can be integrated into the oven (removable or non-removable), but you can easily install it yourself. It is a coil or container with a volume of several liters with pipes to create a circuit.

What is the design

- Initially, a tank for heating water in a bathhouse was equipped with a heat exchanger - the design is quite simple. A special heating metal tank with a capacity of no more than 5 liters is built into the heart of the furnace, the firebox, or in an area with high temperatures. Which in turn is connected by pipes to the main tank in the next room; the tank can reach a volume of 120 liters.

Important: water must be poured into the system before using the sauna stove, otherwise if the stove is lit and water is then added, the water in the pipes may instantly boil and, as a result of a steam shock, the system will simply burst.

- The principle of operation is that from a large tank to a small one, cold water flows through the drive pipe, is heated in the small tank, which is called a heat exchanger, and returns through the outlet pipe to the main tank, already heated.

- If the drive and outlet pipes are positioned at the correct angle, then the water will successfully circulate by gravity thanks to natural physical laws. But in order to avoid the formation of air pockets in the system and ensure faster and more uniform heating of the water, the tank for the heat exchanger in the bathhouse is equipped with an electric pump for forced circulation of liquid in the system.

- The heat exchanger can be located directly next to the firebox itself, in which case it is installed at the stage of construction of the furnace inside the structure. Or it may have the so-called samovar operating principle, when a small tank is mounted around a metal chimney for a bathhouse directly next to the firebox.

- But regardless of the location of the tank, professionals prefer systems in which the liquid circulates freely, without additional pressure.

Schematic diagram of a samovar-type system.

System Features

When installing a heated water floor in a bathhouse powered by a wood-burning stove, there is no need to install a boiler. However, a heat exchanger needs to be built above the firebox. Any stainless steel tank that is not prone to corrosion is suitable for this. A circuit extends from it into the room where the heated floor will be installed.

To return the waste liquid to the tank, you will need to install a small pump. Without it, the design will only work when the stove is located below the level of the floor covering. The diameter of the pipe with this scheme should be taken equal to 16 mm; the usual 24 mm ones will not work.

The main feature of the stove floor design is the inability to adjust the temperature level. The recommended temperature of heated floors in the bathhouse is 40 degrees, but the heat carrier from the stove will heat up to boiling water.

Video

Therefore, it is necessary to make a mixing block in which hot water will be mixed with already used water, thereby reaching the desired temperature level.

Since it is not possible to install a large container in the furnace, you can place a battery tank near it and stretch steel pipes from it to the heat exchanger.

Let's talk about the rules of installation and operation

System calculation

If you decide to install the system yourself, you will have to make certain calculations. It will be difficult to absolutely accurately calculate the dimensions and volume of the system, and there is no urgent need for this.

For example, 5 kW is enough to heat a medium-sized room. This power can be provided by a heat exchanger with an area of 1 m². But the temperature in the furnace constantly fluctuates; when fully heated, 1 m² provides up to 9 kW, and when the furnace goes out, the power begins to drop rapidly and can drop by 5 to 10 times. Therefore, the area of the unit is taken with a significant margin, which makes it possible to equalize the heating of the liquid.

The configuration of the heat exchanger itself can be different; there is no consensus among experts. Some argue that stainless steel pipes are the best option, others prefer plates or manifolds consisting of 2 mating channels.

Connecting the system to the shower stall.

Tips for installation

If you decide to assemble the system yourself, then you should take into account several mandatory requirements.

- Tanks should be welded from metal with a thickness of at least 2.5 mm. The requirements for the upper, large tank are minimal; the main thing is that it does not rust or leak.

- The requirements for piping and the heat exchanger itself are somewhat higher; in the past, the most popular material for a heat exchanger was cast iron. Indeed, the material is very durable, does not corrode and holds the temperature for a long time. But cast iron also has serious disadvantages; it is heavy, which requires serious fastenings. And cast iron takes a long time to heat up.

- At this time, most experts prefer to assemble a system from stainless steel; its price is of course higher than that of cast iron or conventional steel grades that are susceptible to corrosion, but the savings here will cost more in the future. For the heat exchanger, stainless steel grades 08X17 (430) will be the most optimal; or 8-12Х18Н10 (304) they have optimal heat transfer parameters and meet all hygienic standards.

- As for the connecting pipes, naturally they should also be made of stainless steel. The drive pipe with cold water must initially, when leaving the large tank, fall slightly below the level of the heat exchanger; a drain valve is mounted at the lowest point and then rises at an angle of 2˚ to 5˚ to the entrance to the heat exchanger.

- The outlet pipe, through which hot water will flow into a large tank for a heated bath, must exit the heat exchanger, pass through the wall at an angle of at least 30˚ and connect to the tank.

The simplest samovar-type heat exchanger.

Important: pay attention to the cross-section of the pipes in the system must be at least 1 inch, otherwise the system will not operate stably, may overheat and require forced circulation of liquid. The optimal length of the entire pipework should not exceed 3 m.

The system is designed exclusively for heating the room.

- Do not forget that both the piping of the bath and the heat exchanger itself at all interface points must be equipped with special heat-resistant gaskets that provide sufficient damping clearance during thermal expansion of the metal.

How to make your own device

It’s easy to make a simple coil yourself from a copper tube. For a chimney with a diameter of 100 mm, a copper pipe with a diameter of ¼ inch and a length of 3-4 m is suitable. Threaded fittings should be soldered to the ends of the pipe. Then the tube is filled with fine sand, twisted and wrapped around the chimney.

It is convenient to do this work with an assistant. The sand is then washed out of the pipe with water under pressure. Connect the pipes leading to the radiators and expansion tank.

The Kuznetsov heat exchanger is made using welding. The simplest option is to make a housing from a gas cylinder or large diameter pipe.

For manufacturing you will need the following materials:

- Gas cylinder, large diameter pipe (300 mm) for the housing.

- Pipe with a diameter of 32 mm (it is better to take one piece with a larger diameter - up to 57 mm). The length of the blanks is 300-400 mm, the total quantity should be sufficient for cutting the blanks.

- Two small pipes of the same diameter as the chimney; It is advisable to use a chimney pipe - if the chimney is prefabricated, then on one side of the structure the pipe will have a socket, which is necessary for installing the heat exchanger.

- Two pieces of steel sheet, sufficient to cut out the end caps of the housing.

Air heat exchanger manufacturing technology:

- A large pipe or cylinder is cut to the required size.

- 9 blanks of the same length are cut from thin pipes.

- Circles are cut out for the plugs.

- 9 holes for small diameter pipes are cut in the circles; if one tube of larger diameter is taken, then a hole for it is cut in the center.

- Thin pipes are inserted into the holes of the plugs, attached by welding, and then welded.

Holes with a diameter equal to the diameter of the chimney are cut in the sides of the body.

A structure of thin tubes and plugs is inserted into the body and welded at the junction of the plugs and the body of a large pipe.

The pipes are inserted into the holes on the sides of the body and also boiled.

Alternative option:

What materials can be used

The ideal option is (for example, food grade austenitic stainless steel 08Х18Н10 or AISI 304) or copper. Industrially produced products are sometimes made from titanium. But the price of these materials is quite high. But they are durable, do not rust, are reliable and durable. If you have a potbelly stove in the garage or a homemade heater from scrap materials in the bathhouse, it is quite possible to use ferrous metal (carbon steel).

You can use a high-quality corrugated stainless steel pipe. Aluminum pipes can also be used for the coil (just not for chimneys of solid fuel stoves).

Sometimes galvanized steel is used, but it should be borne in mind that during welding work the zinc layer evaporates, and all the advantages of galvanizing (corrosion resistance) come to naught. At temperatures above 400 °C, zinc begins to evaporate (zinc vapor is toxic), so you should not use galvanization for heat exchangers on the chimneys of solid fuel boilers.

All about heat exchangers

The heat exchanger is used to heat the water in the bath. Its operating principle is based on the physical properties of hot water to expand and rise, while cold water remains at the bottom.

Typically, heat exchangers are small in size and the water in them heats up quickly. Two pipes are connected to the heat exchanger - bottom and top. Thus, hot water through the upper pipe, displaced by cold water from below, rises into the water tank, which can be located either in the steam room or in an adjacent room, usually in the sink. In this case, cold water through the lower pipe is constantly independently added to the heat exchanger for heating in it. No additional mechanisms or pumps, engines or motors – pure physics!

The Termofor company produces two types of heat exchangers for heating water in a bath:

1. Built-in heat exchanger installed inside the Termofor sauna stove;

2. Kostakan “samovar” type heat exchanger, installed on the stove chimney and using the heat of the gases escaping into the pipe to heat water (purchased separately from the stove).

All Termofor heat exchangers are made of high-alloy heat-resistant steel with a chromium content of at least 13%.

Specifications

According to physical properties, warm air masses rise upward, and even in a steam room, where it is hot, the floors are cold. But such a dissonance between the heat from above and the cold from below makes bathing procedures uncomfortable.

Modern technologies make it possible to improve the microclimate in the bathhouse by installing different types of heated floors under the floor covering:

cable - are a heating cable laid under the finishing coating, powered by electric current;

infrared - a film with infrared plates inside that heat up when energy is supplied, the simplest structure in terms of self-installation;

water - a pipeline located under the floor in the bathhouse, the coolant is heated water.

However, the bathhouse has high humidity, so many building owners do not risk installing electric heated floors themselves.

In this regard, water heated floors are considered more popular. After all, the bathhouse is equipped with a stove, and it is possible to heat the coolant from it, so this combination is also economically profitable.

Termofor sauna stoves with built-in heat exchanger

The abbreviation TO in the name of the Termofor sauna stove means the presence of a built-in heat exchanger. Thanks to the new design, the water in the heat exchanger is heated directly by the flame, and not through the furnace wall, which significantly reduces heat loss, fuel consumption and water heating time.

Termofor sauna stoves with a built-in heat exchanger have symmetrical holes on the side walls. A heat exchanger is installed on one side of the stove inside the firebox, and the holes on the opposite wall are closed with heat-resistant plugs.

To install a water heating system according to this scheme you will need:

1. Termofor sauna stove with a built-in heat exchanger, for example, Angara 2012 Inox Vitra ZK TO Anthracite stove.

2. Select connecting pipes with an operating temperature of at least 95 °C and a G ¾ connecting thread.

3. The Termofor “Baikal” remote-type tank is available in volumes of 42/52/68/75/80 l.

4. Three taps: for dispensing hot water (6), for draining water from the system (9) and a three-way tap (7). A three-way tap is connected to the hot line pipe and serves to dispense hot water before it enters the tank, i.e. when the water in the tank has not yet warmed up, but you urgently need boiling water, for example, to fill the brooms.

Electric heater

Special electric heaters for bath needs are traditionally divided into two classes: storage-type boilers and units with flow-through action. When choosing a type suitable for given conditions, it is recommended to proceed from the following considerations.

In areas where there are frequent power outages, a storage tank is more suitable for installation in a bathhouse; in the simplest case, it is a container with a useful volume of 30 to 200 liters. A heating element and a special heat-sensitive sensor are installed in its internal space, which is responsible for maintaining the water temperature at a given level.

Among the advantages of such heaters it should be noted:

- increased level of electrical protection;

- the ability to use heated water for some time even in the absence of electricity;

- availability of several designs (vertical and horizontal);

- efficiency.

For areas with a reliable power supply, less common flow-through heaters that operate on approximately the same principle as a gas water heater may also be suitable.

The disadvantages of units of this type include significant energy consumption and the need for equipment in a bath with powerful electrical wiring. In addition, in order to maintain a fixed level of water heating in this case, it will be necessary to ensure the stability of its supply.

Termofor sauna stoves with built-in heat exchangers

You can view all Termofor sauna stoves with built-in heat exchangers here . On the same page, in the filter on the left, you can select the required volume of the steam room, wood or gas sauna stoves, the firebox material - it can be Carbon structural steel or Inox chrome-containing steel, the design possibility of heating the stove directly from the steam room (short fuel channel) or stoves equipped with an extended fuel channel for the firebox from the adjacent room, as well as the color of the stove and the design of the door - a steel door or a door with translucent Vitra glass.

Joint connection of two boilers

To increase the heating comfort of a private home, many owners install two or more heat sources that run on different energy sources. At the moment, the most relevant combinations of boilers are:

- natural gas and wood;

- solid fuel and electricity.

Accordingly, the gas and solid fuel boiler must be connected in such a way that the second automatically replaces the first after burning the next portion of firewood. The same requirements are put forward for connecting an electric boiler to a wood boiler. This is quite simple to do when a buffer tank is involved in the piping scheme, since it simultaneously plays the role of a hydraulic arrow, as shown in the figure.

The boiler supply lines are connected to the upper pipes of the heat accumulator, the return pipes to the lower ones

Advice. Information on calculating the volume of the buffer tank can be found in a separate publication.

As you can see, thanks to the presence of an intermediate storage tank, 2 different boilers can serve several heating distribution circuits at once - radiators and heated floors, and in addition load an indirect heating boiler. But not everyone installs a heat accumulator with a TT boiler, since this is not a cheap pleasure. In this case, there is a simple diagram, and you can install it yourself:

The circuit takes into account the peculiarity of the electric boiler - the built-in circulation pump always works

Note. The scheme is valid for both electric and gas heat generators operating together with solid fuel.

Here the main source of heat is a wood heater. After a stack of firewood burns out, the air temperature in the house begins to drop, which is registered by the room thermostat sensor and immediately turns on heating by the electric boiler. Without a new load of firewood, the temperature in the supply pipe decreases and the overhead mechanical thermostat turns off the pump of the solid fuel unit. If you ignite it after some time, everything will happen in the reverse order. This video is described in detail about this joint connection method:

Heat exchanger for the Termofor sauna stove on the chimney

If you want to increase the efficiency of your sauna stove and use the heat of gases escaping into the chimney to heat water, a Kostakan “samovar” type heat exchanger is suitable for you.

Named after a lake in Kamchatka, it has an increased volume and allows you to quickly heat water in large capacity tanks. The Kostakan heat exchanger is usually installed as the first element of the chimney in order to remove heat from the very first hot gases, as well as to maintain the height difference between the heat exchanger and the tank. The Kostakan heat exchanger is available in 4 modifications for different chimney diameters: Ø115 – 8l, Ø120 – 8l, Ø140 – 9l, Ø150 – 9l; The connecting thread for all is standard - G ¾.

As you can see, the installation of a water heating system with a remote heat exchanger is identical to the installation of a water heating system using a sauna stove with a built-in heat exchanger.

For efficient operation of the water heating system, the height difference between the heat exchanger and the tank must be significant - at least 30 cm between the upper fitting of the heat exchanger and the bottom of the tank. It happens that it is not easy to comply with this requirement, since the ceilings in the baths are low, the heat exchanger is installed on the stove quite high, and most water tanks are vertical.

For such cases, the Termofor company produces a horizontally oriented external Zeppelin tank, with a shape and shine reminiscent of the German airships of rigid construction of the last century, after which it was named. It heats up better and is much more convenient to maintain. The large, long neck makes it easy to fill the tank with water, clean the tank and service the fittings.

Precautionary measures

Please note that any water heating system, like the sauna stove itself, is a fire hazard and requires a responsible approach during operation, therefore we strongly recommend that you carefully read the instructions for Termofor products and strictly follow all safety precautions!

Here are the basic requirements for the installation and operation of water heating systems in a bath using heat exchangers:

- Do not operate the oven with an empty heat exchanger and hot water tank or an unconnected water heating system.

- It is prohibited to pour water into an empty tank, heat exchanger or water heating system after lighting the stove - you must wait until the stove and tank have completely cooled down.

- Do not connect a heating system to the heat exchanger. For this purpose, the Termofor company produces tube heaters, which are identical in principle to a “samovar” type heat exchanger, only designed not for water, but for hot air.

- The bottom of the remote hot water tank must be at least 30 cm above the level of the upper fitting of the heat exchanger.

- When installing pipelines, the use of pipes with an operating operating temperature of less than +95 ° C is not allowed. It is recommended to install pipes for hot water at an upward angle of at least 30°, and for cold water – 1-2°. Sagging of pipes in horizontal sections is not allowed. Connecting pipes expand as the water temperature rises, so they cannot be fixed to the walls.

- The maximum length of the pipeline for hot water is 3 m.

- Threaded pipe connections must be sealed with plumbing sealant.

- Fill the water heating system only with clean water. It must meet quality requirements in terms of the content of salts, iron, lime, etc. It is prohibited for corrosive substances to enter the tank.

- It is necessary to ensure that the hot water tank is secured to the wall as securely as possible to avoid burns and injuries. The wall must be able to support the weight of a fully filled tank.

- Do not pour water into the tank right up to the lid, otherwise the water may splash out when boiling. When boiling, drain the hot water and add cold water.

- Do not operate the hot water tank under pressure other than atmospheric pressure. When operating a stove with a built-in heat exchanger, it is not allowed to exceed the operating pressure in the water heating system by more than 0.05 MPa (0.5 kgf/sq.cm). Pressure testing of the system with higher pressure should be carried out with the heat exchanger turned off.

- Do not use a heat exchanger or a faulty tank that has visible damage and/or leaks. Do not use the water heating system if the water circulation is not possible.

Types of maintenance

Diagram and principle of operation of a recuperative heat exchanger

According to the principle of operation, equipment is divided into recuperative and regenerative. In the first, moving coolants are separated by a wall. This is the most common type and can come in various shapes and designs. In the second case, hot and cold coolants alternately contact the same surface. High temperature heats the wall of the equipment during contact with a hot medium, then the temperature is transferred to the cold liquid upon contact with it.

According to their purpose, heat exchangers are divided into two types: cooling - they work with cold liquid or gas, while cooling the hot coolant; and heating ones - interact with the heated environment, giving energy to cold flows.

There are several types of heat exchangers by design.

Collapsible

They consist of a frame, two end chambers, separate plates separated by heat-resistant gaskets and mounting bolts. Such equipment is easy to clean and can increase efficiency by adding plates. But collapsible maintenance units are sensitive to water quality. To extend their service life, additional filters must be installed, which increases the cost of the project.

Lamellar

The plate heat exchanger requires the installation of additional filters for the coolant

They differ in the method of connecting the internal plates:

- In brazed TOs, corrugated stainless steel plates 0.5 mm thick are made by cold stamping. A gasket made of special heat-resistant rubber is installed between them.

- In welded plates, plates are welded together to form cassettes, which are then arranged inside steel plates.

- In semi-welded maintenance, cassettes are fastened together using paronite joints in a structure consisting of a small number of welded modules. These modules are sealed with rubber gaskets and connected by laser welding. Then they are assembled between two plates using bolts.

Plate heat exchangers are used in high pressure and extreme temperature environments. Such devices require minimal maintenance, are economical and are highly efficient. In addition, the efficiency of the equipment can be increased or decreased as needed by increasing or decreasing the number of steel plates.

The only drawback of a corrugated stainless steel heat exchanger is its sensitivity to the quality of the coolant; it requires the installation of additional filters.

Shell and tube

They consist of a cylindrical body in which bundles of tubes arranged in grids are placed. The ends of the pipes are secured by flaring, welding or soldering. The advantage of such equipment is that it is undemanding to the quality of the coolant and can be used in technical processes where aggressive environments and high pressure are present (in the oil, gas, chemical industries). The disadvantages of shell-and-tube maintenance are relatively low heat transfer, large dimensions, high cost and difficulty in repair.

Spiral

Consist of two sheets of metal rolled into spirals. The inner edges are connected by a partition and secured with pins. Such heat exchangers are compact and have a self-cleaning effect. They are capable of working with liquid inhomogeneous media of any quality. As the speed of fluid movement increases, the intensity of heat transfer increases. Disadvantages: difficulty in manufacturing and repair, limitation of working fluid pressure to 10 kgf/cm².

Double-pipe and pipe-in-pipe

Diagram of a “pipe-in-pipe” heat exchanger

The first ones consist of pipes of different diameters. Liquid and gas are used as coolant. The devices are used in places with high pressure and have a high level of heat transfer. They are easy to install and maintain. The only drawback is the high cost.

A pipe-in-pipe heat exchanger consists of two pipes of different diameters connected to each other. They are used for low coolant flow and to equip a chimney.

Heat exchanger - what is it

A heat exchanger is a hollow container filled with water, built into the furnace structure. The heat exchanger is connected to a system of pipes and/or tanks through which water circulates, heated during the firing of the furnace.

Depending on the design, the movement of water through the system is carried out naturally or forced (using a pump). The principle of operation of the heat exchanger of a sauna stove is that heated water enters the heating radiators and shower tank, and cold water flows into the heat exchanger and is heated. The process occurs during the entire combustion time.

There are several designs of heat exchangers:

- Internal heat exchanger - a container with water for heating is placed in the furnace firebox. The design of the container can be any - in the form of a tank that forms one wall of the firebox or a coil of pipes surrounding the combustion chamber.

- External heat exchanger - the module is placed outside the stove; it usually surrounds the stove pipe, heating up from the temperature of the hot gases discharged through the pipe during the combustion of fuel in the stove.

The water circulating in the system can be used both for heating the room and for heating water for washing. Structurally, a stove for a bath with a heat exchanger for water is no different from a conventional stove with local water heating.

To install a system with two functions (room heating and hot water), you will have to provide a water tank and correctly calculate the length and diameter of the pipes for optimal operation of the system.

The highest efficiency is achieved by a system in which the following conditions are met:

- The length of pipes is no more than 3 m;

- The diameter of the pipes is more than 1 inch - with a small clearance, the liquid will not be able to circulate normally without the help of a pump;

- Open water heating system - air access is organized into the expansion tank.

This design will not require additional energy costs (including electrical energy for the pump) and will provide room heating and hot water.

Note: to heat the room in the local heating system, you can use antifreeze - it is not afraid of low temperatures, so during long periods of downtime in winter you will not have to drain the liquid from the system. In practice, such a coolant is used very rarely due to its high cost.

Other nuances of choosing a tank

Capacity volume

Many people are interested in how much water needs to be heated for a bath. The calculation is made depending on the number of users. The norm for one person is about 8-10 liters; for steaming brooms you may need the same amount. If the shower is powered from the reservoir, the consumption increases even more. Factory models of containers have an average volume of 50 to 80 liters, products with built-in tanks - about 22-30 liters. When making a tank with their own hands, craftsmen are guided by the rule “the bigger the better,” but, obviously, it is impossible to endlessly increase the useful volume, because water also weighs something (there may be problems with reliable fixation), and it will heat up more slowly.

Material of manufacture

Naturally, metal is used. In artisanal conditions, craftsmen use sheets of black steel (which is easy to weld) about 3-5 mm thick. The more massive the walls of a homemade tank, the longer it will last and the more reliable the weld will be. Industrial products are usually made from stainless steel. Since there is no need to worry about corrosion and burnout, the wall thickness of a medium-sized stainless steel tank is usually in the range of 0.8-1 mm, which has a positive effect on the rate of heating of water. As the volume of the tank increases, the thickness of the metal also increases, which can reach one and a half millimeters. Sometimes branded tanks are made of cast iron - a durable, and most importantly, heat-intensive material, although expensive and heavy. You can also find factory-made steel containers, the bodies of which are coated with heat-resistant paint. This is a completely working option, but such tanks must be handled very carefully so as not to damage the coating.

Calculation of heat exchanger area

A stove for a bath with a heat exchanger for heating should produce 5 kW of heat with a standard area for an ordinary family. When independently calculating the dimensions of the system elements, we proceed from the fact that 1 m 2 of heat exchanger area gives about 9 kW.

It is recommended to make dimensions with a large margin, since the efficiency of the system is affected by the location and shape of the boiler, and the quality of the fuel.

When designing a system for obtaining hot water (with a remote tank), it should be taken into account that the tank itself will additionally heat the room.

The connection diagram for the heat exchanger in the bath is simple for factory-made stoves in the corresponding models. However, for people with welding skills, it is quite possible to assemble the system on their own for a brick oven. For a system with natural circulation, you will need pipes, fittings, fittings (2 taps), and a water tank.

Metal sheets are needed if the water tank or heat exchanger is to be welded independently (in the shape of a cube or parallelepiped).

Trim option with buffer tank

The presence of a buffer tank is extremely desirable for the operation of a boiler using solid fuels and here’s why. In order for the unit to function efficiently and produce heat with the efficiency declared in the passport (from 75 to 85% for different types), it must operate at maximum mode. When the air damper is closed to slow down combustion, there is a lack of oxygen in the firebox and the efficiency of wood burning decreases. At the same time, emissions of carbon monoxide (CO) into the atmosphere increase.

For reference. It is because of emissions that in most European countries it is prohibited to operate solid fuel boilers without a buffer tank.

On the other hand, at maximum combustion, the temperature of the coolant in modern heat generators reaches 85 ° C, and one load of firewood lasts only 4 hours. This does not suit many owners of private houses. The solution to the problem is to install a buffer tank and connect it to the TT boiler piping so that it serves as a storage tank. Schematically it looks like this:

By measuring the temperatures T1 and T2, you can configure the layer-by-layer loading of the container with a balancing valve

When the firebox is burning with all its might, the buffer tank accumulates heat (in technical language, it is loaded), and after extinguishing it releases it into the heating system. To control the temperature of the coolant supplied to the radiators, a three-way mixing valve and a second pump are also installed on the other side of the storage tank. Now it is not at all necessary to run to the boiler every 4 hours, because after the firebox goes out, the heating of the house will be provided for some time by the buffer tank. How long depends on its volume and heating temperature.

Reference. Based on practical experience, the capacity of a heat accumulator can be determined as follows: for a private house with an area of 200 m², you will need a tank with a volume of at least 1 m³.

There are a couple of important nuances. In order for the piping circuit to work safely, you need a solid fuel boiler whose power is sufficient for simultaneous heating and loading of the buffer tank. This means that power will be required 2 times higher than the calculated one. Another point is to select the pump performance so that the flow rate in the boiler circuit is slightly higher than the amount of water flowing in the heating circuit.

An interesting option for connecting a TT boiler with a homemade buffer tank (aka an indirect heating boiler) without a pump was demonstrated by our expert in the video:

Do-it-yourself heat exchanger for a bath

The heat exchanger is made of metal of at least 2.5 mm or pipes bent into a snake or spiral.

The water tank is located above the level of the stove - this is necessary for water circulation. Then these elements are connected to each other by pipes: upper and lower contours.

To drain water (when flushing the system or during periods of long downtime in winter), a tap is cut into the return circuit at the lowest point of the pipe.

Installing a heat exchanger on a sauna stove requires high-quality connection of all elements and tightness of welds. The heat exchanger itself can be checked with compressed air by lowering it into water. After assembly, check the tightness of the connections of the entire system.

Note: to heat adjacent rooms, the water tank can be thermally insulated - in this case it will have the additional function of a heat accumulator.

Bronze model

Bronze bath taps are controlled using valves, spindles, disks and plugs. Hence their classification. They also differ in the type of mixer head. The housings are made of metal with double-sided threads and a supply pipe. In addition to a replaceable fitting element with a head, the faucet has a nose that determines the direction of the water jet

When purchasing, you need to pay attention to the material from which the faucet is made, its characteristics, spout, design, price and functionality. For example, one made of brass is more expensive than models made of stainless steel, but is stronger and more functional in operation.

Recommendations from experienced professionals

When installing a heat exchanger for hot water in a bathhouse, you need to remember that:

- A remote water tank should be selected in accordance with the power of the sauna stove - a container that is too large will take a long time to heat up. In a small tank, the water will boil early and fill the washer with unnecessary steam.

- The heat exchanger must also match the furnace - too large a design will reduce the efficiency of the furnace. The optimal option is when the system takes 10 percent. on the power of the stove.

- The system pipes should not be fixed rigidly to the walls - their linear dimensions change when heated.

- For threaded connections of the system, only a sealant that can withstand high temperatures is used.

- In a system with natural heat exchange (without using a pump), it is necessary to maintain a slope of 2 - 5 degrees for the upper and lower contours of the pipes.

- The sauna tank with a heat exchanger should not be empty when the stove is fired.

After heating the system to high temperatures, it is undesirable to add cold water - a sharp drop will negatively affect the service life

A sauna stove with a heat exchanger will allow you to get maximum comfort and, at the same time, preserve the charm of this favorite traditional procedure.

Operating principle

There's nothing complicated here. Water is one of the most heat-intensive substances, so heating it requires a lot of energy. We can take this energy either from the stove body or from the chimney.

Brick stove for a bath with a water tank

It is clear that inside the stove there is “working” heat that is used to heat the steam room, but in the chimney it is already considered a loss, because the gases do not have time to cool while passing through the pipe, and in this form they escape into the atmosphere.

It follows from this that the idea of purchasing a sauna stove with a water tank can be useful for increasing the efficiency of the stove - for this you need to take a model with a tank on the chimney.

Water heaters

Modern water heaters can be divided into three groups depending on the type of fuel:

- wood;

- gas;

- electric.

Electrical

There are two types of electric water heaters:

- Flow-through devices are compact devices that quickly heat the liquid flowing through them. Can quickly dispense hot liquid. In winter, water is heated slowly; it may not have time to heat up to the optimal temperature, and it may flow out of the tap or shower cold.

- Storage electric heaters - boilers. Not suitable for small rooms as they take up a lot of space. If the sauna is rarely heated in winter, the liquid inside the system may freeze. This will damage the boiler.

To prevent water from freezing in the storage electric heater, you can:

- Install the boiler and turn on the minimum temperature setting. Disadvantage: extra electricity costs.

- After each use, drain all liquid from the device.

It is better to install a boiler in rooms with constant heating.

Wood burning

If there is no electricity or gas, the only way to get hot liquid is by using a wood heater. It consists of four elements:

- metal case;

- solid fuel combustion chambers;

- chimney for gas removal;

- containers with liquid located above the firebox.

You can burn a wood stove with different types of wood. It is necessary to regularly clean the chimney and combustion chamber from soot and ash.

Gas

A gas heater is a flow-through column that runs on natural or liquefied gas. This is an economical equipment that works equally effectively in winter and summer.

Disadvantages of geysers:

- expensive and complex installation;

- To connect to the central gas supply system, you need to fill out a lot of paperwork.

To install a gas pipeline, you need to perform a large amount of earthwork.

Source of water supply

A water source is rarely constructed exclusively for a bathhouse. In the absence of a centralized water supply system, a water supply system is needed primarily for residential buildings and household needs. Therefore, as a rule, a bath water supply system is built into an existing private water supply system. For this purpose, a collector distribution line is installed, where the pipe is routed to the bathhouse building.

The most common source of water is a well. It most often reaches the second aquifer, and its depth is 10-30 m, depending on the depth of the groundwater. If the task is specifically to make water in a bathhouse of a wooden or other structure, then the potable degree of purification is not necessary, which means that it is enough to open the uppermost water carrier at a depth of 5-10 m. Such water should not be used for cooking, but for It's quite suitable for swimming.

Water supply diagram from a well

The depth of the well shaft is important for choosing the type of pumping equipment. The fact is that when lifting from depths of up to 12-15 m, you can safely use conventional centrifugal, surface pumps. With a deeper fence, you will have to lower the deep, submersible installation, which is somewhat more expensive and more difficult to operate.

Another option for a water source is a well. Its depth is 30-50 m, which makes it possible to reach the lower artesian layers, which provide especially pure water, and most importantly, a large and stable volume of liquid for a long time. It is the inextricability of the well source that is considered its main advantage, because wells tend to dry up periodically. The lifting of water from the well is ensured only by deep pumps.

In principle, a third option is also possible - pumping water from a natural reservoir. However, such a system is used quite rarely, and most often unofficially, because requires approval from the relevant authorities. The most important thing is that in this case you will have to solve the problem of installing a rather complex treatment plant.

Selecting the boiler power

It is important to take care of the installation of an RCD (residual current device). This will prevent accidental electric shock to bathhouse visitors.

This will prevent accidental electric shock to bathhouse visitors.

Based on the design features and range of water heaters, we can state the following:

- If you don’t have gas, then the heaters and boilers using this fuel will “pass” by your bathhouse. If you are the happy owner of a gas bath, then you can no longer consider other options.

- Electric water heaters are expensive, but there are no problems with installing the device. It is cut into the water supply and plugged into an outlet. And that’s it – you can use it. Moreover, an electric boiler is a “one-time” device - this device will prepare the next portion of hot water after 3-4 hours. In addition, instantaneous and electric storage water heaters are afraid of excessive humidity in the bathhouse “atmosphere”.

- If you are a supporter of budget solutions and want to have a supply of hot water until the heater goes out, then you will undoubtedly like wood-burning water heaters. In this case, the water in the tank is heated by the stove itself, which imposes some restrictions on the process of installing such water heaters. They are installed during the construction of the heater. But if you haven’t missed the moment, then you won’t find anything better.

Well, now let's talk about volume:

- Large companies need an appropriate amount of water. Therefore, for a company of 4-5 people, you need either an instantaneous water heater or a boiler with a capacity of 100-150 liters.

- One or two people or a company of three people will get by with a 50-80 liter boiler.

- The bathhouse for one “user” is equipped with a 30-liter boiler.

water heaters “Success”,

which are tanks with a capacity of 40 to 250 liters, heated by heating elements at 1.5-2 kW.

Water heater “Success” 125 l

The tank is made of sheet steel, at least a millimeter thick, and the heating element is equipped not only with a thermostat, but also with a mechanical temperature regulator.

Less sociable bathhouse owners will be interested in

model GARANTERM ER 150 V

Water heater GARANTERM ER 150 V

electric boiler for 150 liters, boiling water heating element for 1.5 kW. This dressing can serve a company of 3-4 people, who can not only rinse off in front of the steam room, but also take a full-fledged hot shower. Moreover, the heater body, as well as the outlet fittings, are made of stainless steel, and moisture-resistant polyurethane foam is used as a heat insulator.

The cost of the heater is 10-11 thousand rubles.

model Ermak KVS-10-2-90

Water heater model Ermak KVS-10-2-90

wood-burning storage water heater made of stainless steel with a capacity of 90 liters. This boiler boils water using both wood and heating elements with a power of up to 2.5 kW. Moreover, this boiler has relatively modest dimensions - the wood-burning firebox is built directly into the storage tank of the heater.

The cost of a stainless steel model is 15,000 rubles.

The easiest way

Manufacturers make sauna stoves with ready-made water tanks. This option is the simplest for installation and further operation. Relevant for buildings that do not have gas and water supply communications; a limit on the use of electricity has been determined.

Hot water tanks can be installed in two ways:

- The tank is placed directly on the chimney pipe of the stove, the liquid is heated by the heat of the smoke coming out. At the same time, the pipe can heat up to very high temperatures (500⁰ C), quickly warming up the contents of the tank. The bottom of the container is equipped with an opening equal to the cross-section of the chimney pipe. It is necessary to ensure the tightness of the joints of the pipe and the tank at the inlet so that water does not leak out. The joint can be treated with a heat-resistant sealant, clay-lime-sand mortar. Cement mortar becomes cracked when exposed to heat. At the same time, such placement allows you to heat the water with heat, which is usually removed outside. And it is easier to install a chimney pipe inside the attic space, since excess heat is transferred to water.

- Mounted tank. It is placed wall-mounted on one side of the stove, most often inside the steam room (capacity 40-70 l). A wood stove heats the water in the tank in 1.2-1.6 hours. To speed up the process, you can thermally insulate the tank. It is also a simple, low-cost method that does not require significant material costs and is easy to maintain.

Placing such a tank inside the steam room is considered a disadvantage due to the large release of water vapor. For bathhouses located in the country, this is one of the few available ways to heat water that does not require any effort in winter arrangement. A current option for a classic Russian bath. It is not recommended to equip a sauna with such a tank.

Material for production

Steel types are also considered productive today. This kind of substance has many advantages; it is resistant to changes in temperature and pressure, retains and conducts heat well. It is resistant to rust, corrosion and deformation. Cast iron products for water have similar properties, although it is worth noting that they are much heavier in weight, despite the fact that they maintain temperature for a long time and take a long time to build up the required level of heat.

As experience shows, devices have long been widely used in practice, but they also have their own characteristic disadvantages. If you install the container incorrectly, the water will boil faster than the room begins to fill with steam. Subsequently, the steam room produces moist, heavy air, which does not act as effectively on the body as dry steam.