Why is sand poured into the base of the foundation? Is such a pillow necessary at all? What material is best to use for this purpose? We will try to answer all questions. You will receive information about the role of sand under the foundation of a house and the criteria for its selection.

From the Soil Trucks company you can buy sand for foundation cushions with delivery to your site.

Price for Sand for foundation cushion from RUB 1,270.

for 1m3 Order So, sand performs several functions:

- Levels the surface of the trench.

- Evenly distributes the load from the upper layers and prevents subsidence of the building.

- Partially replaces problematic soil (clayey, peat, organic-rich chernozem).

- It is one of the components of the drainage system under the building.

Which sand is best for foundation cushion?

Sand is a high-density bulk material and is successfully used both in construction and for the construction of wastewater treatment plants.

Creating a sand cushion is one of the important stages of construction. Unfortunately, not all experts will be able to answer the question about the need to place it under the foundation and what sand should be used.

When the question arises of what kind of sand is needed for a cushion under the foundation, it is first of all necessary to understand what functions this embankment performs.

The alignment function is relevant in situations that can be called ideal. The soil is homogeneous, motionless and does not contain impurities of organic soil or clay. Consequently, the job of sand is limited to leveling the trench bottom or the bottom of a pit.

In cases where organomineral soil (peat) is located under future construction, you can be sure of the mobility of the soil and a decrease in its bearing capacity. To avoid destruction of structures, it is necessary to remove a large amount of soil until the organic layer is exhausted. The greater depth created after the excavation of organic soil is filled with sand.

Compensating for deformation is the main task of sand when performing the third functional purpose. Clay and other heaving soils, being under the support of a house, significantly affect the distribution of loads. Which, as is known, can lead to the complete destruction of slabs or concrete strips.

How it works.

The thickness of the cushion that performs leveling functions, as a rule, does not exceed 200mm. Sand is poured once onto the bottom of the trench and leveled. Then it is slightly moistened and carefully compacted. All other varieties of this necessary element directly depend on the size of the foundation base. They are calculated individually in each case.

Selection of material.

What sand to use for foundation cushion? Unfortunately, few people think about this issue. Construction continues with the material that will be delivered to the site. But the basic properties of the building material itself greatly influence the strength of the structure.

It is necessary to note what kind of sand should not be used for the foundation cushion:

- With small grains. The higher the particle size modulus, the better and better the quality of the embankment for the foundation. The pillow will be easier to compact and be affected by humidity.

- Dirty. The presence of large stones or particles of organic soil in the bulk material radically changes the physical properties of the pillow. Clay particles are especially dangerous. The presence of its impurities in sand contributes to greater soil mobility and a decrease in its bearing capacity. Clay retains moisture, which will negatively affect the sand bed.

- The sand used for the cushion under the foundation must be washed. It is best to use river sand or quarry sand. Also, the optimal solution would be to use gravel material.

The use of river sand significantly increases the cost of construction work. Quarry sand, thoroughly washed with a huge amount of water to remove clay and silt impurities, will cost an order of magnitude cheaper.

The pillow under the foundation has a difficult task - the correct distribution of the load, so you should not save much on the material on which further construction work depends.

Reinforcement

Laying reinforcement under the future foundation adds strength to the concrete being laid, turning it into reinforced concrete. Ordinary concrete withstands compression well, but does not withstand tension and bending well.

This disadvantage is corrected by reinforcement with rods and welded steel frames. Such a foundation does not respond to soil shrinkage and firmly holds the structure.

Reinforcing steel 12 mm – lightweight reinforcement, supplied in quarts. Reinforcement of greater thickness (heavy) is supplied in rods. Before pouring, lathing is performed: two types of reinforcement are connected by welding or twisting wire.

The rods are laid parallel in 10cm increments. Similar to them, but perpendicular, the next level of rods is laid. Each joint of the reinforcement is tied with galvanized wire. To do this you will need an automatic gun and a hook for manual dressing. A 20cm piece of wire is aligned with the rod, bent in half and tied. The ends are then threaded through the loop and tightened tightly with a hook.

What kind of sand is needed for a foundation cushion: the right choice.

What kind of sand is needed to cushion a strip foundation.

A solid foundation for the house will allow the structure to stand for decades. The construction of a home begins with laying the foundation, and the choice of materials for it should be approached responsibly and competently.

Reliable support for a building requires not only high-quality concrete and reinforcement, but also proper filling of the pit. What kind of sand is needed for the foundation cushion should be chosen before starting work.

Crushed stone bedding

The crushed stone cushion under the foundation is considered stronger than the previous version of the foundation. You can also do it yourself. At the initial stage, the bottom of the excavation is covered with a 10-15 cm layer of coarse sand, after which it is leveled and thoroughly compacted with moisture.

Next, crushed stone of the middle fraction (20-40mm) is laid in a layer 20-25cm thick. To compact it, use a vibrating plate. For what? Yes, only because it would be too labor-intensive to do it using old-fashioned methods.

A crushed stone cushion under a strip foundation is capable of absorbing loads from low-rise brick and stone houses.

Often the project provides for a crushed stone-sand foundation. It is filled in layers with alternating materials and compaction. This type of backfill has proven itself well in the construction of facilities on weak-bearing soils.

Why is a sand cushion poured?

A capital structure must have a solid foundation. It is provided by a monolithic foundation on a special pillow. After digging a pit to a depth that allows the soil to avoid freezing in winter, sand is poured into the bottom of the hole.

What kind of sand is needed for the foundation.

This bedding is recommended in several cases:

- When installing a house on empty ground. The sand layer replaces the excavated soil, which avoids deformation after freezing and thawing cycles;

- The horizontal level is important during construction; an embankment of sedimentary rock helps to ensure it; it conceals all unevenness, is easily distributed and levels the construction site;

- The layer will serve as an additional barrier protecting against dampness and groundwater;

- The embankment will reduce the settlement of the building, the material perfectly resists compression forces, while its costs are minimal;

- When constructing a building with several floors, the cushion serves for shock absorption.

A funny and sad story about ordering crushed stone

It turned out that ordering crushed stone and gravel in Georgia is a whole quest. We are not talking about all of Georgia; the situation is probably different in the regions. But this is how it turned out for us.

The first machine of "happiness"

Local friends helped us order building materials. If it weren't for their connections, it would have been even more difficult for us. Not only are they “new”, but the language barrier sometimes makes itself felt.

We arrived at the quarry and looked at the gravel. They pointed to the one they needed and asked: “Bring me such and such a size. And please try to have less sand. After all, we buy gravel, not sand.” But the delivery was carried out by a driver not associated with the quarry. A few days later they called us and said that the cards were aligned and everyone involved was able to ship and deliver gravel to us.

According to our plan, it should be like this: a car arrives, we tell the driver how to drive in and where, he drives in, pours gravel into the pit.

In reality: a MAZ car arrives, without any delay drives to the open gate and gets stuck right in the old drainage ditch at the very entrance to the site, 30 meters before the pit.

The driver runs out of the car, shouts something in Georgian, and waves his arms. Then he jumps into the back, pours gravel where he stands, and drives away. He finally shouted something about the tractor. Our friend translated that he advises hiring a tractor to drag stones into the pit.

To say that we were upset is to say nothing. 30 meters is a small distance for a car, but such a long distance for a person with a wheelbarrow and a load of several tons. But, of course, it’s their own fault, they didn’t realize that the ditch would become an obstacle.

A tractor is, of course, good. But first of all, where to look for it? “Okay, Google” doesn’t work here. Secondly, how much will it cost? It turns out that you have to pay twice for the delivery of gravel. Thirdly, he will make ruts for us all over the site, rainwater will stand in them, the earth will become loose, and no one else will definitely pass by us later.

Our friend assured us that everything would be fine with the tractor and went to try his luck in search. And we, sensing that waiting was just a waste of time for us, took up the wheelbarrow and shovel. It turned out that it was not in vain. The tractor was never found.

We have already experienced more than once that any losing situation has some positive meaning in the long term. The same thing happened here. Plunging a shovel into the eight-cubic-foot rock, we discovered that there was a lot of sand in the middle. This is exactly what we didn't need. If we had not dragged the gravel by hand, but poured all this stuff straight into the pit, we probably would not have noticed the sand, but there was half a cube of it there. In the future, it could be washed out through drainage ditches, and the foundation would begin to sag unevenly.

Everything that is not done is for the better. Even if “for the better” means moving 8 cubic meters of gravel by hand.

Sand and gravel mixture (SGM). In our case, it is not suitable for backfilling a pit.

Second car

We made the second order a day later. During this time, the first 8 cubes of gravel were already located in the pit. We removed the soft fertile layer of soil from the drainage ditch, filled the bottom with large cobblestones, and leveled the top with small stones. They reminded us to bring us clean gravel, without sand. In general, we prepared as best we could.

MAZ arrived, the driver is the same. They stopped him at the entrance and explained which way to approach the pit, where we had more solid soil. The driver listened, but stepped on the gas and almost got stuck. Fortunately, they managed to stop him and redirect him.

This operation was the most successful; gravel was poured as close as possible to the pit. True, there was again a lot of sand there and we had to separate the “wheat from the chaff.”

Third car

We were in a hurry, we scattered the first two cars in 4 days. 16 cubic meters of gravel with a fraction of 5-10 centimeters. Those who have ever encountered this will understand what it is like. There were good reasons for the rush; they really wanted to fill the pit before the rains. We were afraid that the rain would soften the ground and it would be even more difficult for heavy trucks to get to us. And after a good rainfall in our area, everything dries out in a few days.

But when we were ready, it turned out that the quarry would be able to ship crushed stone to us within a week at the earliest. This was due to the massive repair of roads in our area, all resources were directed there. It was difficult to come to terms with this, we learned about the delivery of crushed stone from the neighboring area, but they also seemed to be involved in road repairs.

Forecasters showed that the rains would continue for a week from Monday, and the crushed stone was supposed to be delivered on Sunday. And what do you think? The rain started on Sunday at 7am.

We understood that we were taking a risk, the car might not start, but we could not agree to a second week of downtime at the construction site. There was hope that the morning rain did not have time to critically wet the ground.

And now, again MAZ, again the same driver. It would seem that in two visits to us you can remember where to stop by and where not to. But we reminded you just in case.

However, our beloved Schumacher drove exactly where he shouldn’t, and, of course, got stuck. He again, like the first time, jumped out of the car and began waving his arms, shouting something in Georgian and looking at us as if we were the geniuses of the joints here.

We didn’t have the time or desire to figure out who the donkey was. We offered to dig up and put branches under the wheels, fortunately we have enough of this stuff on the site. To which Schumacher replied that this was all nonsense and did not allow us to do anything. He called someone and five minutes later his friend arrived in a KAMAZ. And a silent movie unfolds in front of us: KAMAZ and MAZ are standing, chatting about something, looking at us, laughing, it’s clear from their faces that our Schumacher is telling us what sheep we are, dragging the poor man into a quagmire. After a while they ask if we have a metal cable! To which we, of course, answer: “No!” If two truck drivers do not have a cable for such a case, then where will we get one in our empty lot? We don't even have a car! In response to our answer, Schumacher waved his hand, saying they didn’t even have a cable.

They called the authorities, and half an hour later he brought a cable and pulled out our poor fellow. We talked something about how difficult our area was, dumped the rubble behind the fence (even further than the first car), sympathized, smiled and went home. And we, accustomed to such a development of events, became sad for 5 minutes and began to transport crushed stone in a wheelbarrow.

The foundation cushion is made from coarse gravel and crushed stone.

What kind of sand is best to pour under the base?

To lay the bottom of a pit, you should not take the first sand you come across; there are rules and regulations for its selection. Three types of sedimentary rock are sold on the construction market.

What kind of sand is needed for the foundation cushion.

Quarry - has low quality due to the large volume of impurities of clay and other substances. Its popularity is due to its low cost. Developers often use quarry sand in zero cycles, which is quite acceptable, but it is worth monitoring the quality.

Marine - its development is carried out from the bottom of the sea, so the sedimentary rock contains a lot of shells and impurities. Manufacturers perform mandatory cleaning of their product. It is also suitable for creating a pillow.

What kind of sand is needed for the foundation cushion.

River sand is a universal type of sand used at all stages of construction. Due to natural grinding, it obtains the ideal particle shape, allowing you to make a reliable solution. The material is characterized by the absence of clay and organic compounds.

This type is the best option for a pillow under the foundation. The high cost of the material forces budget-conscious builders to abandon it in favor of a lower quality, but more affordable one.

The material extracted from the bottom of rivers is not uniform. When choosing what kind of sand is needed for a special cushion for a reliable foundation, it is worth understanding the size of the rock.

What kind of sand is needed for a pillow under the foundation.

There are several fractions of the material, their sizes range from 0.7 mm to more than 3.5 mm. The small size of sand grains is not suitable for adding to the foundation pit; it shrinks and compacts very tightly. Sand with this fraction can only be used for light outbuildings.

Residential one-story buildings are built on an embankment of medium or large sand of 2 to 3 mm. The construction of multi-storey structures requires extremely coarse material. As the size of the sand grains increases, the value of the sediment also increases.

Purely theoretically

The main criterion is cleanliness.

Any person who is not knowledgeable in the construction business and its nuances can guess that it is necessary to choose clean sand for the foundation. The sand may initially contain various organic elements, such as grass, branches, etc. Such sand is not suitable for work, but it can be easily cleaned. Perhaps you have seen more than once how workers sift sand, clearing it of unwanted elements.

But if we talk about impurities such as clay, lime and other similar ones, then simple sifting is not enough. It is more difficult to clean such sand, so you need to immediately pay attention to this when purchasing. The presence of clay in sand should not exceed 5% of the total mass, especially when it comes to foundation mortar. Otherwise, the future structure will not be reliable, it will shrink, and this will lead to cracks. It is important to check how clean the sand is before purchasing. You can use a simple method to check.

You will need a clear bottle, either glass or plastic. You need to fill it 1/3 with sand and fill it with water up to half. Next, shake the bottle vigorously so that the sand is mixed with water and completely wet. After that, put it down and wait 5-10 minutes. If the water has become dirty, this sand will not be suitable for the foundation. If a foreign substance has formed on the surface in a layer of more than 5 mm, such sand cannot be taken. Let's look at what types of sand there are, how they differ and what type of sand is best to purchase for the foundation.

Requirements for the quality of the material and the thickness of the pillow.

In addition to particle size, important requirements for material quality are:

- The absence of clay, which retains moisture and makes the bedding layer mobile;

- Cleanliness of the mixture - removal of branches or other foreign objects;

- Sand moisture – excessive or insufficient amount of water negatively affects the properties of the material;

- The presence of gravel in the composition improves the characteristics of the embankment.

The layer of sedimentary rock is the first thing that is poured into the hole dug for the foundation. It is determined by the composition of the soil and the purposes for which it is intended.

What kind of sand is needed for a pillow under the foundation.

A small embankment for leveling the site is 10 cm, the depth of the layer in case of heaving soil should reach 20 cm. In any case, the size of the embankment should not exceed 1/3 of the width of the foundation.

Important! Before pouring sand into the pit, it is better to sift it to avoid unnecessary inclusions.

Device

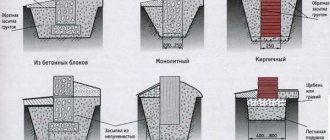

The foundation pillow has a fairly simple design, which makes it possible to make it yourself. You can consider a typical scheme of a full-fledged, combined cushion, which is suitable for fairly heavy structures and weak soils.

The manufacturing technology is described by the following diagram:

- Digging a trench (pit).

- Leveling and compacting the surface layer of soil at the bottom of the trench. This creates a dense base.

- Laying geotextiles. This fabric does not disrupt the circulation of moisture, but prevents sand from migrating into the ground (washing out).

- Backfilling the sand layer with coarse-grained quartz sand. It is covered in layers with moistening and compaction. The minimum thickness of the sand layer is 20-25 cm.

- Filling with crushed stone or gravel up to 5 mm in size. The thickness of the layer is 15-20 cm. This element of the pillow increases strength and increases resistance to crushing. The layer is carefully compacted.

- Laying waterproofing. It is made of roofing felt or thick polymer film. Waterproofing should cover the entire surface of the pillow without gaps. An overlap of about 15-20 cm is provided at the joints.

When making a slab foundation, it is recommended to strengthen the cushion with an additional element - concrete preparation or footing. It not only increases the reliability of the base, but also helps reduce the consumption of mortar during the main pouring of concrete. The footing is made by pouring the so-called “lean” mortar from low-class concrete (up to B12.5).

How to properly lay the foundation for pouring the foundation?

Initially, the perimeter of the future walls is marked at the construction site and a trench is dug. Depending on the depth and width of the pit, they work with a shovel or order an excavator.

What kind of sand is needed for the foundation.

We figured out what kind of sand is needed for the cushion under the foundation, now we need to figure out how it is laid and compacted. It is necessary to lay a geotextile sheet under the layer of sand. This will create additional drainage and protect the embankment from silting and mixing with the soil.

The poured material needs to be moistened for better compaction. It is filled in parts, each of which is compacted tightly with a homemade timber tamper with handles or a special tool - a vibrator.

What kind of sand is needed for the foundation of a house.

Important! It is impossible to properly compact 20 cm of sedimentary rock poured at the same time, so sand is added gradually. Compaction should reach the point where footprints no longer remain on the surface.

The quality of the compaction determines whether the building will subsequently sag. We must not forget about the horizontality of the sand embankment.

About the preparatory work for the foundation in the video:

A framework of reinforcement is laid on the finished pillow - metal rods are tied together with wire. Removable formwork from boards is installed and concrete is poured. A reliable and high-quality foundation will allow the building to stand for a long time without shrinkage or damage to the foundation.

Useful functions of geotextiles

Strengthening load-bearing capacity. When a foundation is laid on heaving soils, there is a risk of its excessive shrinkage and even failure. In such a situation, the soil needs to be strengthened. There are different methods, but the simplest is laying a geogrid. To do this, material is placed in the pit, on which crushed stone is laid out and on top of it, the material is again placed. The elasticity of the geogrid is very high. It allows you to evenly distribute the load in the pillow. In addition, separation occurs between the layers of sand and crushed stone.

About the choice of geotextiles : its density is determined in each specific case and depends on the soil. The main indicator is the pressure applied. Therefore, the best solution is to consult a specialist.

I will add that the material reduces the seepage of water located under the sand and tending to the foundation. Effective in arranging drainage, actively preventing siltation, etc. In general, useful and quite worthwhile material. By the way, numerous reviews and recommendations of construction professionals speak about this.

I'm glad if my information was interesting and understandable. Thank you for your time and I invite you to subscribe to updates on this blog. If you find the article useful, recommend it to your friends online. See you soon!

Wisdom Quote: What interests everyone interests no one.

How is a sand cushion created for a strip foundation?

The foundation cushion is a layer of a certain material (crushed stone, sand, gravel, concrete) laid under the base. Its main purpose is to give the future foundation of the house stability and a stable location with subsequent minimal shrinkage. The choice of a specific type of pillow is made based on the location of groundwater, type of soil, number of storeys of the building, climatic conditions of the area, materials used to build the house.

What kind of sand is needed to cushion a strip foundation.

The advantages of a sand cushion: low cost and ease of construction; the main disadvantage is the inability to erect heavy buildings on it.

A sand cushion for the foundation is the most acceptable option for those who want to save significantly on construction work. Sand best softens the load on the foundation of a building. The laid layer of material is an intermediate link between the soil and the foundation of the house, which prevents the harmful effects of moisture on the foundation.

What kind of sand is needed for the foundation of a house.

Strip foundation on a sand cushion.

In addition, the advantages of using a sand cushion under the foundation are:

- availability of material (there are sand deposits in every region);

- low thermal conductivity (large losses of thermal energy are prevented);

- suitability for dense compaction;

- ease of creation.

Perhaps the only drawback of a sand bed is the impossibility of building multi-story and heavy buildings on it.

It is most advisable to construct a sand cushion in the following cases:

- location of groundwater at a decent distance from the surface;

- construction of houses from light materials (foam blocks and frame structures);

- construction of a one-story building.

Summarizing

When answering the question of what kind of sand is needed for the foundation, it should be noted that river grains of the middle fraction are considered the ideal option. This material has excellent properties for construction purposes. It allows you to build the strongest possible foundation, which will last for a long time and will be an excellent basis for construction.

It is necessary to purchase sand from reliable manufacturers so as not to stumble upon low-quality raw materials. It is recommended to check the material before purchasing for moisture levels and the amount of foreign impurities. It is also worth paying attention to the size of the purchase. As a rule, there should be about one and a half tons of sand per cubic meter.

When laying the foundation, it is important to choose building materials correctly and competently. It is necessary to select sand especially carefully, since the strength of the foundation mortar , and therefore the strength of the entire foundation, depends on it. The question of which sand is best to choose for the foundation will be answered in this article.

Minimum figures according to SNIP, SP

SNiP 2.02.01-83 SP 50-101-2004 the minimum height of the entire foundation structure, taking into account all layers, will be no less than 0.6 m

Subject to compliance with the rules of SNiP and SP, the lowest value of the parameter can be used if concrete of a grade not lower than M300 with a strength of B22.5 is selected.

In order to provide the necessary reserve strength, the developer must reinforce the slab, which will ultimately allow the foundation to be resistant to deforming influences from the soil.

Choosing an unreasonably thick slab will not only lead to excessive consumption of material and labor resources. Significant pressure from the house together with a monolithic foundation will over time be accompanied by subsidence of the structure in the ground.

Excessively “light” pressure, in turn, will lead to the fact that the slab will move at the slightest movement of the soil (for example, when the ground thaws in the spring), reducing the service life of the entire building.

We construct a pile and pile-screw type foundation for clay soils

For clay soils, a pile or pile-screw foundation is also used. In the first case, the supports are driven into the soil using special equipment, and in the second, the piles are screwed into the ground. This type of foundation has a number of advantages. When installed, the supports reach solid layers of soil, which provide increased structural strength and are not subject to deformation when the soil freezes.

The following are used as supporting elements of a pile foundation:

- drilled type columns. They are created by drilling, followed by installation of reinforcing mesh and concreting;

- metal piles of a screw design. They are made of pipes with a special tip and screwed tightly into the ground;

- reinforced concrete elements. They are driven into the soil using special equipment and are used for massive buildings.

Pile or pile-screw foundation is also used for clay soils