The purpose of the chimney consists of three key components: it removes combustion products outside, creates draft in the combustion space and initiates additional thermal convection in the heated room, at least in the first third of its stroke. If the pipe is metal, then when going outside, condensation may form in the body of the pipe. For stainless steel structures this phenomenon is at least unpleasant, but for ferrous metals it is fraught with corrosion, up to the formation of through fistulas. Is there any effective recipe that will avoid the appearance of dew point and the formation of harmful moisture? The sauna sandwich pipe is positioned as a universal miracle cure that allows you to make your chimney balanced and efficient. Is it really true? Let's figure it out.

Design Features

Modern channels for removing smoke from sauna stoves are assembled from pipe sandwich parts. The products are popular among owners of country houses, despite the large selection of materials for creating chimneys.

The sandwich pipe is a double-circuit design. It consists of the following main parts:

- internal chimney;

- layer of thermal insulation material;

- protective decorative shell - an external contour in the form of a pipe product of a larger diameter compared to the internal chimney.

The double-circuit pipe has become widely used by homeowners when installing chimneys. It came to replace single-circuit similar products made of 0.5 mm thick steel. After all, a steel pipe product is not suitable for installing a smoke exhaust duct outside a building. The reason for this is its design, which does not retain heat in the off-season and winter period of the year. In cold weather, condensation forms in a steel channel with one circuit due to a sharp temperature difference. Therefore, the traction effect in the chimney decreases, and even traffic jams appear.

Design features of a thermopipe with two casings Source pechnoy.guru

The internal contour of the pipe sandwich product for removing combustion products is made of stainless steel. Its one-piece design is manufactured using TIG welding. It allows you to make neat, thin seams.

The outer casing is also made by welding from stainless or galvanized steel. The second type of metal allows manufacturers to produce more affordable products. In cooperation with a construction and installation organization, you can also order a chimney made of a sandwich pipe with an outer casing coated with enamel in the required color.

The thermal insulation layer in a product with two circuits is created from a material that is resistant to fire. Manufacturers use high-density mineral wool made from basalt raw materials. Typically the thickness of the thermal layer is 25-100 mm. Design engineers select this parameter taking into account the specifics of installation work and the conditions of use of the chimney.

Chimney with a thermal insulation layer made of basalt mineral wool Source festima.ru

The ends of the sandwich parts for the smoke exhaust duct are made in the form of sockets and narrowed ends. This interface system simplifies the installation process and allows elements to be tightly joined. To increase the strength of joints when installing a chimney, special clamps are additionally used. Depending on the design features of the smoke exhaust channel and the work conditions, parts connected to each other and other elements of the furnace system using flanges can be used.

Crimp type clamp for sandwich chimney Source ytimg.com

Advantages of chimneys made from sandwich channels

Metal pipelines have been used for decades to remove smoke from furnace devices. This is explained by their optimal cross-section for the passage of combustion products. They have a smooth surface inside that does not interfere with the removal of gases. There is less soot accumulation on their smooth walls. In addition, installation work is carried out using large parts. Therefore, installing a sandwich chimney is simpler and faster compared to laying a brick channel.

The use of double-circuit products for smoke removal also has the following advantages:

- the outer surface of the pipes heats up less due to the presence of a heat-insulating layer between the two circuits;

- the operating temperature of the exhaust gases can reach 850 degrees;

- the level of fire safety of the building increases;

- There is no noise when removing smoke.

The use of stainless steel in the manufacture of sandwich pipes increases the resistance of chimneys to corrosion. After all, its occurrence is well facilitated by the exhausted aggressive gases.

Chimney sandwich parts made of stainless steel have high corrosion resistance Source roof-tops.ru

Compared to conventional metal chimneys, channels made of sandwich pipes have improved technical characteristics and provide a higher level of fire safety. Thanks to the design, it was possible to achieve minimal condensation formation when removing smoke through dual-circuit products.

The sandwich chimney is characterized by stable draft due to a more even internal temperature along the entire length of the channel. In addition, the external circuit does not heat up much. Therefore, upon contact, a person will not receive a burn, with the exception of contact with the initial section of the chimney near the heating device. Indeed, at this point, even the outer thermally insulated wall of the structure becomes very hot. Therefore, it is dangerous for humans and can even cause a fire in the bathhouse.

The lower, very hot section of the sandwich chimney near the stove Source topijar.ru

Another advantage is the service life of the chimney sandwich pipe. Its durability is 15-20 years if installation technology is followed.

Characteristics of sandwich pipe

Sandwich chimneys are made with the same appearance. The production of these products brings good income. Therefore, unscrupulous manufacturers have appeared that produce low-quality products. They don't care about reputation. Their goal is to obtain maximum profit. Therefore, to create a durable and efficient chimney, you need to seek help from a specialized construction and installation company with an unblemished reputation that cooperates with reliable sandwich pipe manufacturers.

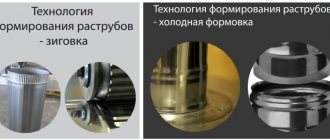

Metal fabrication

Professionals pay special attention to the quality of the metal of sandwich pipes, especially from which the inner casing is made. Because products made from low-grade steel are deformed when exposed to high temperatures and even burn out. Such defects also occur during operation if the metal does not meet the operating characteristics of the furnace.

Burnt-out inner casing of a low-quality sandwich chimney Source ad-cd.net

Responsible manufacturers label their products and supply them with technical data sheets. They indicate the grade of steel.

The universal metal is AISI 316i stainless steel. This steel has ductility, high resistance to corrosion and can withstand temperatures up to 850 degrees. For bathhouse stoves, chimneys made of alloyed stainless steel AISI 316 and durable alloy AISI 439 with titanium additives are also suitable.

See also: Catalog of companies that specialize in engineering systems and related work

Inner diameter

An important technical parameter is also the diameter of the internal contour. It is selected by engineers taking into account the thermal power of the furnace device. The most commonly used sizes of sandwich chimney pipes are:

- 158 mm – up to 3500 W;

- 189 mm – 3500-5200 W;

- 220 mm – 5200-7000 W.

The indicated diameters are the minimum permissible values. However, the cross-section along the entire length of the smoke channel must be no less than the size of the stove outlet pipe.

Inner diameter of the smoke exhaust sandwich duct Source ytimg.com

Thermal insulation

Significant characteristics also include the type and thickness of the thermal insulation layer. High-quality chimneys with a sandwich structure are made using mineral wool. It does not burn and has a significant coefficient of thermal resistance.

The thickness of the heat insulator is affected by the type of heating equipment and smoke temperature. Wood-burning stoves typically discharge combustion products heated to a maximum of 600 degrees. For such operating conditions, a chimney is assembled from sandwich pipes with a thermal insulation layer 50-100 mm thick.

Chimney outlet options

The design features of the bathhouse affect the installation of sandwich pipes. It can be performed inside or outside the building. When laying internally, holes are created in the ceiling and roof. During external installation, the chimney is fixed to the wall with a preliminary hole created in the supporting structure for laying the pipe.

Basic options for installing a sandwich duct for smoke Source feflues.ru

Internal installation

It is the installation of a chimney from sandwich pipes through the roof with the preliminary creation of a passage in the attic floor that makes it possible to reduce the negative external influences on the smoke exhaust system. With this installation method, the appearance of condensation in the channel is practically eliminated.

This option is often used in a bathhouse because it does not complicate the installation of a water tank. After all, its installation is carried out above the stove. It is mounted at the initial section of the smoke exhaust system. Often, a mesh section is installed in the same section, allowing stones to be placed for better heating and creating steam in the room.

Mesh sauna heater Source oteplicax.ru

A module without thermal insulation is always installed between the furnace and the sandwich pipe. The section is usually equipped with a gate. It is a damper to change the amount of heat removed along with the smoke.

Installation inside an object is a labor-intensive process, since you have to create at least two holes. This option is not suitable if you need to save the free internal space of the bathhouse.

External installation

When a chimney is laid through a wall, labor costs are reduced. After all, you need to create one penetration in the supporting structure. The parts are attached to the outer surface of the wall using special brackets.

Less labor-intensive installation of a chimney from sandwich pipes through the wall helps to save free internal space. This option reduces the likelihood of fire and minimizes the risk of poisoning from combustion products.

The disadvantage of such a gasket is the negative impact of the external environment on the channel. It creates more condensation. Some people are still not satisfied with the placement of a metal pipe on the wall.

Types of ceiling penetrations

The chimney through the ceiling and roof of the bathhouse passes through protected openings. One of the main conditions for the safety of people in a heated building is heating the roof, ceiling and walls structures near the pipe to a temperature not exceeding 50 °C. Fire safety requirements for the installation of chimneys are set out in SP 7.13130.2013. Heating, ventilation and air conditioning. Fire safety requirements.

To pass the pipe from the bathhouse through the ceiling or roof structure, a through-ceiling assembly is installed - a prefabricated box with flanges. Insulation is placed between the flanges. The box insulates the surrounding structures from the heated surface of the pipe. You can make it yourself, it's not very difficult.

For the speed and convenience of passing pipes through the roof and ceiling, the industry produces ready-made passage units. They are round and square. As a rule, these units are made of stainless steel with a heat insulator, sometimes mineralite - cement boards with fiber fiber (mineral, cellulose). Previously, asbestos-cement slabs (flat slate) were used, but asbestos is carcinogenic, and their use indoors is prohibited by sanitary standards. This is still not a roof or a fence, the asbestos dust from which is washed off by rain and carried away by the wind. Sometimes there are pass-through units made of galvanized steel, but in humid bath air they will quickly rust, so they are used only as a last resort.

Mineral wool is mainly used as insulation (thermal insulator), but expanded clay, clay, and a mixture of clay and expanded clay are allowed. Mineral wool has a very significant drawback - when wet, it becomes thermally conductive (due to water), and after drying it does not completely restore its thermal insulation properties.

If the flange or body of the passage unit is made of steel, and the ceiling structures include flammable elements (wood, foam), then a layer of mineral wool must be laid between the structures and the steel elements. Otherwise, the structures may char or even burn.

Chimney equipment

The installation company completes the chimney in accordance with the approved installation diagram. It is not difficult for a specialist to select the necessary parts. After all, manufacturers produce a full set of required sandwich elements. They allow for quick and high-quality installation of a sandwich chimney.

When installing a smoke exhaust system from a stove in a bathhouse, the following is usually used:

- a transition piece that allows you to connect the chimney with the outlet of the furnace equipment;

- a right-angle bend designed to change the direction of the channel;

- tee with a central pipe at an angle of 87 degrees - used to transition from a horizontal section to a vertical pipe;

- a part with a hermetically sealed hole for cleaning the channel;

- a support platform equipped with a tap designed to drain accumulated moisture - used together with an inspection element;

- a wall bracket that allows you to attach the chimney to the wall;

Fastening structure for fixing smoke ducts to the wall together with an inspection element and a support platform Source katlavan.ru

- a tee with a central pipe located at 45 degrees - used when installing a single chimney for two stoves;

- a metal plug for closing unprotected heat-insulating material when connecting a single-circuit pipe with a thermoelement - prevents the penetration of a humid environment into the heat insulator;

- 45 degree bend - used to bypass protruding structural elements of a building, for example, a roof canopy;

- clamp for strengthening the connections of sandwich parts;

- straight pipe elements 1000 mm or 500 mm long;

- a conical roof with different angles depending on the slope of the roof slope - used when laying a chimney through roofing material and used in conjunction with a metal apron;

Cone roof Source ytimg.com

Okapnik Source prom.st

- a cone-shaped part with which the thermal chimney ends - usually installed with a spark arrester and a fungus in the usual design or a similar thermoelement, deflector, weather vane.

Welds

The weld seam is one of the most vulnerable places in a chimney. Welding destroys the protective layer of metal and this is where the chimney is most susceptible to corrosion.

A poor-quality seam may not be airtight and, as a result, flue gases will escape. An unacceptable option for a chimney sandwich is spot welding or an overlap connection. The best and most reliable connection is a continuous butt seam.

Important! Always look at the welds. First of all, the seams of shaped elements - tees, bends, support plates. Here, welding costs an order of magnitude more than on straight pipes, and unscrupulous manufacturers can save on it.

Basic rules for installing a sandwich chimney

The number of all components depends on the length of the chimney. Regardless of the configuration, it is not created with a length of less than 5 m. If the chimney is installed through the wall directly in the steam room or its installation is carried out elsewhere in the bathhouse, conditionally parallel to the floor, then the length of the straight “horizontal” section should not be more than 1000 mm. In this case, such a segment is fixed with an inclination of 3 degrees towards the condensate collector. This allows moisture to flow in the opposite direction from the heating equipment.

When installation is carried out next to a wall, the channel is fastened at a distance from the supporting structure of the building, which is determined by the manufacturer of double-circuit pipes. However, the minimum distance is 250mm. To simplify the installation process, adjustable brackets are often used. They are fixed at a distance of no more than 2000 mm from each other.

During installation, the distance from the chimney to the wall must be at least 250 mm Source krovlyakryshi.ru

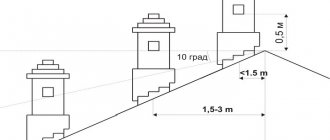

If the sandwich pipe is located at a distance of 1500 mm from the ridge, it must rise above it by no less than 500 mm. When the distance is 1500-3000 mm, the head of the chimney should be flush with the ridge. If the thermal pipe is mounted at a greater distance, then the height of its upper cut is determined by drawing a conditional line from the ridge at an angle of 10 degrees relative to the horizon.

The height of the chimney above the roof Source stroyfora.ru

If there is a flat roof, the thermal pipe must rise above it by at least 500 mm. When the roof is covered with a fire hazardous material, the height of the sandwich chimney above it must be at least 1200 mm. Typically, a structure of this or greater length is secured with braces.

Important! The smoke exhaust channel is installed with a minimum number of bends. Its effective operation will be ensured if the pipe changes direction no more than 3 times.

Buy or make it yourself

Buying a chimney for a bathhouse is easier than making it correctly yourself. But simpler does not mean better, especially if you have the necessary skill, free time and a desire to save money. With the right approach, making a good design will not be difficult. You can use a compromise option: make some elements yourself, and buy some complex components.

approximate price

How much a pipe for a bathhouse costs depends on the number of offers in a particular region of the country, what size the bathhouse itself is, etc.

I collected average market prices so that preliminary calculations could be made.

Stages of installing a chimney from thermal pipes

After concluding the contract, developing the project and its approval by the customer, the construction company will install a chimney in the wall or roof in stages:

- An adapter is put on the stove pipe. It is lubricated with a sealant that can withstand temperatures of at least 1000 degrees. For reliability, the transition element is secured with a metal clamp.

- A length of single-wall pipe is installed to prevent the sandwich from overheating, which turns to stone when exposed to high temperatures. This leads to failure of the chimney.

- A heater or metal container for heating water is mounted on a single-wall pipe piece.

Metal tank for heating water in a bathhouse above the stove Source pechimax.ru

- If a chimney is installed through a wall in a wooden house, bathhouse or other building, a chimney section no more than 1000 mm long is created with a 3-degree slope towards the street.

- A hole is prepared in the wall for the chimney outlet. Its diameter is always larger than the cross-section of the sandwich pipe. If the wall is made of combustible material, then the gap between the smoke exhaust duct and the supporting structure is at least 200 mm. Often a square hole measuring 400*400 mm is created.

- The walls of the opening are covered with basalt cardboard.

- A factory-made chimney passage through the wall is installed.

Pass-through block in the form of a box Source masterweld.ru

Thermal insulation layer

Thermal insulation plays an equally important role in DS. She must:

- maintain the temperature in the inner pipe so that working draft is created in the chimney and flue gases are removed from the firebox;

- do not transfer high temperature to the structures enclosing the chimney to prevent fire.

Low-quality thermal insulation loses volume, settles, forming voids through which high temperatures will be transferred to the outer shell and, accordingly, to flammable materials. This is fraught with fire.

And also low quality insulation can absorb moisture, bake or coke. In these cases, it immediately loses its characteristics, forms cavities and exposes the outer shell to high temperatures.

The best option for a chimney would be a heat insulator that does not contain adhesive binders that burn out at temperatures of 500–600 °C.

Important! Ask the seller to show the insulation in the pipe. If it is printed from individual fibers, then within the first six months or a year it will lose its characteristics. High-quality insulation will be wrapped around the pipe like a blanket or consist of 2-3 segments.

Unscrupulous manufacturers use a trick - they create an illusion: they install rings consisting of high-quality segmented thermal insulation into the edges of the chimney, and fill the main space with low-grade material.

Video description

Video material will help you understand the principles of creating connections “through smoke” and “through condensate”:

The installation process is completed by installing a cone of the required height and the selected head. If the last section is long, a clamp with eyes is attached to it. This product allows you to fix the final section of the chimney using guy wires that are attached to fixed, durable parts of the roof.

Special clamp for guy wires Source yandex.net

Methods for connecting modules

The chimney can be installed in one of the following ways:

- "By the smoke." Such a scheme is designed, first of all, to 100% protect the heated room from the penetration of dangerous carbon monoxide. The internal pipe of the lower module is mounted in the corresponding socket of the upper one, allowing smoke to freely pass through the joint area and be removed from the chimney. On the other hand, with this arrangement, condensation may enter the joint. If the seams are poorly sealed, this will reduce the service life of the structure.

- "By condensate." Here, on the contrary, the inner pipe of the upper element is placed in the socket of the lower one. This prevents moisture from getting inside, while smoke is quite capable of penetrating into the area where people are staying, seeping through any, even the most inconspicuous, cracks.

We recommend that you read: Purpose and use of clamps for chimney installation

Thus, every owner faces a dilemma - which method to prefer. On one side of the scale is safety, on the other is durability of the structure and savings. What to choose, everyone decides for himself, however, in any case, sealing seams should be treated with maximum responsibility. If you are sure that the joints are absolutely sealed, the “condensate” scheme seems more appropriate .